Patents

Literature

33results about How to "Easy and accurate calibration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

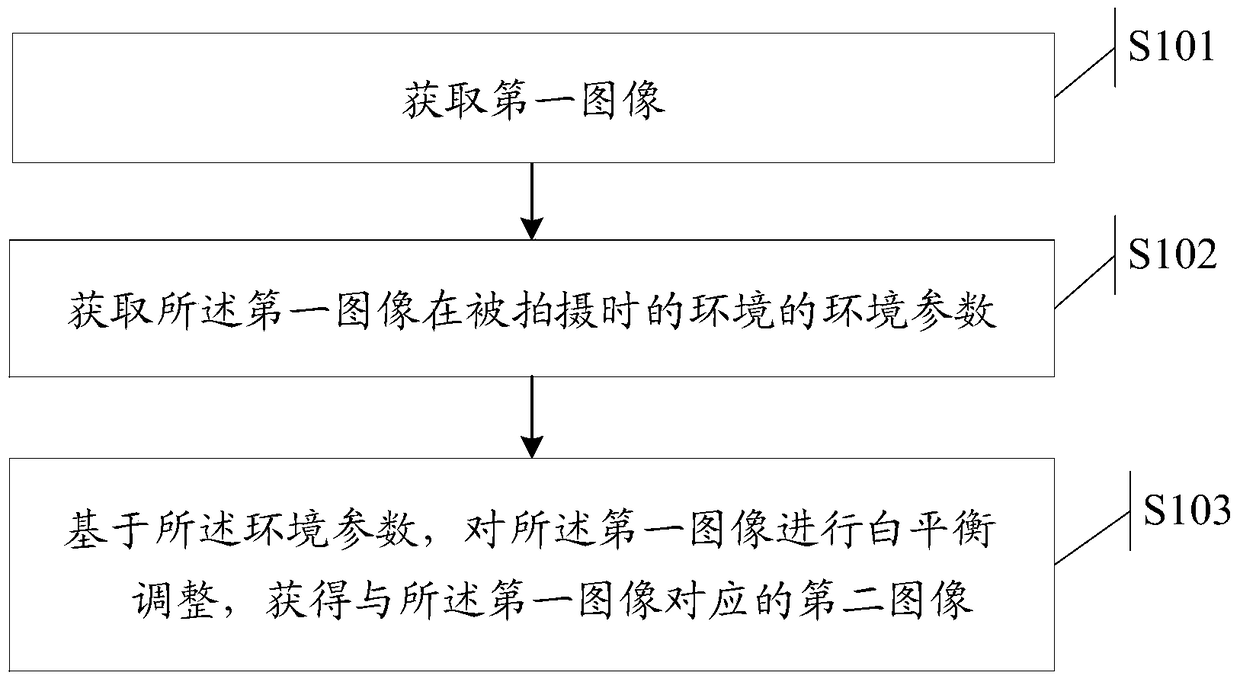

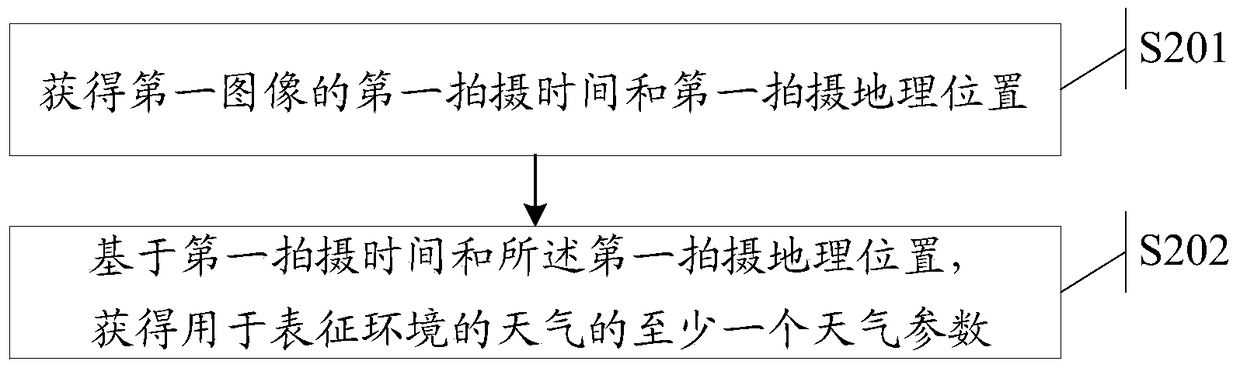

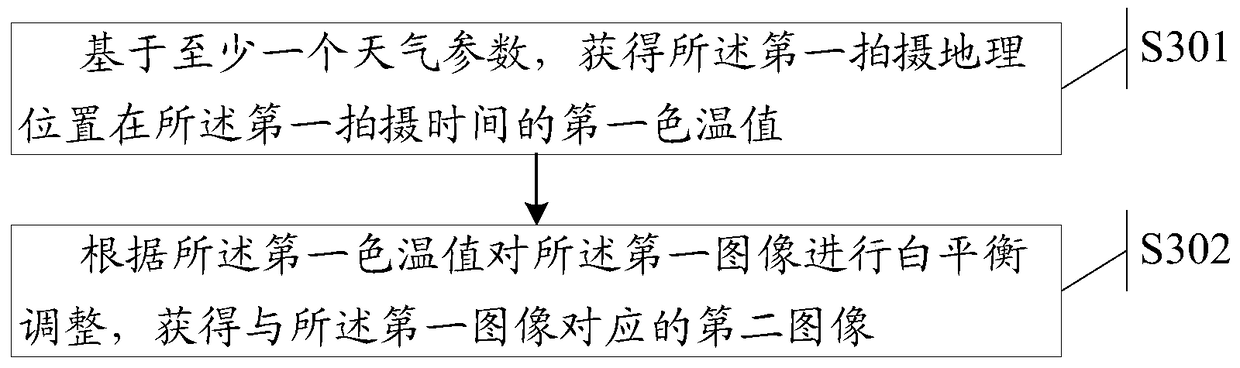

Image white balance control method and electronic equipment

ActiveCN105338333AAccurate correctionEasy and accurate calibrationColor signal processing circuitsPicture signal generatorsState of artComputer science

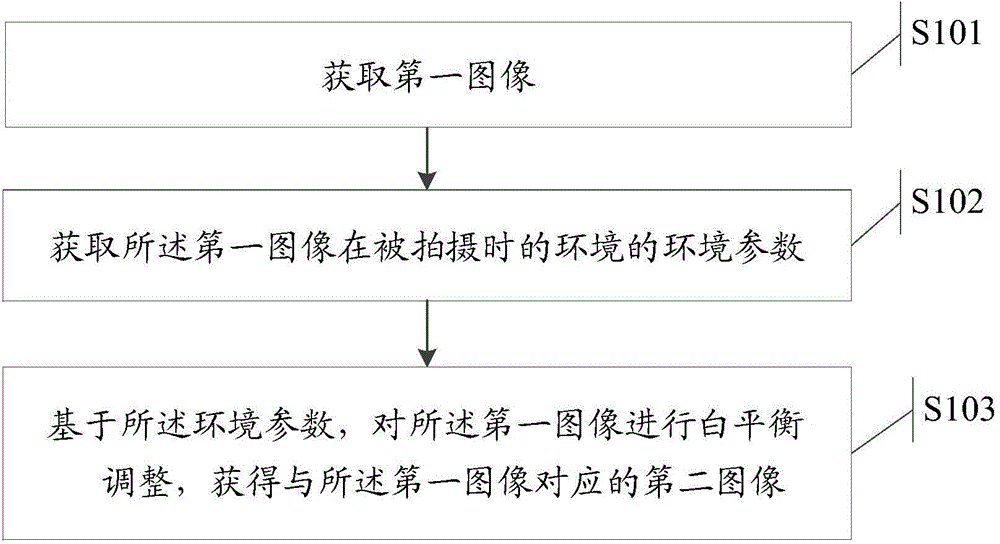

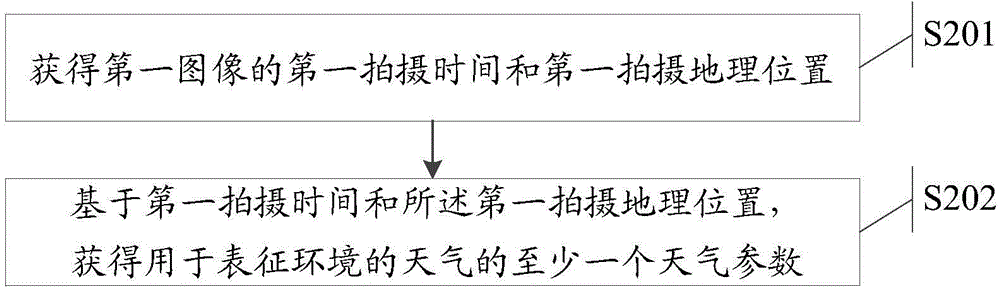

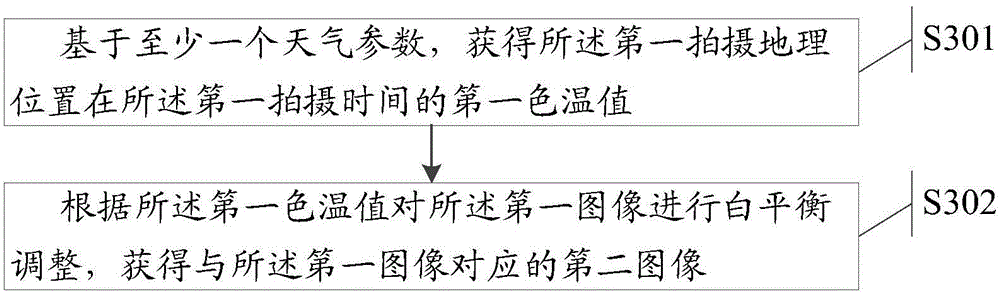

The invention discloses an image white balance control method, and the method is used in electronic equipment. The method comprises the steps: obtaining a first image; obtaining the environmental parameter of the first image during photographing; carrying out the white balance adjustment of the first image based on the environmental parameter, and obtaining a second image corresponding to the first image. The method provided by the invention is used for solving technical problems in the prior art that the image white balance adjustment is lower in accuracy and is complex in process, thereby achieving the white balance adjustment of the image conveniently and accurately.

Owner:LENOVO (BEIJING) LTD

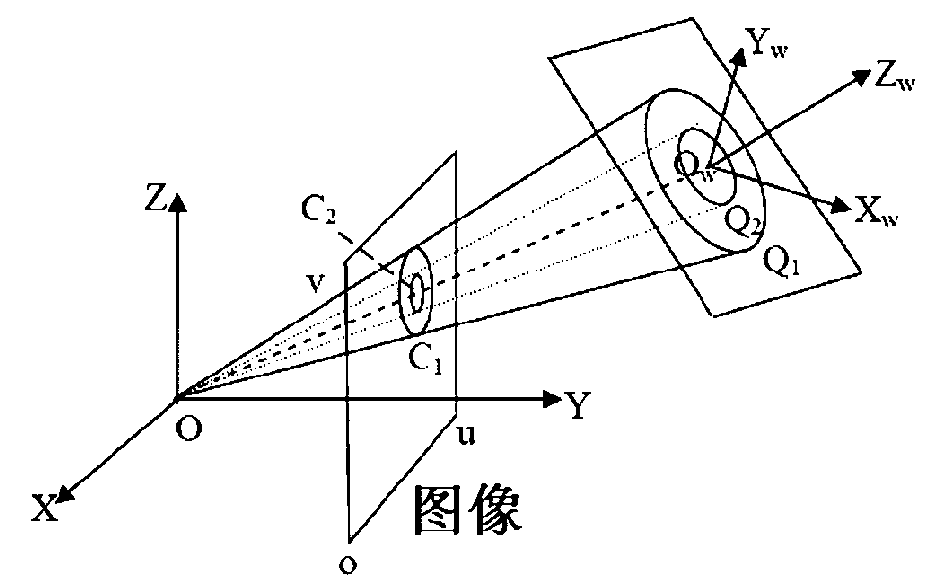

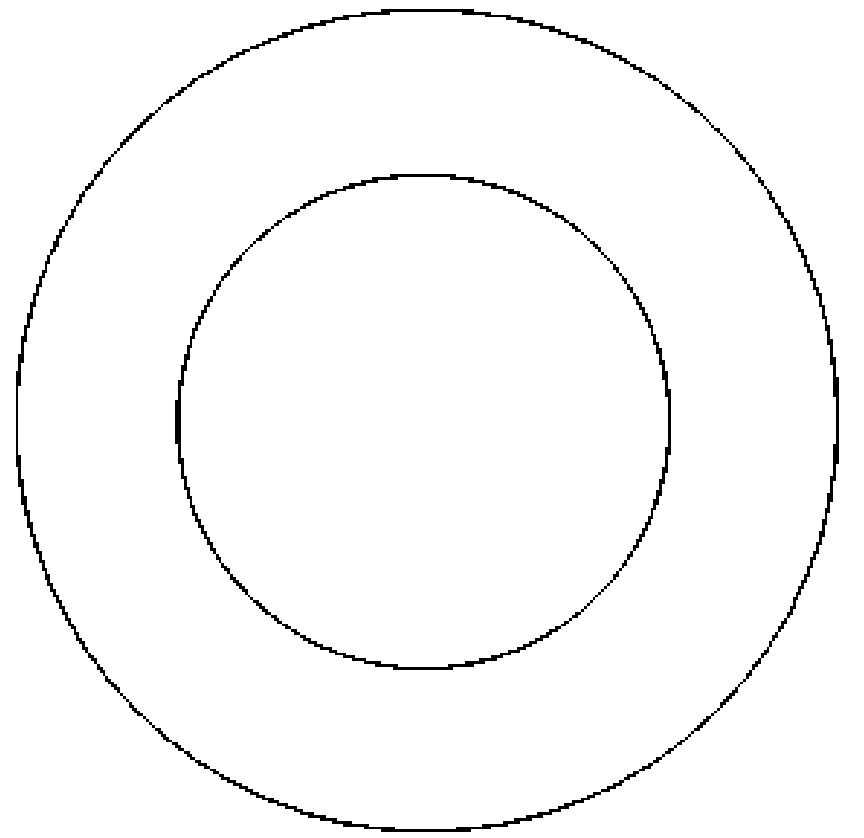

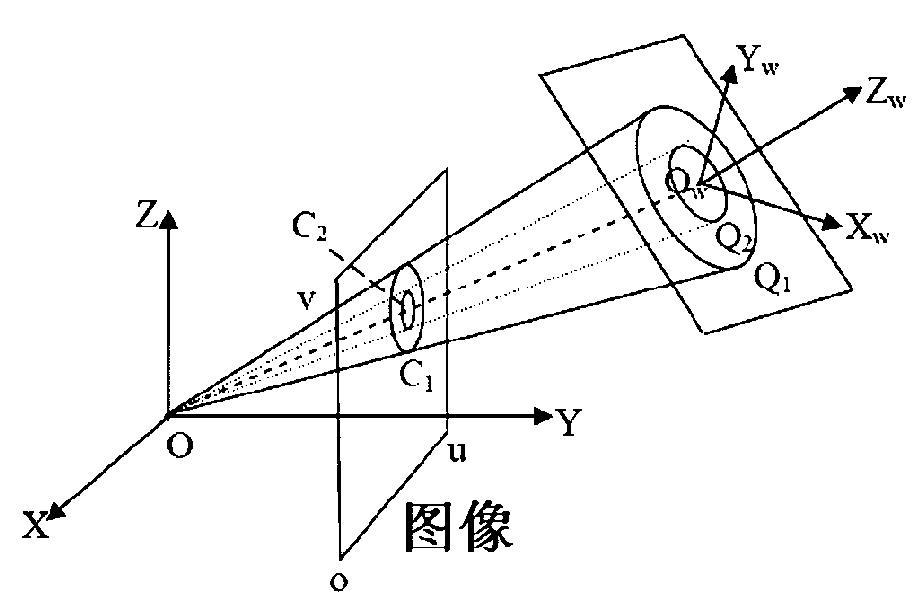

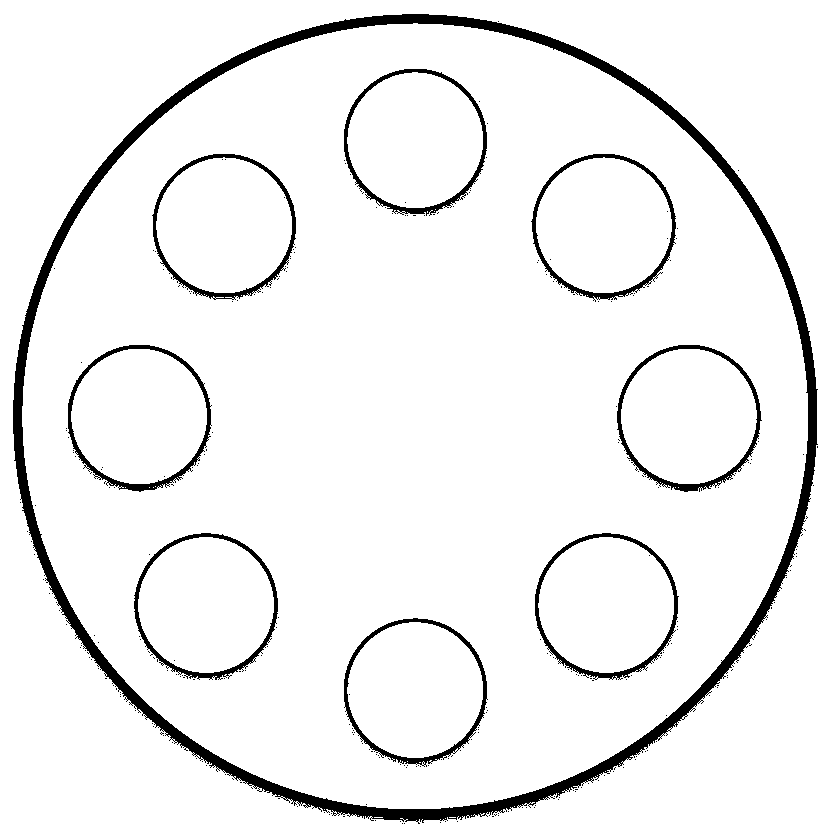

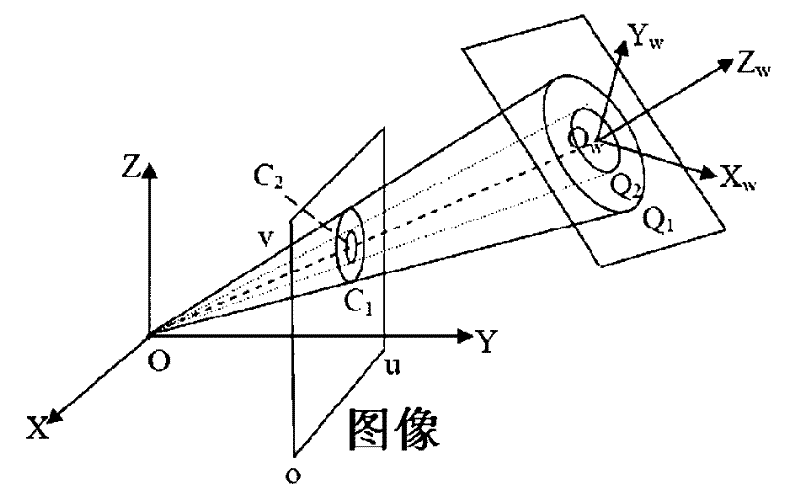

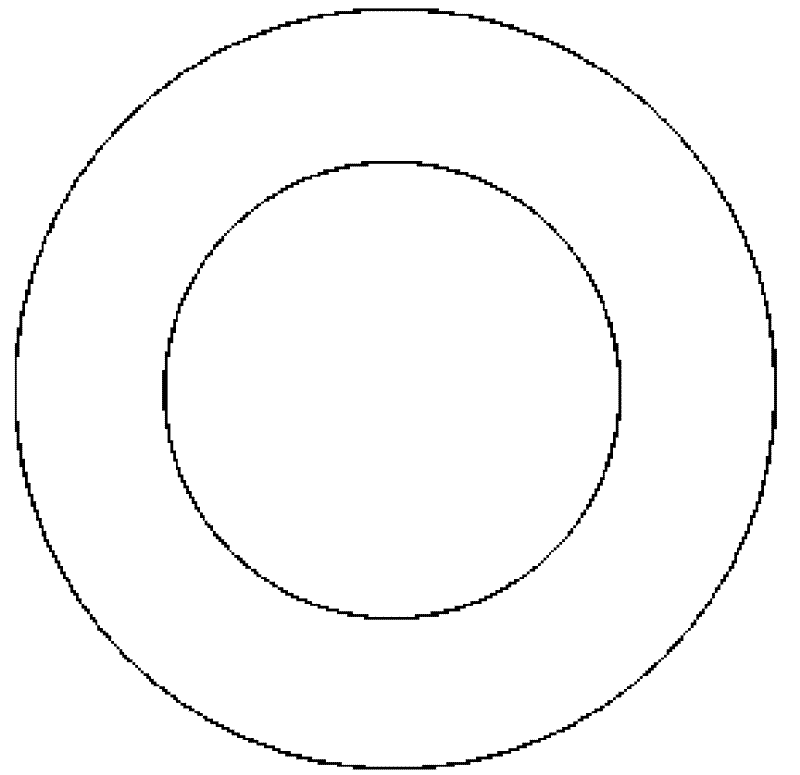

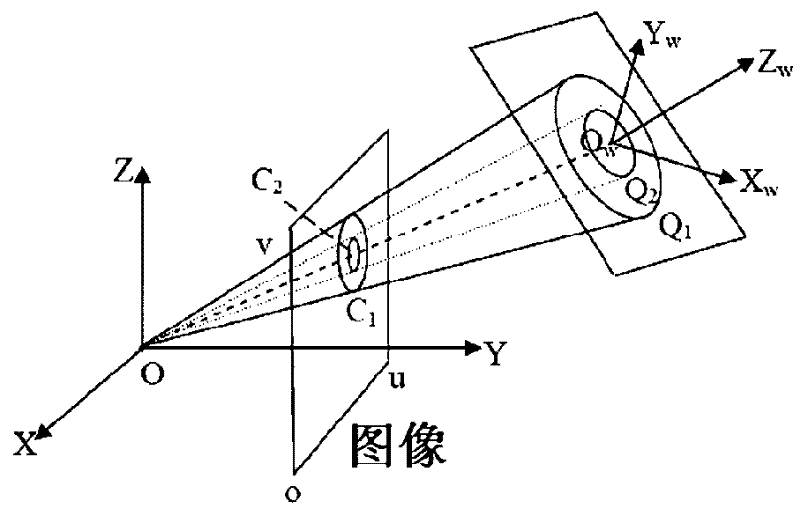

Method for calibrating camera by utilizing concentric circles

InactiveCN101783018AEasy and accurate calibrationRealize CalibrationImage analysisAutonomous Navigation SystemImaging processing

The invention discloses a method for calibrating camera by utilizing concentric circles, and belongs to the technical field of image processing, which comprises the following steps: pasting white paper on a horizontally even panel to prepare a calibration object; acquiring three initial images; fitting according to an elliptical point set to obtain an elliptical image matrix; and obtaining a projection equation of a circle by adopting projective transformation, calculating circle center projection of two concentric circles according to a correlation of a projection equation of the concentric circles, and obtaining a symmetrical matrix according to the circle center projection so as to obtain an internal parameter matrix of the camera and complete the internal parameter calibration of the camera. The method avoids an error caused by a mode that the internal parameters of the camera are determined by calculating imaginary circular points, and a linear method is adopted to simply, conveniently and accurately calibrate all the internal parameters of the camera (including a principal point position, an aspect ratio and an obliquity factor). The method is suitable for vision-based autonomous navigation system and non-contact industrial detection.

Owner:SHANGHAI JIAO TONG UNIV

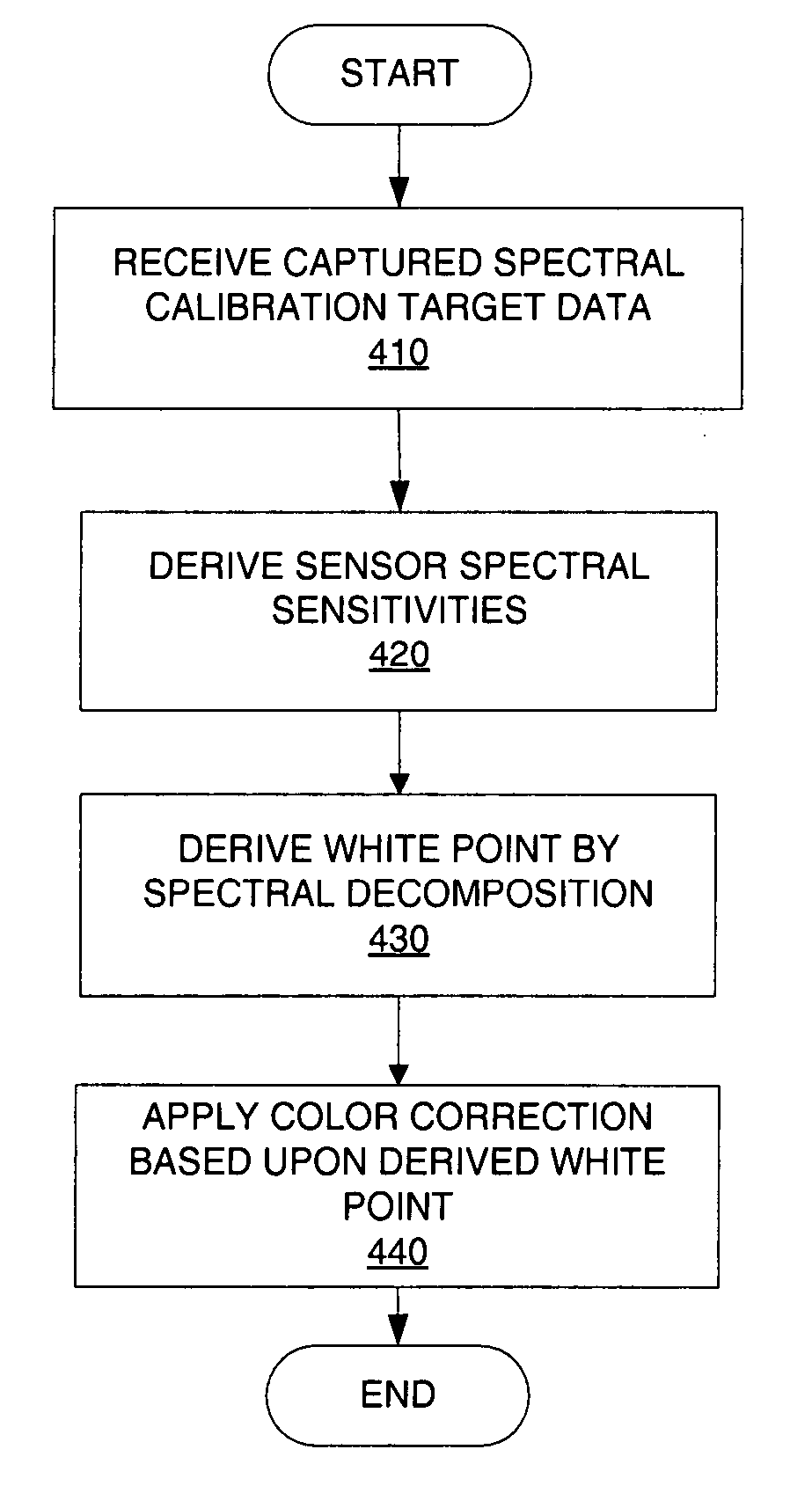

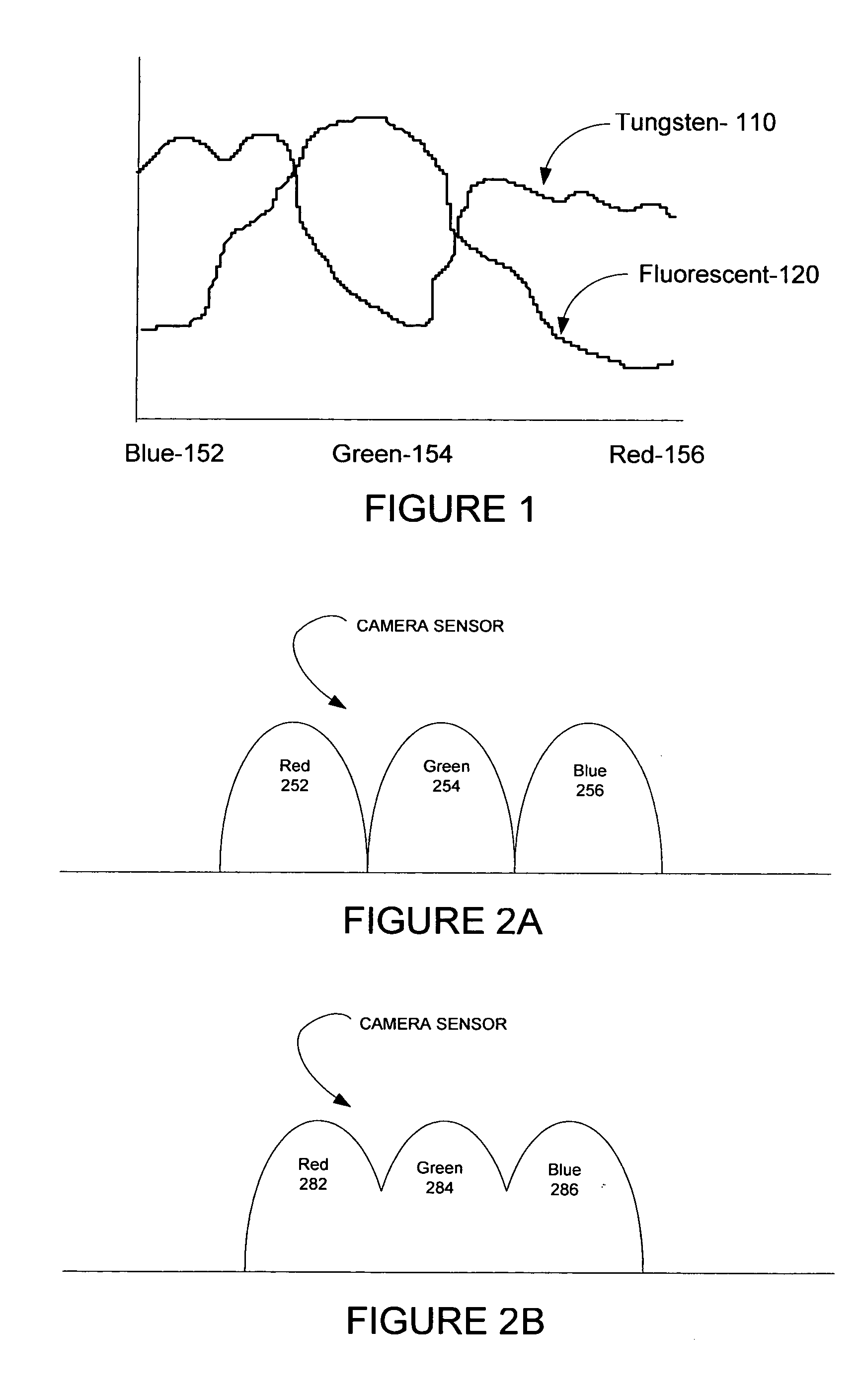

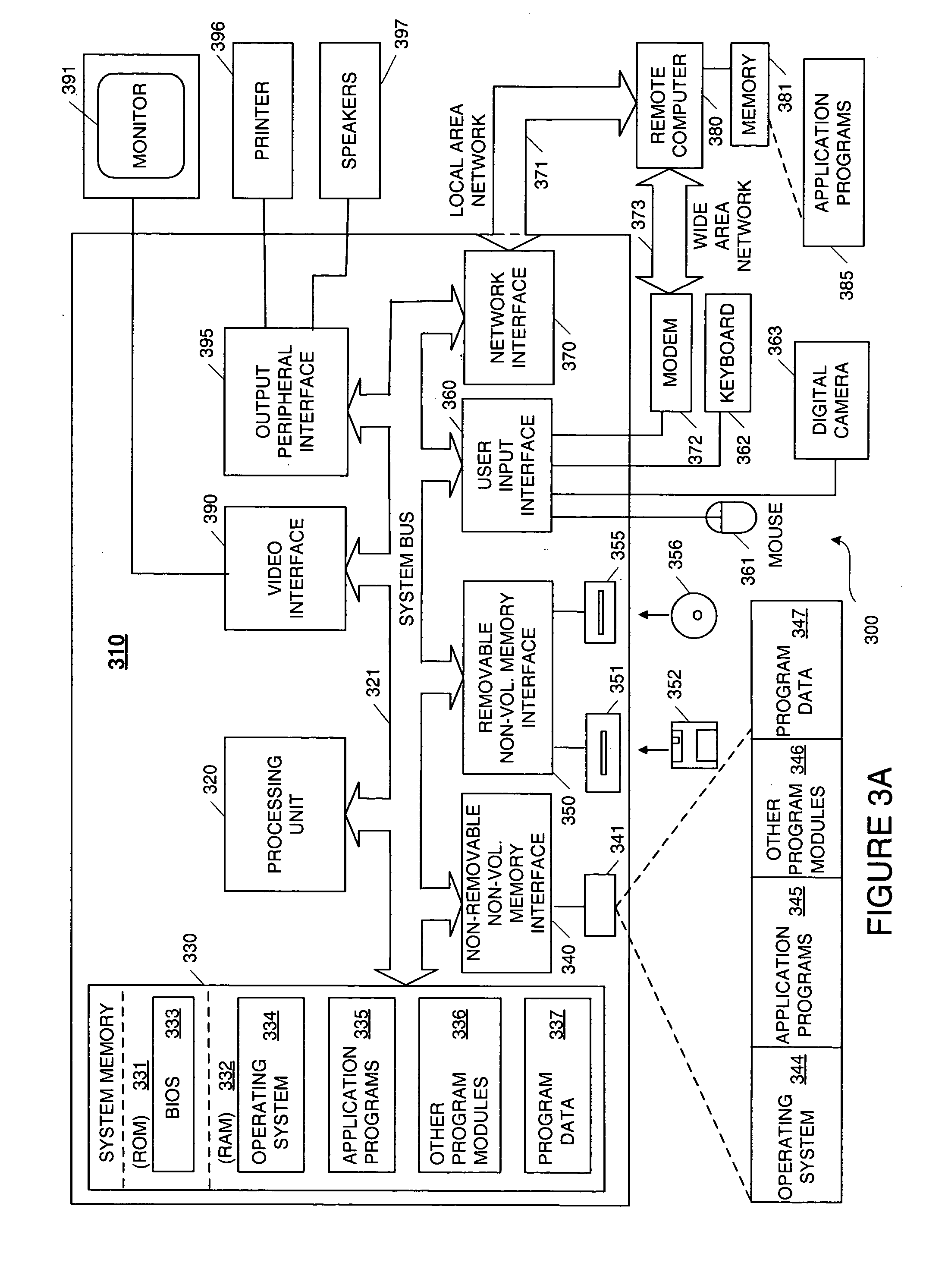

System and method for determination of a white point for calibration of an image capturing device

InactiveUS20050280881A1Easy and accurate calibrationDigitally marking record carriersDigital computer detailsPre-existingImage capture

A method and system for easy and accurate calibration and characterization of an image capturing device is provided. Captured spectral calibration target data is received and sensor spectral sensitivities of the image capturing device are obtained. A determination of white point data for calibration of the image capturing device is made. Sensor spectral sensitivities of the image capturing device can be obtained from data from a manufacturer of the image capturing device or automatically by spectral decomposition methods. The white point data also can be determined by spectral decomposition methods. Captured spectral calibration target data can be obtained from a pre-existing standard, such as IEC 61966-8.

Owner:MICROSOFT TECH LICENSING LLC

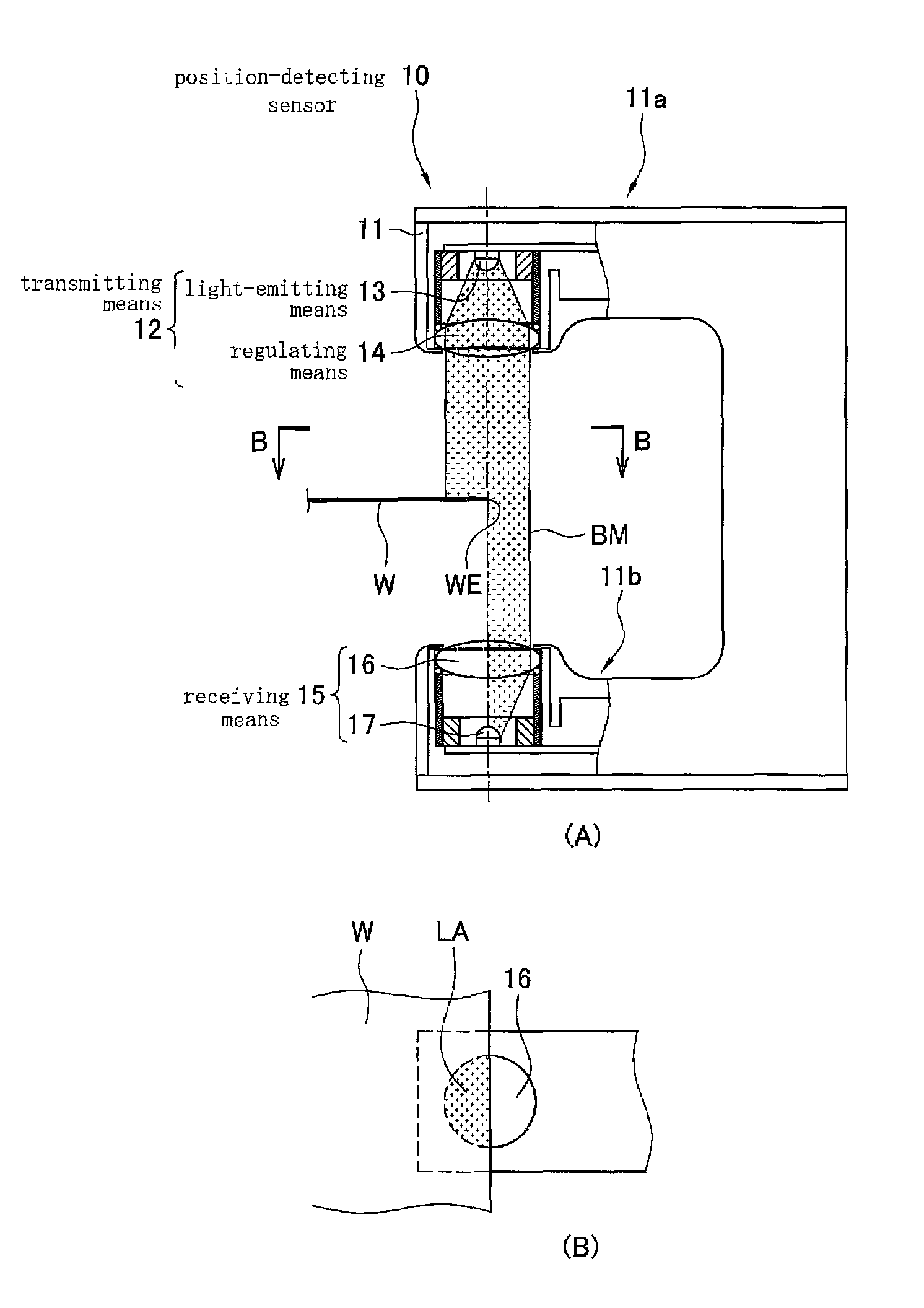

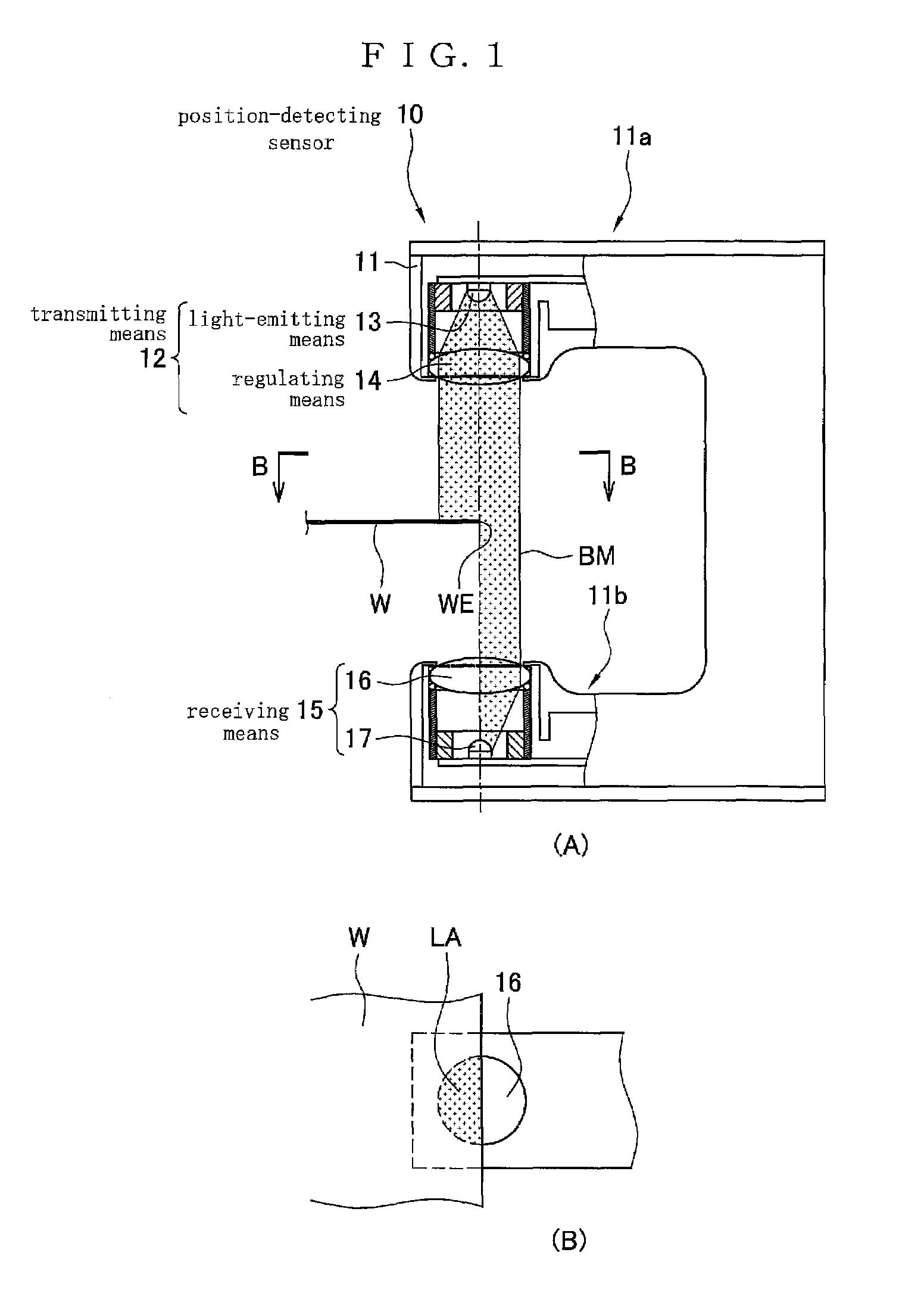

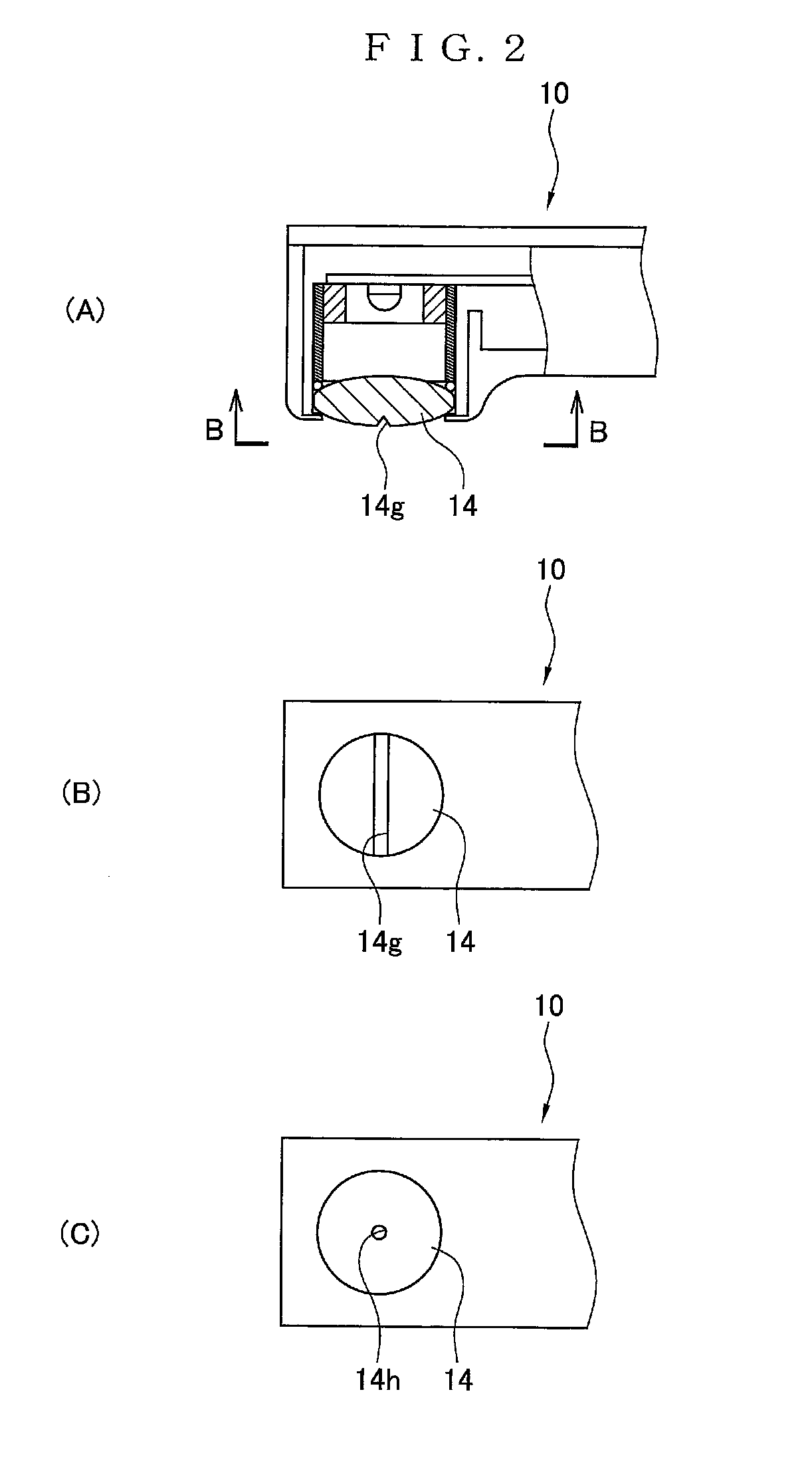

Position-detecting mechanism and position-detecting sensor

ActiveUS7719696B1Easy to judgeEasily and safely judge position of subject of measurementInvestigating moving sheetsUsing optical meansLocation detectionProduction line

This invention provides a position-detecting mechanism and a position-detecting sensor, the calibration of the sensor easy, the deviation of a web from the reference line of the sensor easy to find. The position-detecting mechanism comprises (i) a light-emitting means 13 to emit a beam of visible light to a subject of measurement and (ii) a regulating means 14 to regulate the beam so that its cross section will be in a certain shape at the place of the subject of measurement and detects the position of the subject of measurement. Because the light-emitting means 13 emits a beam of visible light, the spot lit up by the beam on a subject of measurement is visible to the operator. Accordingly, the operator can judge the position of the subject of measurement by using his eyes alone without using a scale and easily, safely judge its position even while it is running on its production line.

Owner:JUSTIN CO LTD +1

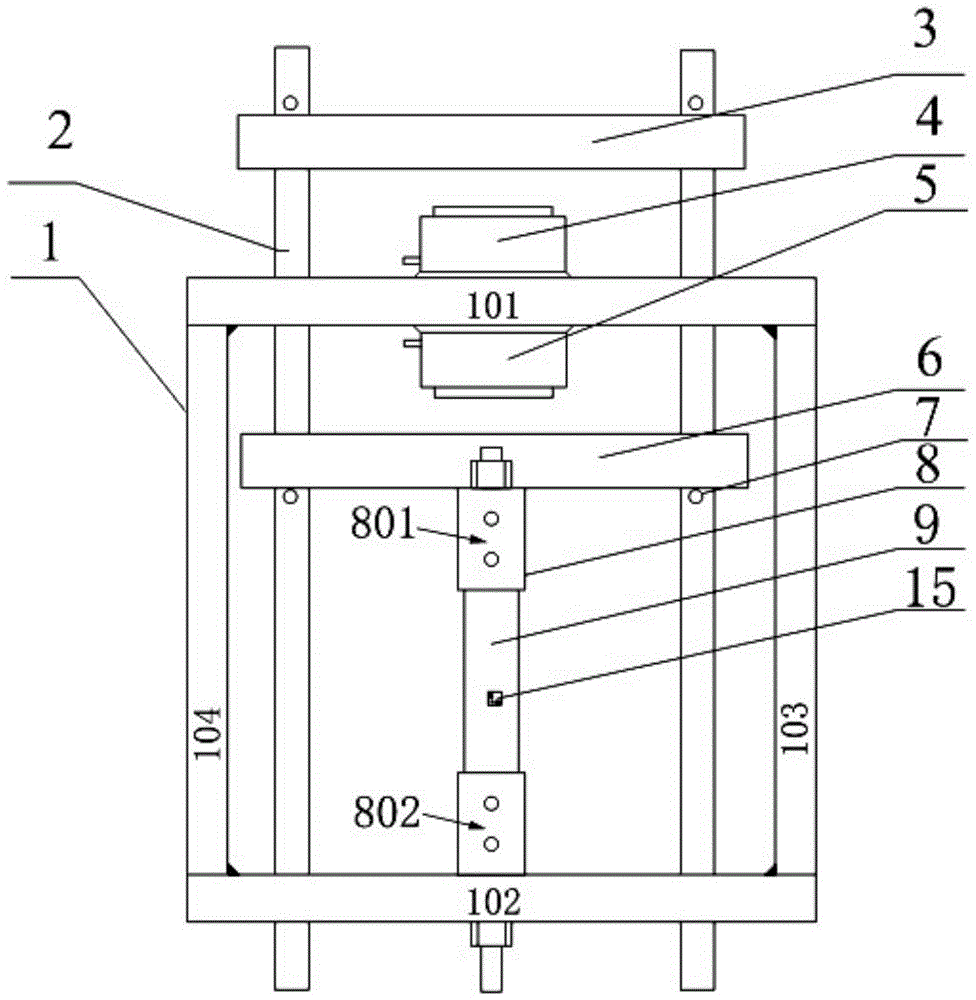

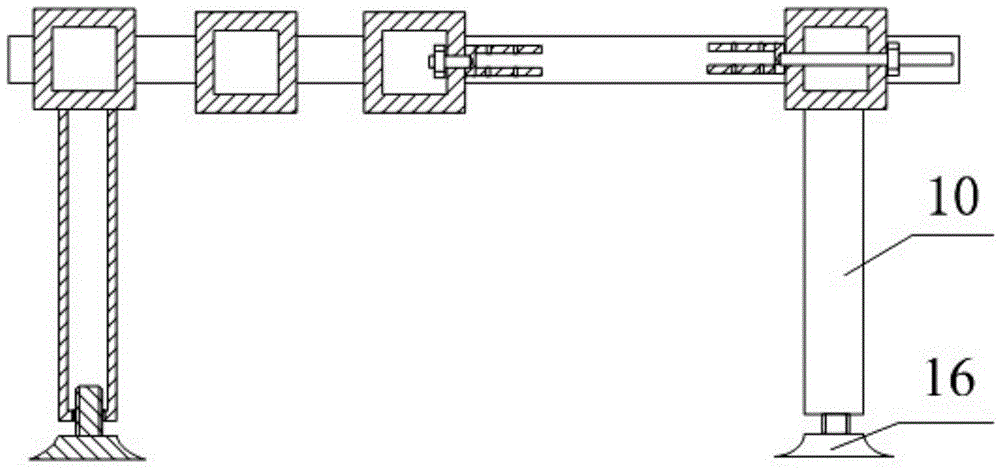

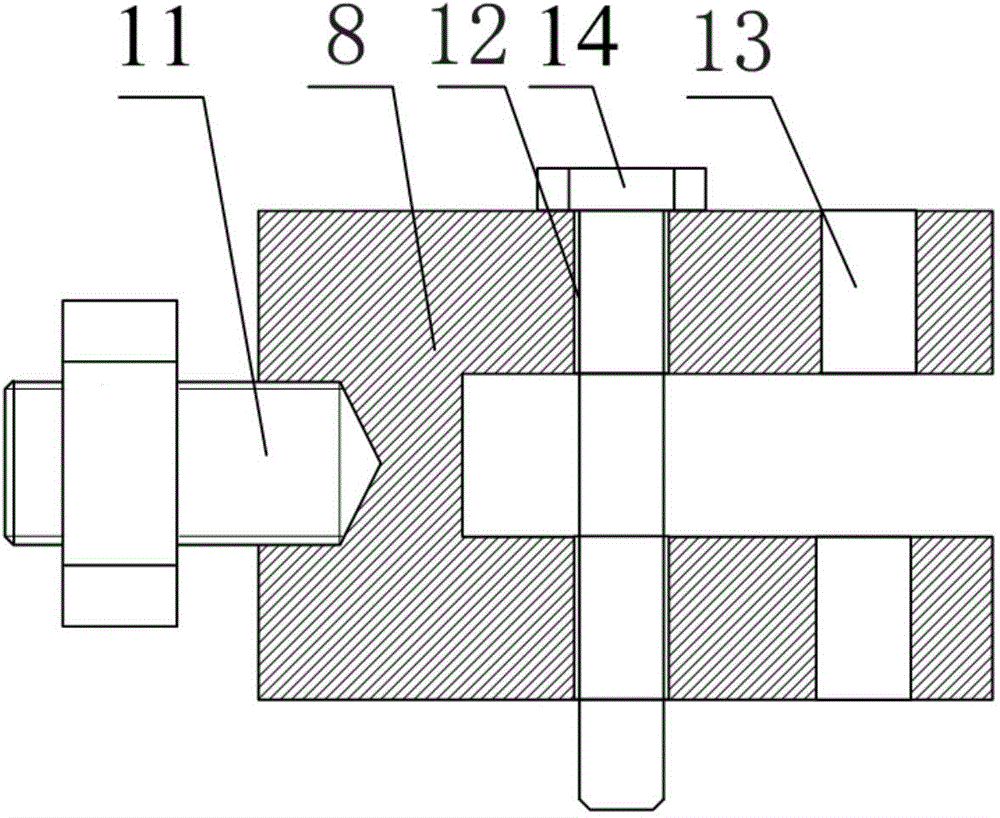

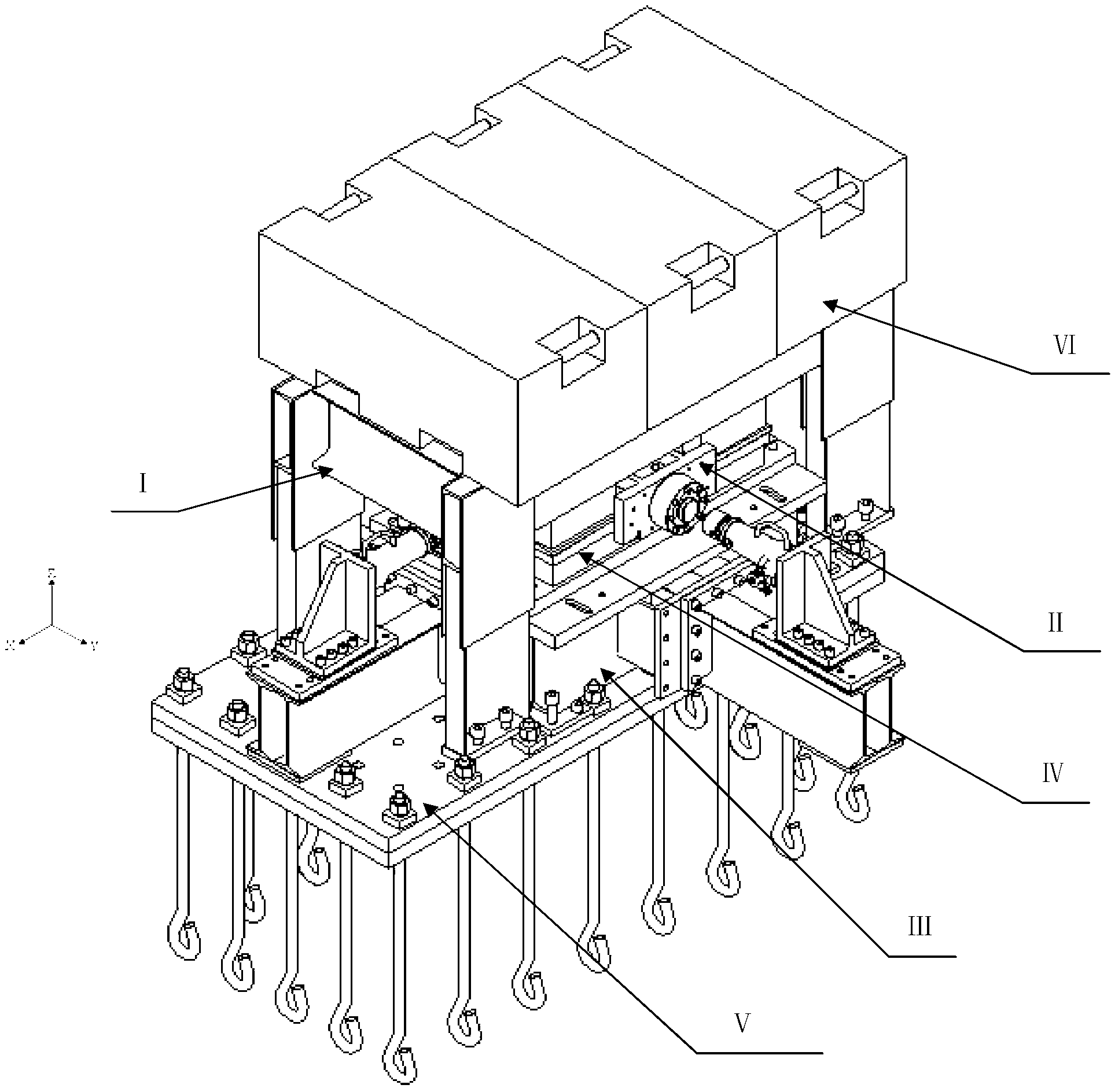

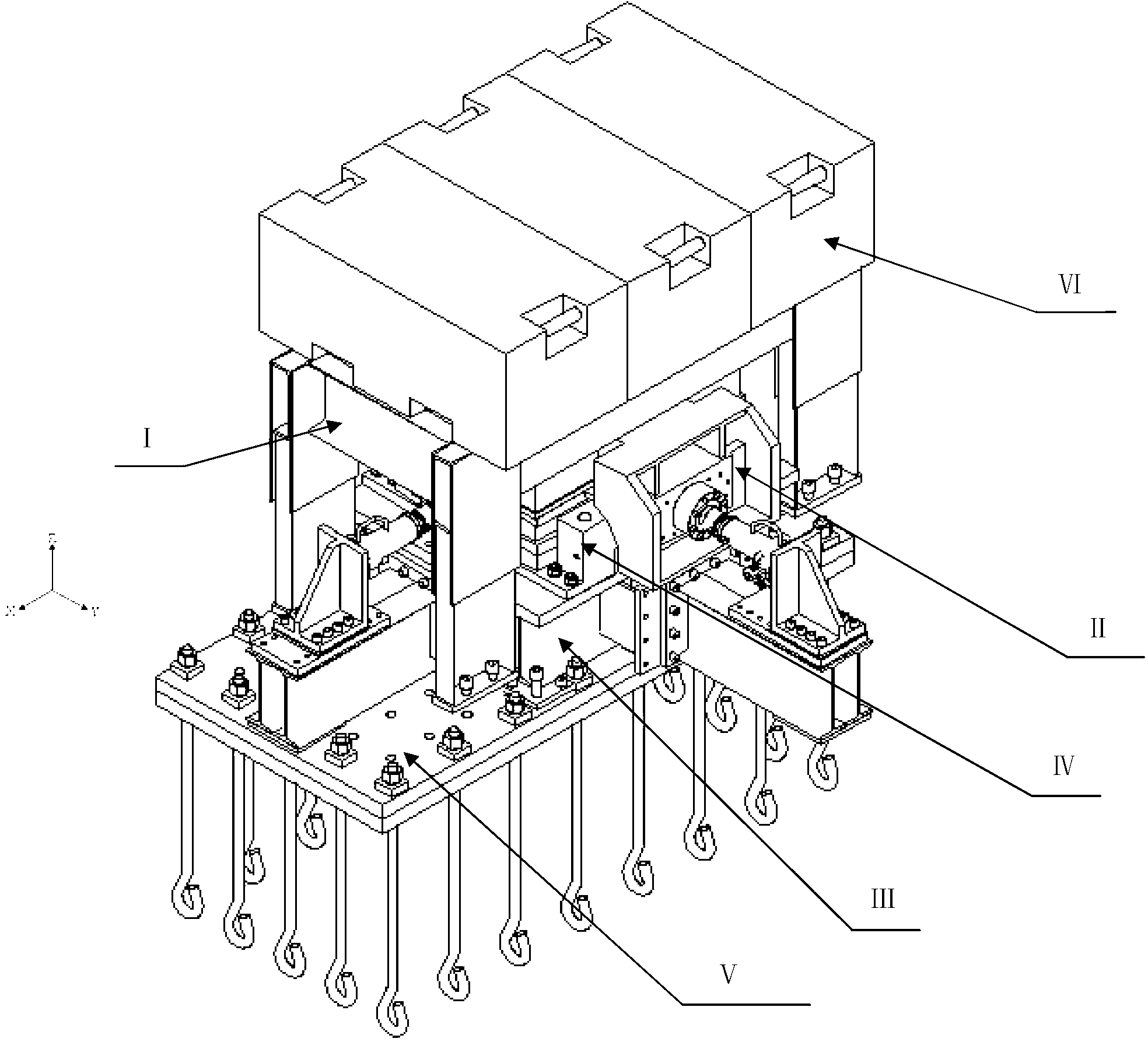

Device for calibrating tension and compression type residual stress

ActiveCN106153458AEasy and accurate calibrationThe stress-strain relationship is convenient and accurateMaterial strength using tensile/compressive forcesStress measurementEngineering

The invention discloses a tension-compression type residual stress calibration device, which belongs to the technical field of experimental stress measurement in material processing. The device includes a tension and compression loading mechanism, a clamping mechanism and a supporting mechanism. The tension-compression loading mechanism applies uniform tensile or compressive stress in the direction of the entire thickness of the calibration material; the clamping mechanism can adjust the clamping position according to the tension-compression type of the calibration material; the tension-compression loading mechanism and Clamping mechanism, and can adjust the height by itself. The present invention can be used as a supporting loading device for residual stress detection methods such as blind hole method, indentation strain method, etc., to accurately calibrate the stress-strain relationship of materials under tensile stress state and compressive stress state. It solves the problems of convenience and ease of use but uneven stress field during three-point bending loading, or the need for large-size samples and difficult loading when using a tensile testing machine for calibration.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

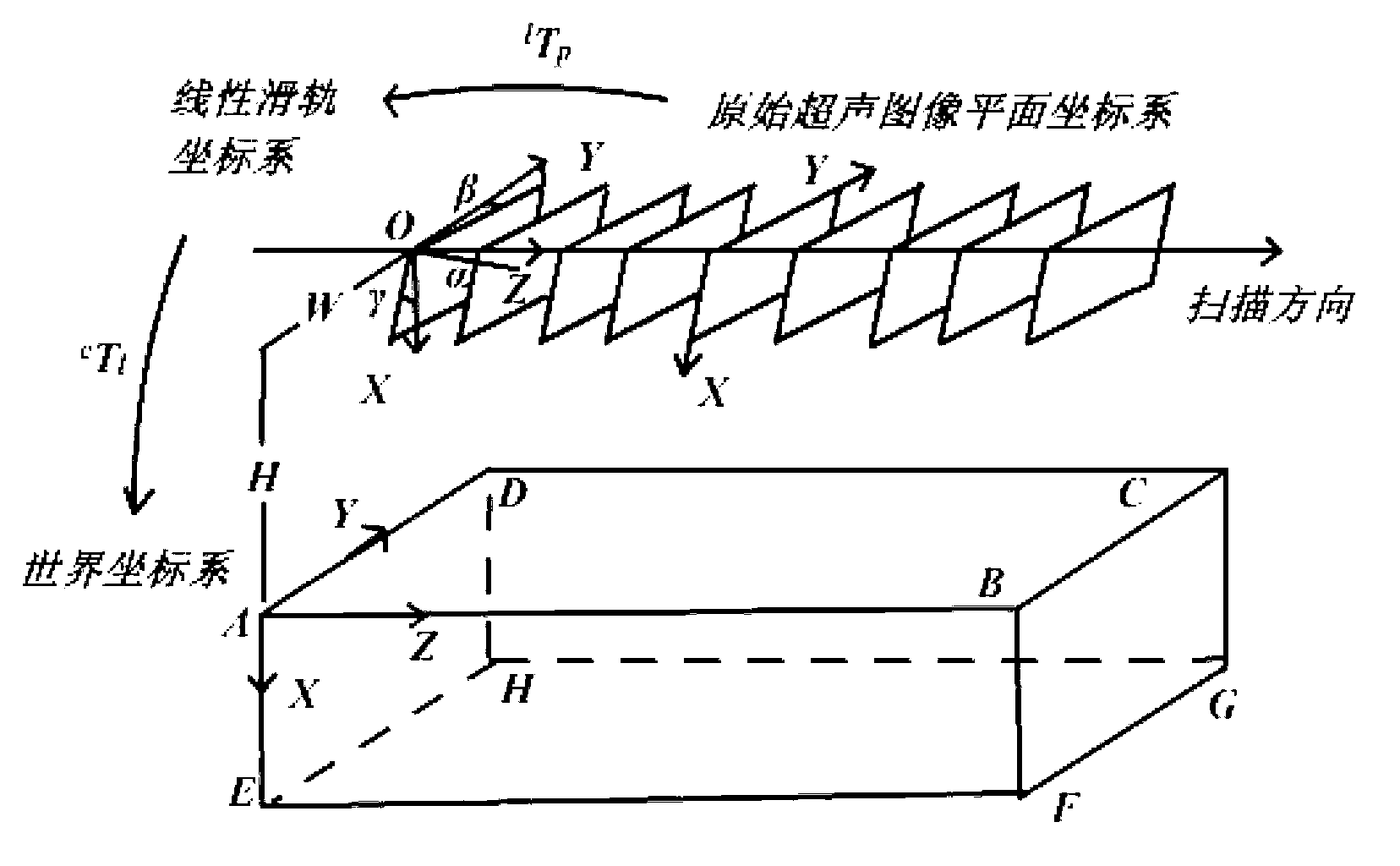

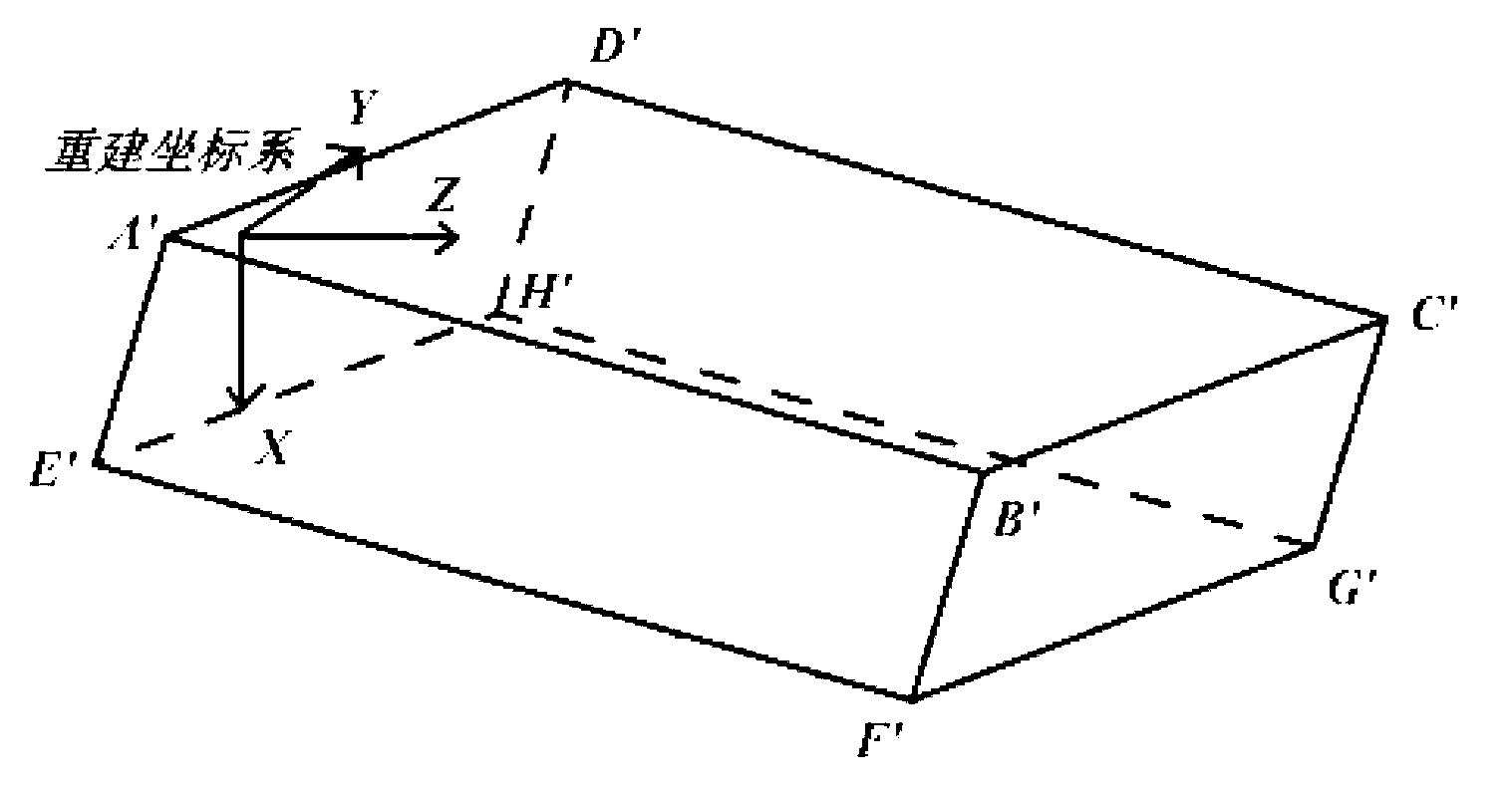

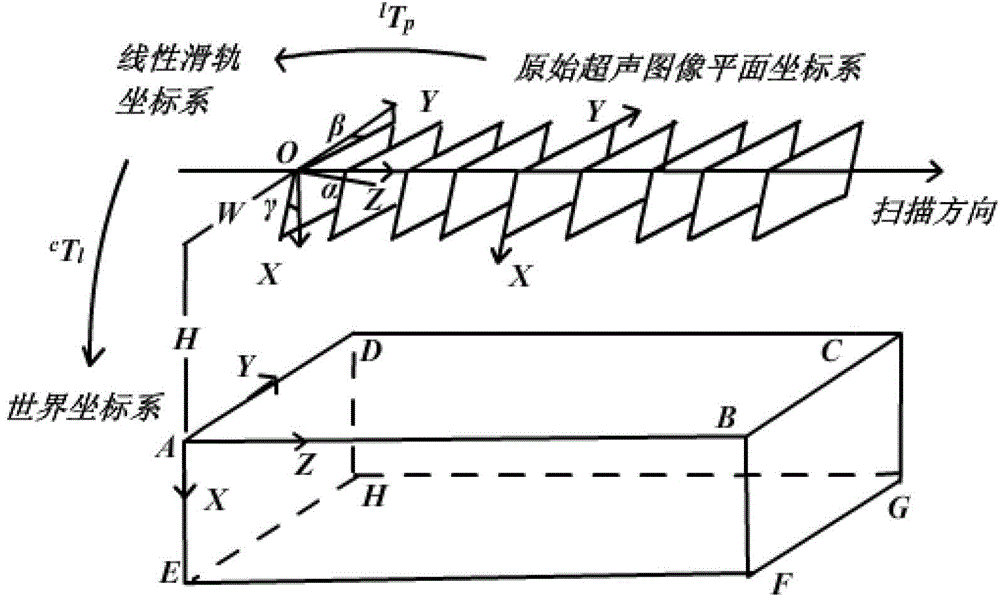

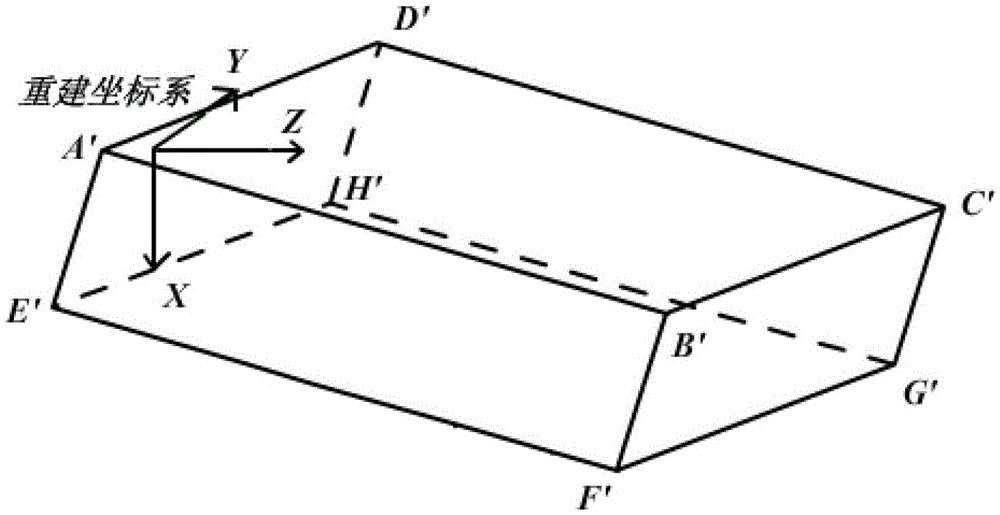

Position calibrating method of medical ultrasonic three-dimensional imaging based on linear scanning

InactiveCN103006263AEasy to operateReduce dependenceUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsUltrasonic imagingLaser scanning

The invention discloses a position calibrating method of a medical ultrasonic three-dimensional imaging based on linear scanning, comprising the steps that a rectangular solid with known sizes is used as a scanning object, on the premise of assuming that an angle conversion relationship does not exist between an original ultrasonic image plane and a linear guide rail, a two-dimensional image is subjected to the three-dimensional reconstruction, and then an actual mathematic relationship of the angle and the deformation amount of the reconstructed rectangular solid between the original ultrasonic image plane and the linear guide rail can be calculated; and in the actual calibrating process, the rectangular solid is scanned by a linear scanning method, the sequence of the ultrasonic image is subjected to the three-dimensional reconstruction, the deformation amount of the reconstructed rectangular solid is substituted into a mathematic relationship to calculate the rotation angle between the original ultrasonic image plane (i.e. the position of an ultrasonic probe) and the linear guide rail, and the rotation angle is the calibrating result of the position of the ultrasonic probe in the linear scanning mode. The position calibrating method has the advantages that the simplicity and the easy understanding are realized, the operability is high, the test is simple, and the calibrating is convenient and accurate. The position calibrating method can be used for a three-dimensional ultrasonic imaging system based on a free arm linear scanning method or a mechanical driving linear scanning method.

Owner:SOUTH CHINA UNIV OF TECH

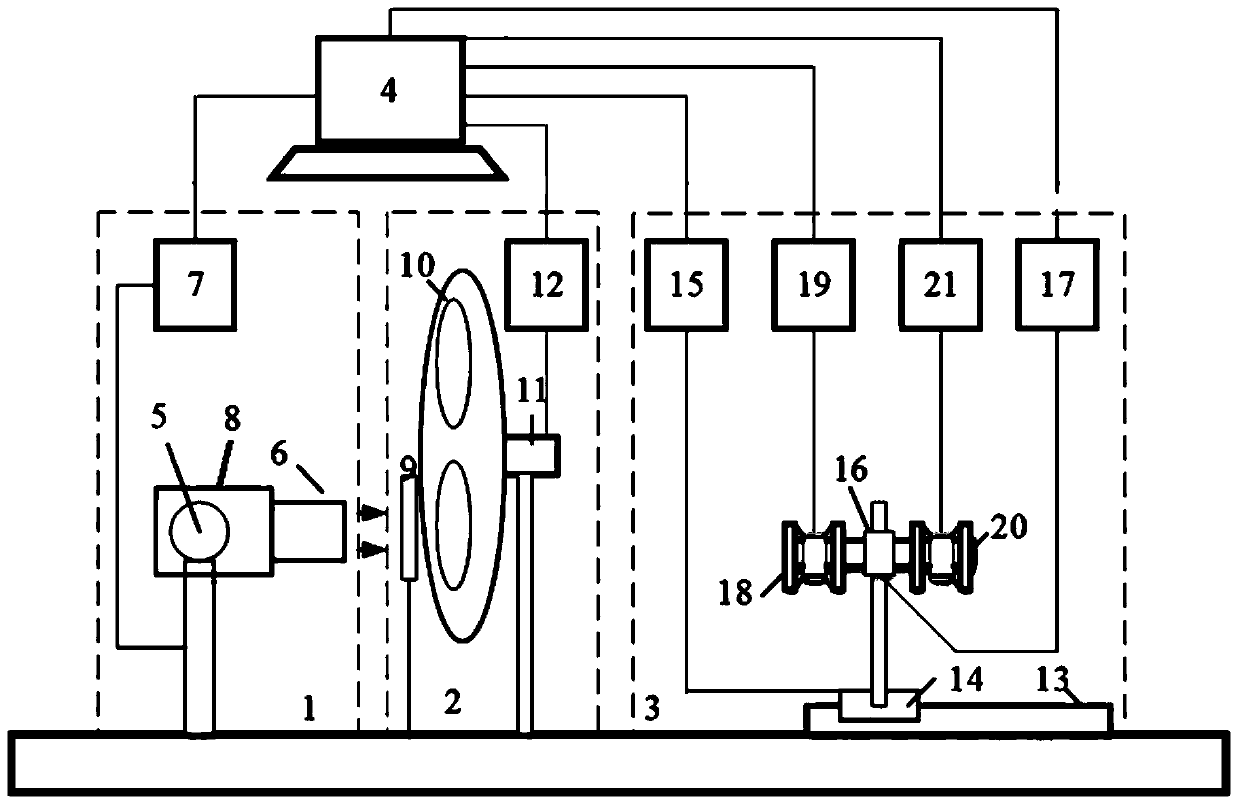

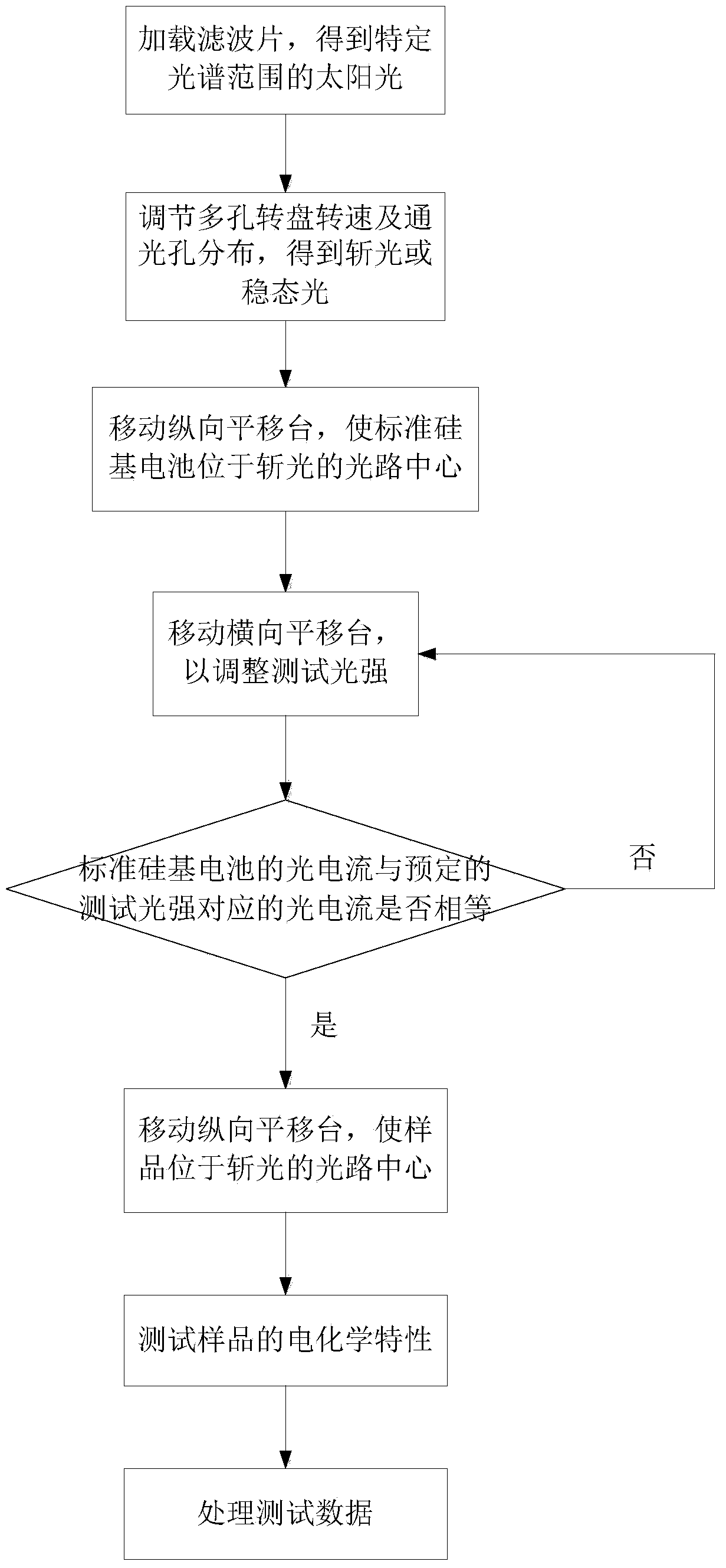

Photocatalysis photoelectrochemistry integrated test system and method based on light control

InactiveCN103728354ATest electrochemical propertiesEasy and accurate calibrationMaterial electrochemical variablesTester deviceEngineering

The invention discloses a photocatalysis photoelectrochemistry integrated test system and method based on light control. The system comprises a sunlight simulator, a photochopper, a testing module and a controller, wherein the sunlight simulator comprises a filtering piece and a multi-hole turntable; the filtering piece is positioned on an output light path of the sunlight simulator and is used for obtaining the sunlight in a specific spectral region, and the multi-hole turntable is used for enabling the output light of the filtering piece to be changed into chopping light with the specific frequency and the duty ratio; the testing module comprises a horizontal translation platform, a longitudinal translation platform, a calibrating tester and an electrochemistry tester, the horizontal translation platform is used for adjusting the light intensity of the testing light of a standard cell or a sample, the longitudinal translation platform is used for enabling the standard cell or the sample to be positioned on an output light path center of the photochopper, and the calibrating tester is used for testing the light current of the standard cell. The photocatalysis photoelectrochemistry integrated test system and the method provided by the invention have the advantages that the electrochemical property of a photocatalyst under different light conditions is tested, the photocatalysis research and improvement are further promoted, and the photocatalyst efficiency is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

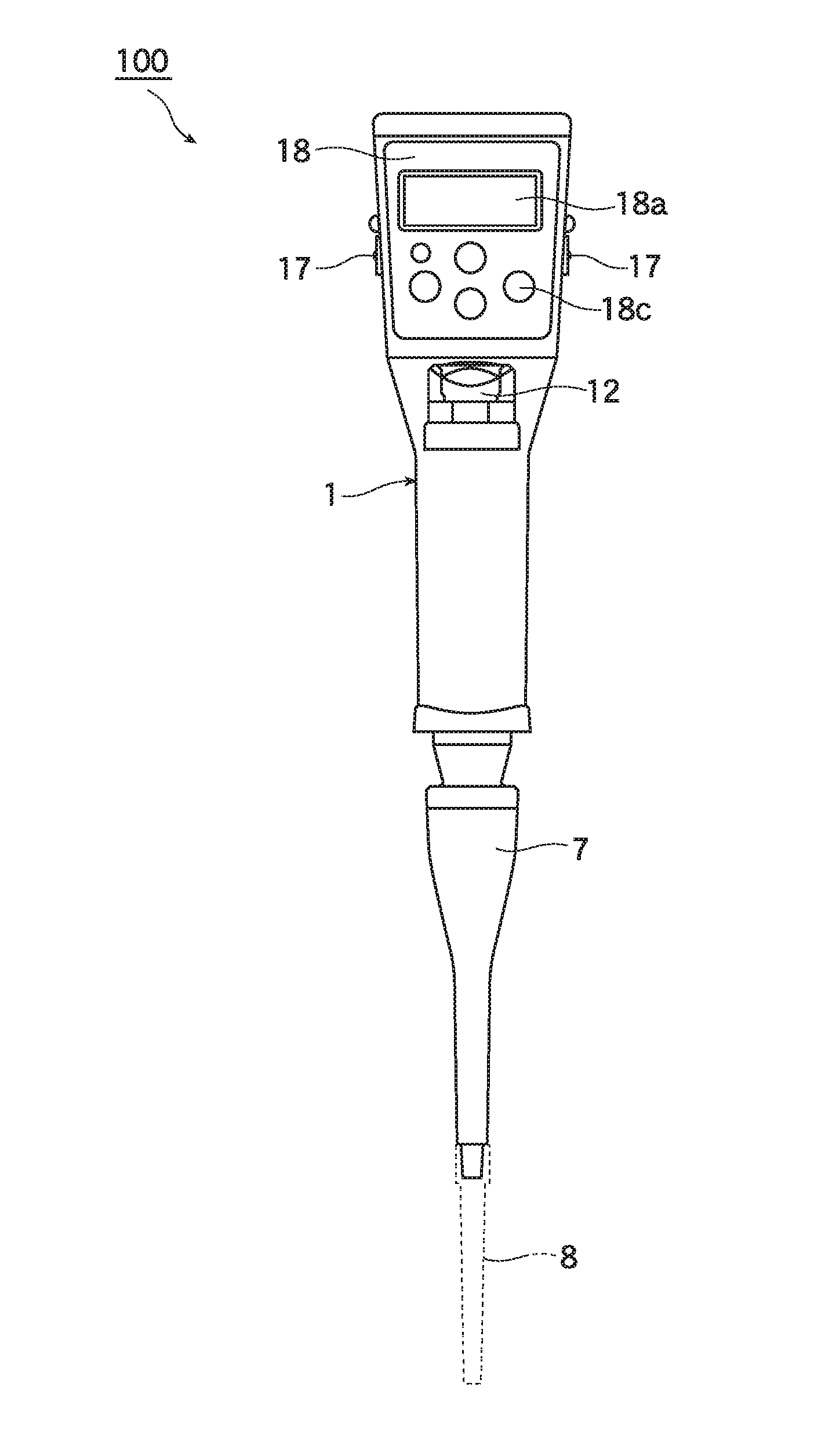

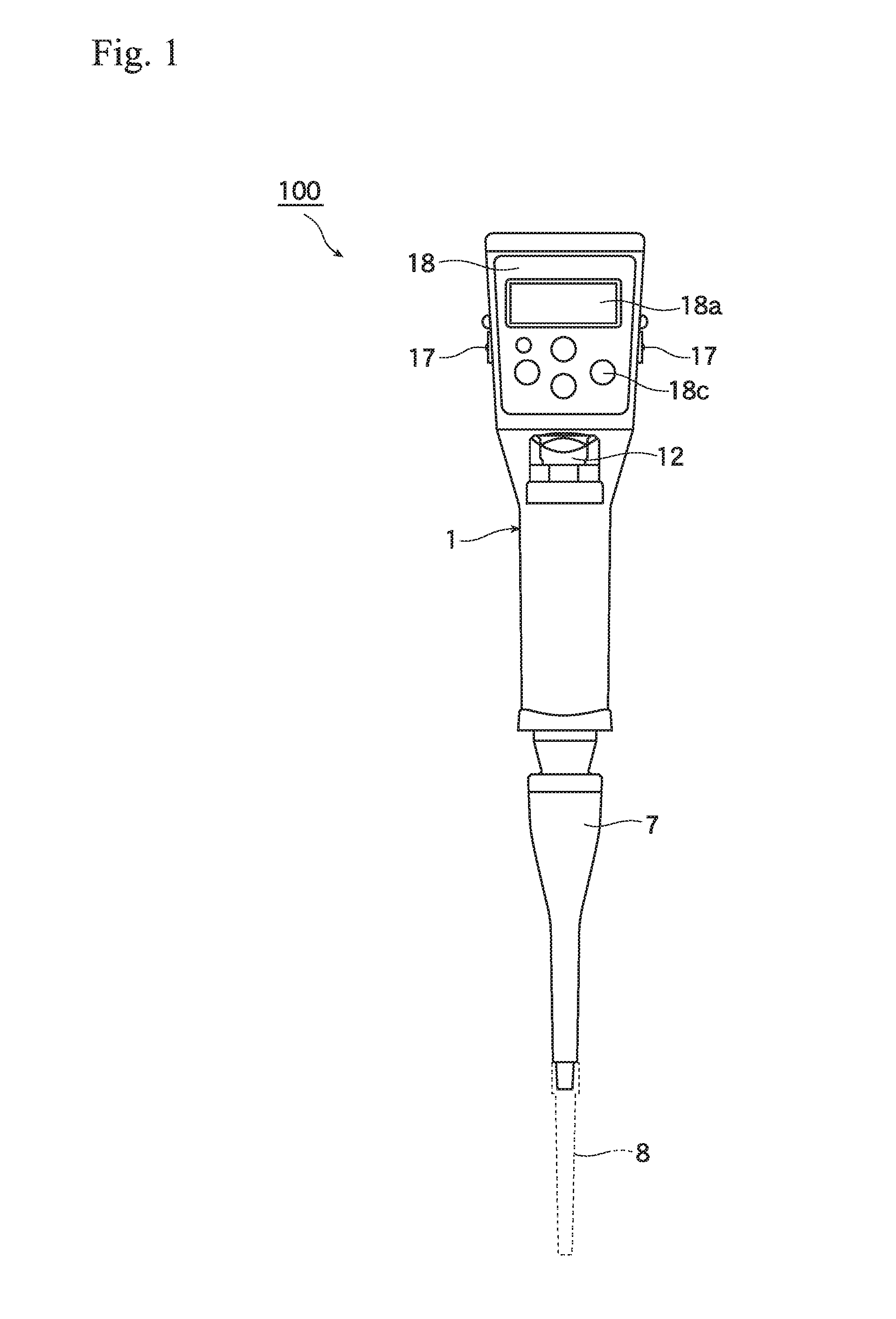

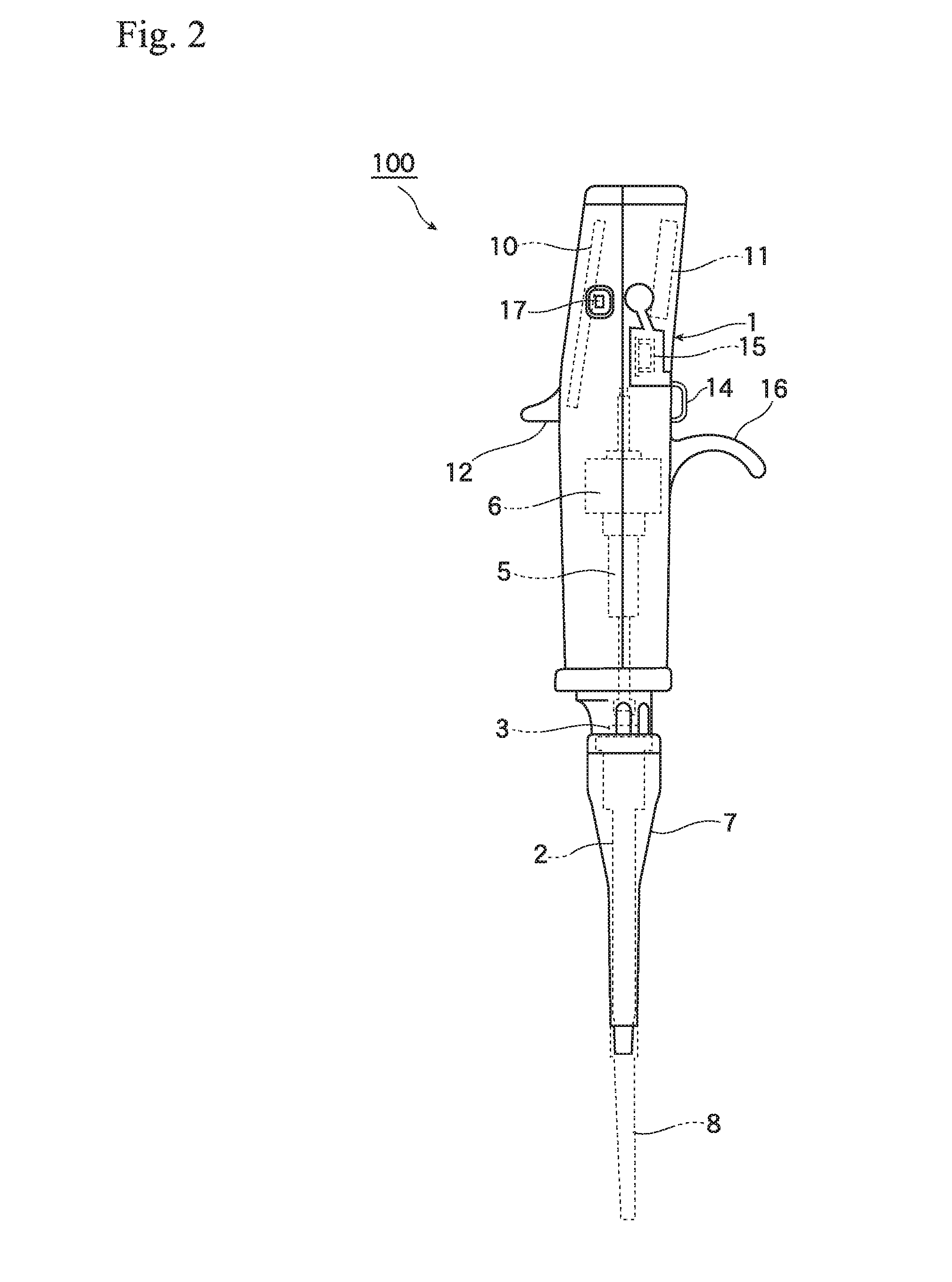

Method for accurately calibrating discharge volume of pipette, and apparatus therefor

InactiveUS20160236189A1Easy and accurate calibrationPrevent wrong dischargeWeighing apparatus using counterbalanceSamplingPipetteEngineering

To provide a method for calibrating a discharge volume of the pipette that enables accurate measurement of the discharge volume under arbitrary conditions, and to provide an apparatus therefor. The method including the steps of, setting a preset volume by the pipette that is actually used in a measurement (S1), sucking liquid that is actually used in the measurement into the pipette chip that is actually used in the measurement while aiming to be sucked the preset volume (S2), discharging the liquid sucked in the pipette chip onto a measuring apparatus (S3), determining an actual discharge volume of the pipette based on the weight measured (S4 to S6) and calculating a ratio between the preset volume and the actual discharge volume and correcting a sucking amount so as to bring the sucking amount to match an amount obtained by multiplying the preset volume by the ratio (S7 to S9).

Owner:A&D CO LTD

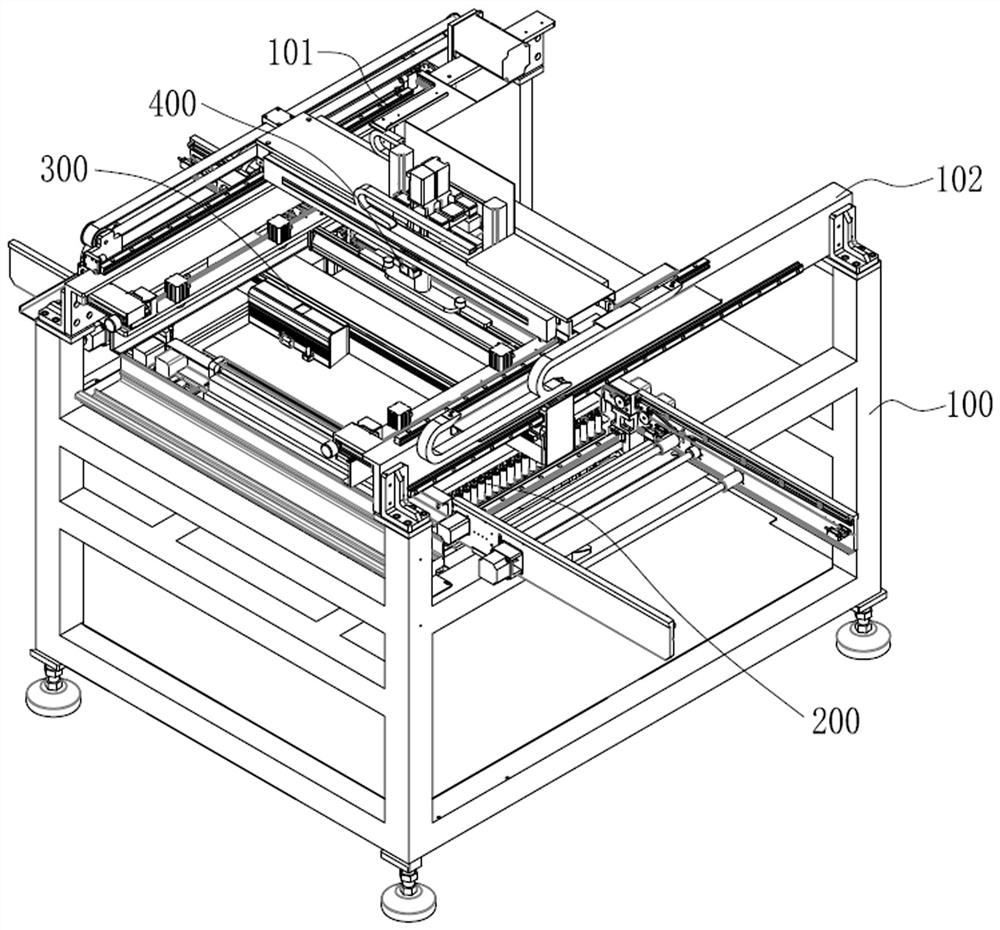

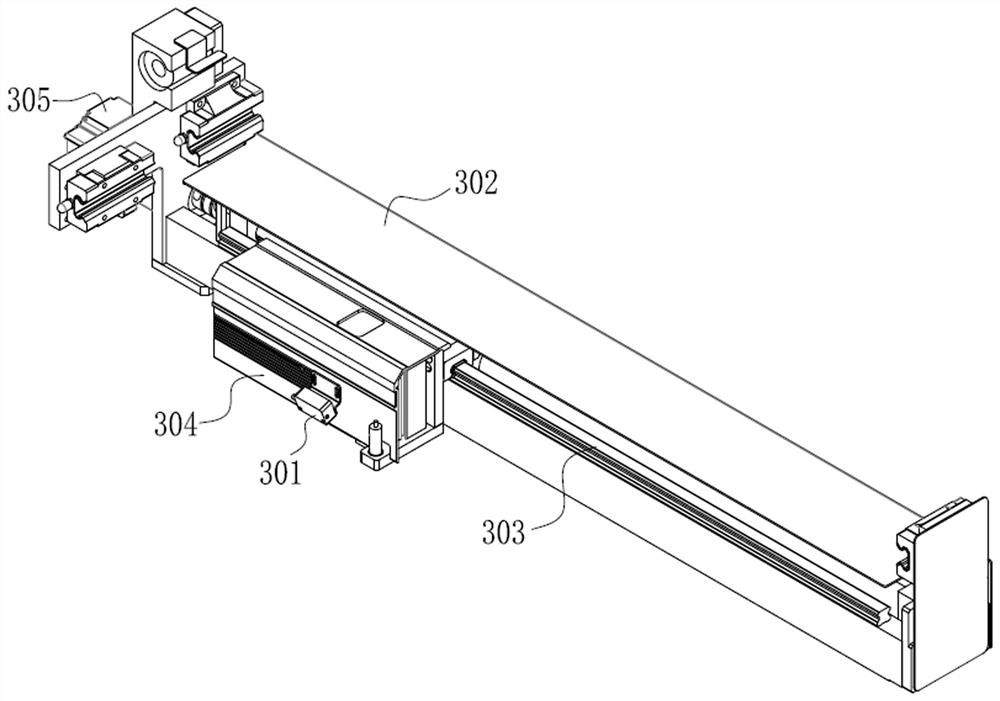

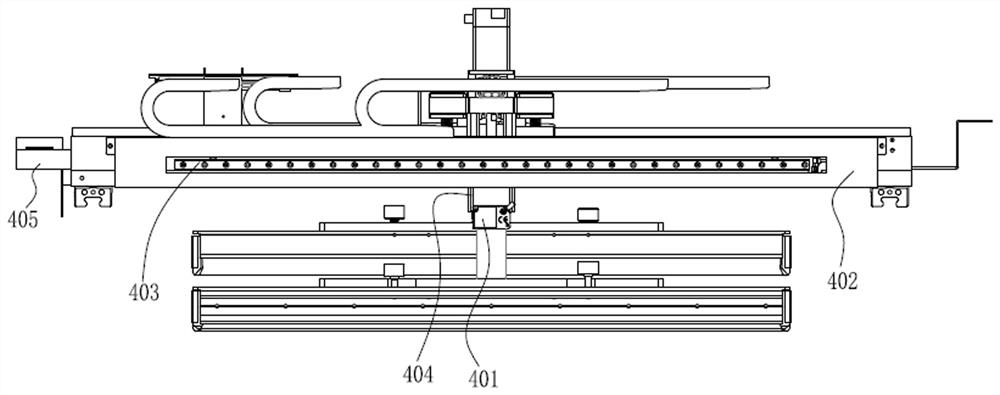

Image calibration device and method for mark on printed board

ActiveCN113079654APrecise positioningEasy and accurate calibrationPrinted circuit assemblingComputer graphics (images)Image calibration

The invention discloses an image calibration device and method for a mark on a printed board, the image calibration device for the mark on the printed board comprises a board feeding unit, a main camera unit, an auxiliary camera unit and a control system, and the image calibration method for the mark on the printed board comprises the following steps: fixing and conveying the printed board by the board feeding unit; the auxiliary camera unit preliminarily shoots a printing plate image, uploads the image to a control system display screen, clicks to determine an image where the mark position is located, then the main camera unit converts the determined position image of the mark into a view, fine adjustment of mark coordinates is carried out, and after the mark position is fine adjusted, clicks, stores and establishes coordinate parameters of the mark, and the mark is calibrated; and then the control system controls the main camera unit to be converted into a view mode, the mark on the printed board is calibrated or scanned and recognized, and the calibration, calibration or detection work of the mark can be completed after calibration or scanning is completed. The calibration method is irrelevant to the shape of the printed board, and the mark calibration is more accurate and rapid.

Owner:HONGYI TECH AUTOMATION EQUIP HUIZHOU CO LTD

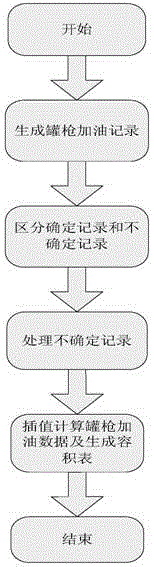

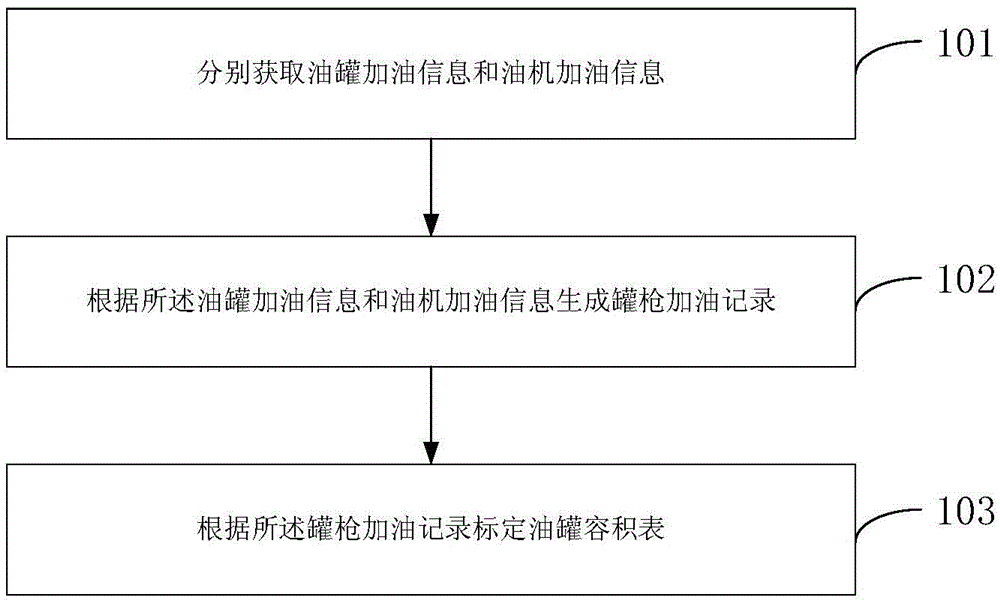

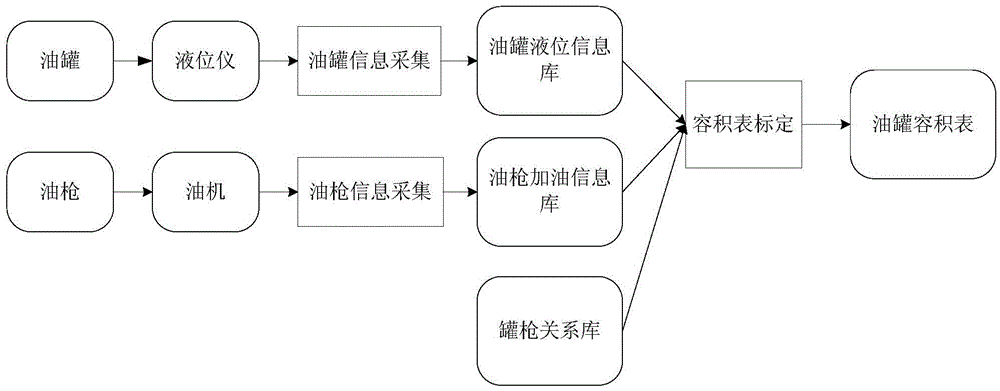

Tank capacity table construction method and device based on real-time data acquisition

InactiveCN105588615AEasy and accurate calibrationContainer/cavity capacity measurementReal time data acquisitionData processing

The invention relates to the field of data processing and provides a tank capacity table construction method and device based on real-time data acquisition. The method includes the steps that oil tank refueling information and oil engine refueling information are obtained; a tank gun refueling record is generated according to the oil tank refueling information and the oil engine refueling information; an oil tank capacity table is calibrated according to the tank gun refueling record. According to the method, the oil tank refueling information and the oil engine refueling information are obtained, the tank gun refueling record is generated according to the oil tank refueling information and the oil engine refueling information, the oil tank capacity table is calibrated according to the tank gun refueling record, a simple and accurate oil tank capacity table calibration method is provided, and capacity tables of oil tanks in any shape and in any position can be conveniently and accurately calibrated.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

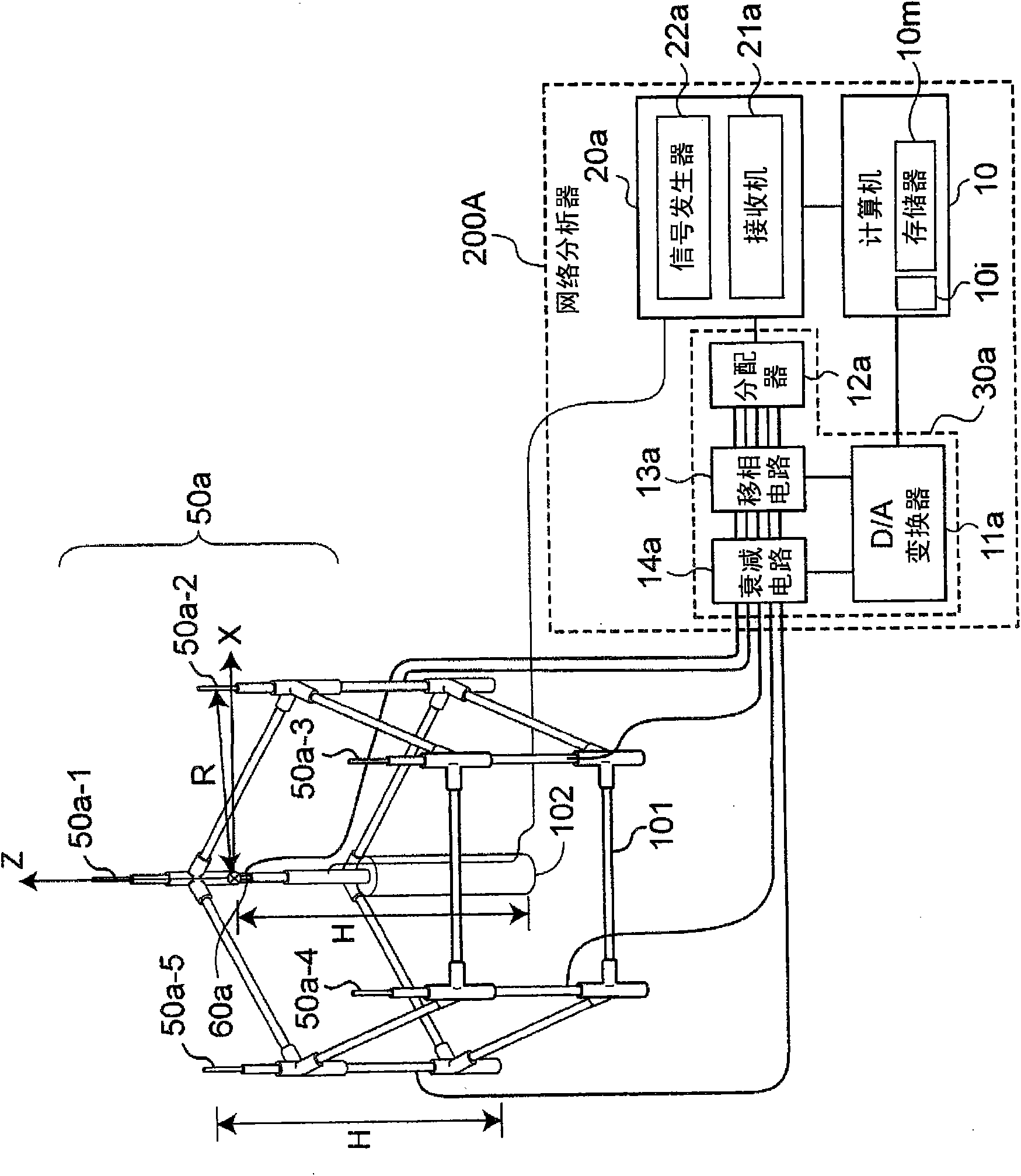

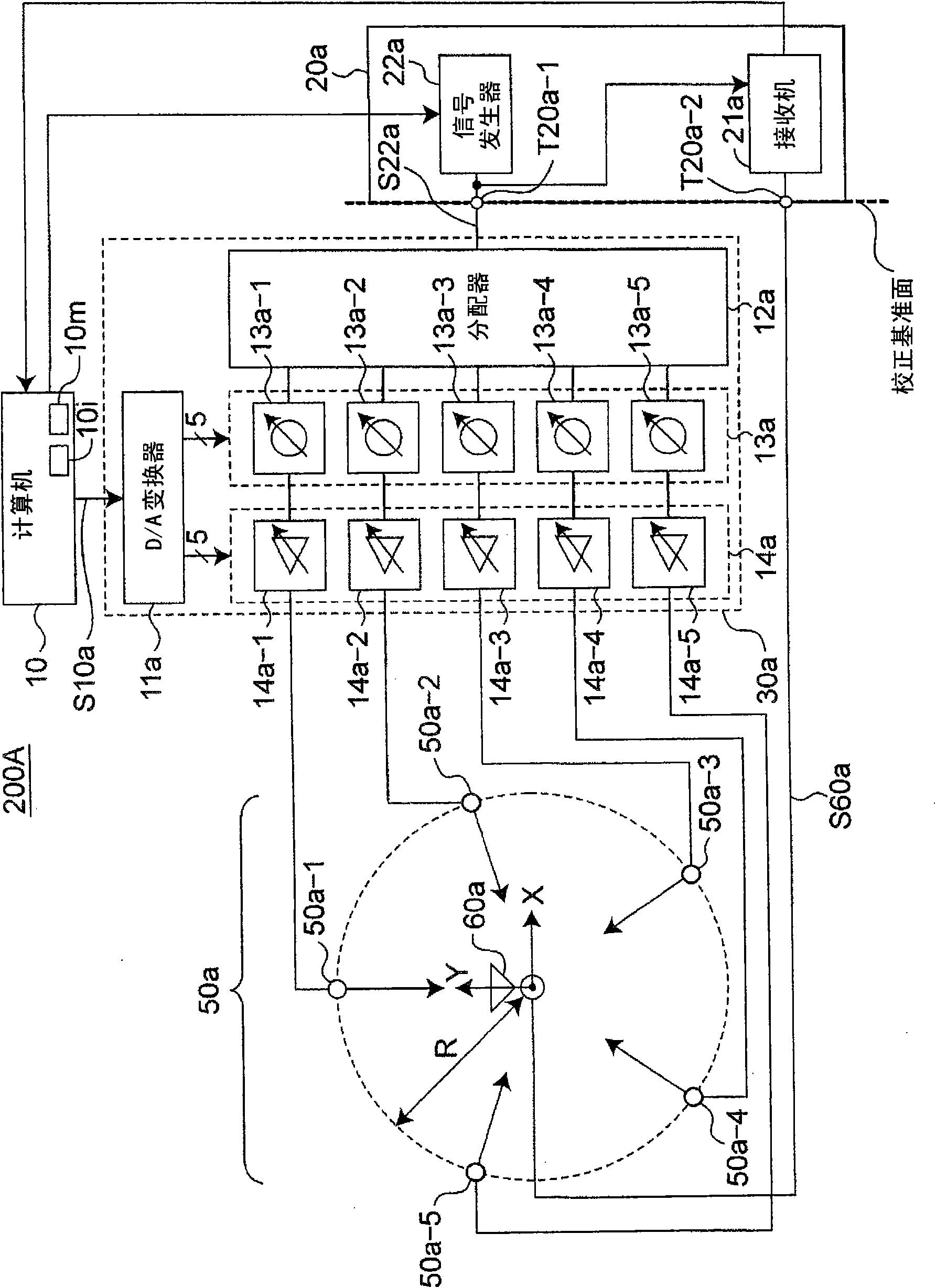

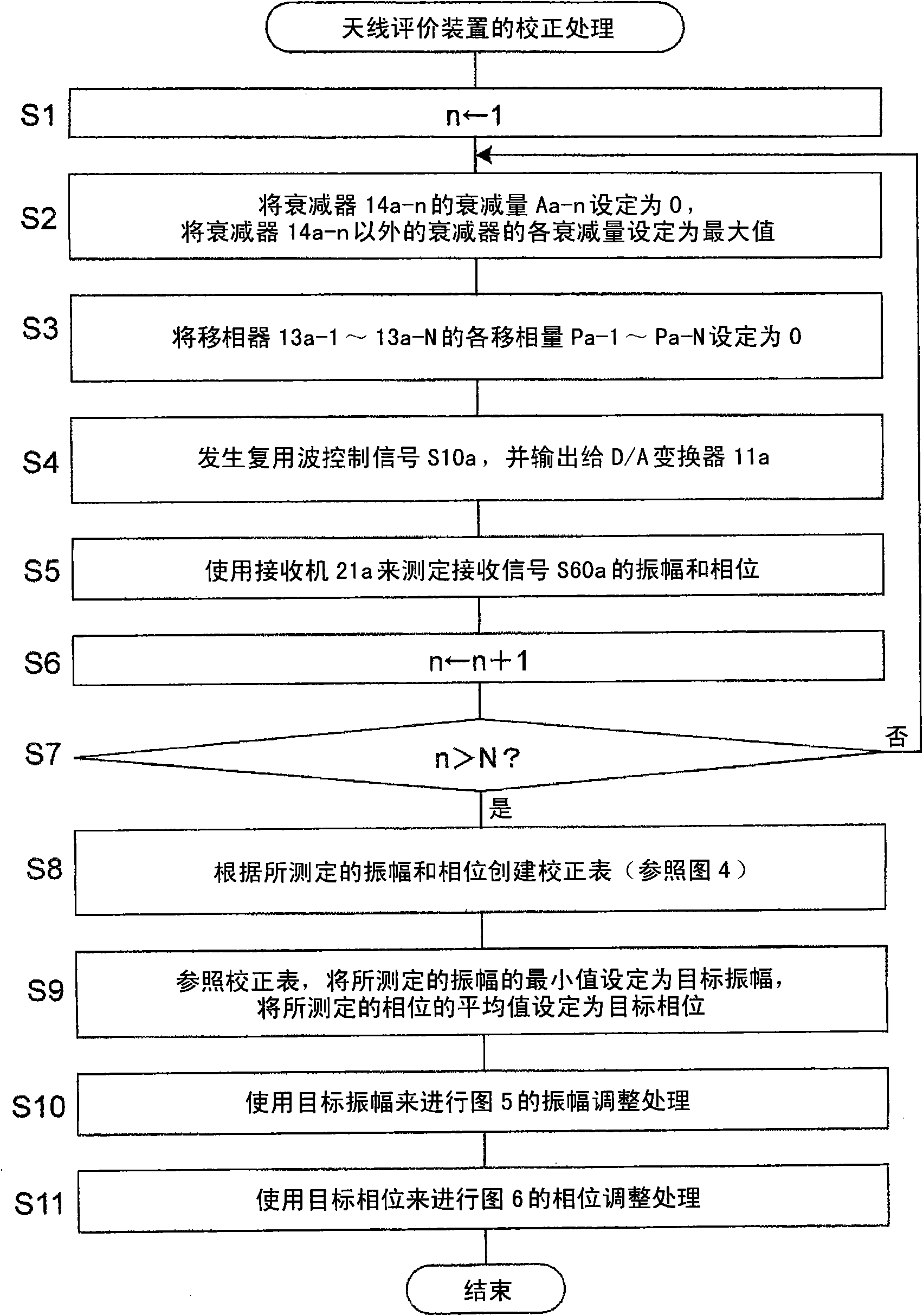

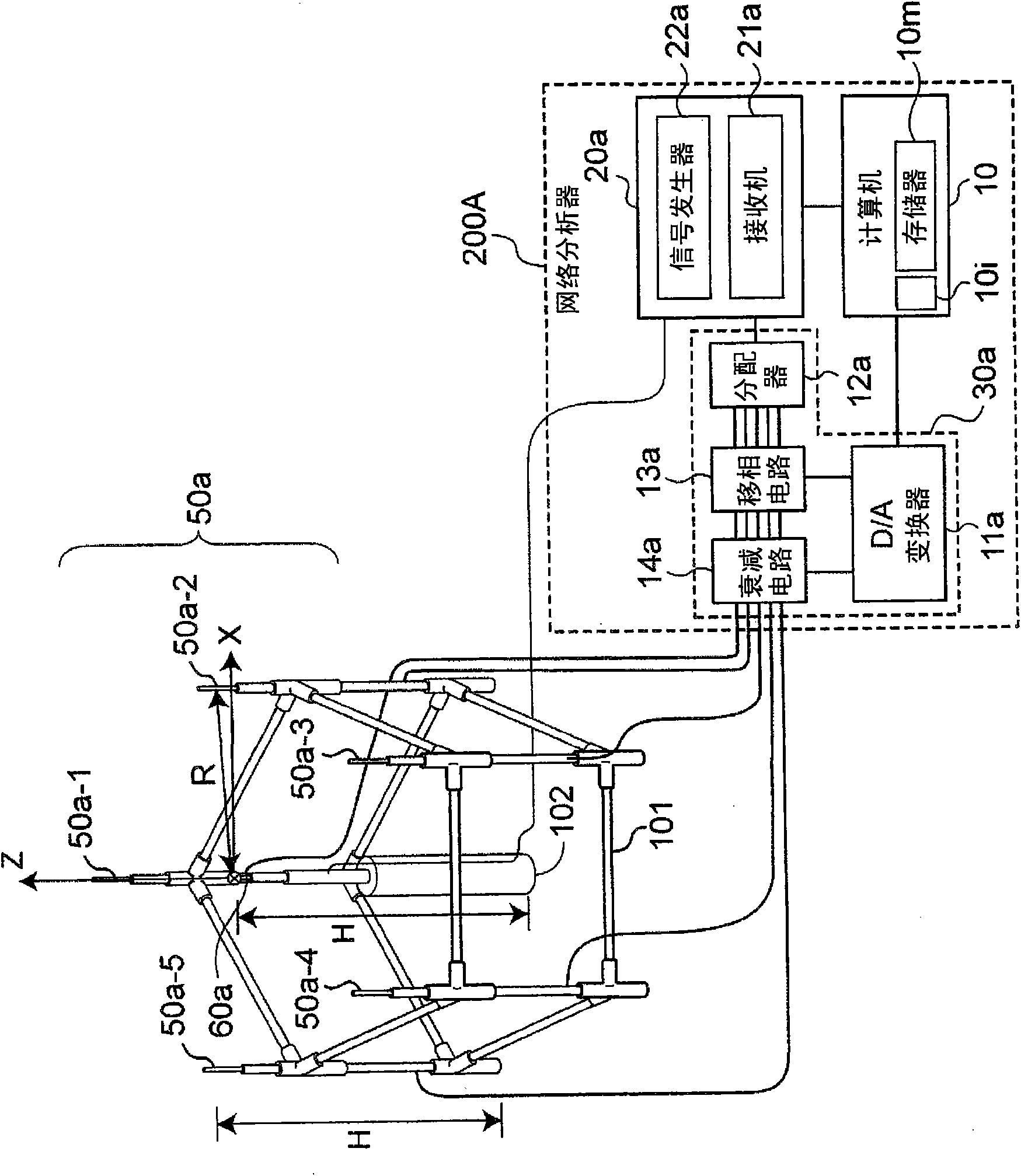

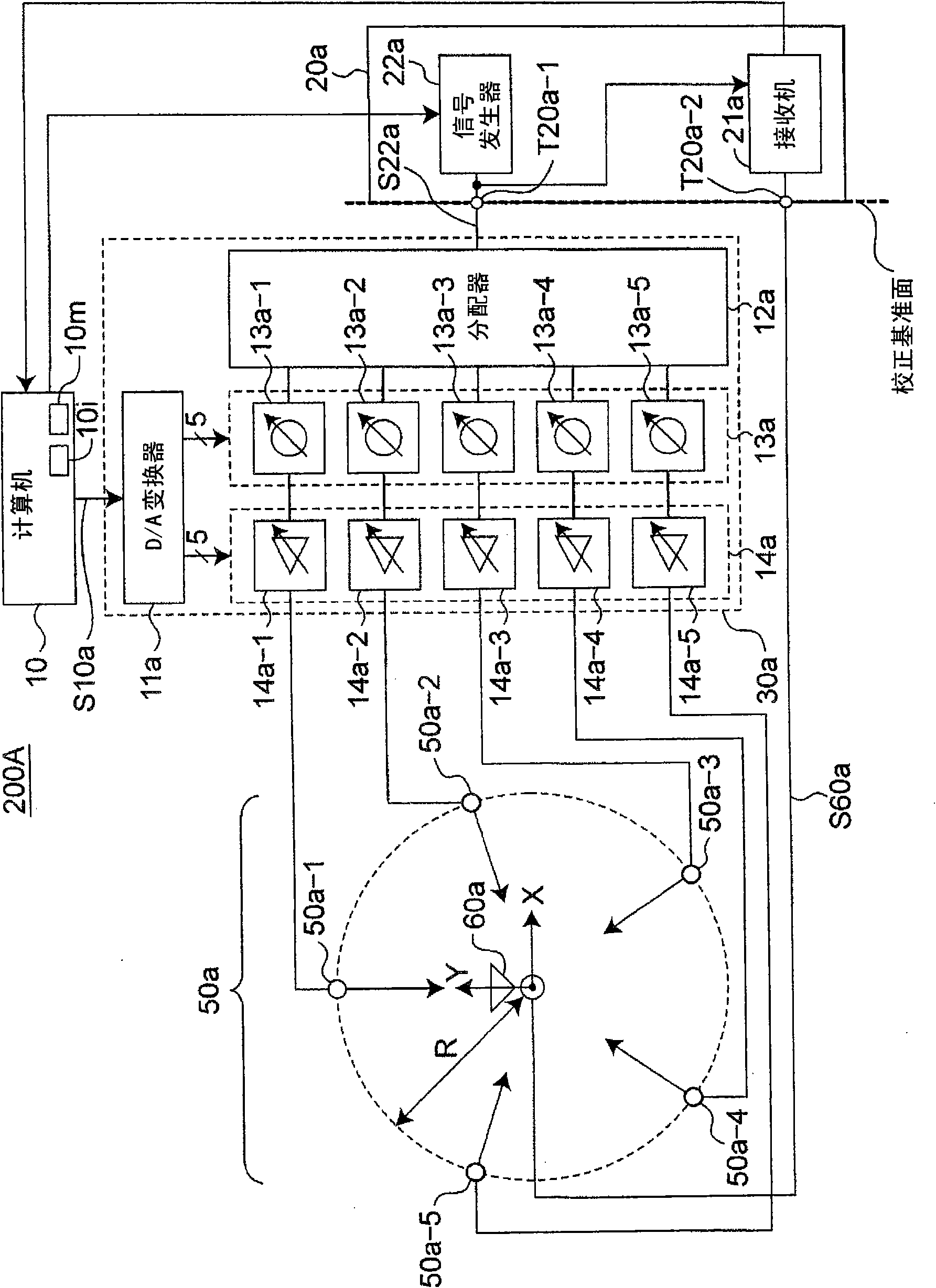

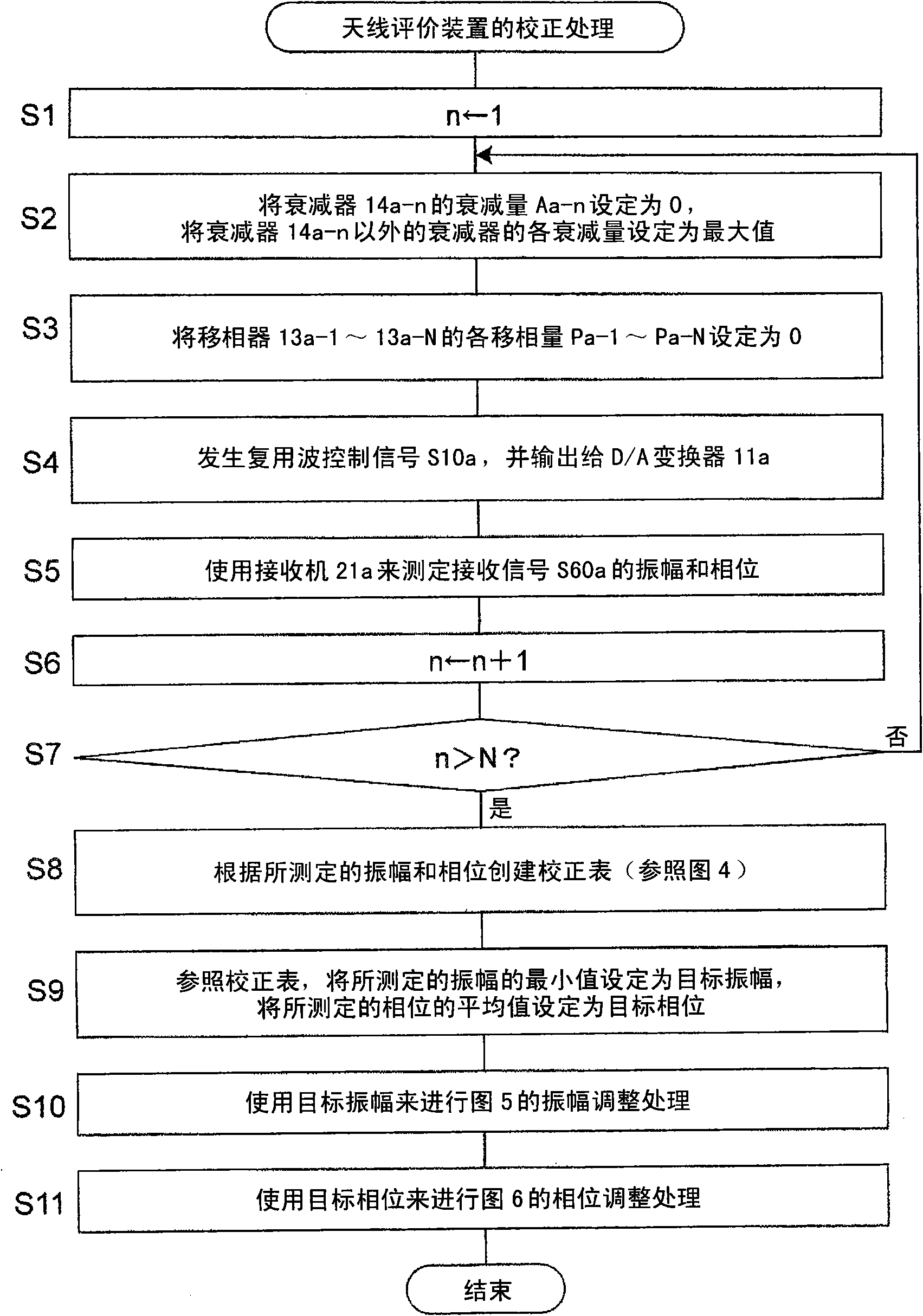

Antenna evaluation device and method

ActiveCN102105805AImprove evaluation accuracyEasy and accurate calibrationAntennasAntenna radiation diagramsUltrasound attenuationPhase shift control

When each radio wave independently emitted from each scatterer antenna (50-n) is respectively received using a receiving antenna for calibration (60a), a computer (10) measures the amplitude and phase of each received signal (S60a), with a transmitted signal (S22a) used as a reference signal, decides the target amplitude on the basis of each amplitude measured, and decides the target phase on the basis of each phase measured. The reference attenuation amount control voltage (VAa-n) for each attenuator (14a-n) is set to each attenuation amount control voltage for bringing each measured amplitude into agreement with the same target phase respectively, and the reference phase shift amount control voltage (VPa-n) for each phase shifter is set to the phase shift control voltage for bringing each measured phase into agreement with the same target phase respectively.

Owner:PANASONIC INTELLECTUAL PROPERTY CORP OF AMERICA

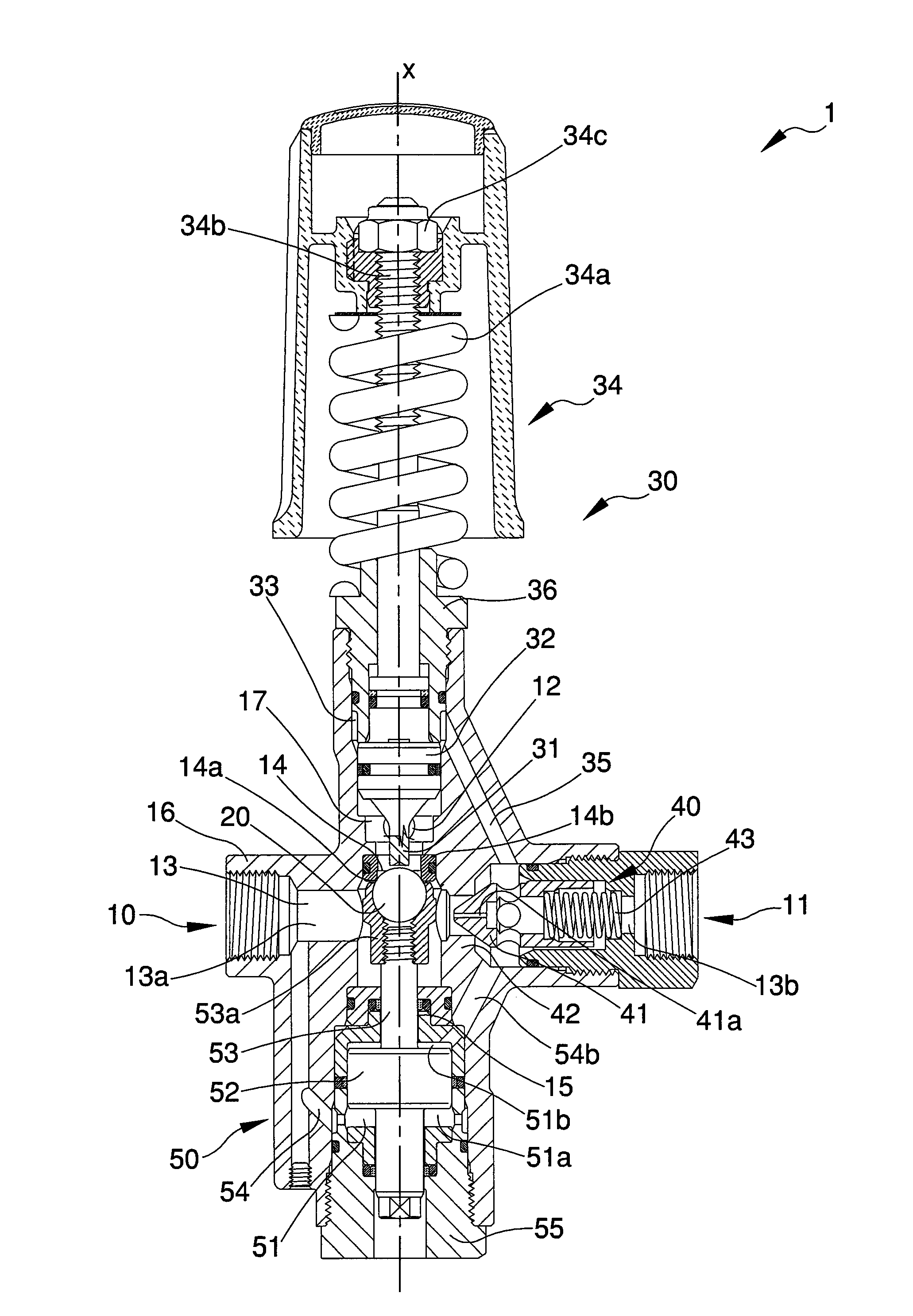

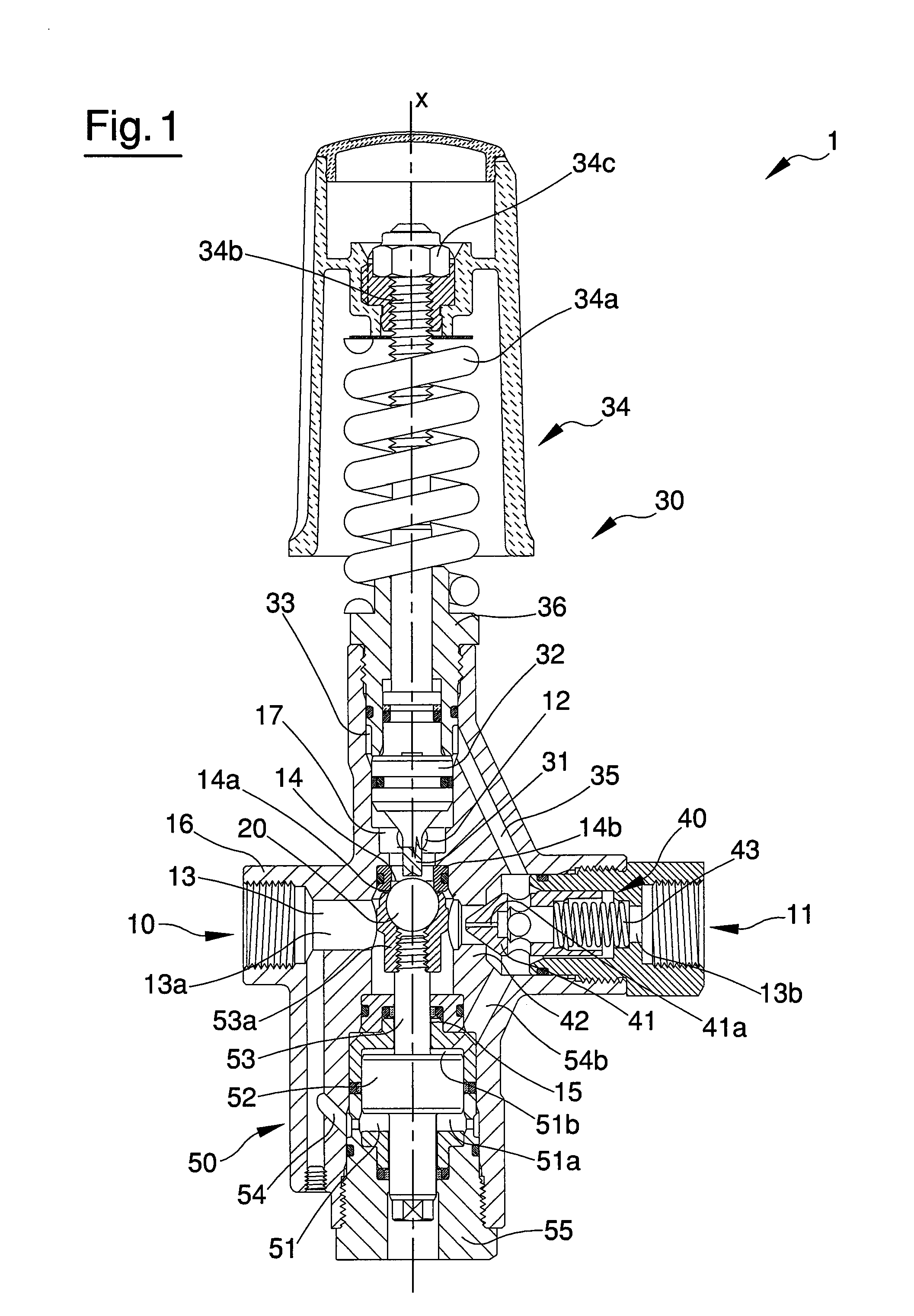

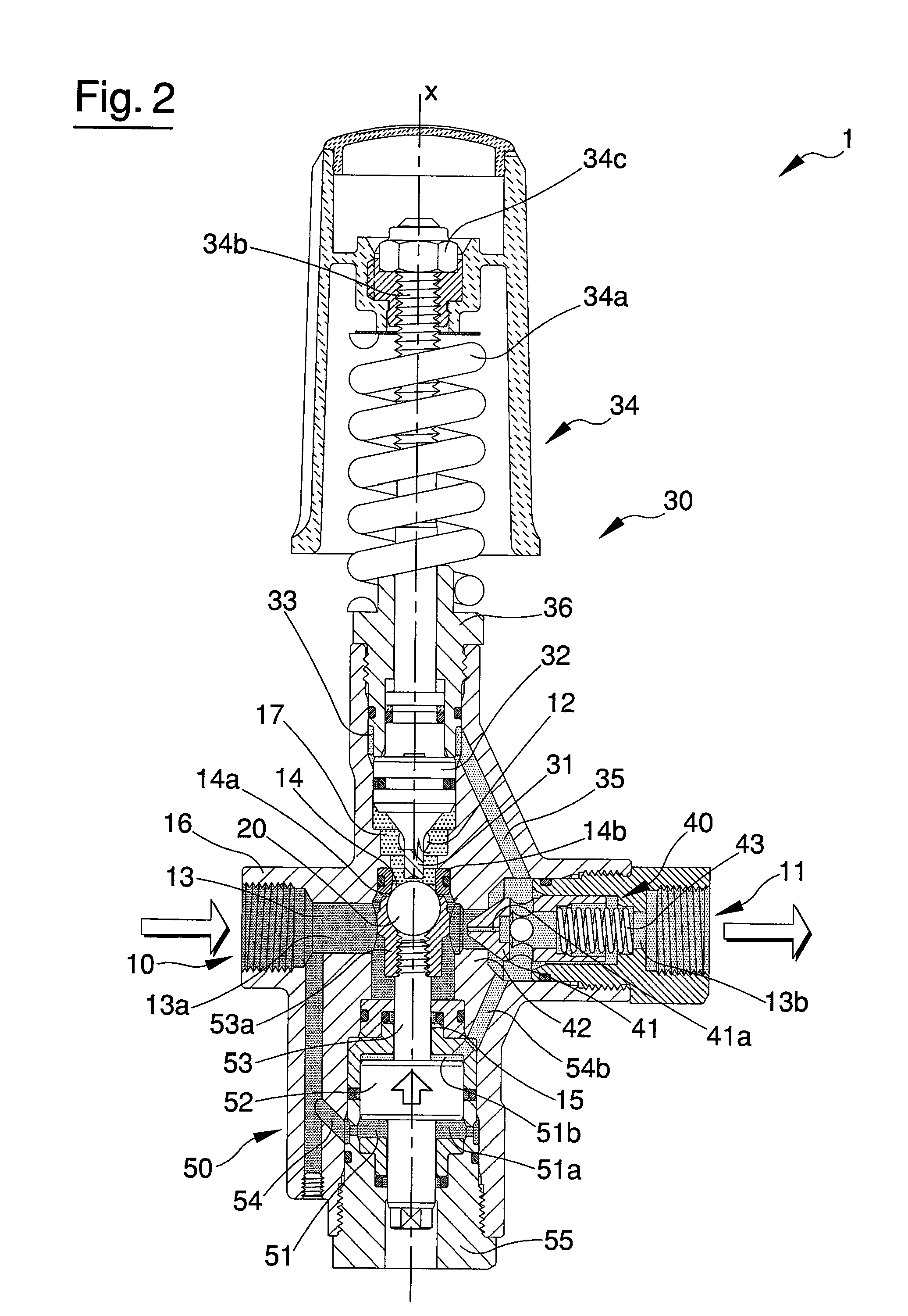

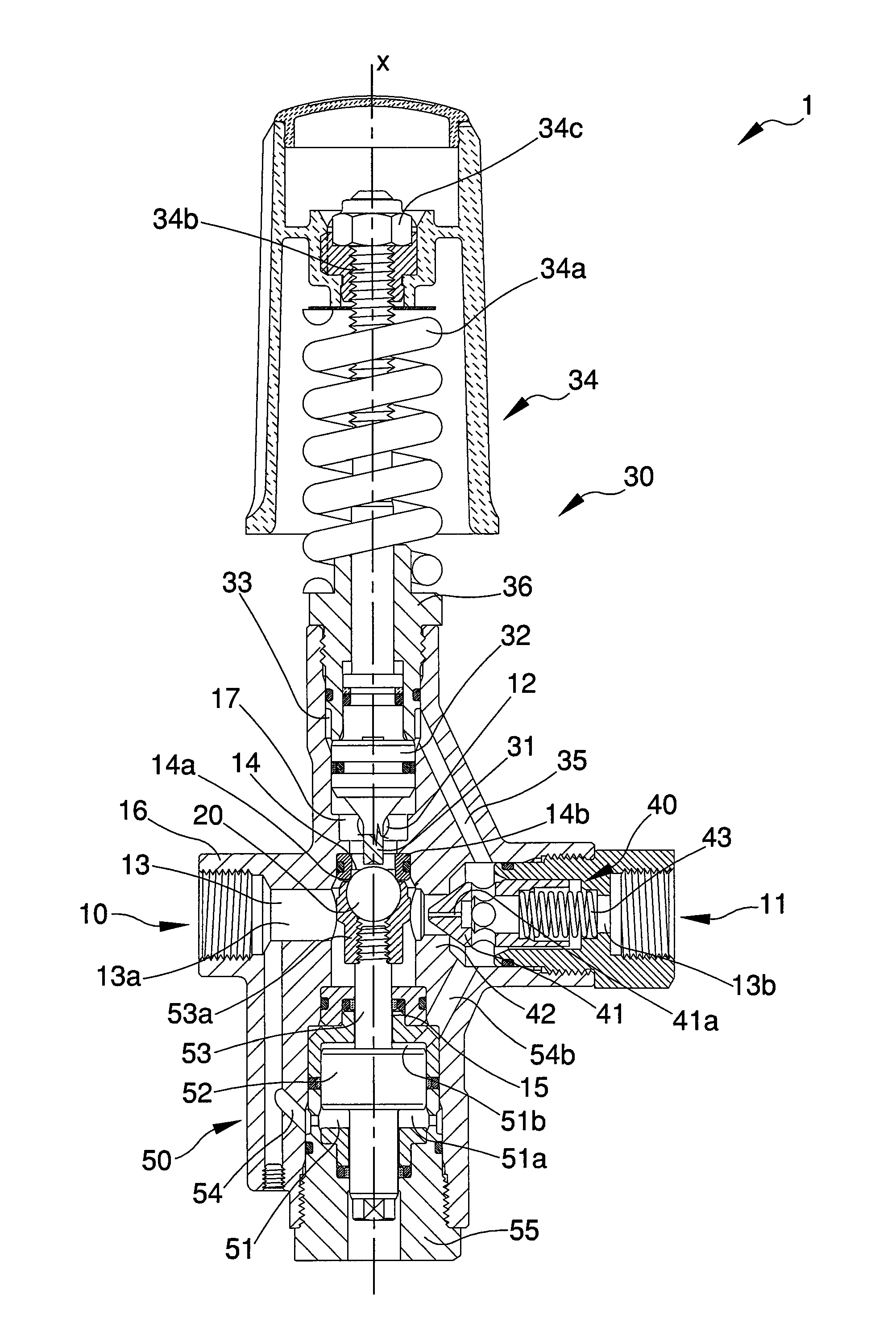

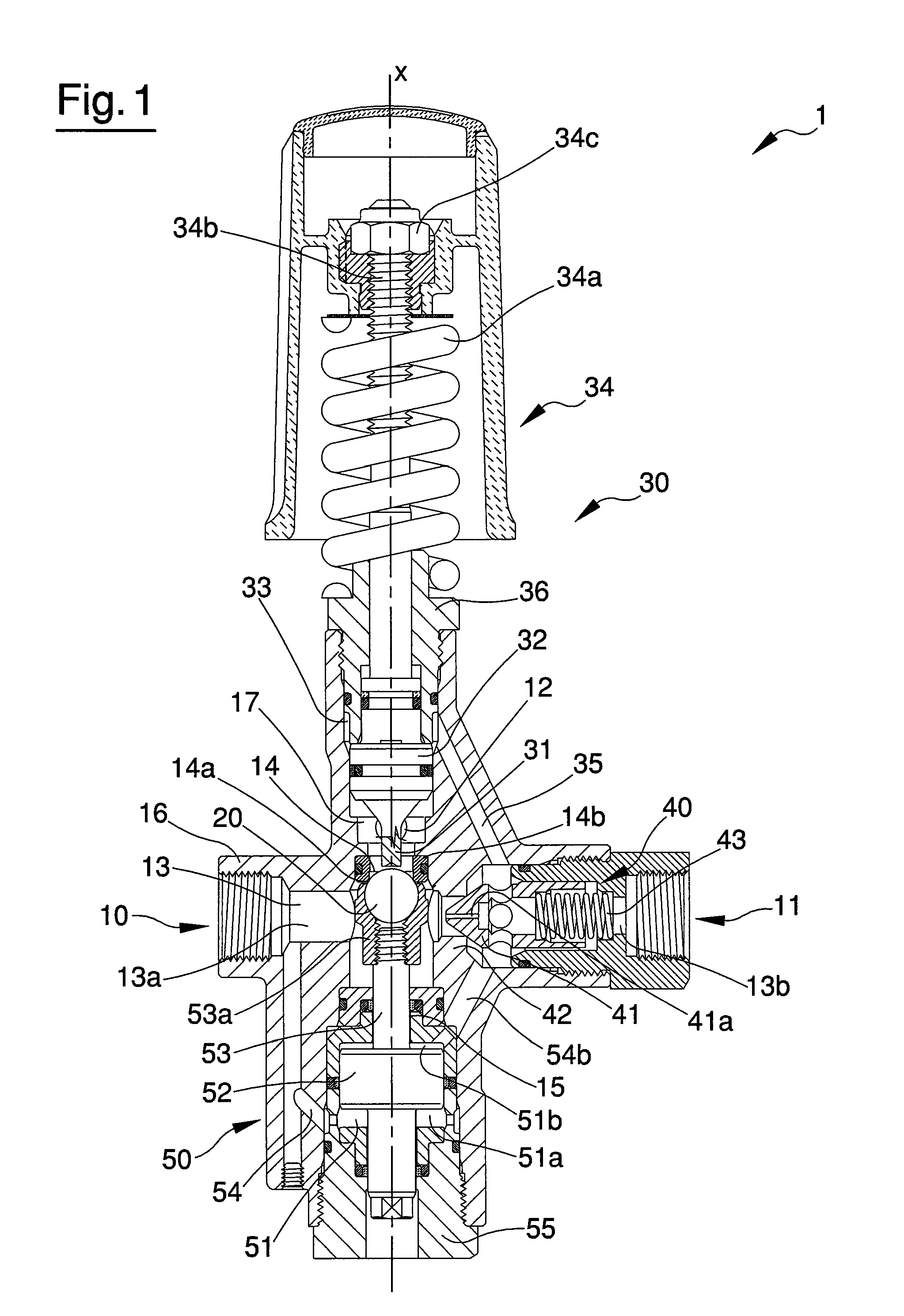

By-pass and pressure regulator valve

ActiveUS20090205716A1Easy and accurate calibrationImprove reliabilityFluid pressure control without auxillary powerRatio controlEngineeringPressure controlled ventilation

A by-pass and pressure regulator valve exhibiting: an inlet mouth and an outlet mouth set in reciprocal communication by a main conduit; a by-pass mouth. The by-pass and pressure regulator valve comprises: an obturator, mobile between at least a closed position, in which it interrupts fluid communication between the main conduit and the by-pass mouth, and at least an open position, in which the fluid communication is not interrupted; operating pressure control means, predisposed to move the obturator from the closed position; means for determining a flow pressure loss in fluids crossing the main conduit, arranged along the main conduit in order to separate a first tract upstream of the main conduit from a second tract downstream thereof; obturator command means governed by a fluid pressure difference between the first tract and the second tract of the main conduit, distinct from the operating pressure control means but operatively connected to the obturator.

Owner:P A SPA

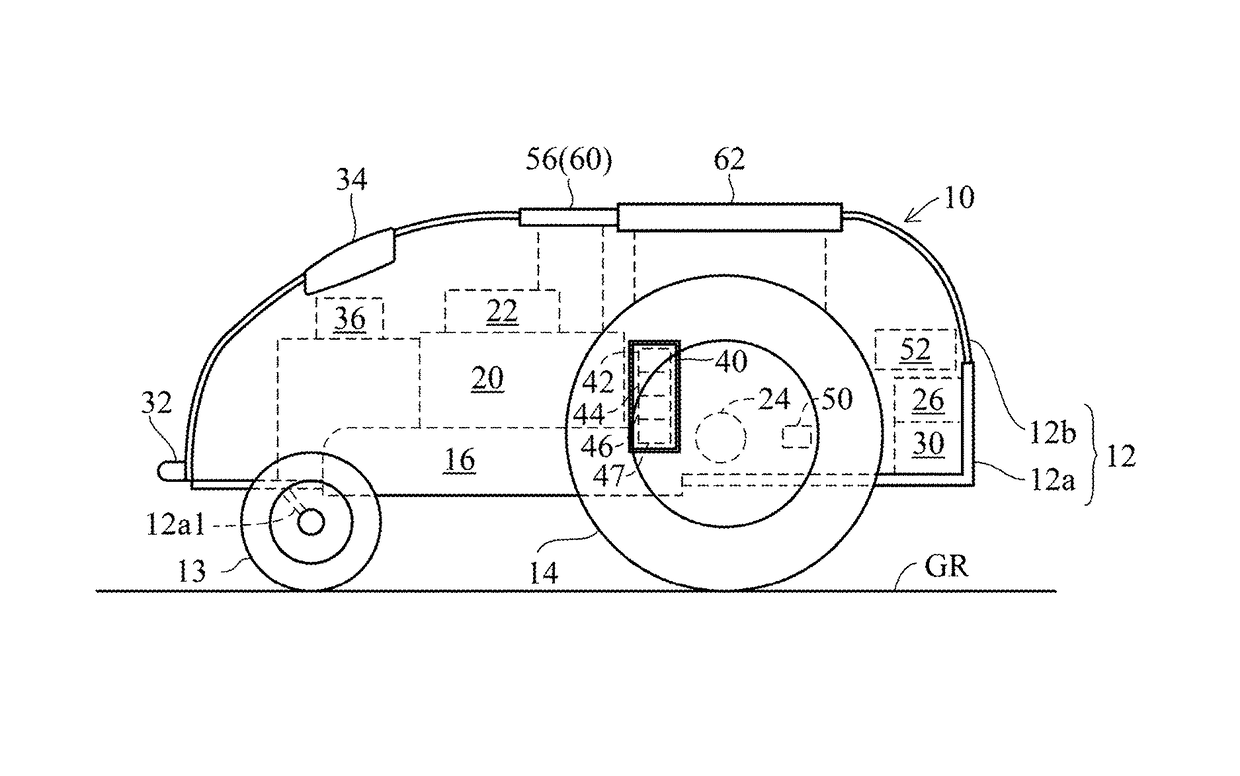

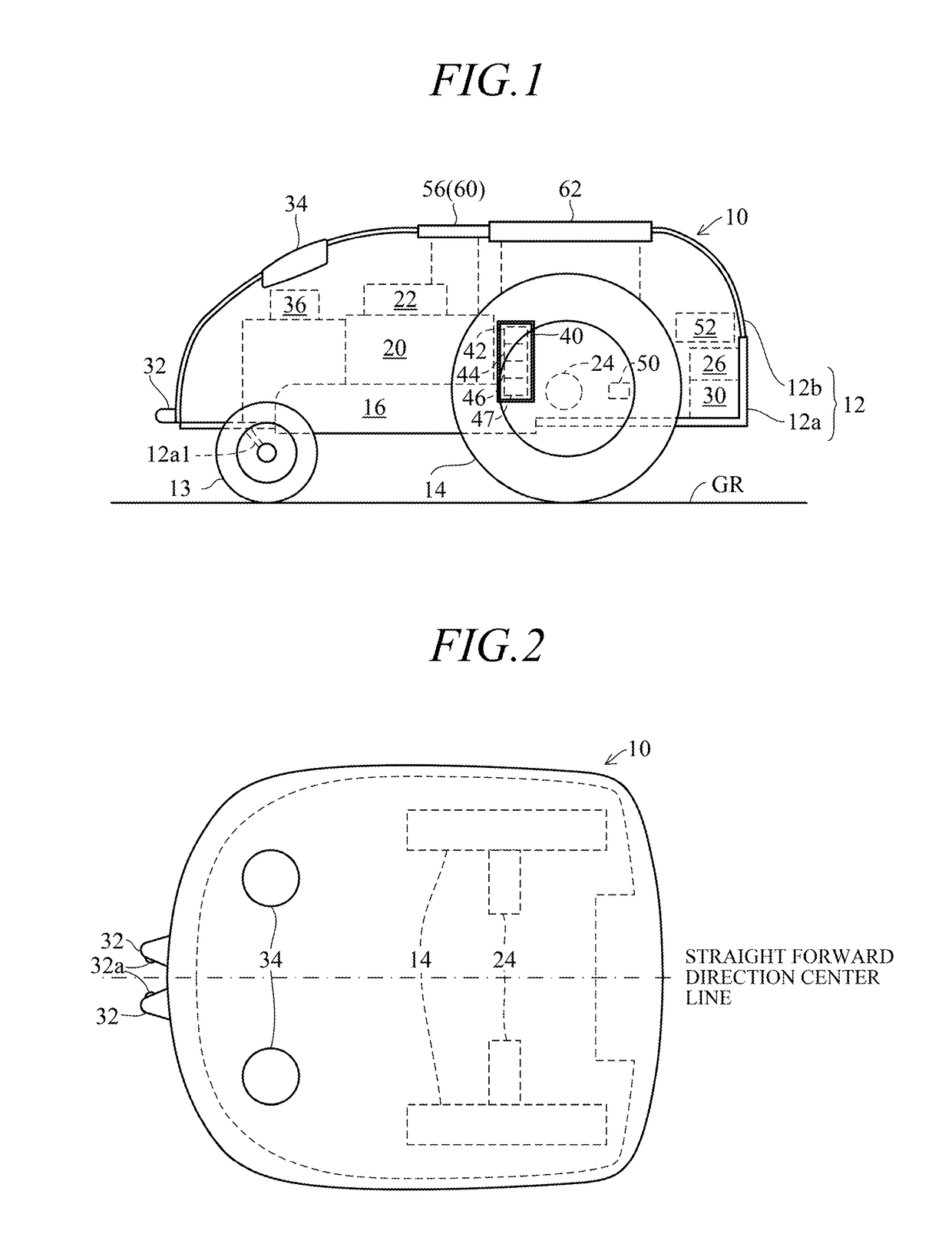

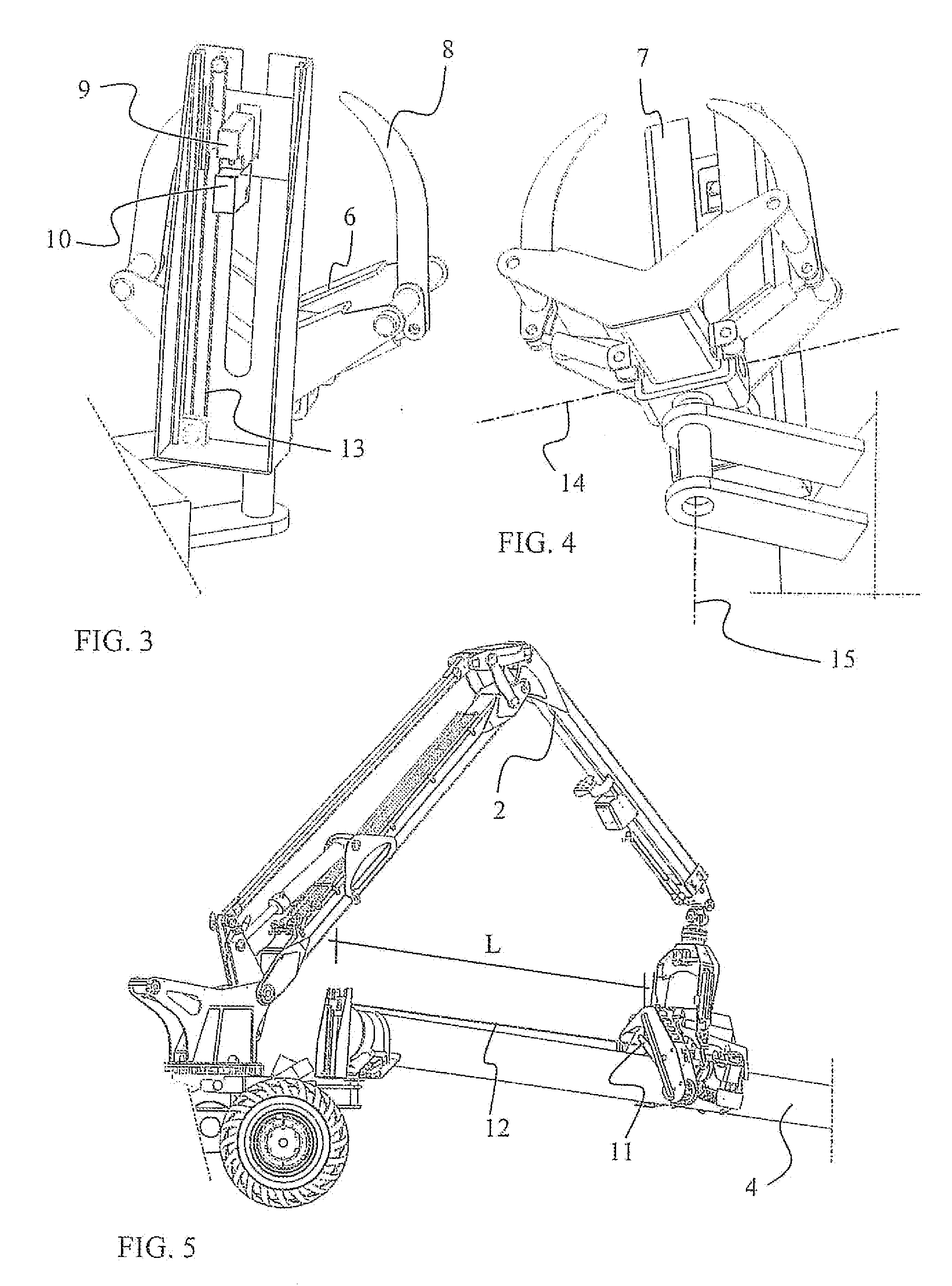

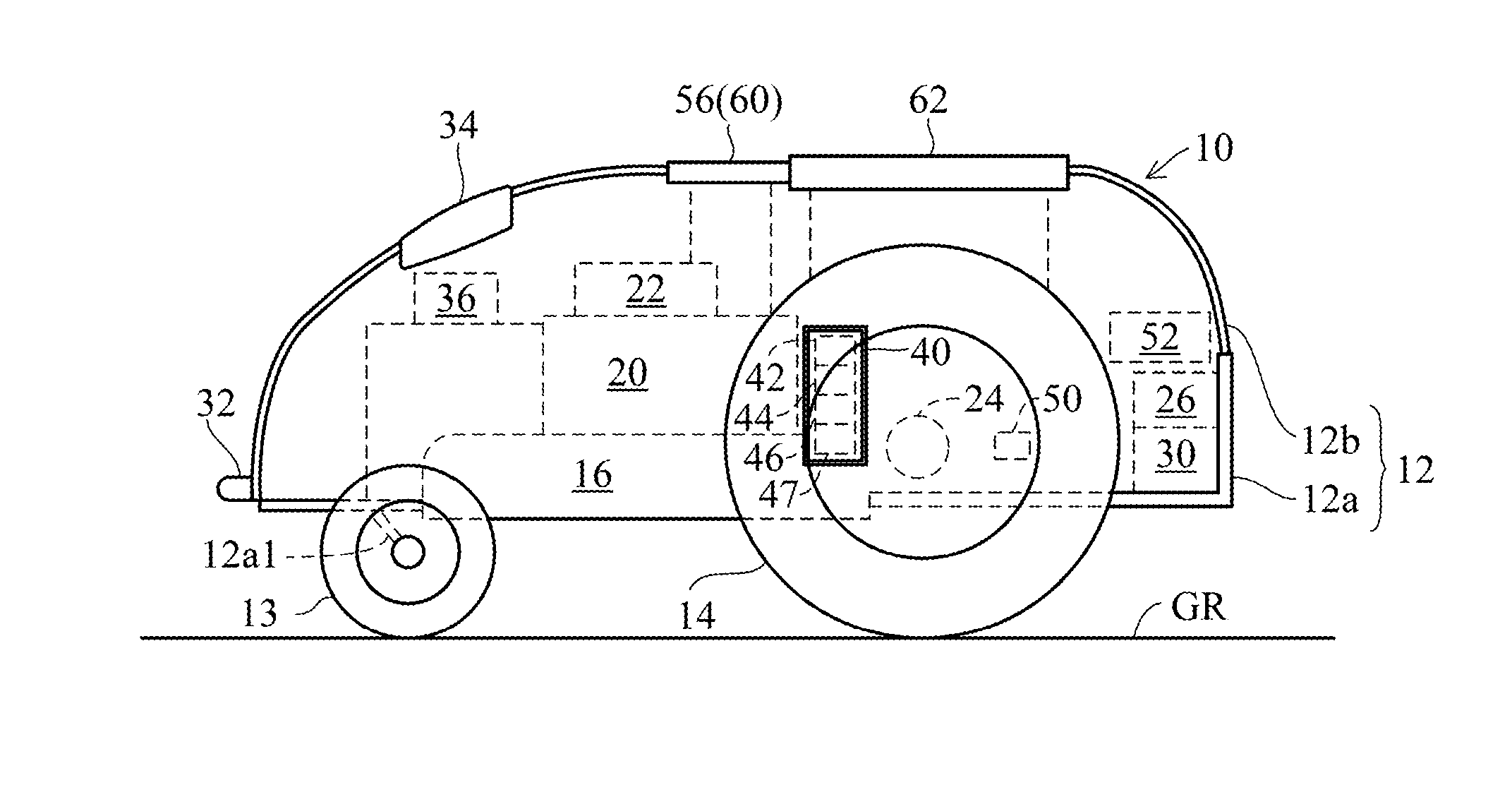

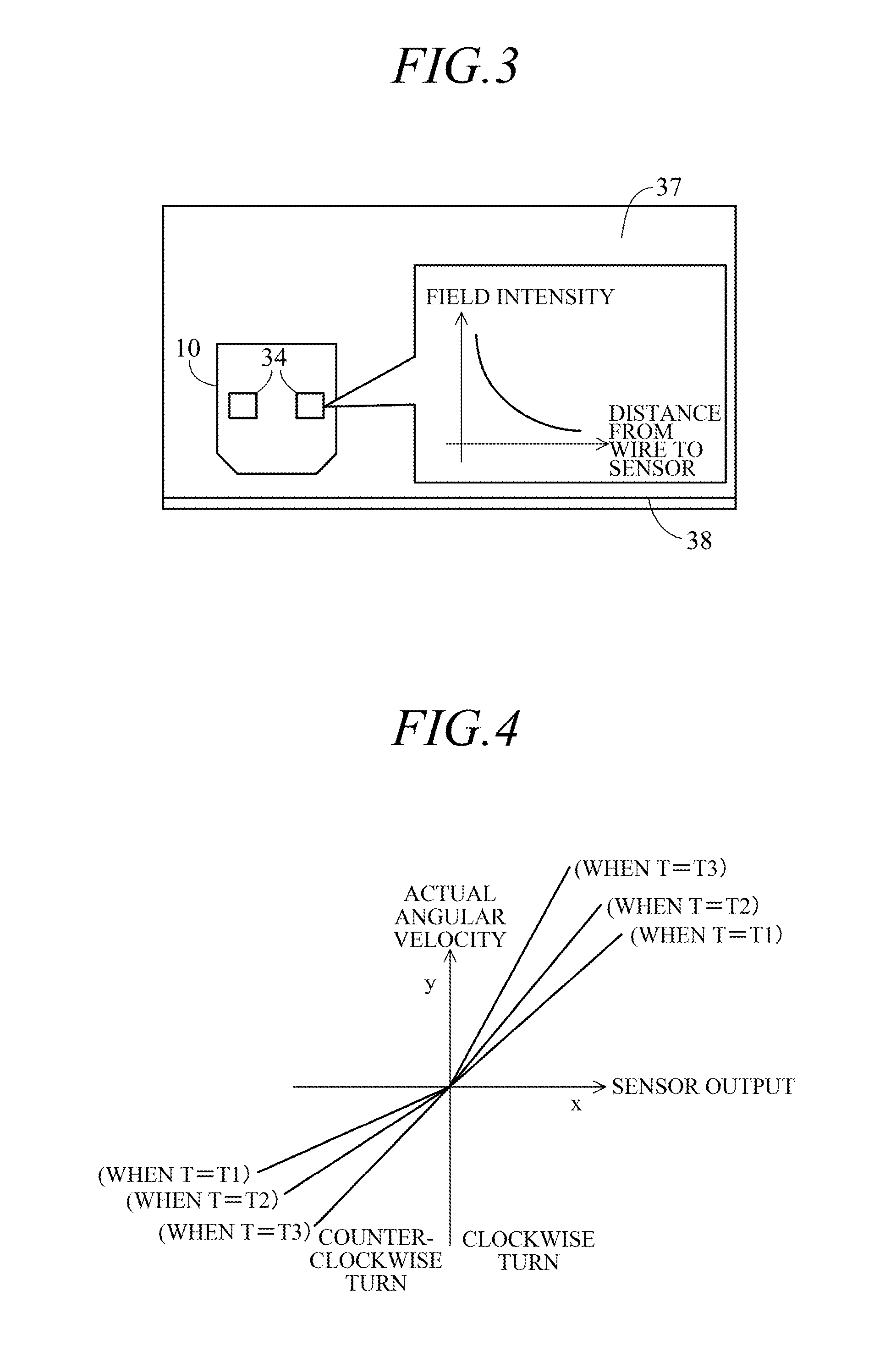

Apparatus for controlling autonomously navigating utility vehicle

ActiveUS9612597B2Easy and accurate calibrationLow costAutonomous decision making processTesting/calibration of speed/acceleration/shock measurement devicesAngular velocityEngineering

In an autonomously navigating utility vehicle adapted to run a working area defined by a laid boundary wire autonomously having a pair of magnetic sensors installed on either sides of the vehicle at positions laterally symmetrical with respect to a vehicle straight forward center line to produce outputs indicating intensity of magnetic field of the wire, an angular velocity sensor adapted to produce an output indicating angular velocity around a vertical axis of the vehicle, the vehicle is controlled to move to a prescribed position at which an angle of the center line relative to the laid wire becomes a reference angle based on the outputs of the magnetic sensors, and to turn by 180 degrees, and calibrates the output of the angular velocity sensor by outputs of the angular velocity sensor obtained at the turning.

Owner:HONDA MOTOR CO LTD

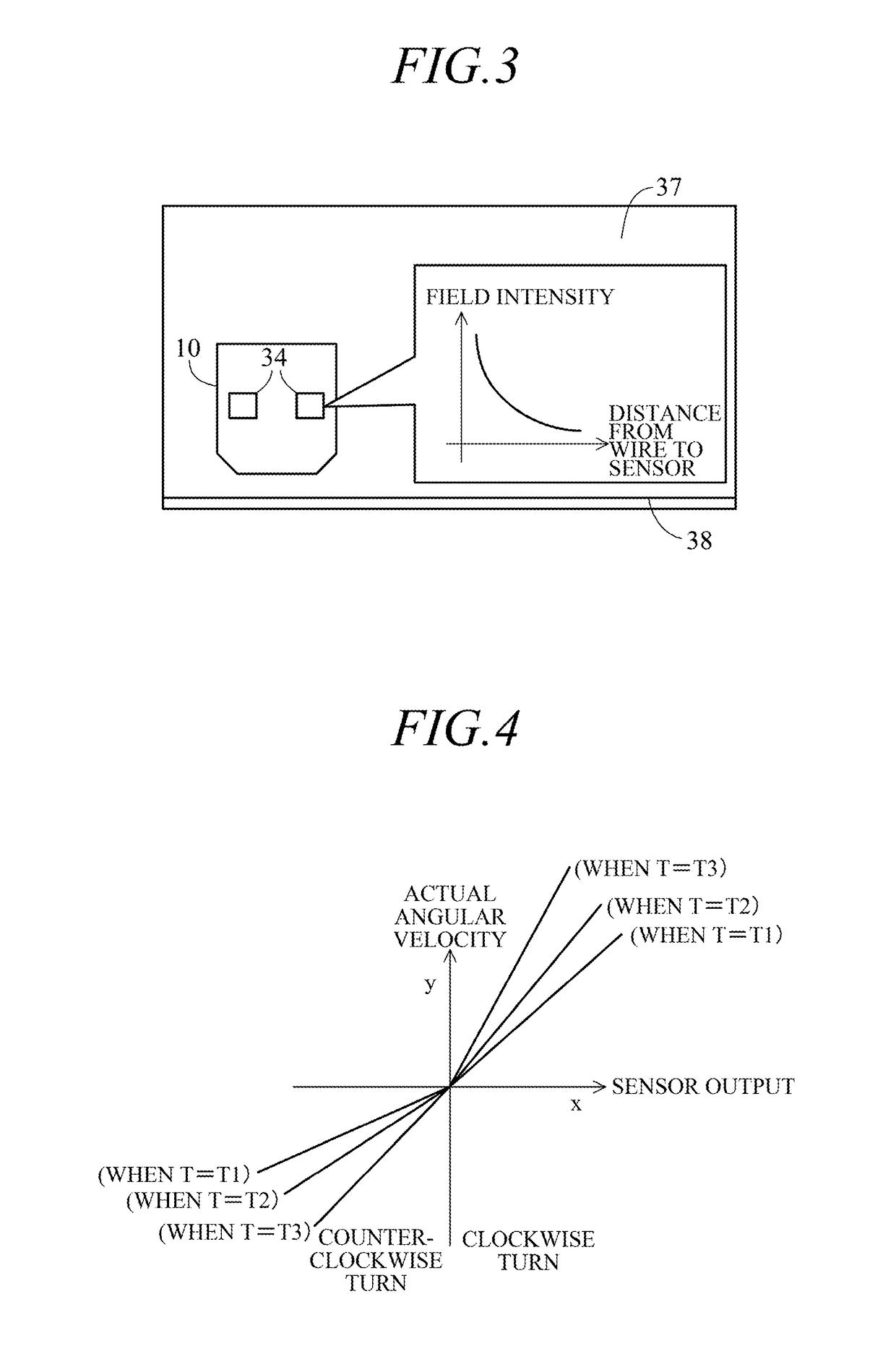

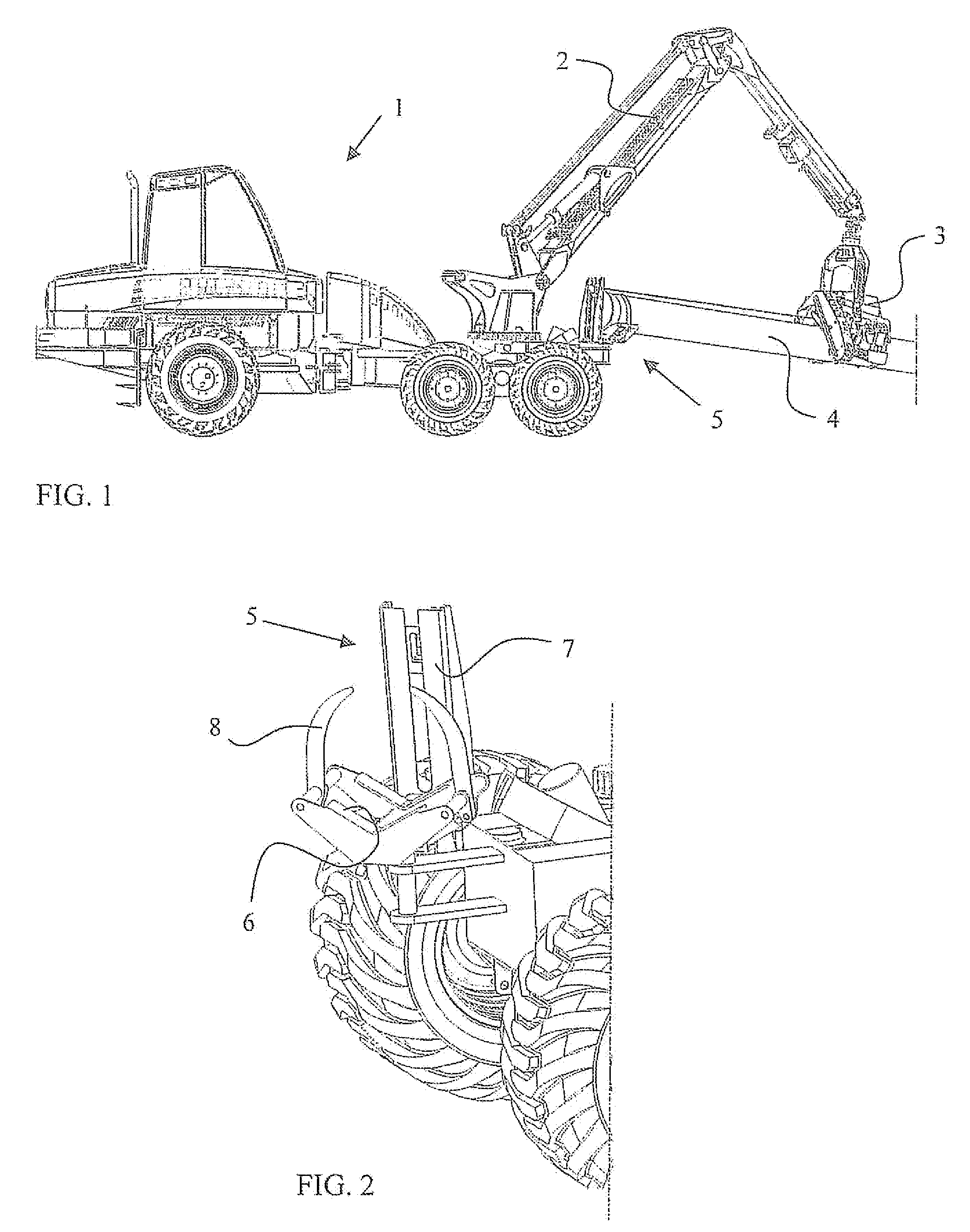

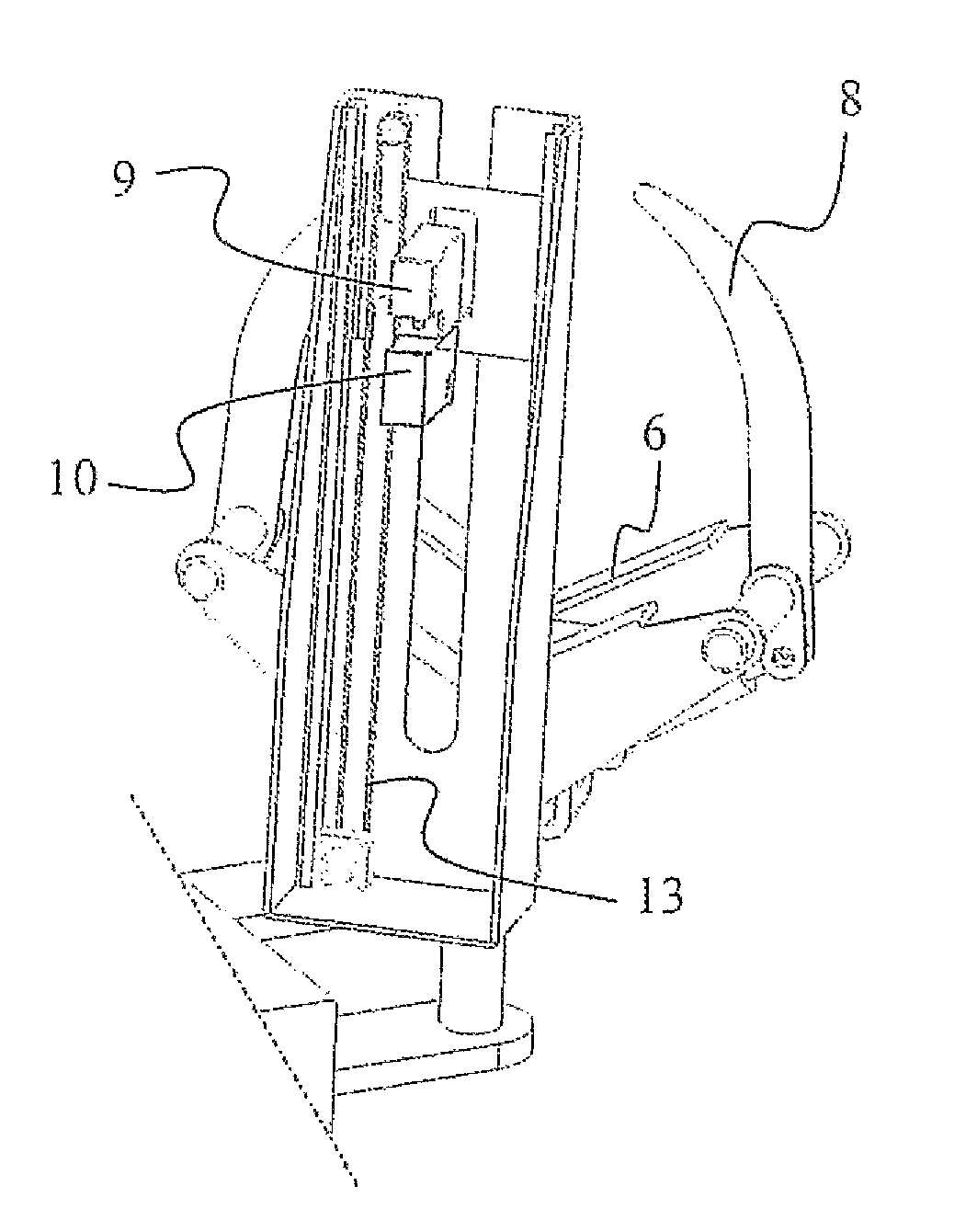

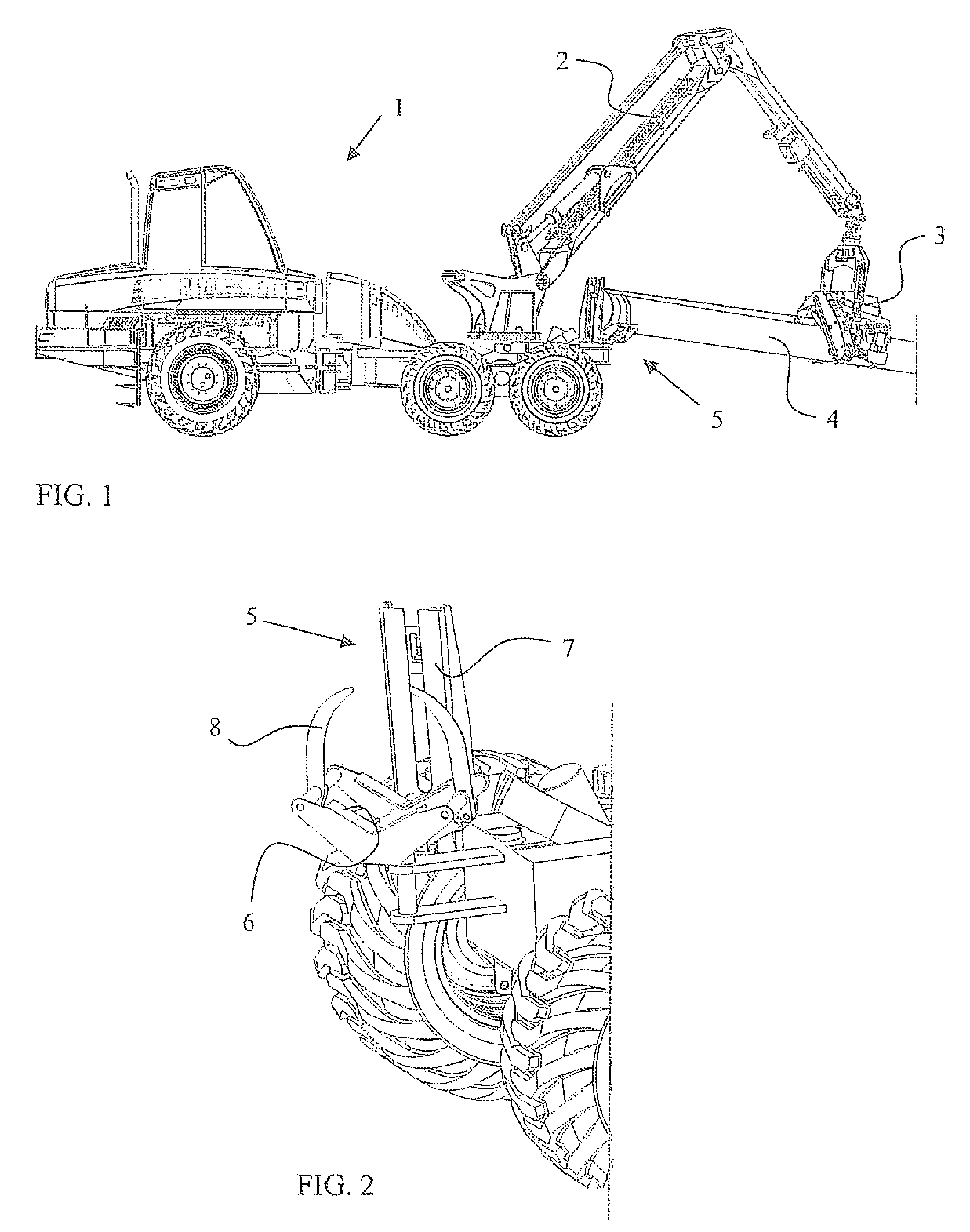

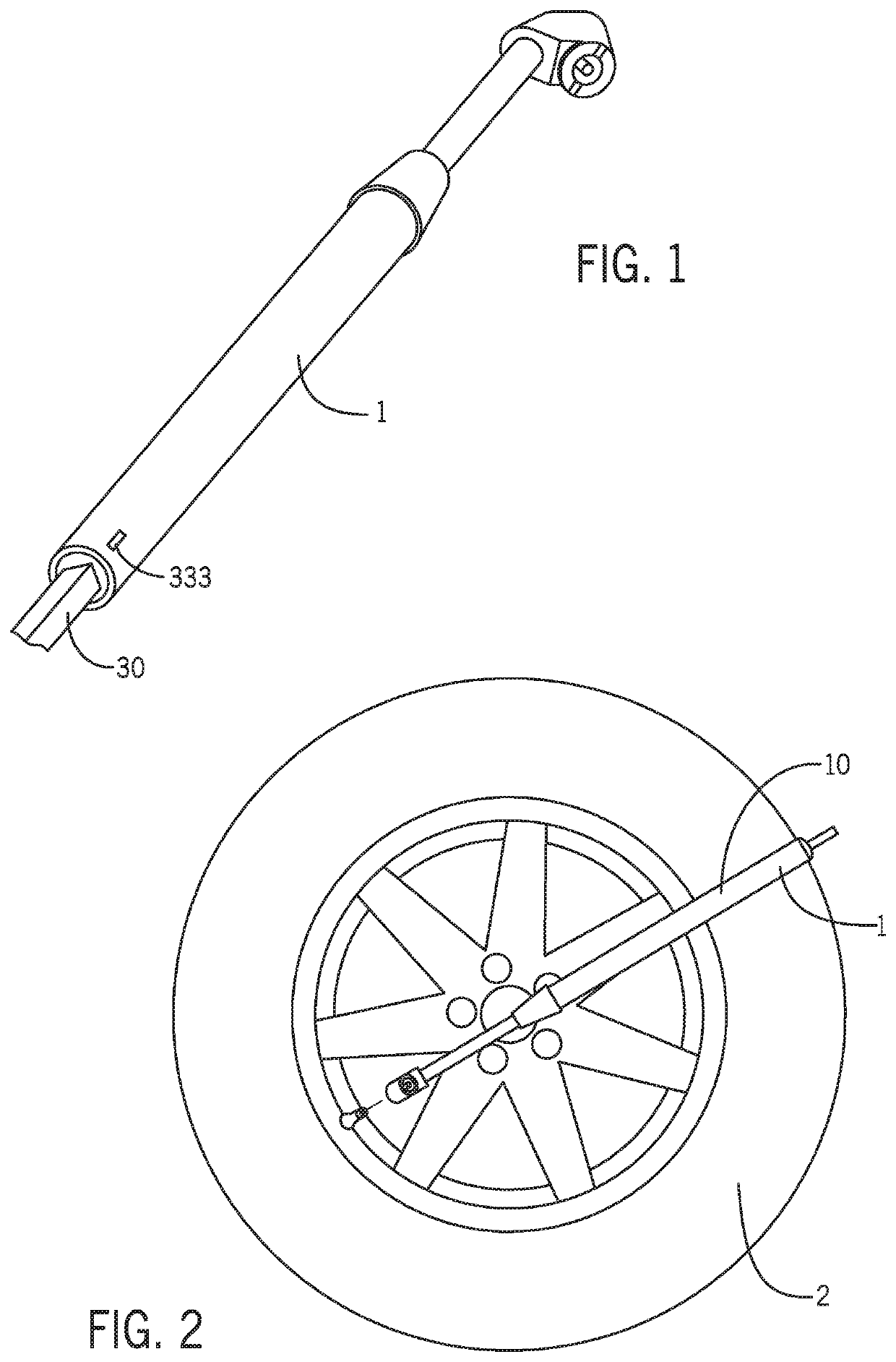

Method and arrangement for measuring timber piece

ActiveUS20100027034A1Reduce the impactEliminate errorsAutomatic control devicesPrecision positioning equipmentWoodchipsMechanical engineering

The invention relates to a method and arrangement for measuring a timber piece (4) in a wood handling machine (1). Such a wood handling machine comprises booms (2) arranged in a base machine and a wood handling device (3) operating therein. In such a wood handling machine (1), a wood handling device (3) grips the timber piece (4) to be handled, after which one end of the timber piece is guided into a measuring carriage (5) in the wood handling machine by the wood handling device. The timber piece arranged in the measuring carriage is subjected to one or more observation measures by observation means provided in the measuring carriage.

Owner:PONSSE

Apparatus for controlling autonomously navigating utility vehicle

ActiveUS20160062358A1Low costEasy and accurate calibrationAutonomous decision making processTesting/calibration of speed/acceleration/shock measurement devicesMechanical engineeringVertical axis

In an autonomously navigating utility vehicle adapted to run a working area defined by a laid boundary wire autonomously having a pair of magnetic sensors installed on either sides of the vehicle at positions laterally symmetrical with respect to a vehicle straight forward center line to produce outputs indicating intensity of magnetic field of the wire, an angular velocity sensor adapted to produce an output indicating angular velocity around a vertical axis of the vehicle, the vehicle is controlled to move to a prescribed position at which an angle of the center line relative to the laid wire becomes a reference angle based on the outputs of the magnetic sensors, and to turn by 180 degrees, and calibrates the output of the angular velocity sensor by outputs of the angular velocity sensor obtained at the turning.

Owner:HONDA MOTOR CO LTD

Method and arrangement for measuring timber piece

ActiveUS8072617B2Eliminate random errorsEasy and accurate calibrationAutomatic control devicesPrecision positioning equipmentPulp and paper industry

The invention relates to a method and arrangement for measuring a timber piece (4) in a wood handling machine (1). Such a wood handling machine comprises booms (2) arranged in a base machine and a wood handling device (3) operating therein. In such a wood handling machine (1), a wood handling device (3) grips the timber piece (4) to be handled, after which one end of the timber piece is guided into a measuring carriage (5) in the wood handling machine by the wood handling device. The timber piece arranged in the measuring carriage is subjected to one or more observation measures by observation means provided in the measuring carriage.

Owner:PONSSE

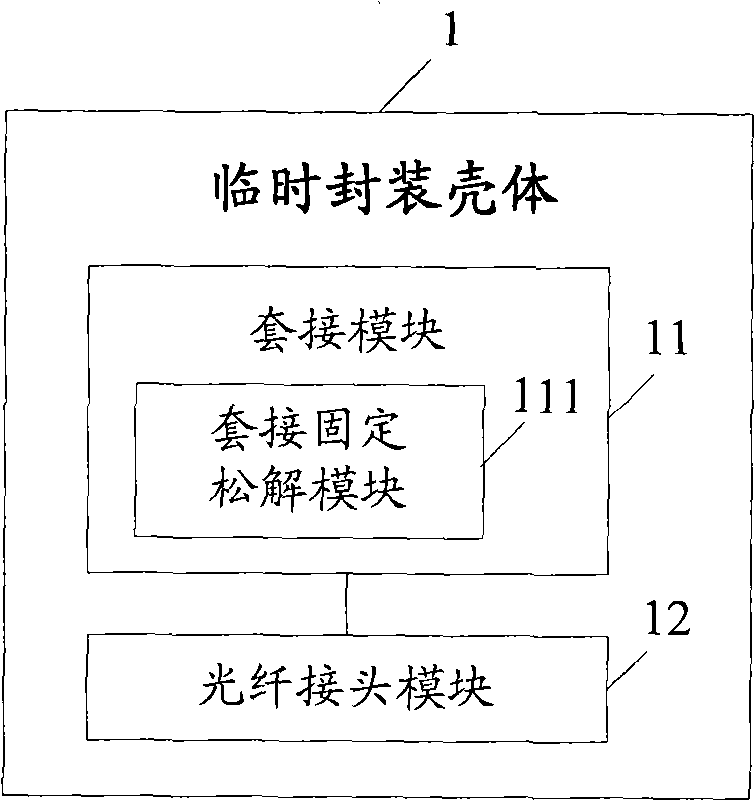

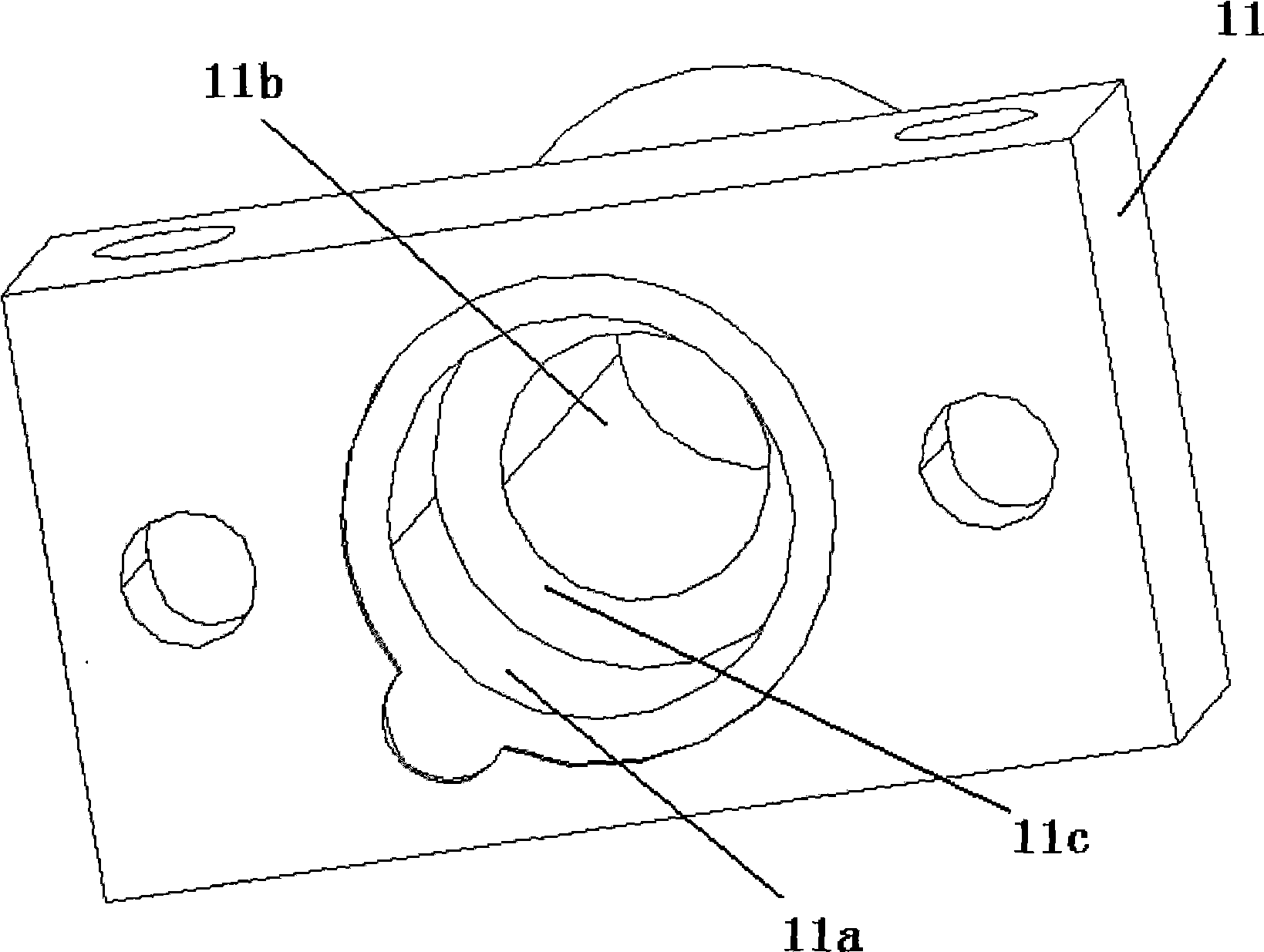

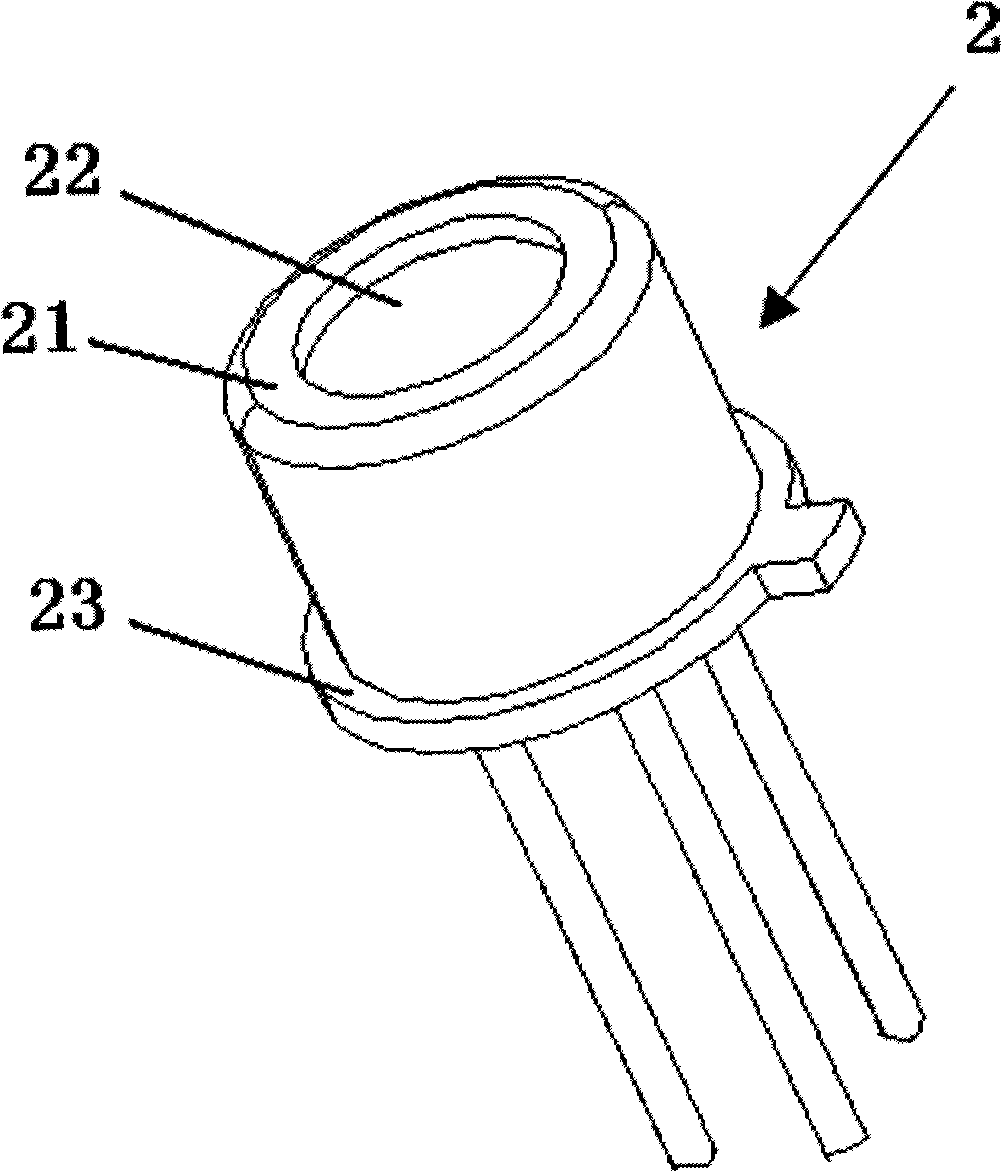

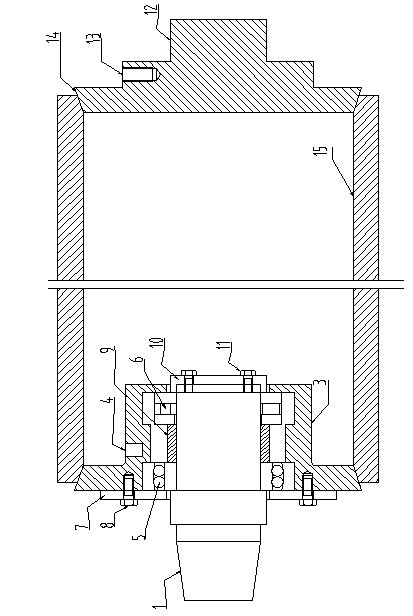

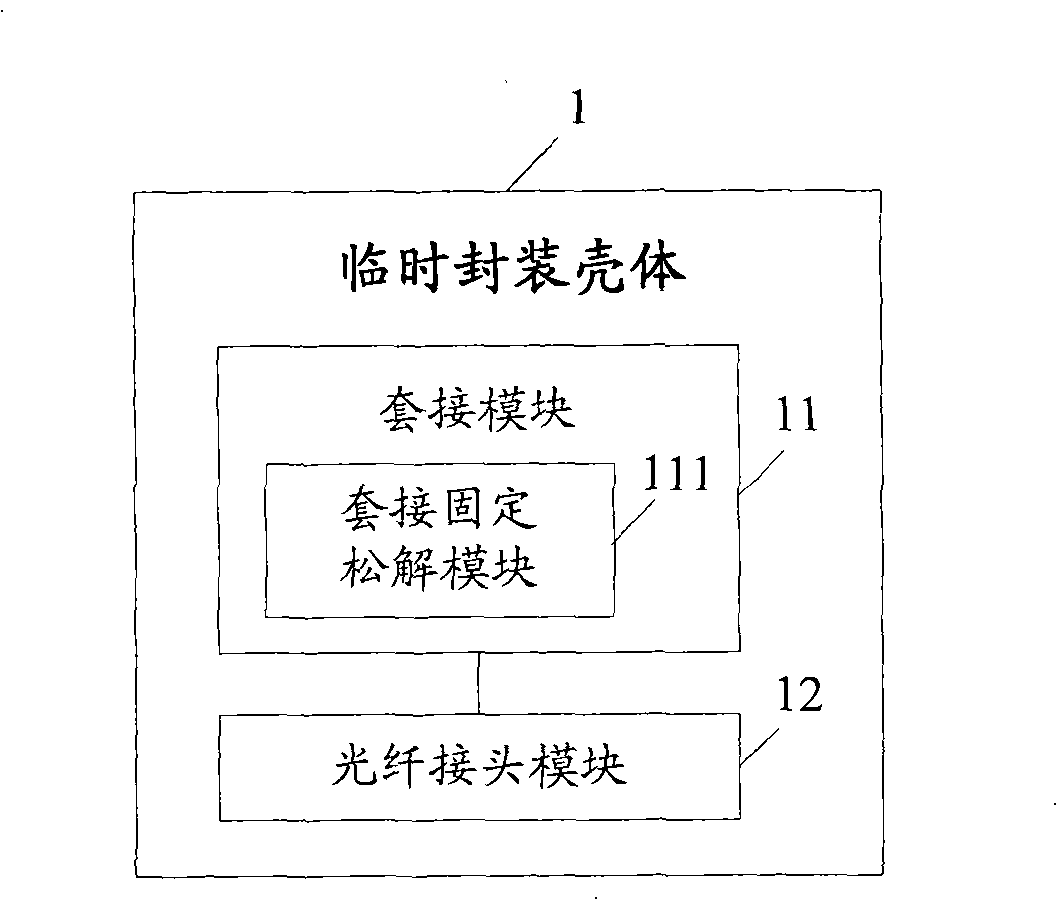

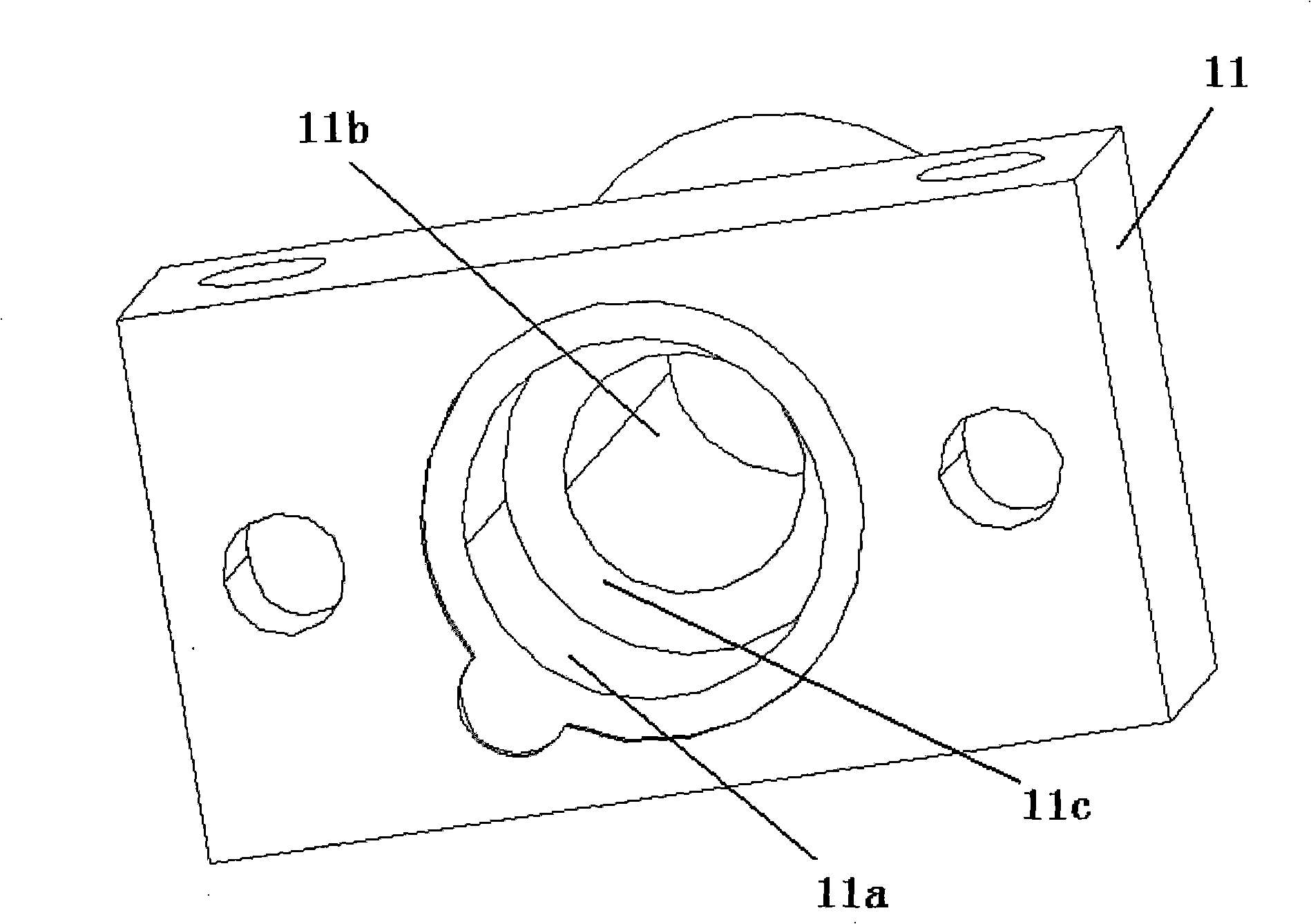

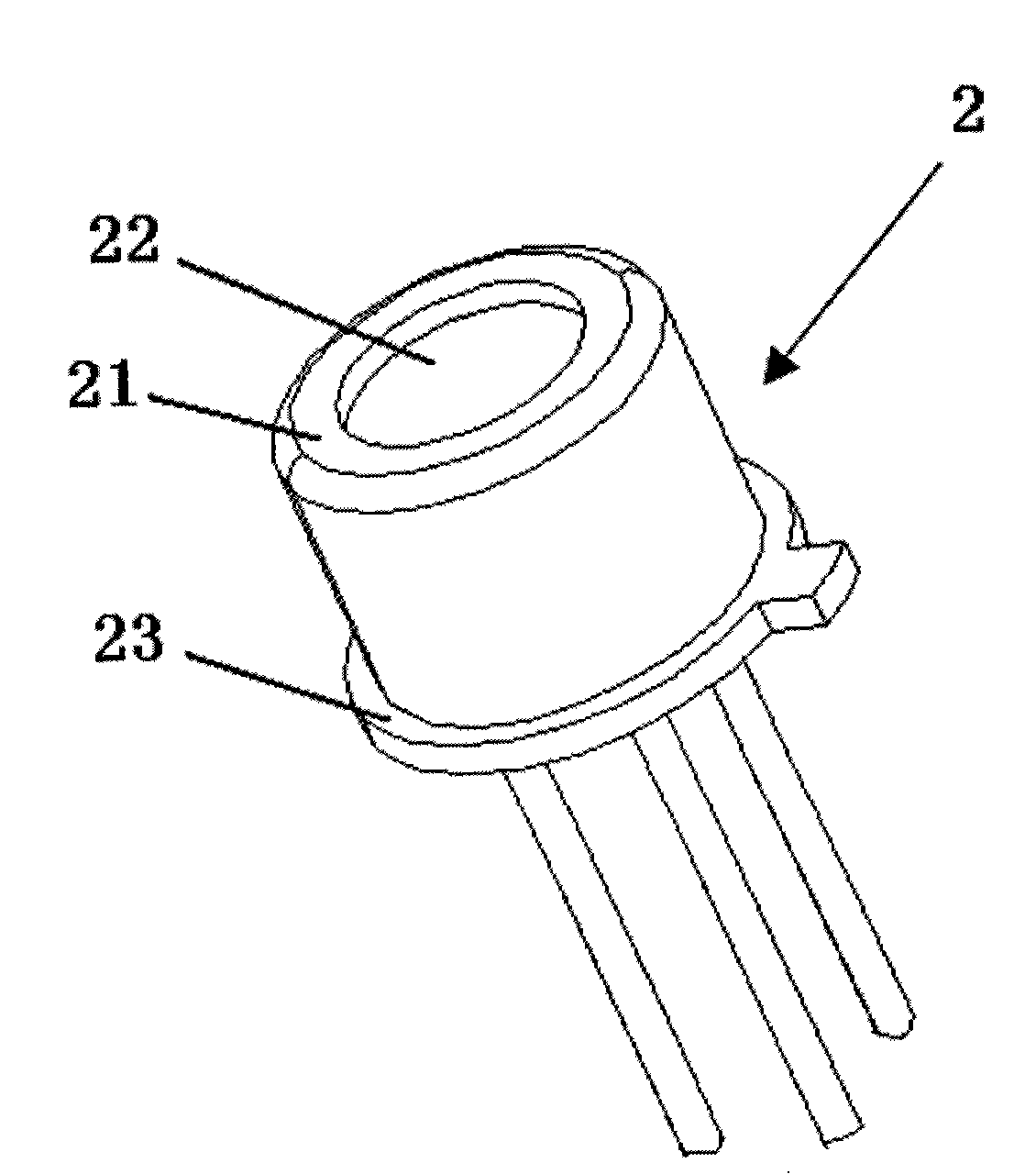

Circuit parameter demarcating method for photodetector for direct coupling and apparatus thereof

InactiveCN101509809AEasy CalibrationEasy and accurate calibrationSemiconductor/solid-state device detailsSolid-state devicesPhotodetectorDirect coupling

The embodiment of the invention discloses a method for calibrating the circuit parameters of an optical detector applied to direct coupling. The method includes the following steps: a tube core of the optical detector is sheathed and connected in a temporary encapsulation shell; after receiving optical information through the temporary encapsulation shell, the tube core of the optical detector calibrates the circuit parameters under analog light attenuation; after the calibration of the circuit parameters is completed, the tube core of the optical detector is removed from the temporary encapsulation shell. Correspondingly, the embodiment of the invention also discloses the temporary encapsulation shell. Through the implementation of the embodiment, the tube core of the optical detector is sheathed and connected in the temporary encapsulation shell, and then is removed from the temporary encapsulation shell after the calibration of various circuit parameters is completed to facilitate the final direct coupling, thus realizing the calibration of various circuit parameters in an analog light attenuation way in the process of producing direct coupling products, improving the calibration efficiency of circuit parameters and leading to more convenient and accurate calibration of circuit parameters.

Owner:深圳市新岸通讯技术有限公司

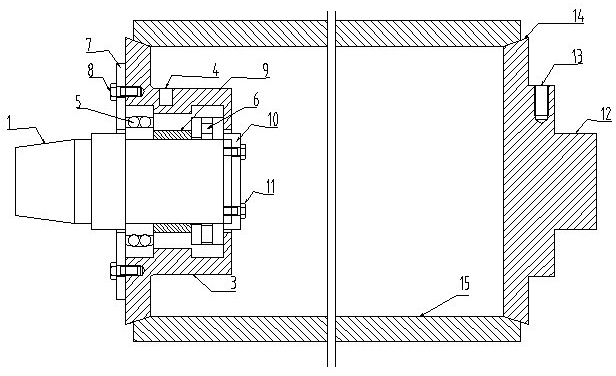

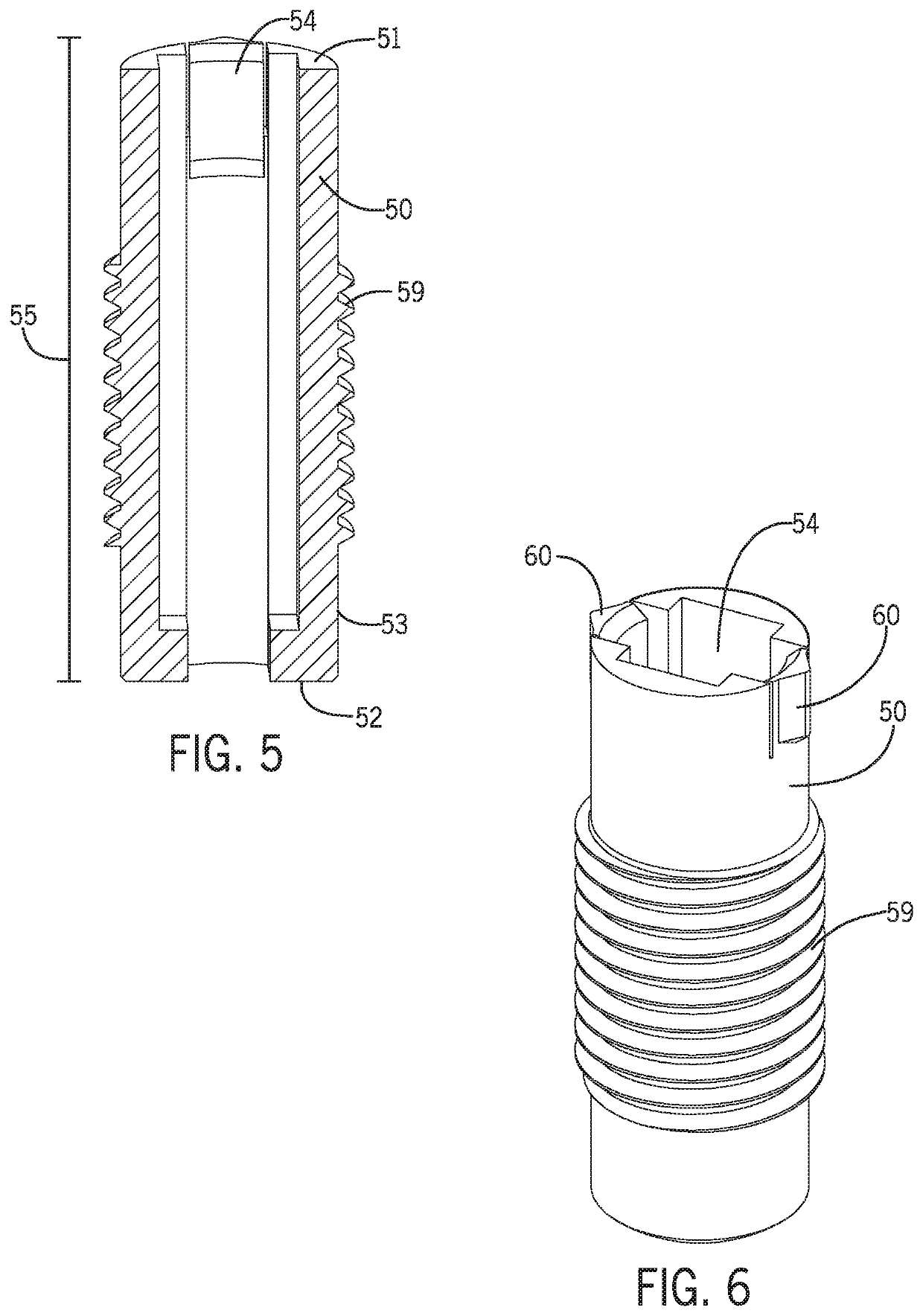

Turning fixture of cast steel sleeve for lathe

InactiveCN102091949AEasy and accurate calibrationOperational securityPositioning apparatusMetal-working holdersEngineeringOperational safety

The invention belongs to the technical field of lathe fixtures, in particular relating to a turning fixture of a cast steel sleeve for a lathe. The fixture comprises a lathe tail end fixture and a lathe head end fixture, wherein the lathe tail end fixture comprises a hollow sleeve positioning block and a taper shaft; the taper shaft is provided with a bearing; the part, which is provided with the bearing, of the taper shaft is positioned in the hollow sleeve positioning block; the lathe head end fixture comprises a sleeve positioning block; the end part of the sleeve positioning block is provided with a lathe chuck clamping bulge end; and the hollow sleeve positioning block and the sleeve positioning block are coaxially arranged, and positioning edges are both oblique. When the turning fixture provided by the invention is used, the taper shaft of the lathe tail end fixture and the lathe chuck clamping device of the lathe head end fixture are fixed at the tail and head of the lathe respectively; the lathe tail end fixture can be adjusted so that the cast steel sleeve rotates along with the lathe spindle without deformation or dislocation under the concentric clamping force at the head and tail of the lathe during a turning process; and in the turning process, the fastening is reliable, the correction is convenient and accurate, the operation is safe and reliable, and the maintenance amount is small.

Owner:胡冠奇

Method and electronic device for controlling image white balance

ActiveCN105338333BAccurate correctionEasy and accurate calibrationColor signal processing circuitsPicture signal generatorsComputer scienceElectronic equipment

The invention discloses an image white balance control method, and the method is used in electronic equipment. The method comprises the steps: obtaining a first image; obtaining the environmental parameter of the first image during photographing; carrying out the white balance adjustment of the first image based on the environmental parameter, and obtaining a second image corresponding to the first image. The method provided by the invention is used for solving technical problems in the prior art that the image white balance adjustment is lower in accuracy and is complex in process, thereby achieving the white balance adjustment of the image conveniently and accurately.

Owner:LENOVO (BEIJING) LTD

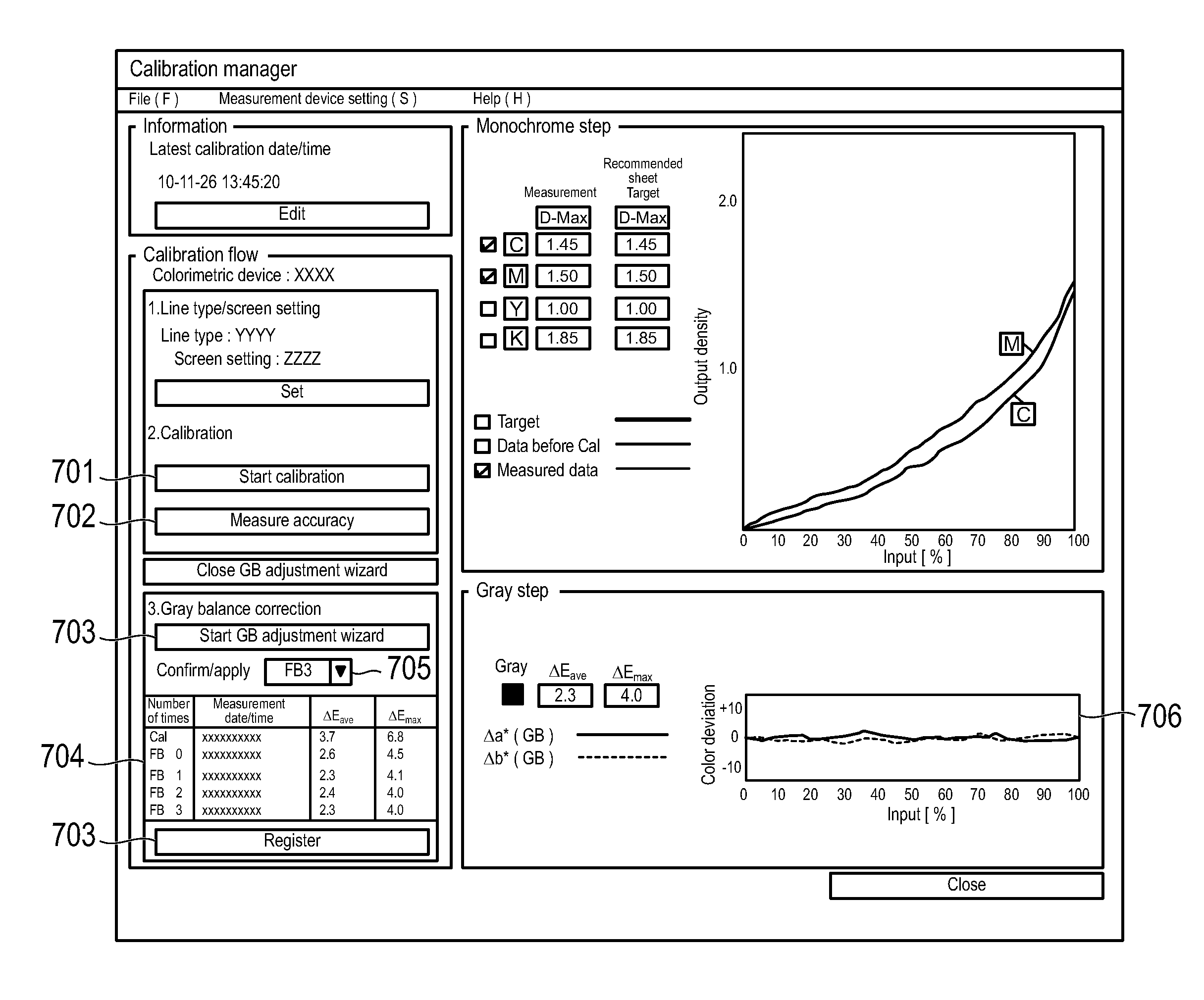

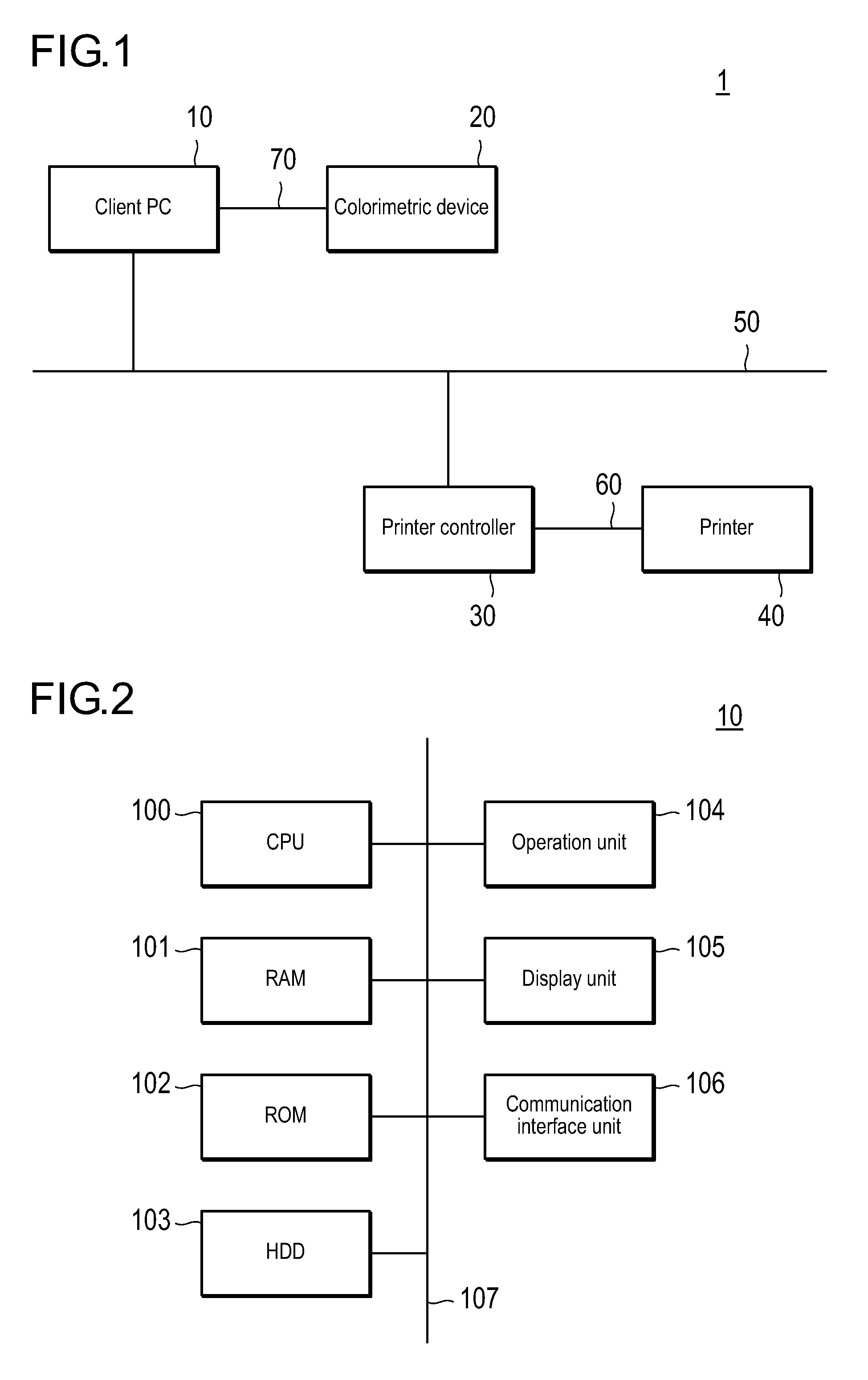

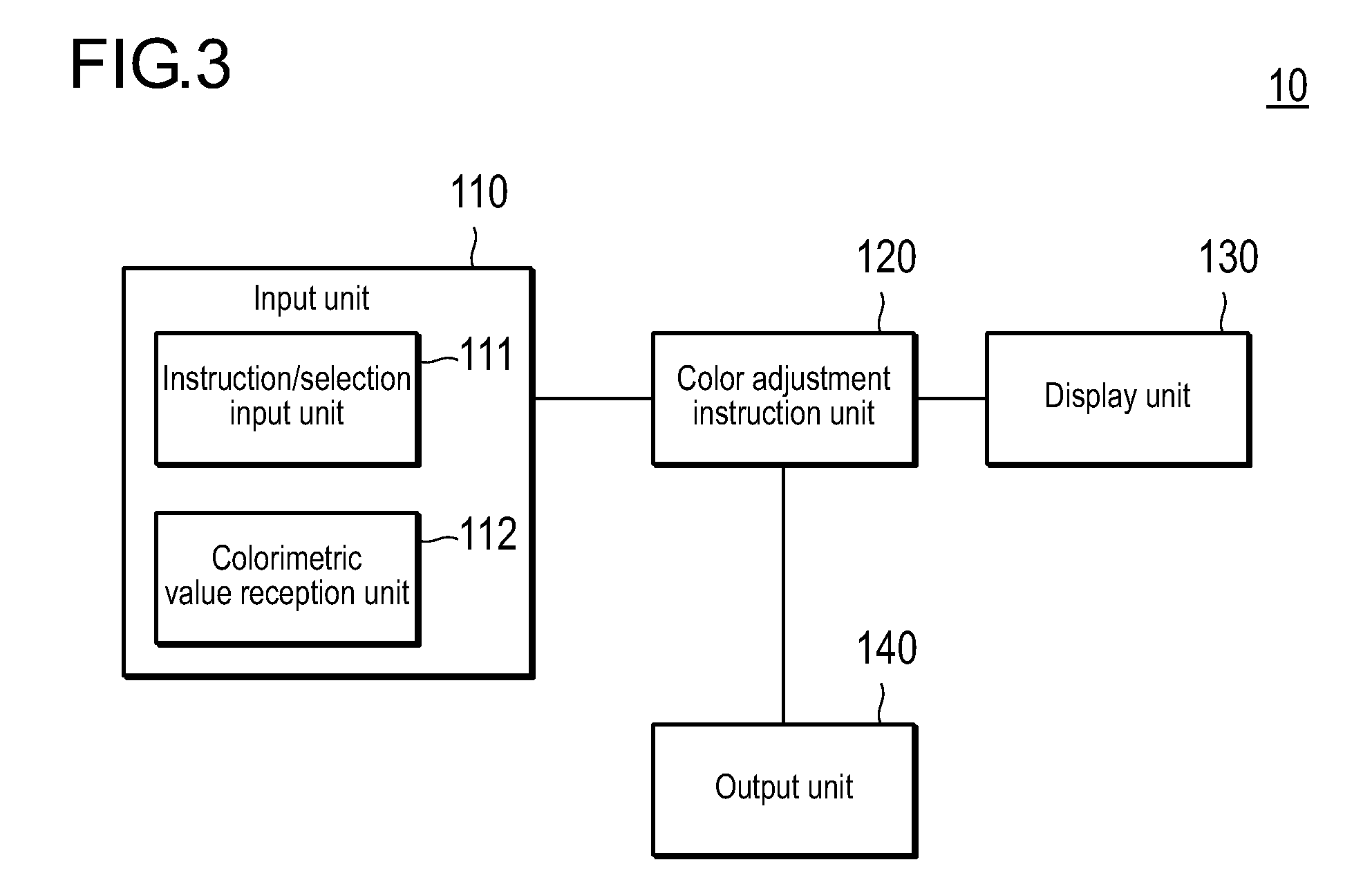

Calibration apparatus for image forming apparatus, computer readable storage medium stored with program for calibration apparatus, and method for calibrating image forming apparatus

ActiveUS8958125B2Easy and accurate calibrationDigitally marking record carriersVisual presentation using printersImage formationLightness

Owner:KONICA MINOLTA INC

By-pass and pressure regulator valve

ActiveUS8091576B2Easy and accurate calibrationImprove reliabilityFluid pressure control without auxillary powerRatio controlEngineeringStress regulation

Owner:P A SPA

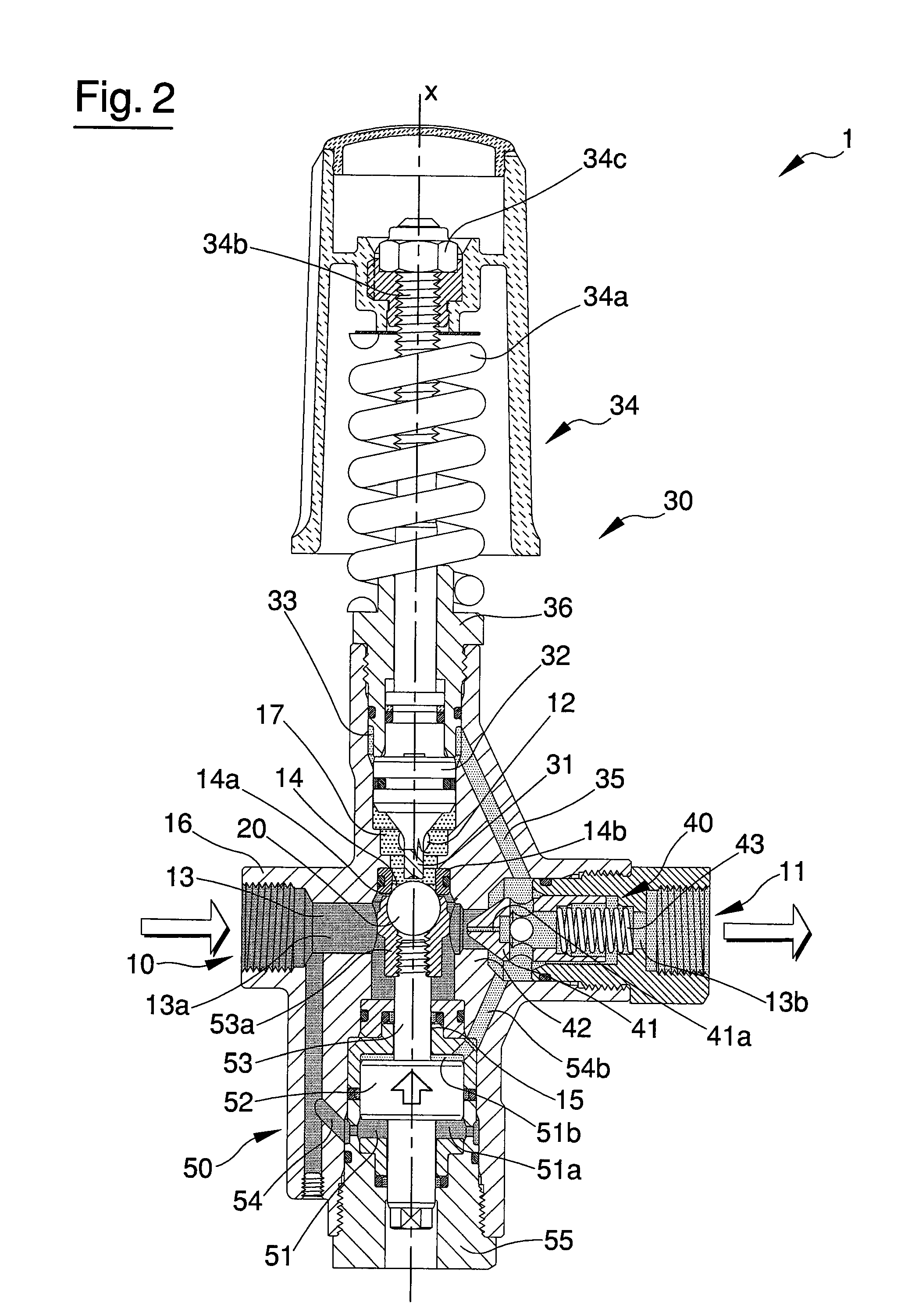

Calibratable tire gauge and system

ActiveUS20200182729A1Easy and accurate calibrationEasy CalibrationInflated body pressure measurementStructural engineeringClicker

The present calibratable tire gauge has a first unit nose piece and a second unit nose piece located partially within a main outer enclosure of the gauge. A clicker mechanism located may allow a user to utilize a special tool to ‘unlock’ the second unit nose piece with respect to the first unit nose piece and immobilize the second unit nose piece with respect to the main outer enclosure. Once ‘unlocked’, a user may twist the scale bar of the gauge to move the first unit nose piece independent from the second unit nose piece. As a result, the measured pressure on the scale bar is altered as a result of the ‘read’ line being lowered or raised with respect to the main outer enclosure.

Owner:MILTON INDS

Antenna evaluation device and method

ActiveCN102105805BImprove evaluation accuracyEasy and accurate calibrationAntennasAntenna radiation diagramsPhase shiftedSoftware engineering

A computer (10) measures amplitudes and phases respective received signals S60a relative to a transmitting signal (S22a) when radio waves are radiated solely from each of the scatterer antennas (50-n) and received by using a calibration receiving antenna (60a), determines a target amplitude based on measured amplitudes, and determines a target phase based on measured phases. Reference attenuation amount control voltages (VAa-n) for respective attenuators (14a-n) are set to attenuation amount control voltages for making the measured amplitudes coincidence with an identical target amplitude, and a reference phase shift amount control voltage (VPa-n) for each phase shifter (13a-n) is set to phase shift amount control voltages for making the measured phases coincidence with an identical target phase.

Owner:PANASONIC INTELLECTUAL PROPERTY CORP OF AMERICA

Position calibrating method of medical ultrasonic three-dimensional imaging based on linear scanning

InactiveCN103006263BEasy to operateReduce dependenceUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsSonificationUltrasonic imaging

Owner:SOUTH CHINA UNIV OF TECH

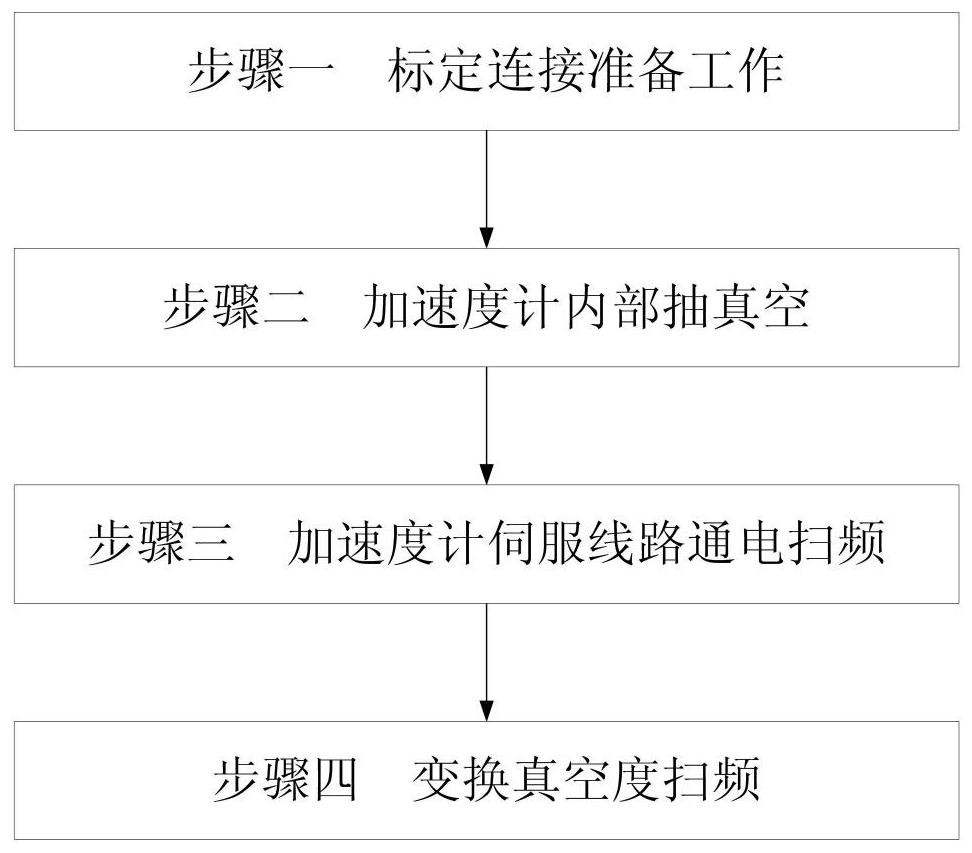

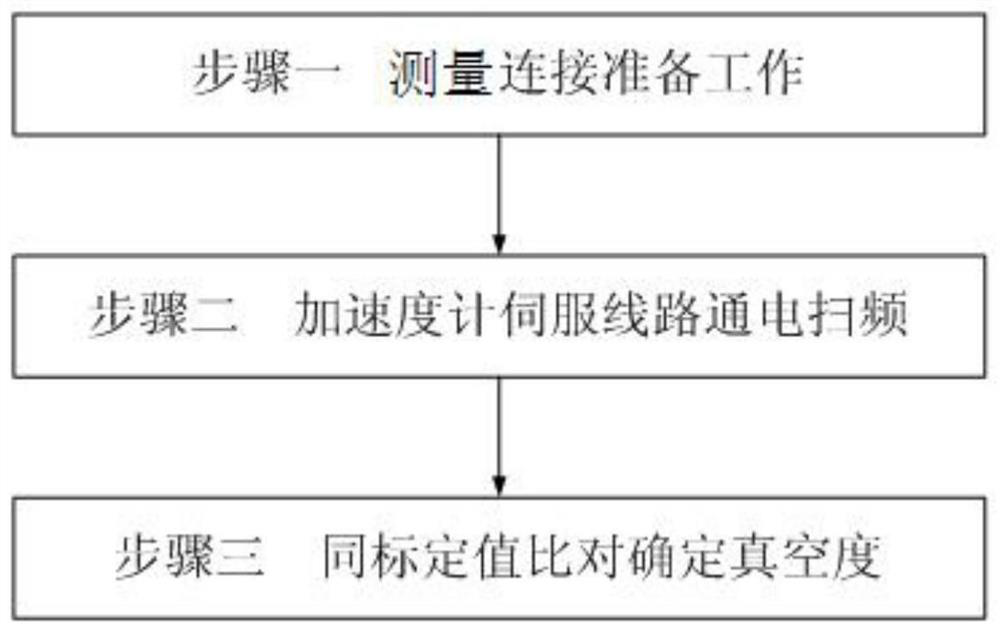

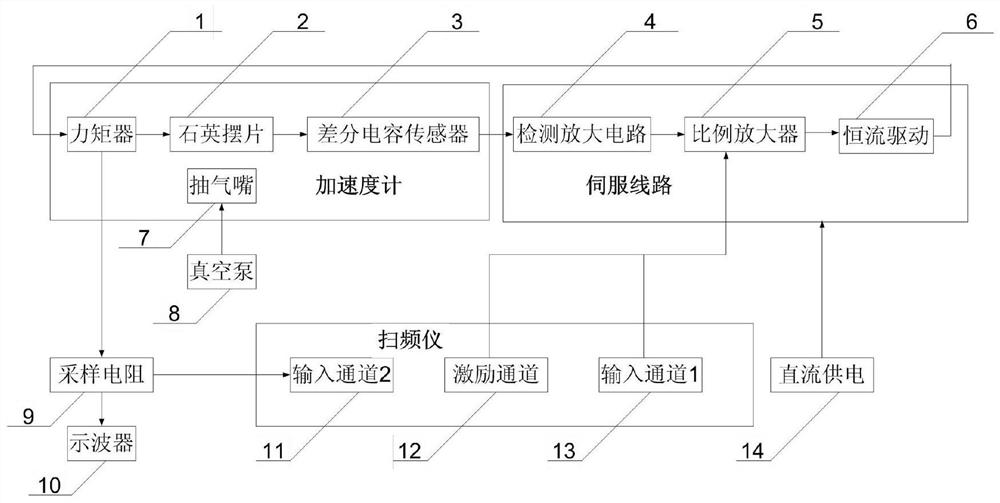

The Method of Detecting the Vacuum Degree Inside the Accelerometer by Frequency Sweeping of the Servo Circuit

ActiveCN107748274BDoesn't change any structureDoes not change the structureVacuum gaugesTesting/calibration of speed/acceleration/shock measurement devicesAccelerometerHemt circuits

The invention relates to a method for detecting the internal vacuum degree of an accelerometer through servo circuit frequency sweeping, which is technologically characterized by comprising the following steps: S1, before vacuum sealing, measuring the frequency sweeping peak amplitude inside an accelerometer through a closed-loop frequency sweeping approach, and calibrating the vacuum degree of the accelerometer; and S2, after vacuum sealing of the accelerometer, measuring the frequency sweeping peak amplitude through the closed-loop frequency sweeping approach, and comparing the vacuum degreewith the previous calibrated value, so as to compete accelerometer vacuum degree test. The vacuum degree is tested through an electrical servo circuit closed-loop frequency sweeping approach, withoutthe need to change the original design of the accelerometer. The servo circuit adopts a pure proportional amplification link, so that frequency sweeping can completely reflect the internal characteristics of acceleration, and the influence of the circuit link on calibration is reduced. The accuracy of vacuum degree measurement is improved by adjusting the gain of a proportional amplifier.

Owner:TIANJIN NAVIGATION INSTR RES INST

Circuit parameter demarcating method for photodetector for direct coupling and apparatus thereof

InactiveCN101509809BEasy CalibrationEasy and accurate calibrationSemiconductor/solid-state device detailsSolid-state devicesPhotodetectorDirect coupling

The embodiment of the invention discloses a method for calibrating the circuit parameters of an optical detector applied to direct coupling. The method includes the following steps: a tube core of the optical detector is sheathed and connected in a temporary encapsulation shell; after receiving optical information through the temporary encapsulation shell, the tube core of the optical detector calibrates the circuit parameters under analog light attenuation; after the calibration of the circuit parameters is completed, the tube core of the optical detector is removed from the temporary encapsulation shell. Correspondingly, the embodiment of the invention also discloses the temporary encapsulation shell. Through the implementation of the embodiment, the tube core of the optical detector issheathed and connected in the temporary encapsulation shell, and then is removed from the temporary encapsulation shell after the calibration of various circuit parameters is completed to facilitate the final direct coupling, thus realizing the calibration of various circuit parameters in an analog light attenuation way in the process of producing direct coupling products, improving the calibration efficiency of circuit parameters and leading to more convenient and accurate calibration of circuit parameters.

Owner:深圳市新岸通讯技术有限公司

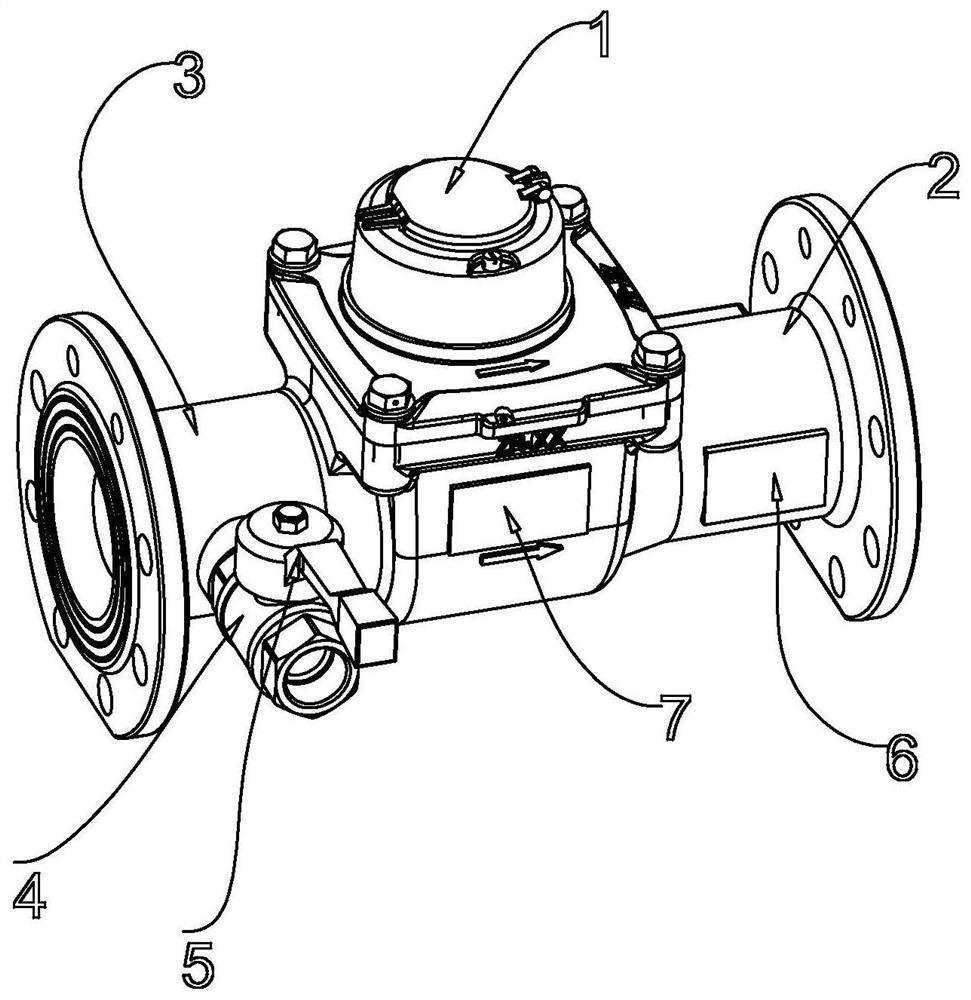

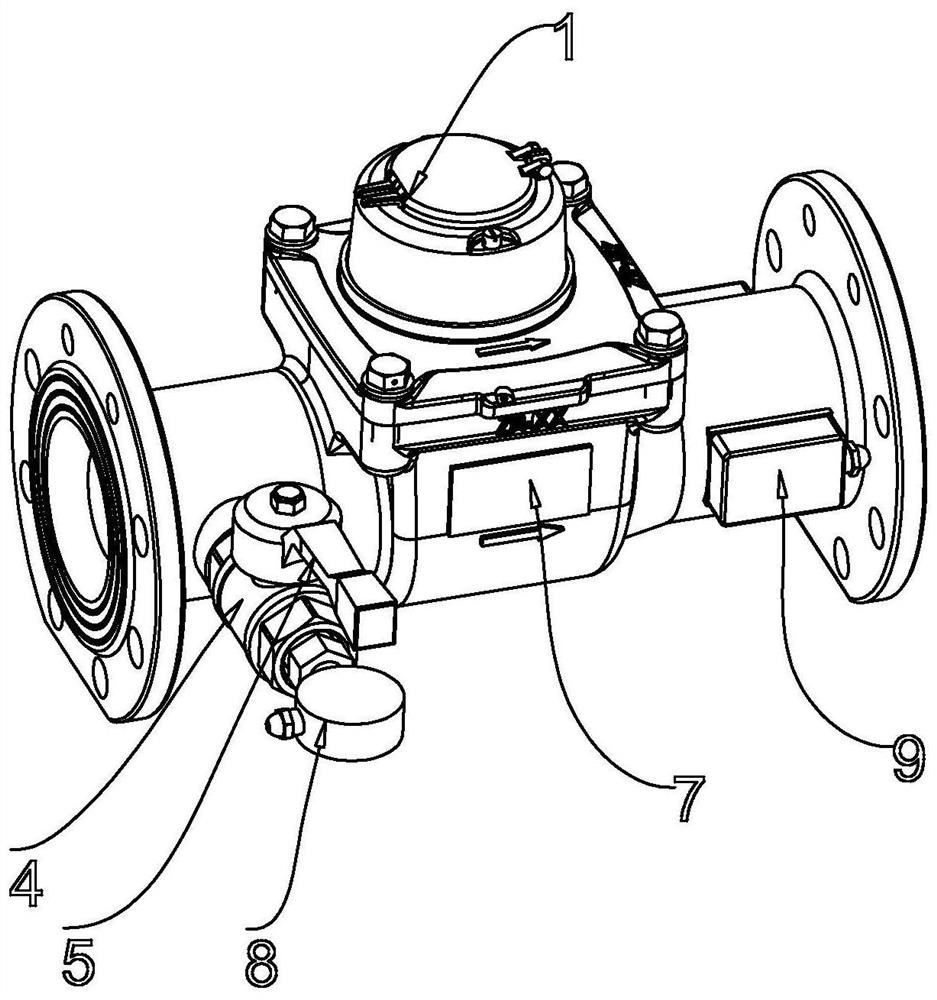

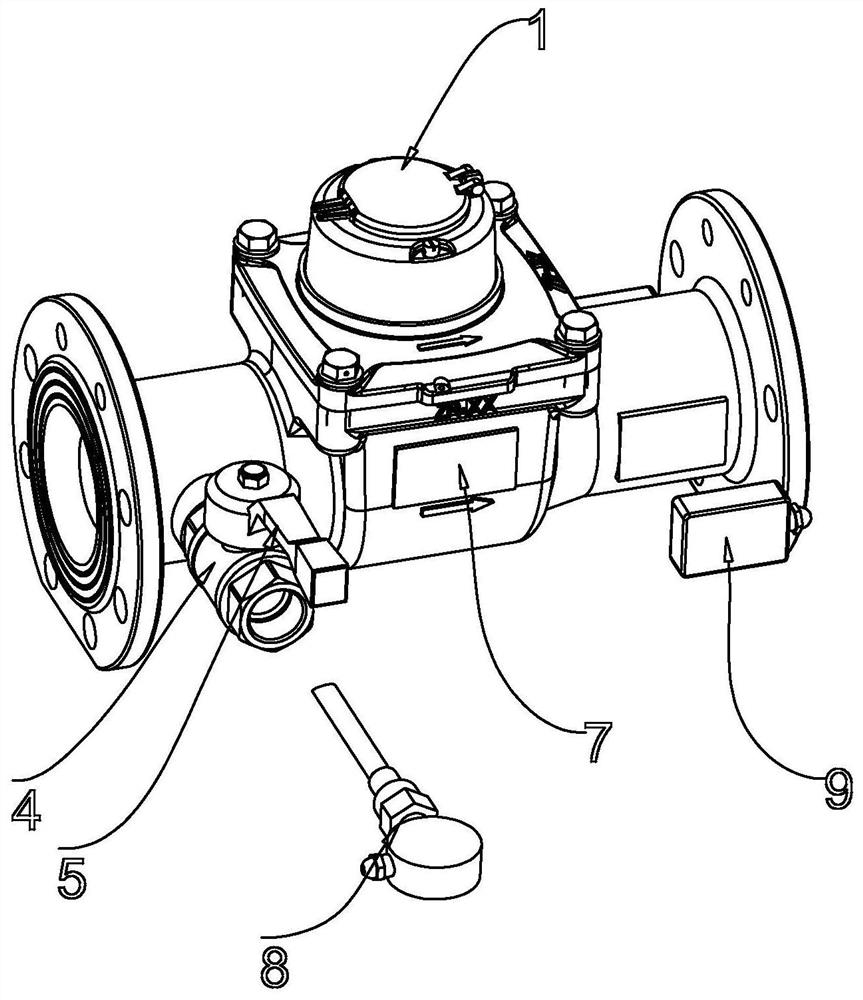

Flow meter convenient to check

PendingCN112611426AImprove verification efficiencyAvoid installing clamp-on flowmetersTesting/calibration apparatusVolume indication and recording devicesEngineeringContinuous flow

The invention provides a flow meter convenient to check. The flow meter comprises a flow meter body, a first pipeline connected with the medium inlet of the flow meter body and a second pipeline connected with the medium outlet of the flow meter body, wherein a third pipeline is connected to the first pipeline or the second pipeline, and is communicated with the corresponding pipeline, a switching valve is arranged on the circulation path of the third pipeline, the medium outlet of the third pipeline is used for connection of a plug-in flow meter so as to carry out continuous flow verification on the flow meter body, and the first pipeline or the second pipeline is further provided with an installation part used for installation of an external clamping type flow meter, so that the flow meter body can be calibrated without interrupting flow. Due to the arrangement, the plug-in flow meter and the external clamping type flow meter are convenient to install, so that the processes of point finding, trepanning, welding and the like of the plug-in flow meter in the past are avoided, the processes of point finding, scribing and the like of the outer clamping type flow meter in the past are also avoided, and convenience and quickness are achieved.

Owner:HUNAN WEIMING ENERGY TECH CO LTD

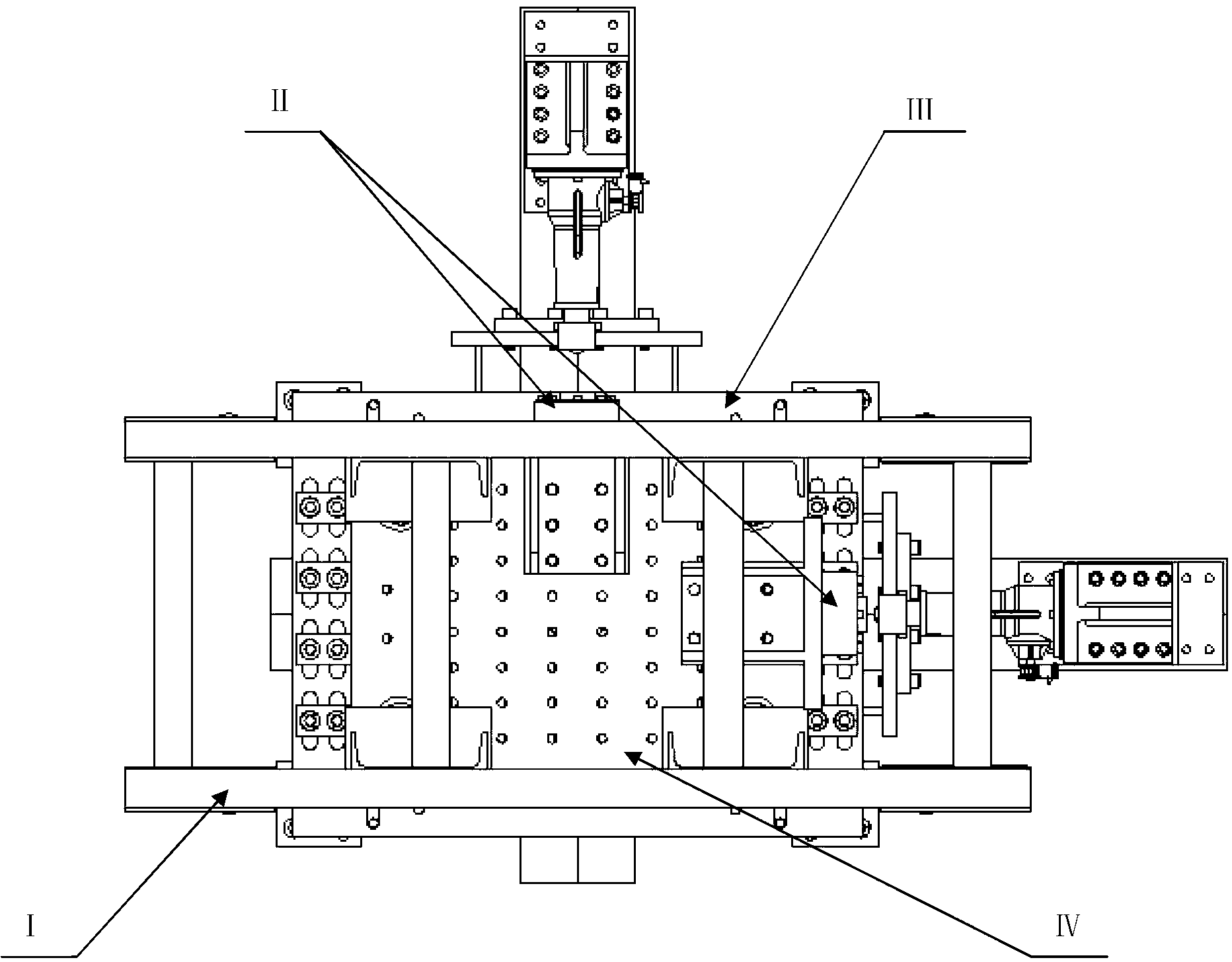

Calibration device for three-dimensional force measuring platform

InactiveCN103308252AEasy to useEasy and accurate calibrationForce/torque/work measurement apparatus calibration/testingLeg cushionEngineering

The invention relates to a calibration device for a three-dimensional force measuring platform, which aims at overcoming the defect that the current force calibration device cannot carry out simultaneous force calibration of three directions on a flat plate type three-dimensional force measuring platform and a convex plate type three-dimensional force measuring platform according to the using needs, and providing a device for carrying out comprehensive and simultaneous orthogonal calibration on the force measuring sensor of the three-dimensional force measuring platform. The device can calibrate the two kinds of three-dimensional force measuring platforms with different appearances. The device is composed of a weight tray assembly, a counter-force plate and spoke type pressure sensor assembly and a three-dimensional force measuring platform calibration device foundation platform assembly, wherein the weight tray assembly is put on the three-dimensional force measuring platform, the counter-force plate and spoke type pressure sensor assembly is connected with the three-dimensional force measuring platform and is fixed by a bolt, and the three-dimensional force measuring platform is connected with the three-dimensional force measuring platform calibration device foundation platform assembly and is fixed by the bolt. The weight tray assembly is composed of a channel steel welding frame and a leg cushion block, and the leg cushion block is connected with the channel steel welding frame through the bolt.

Owner:JILIN UNIV

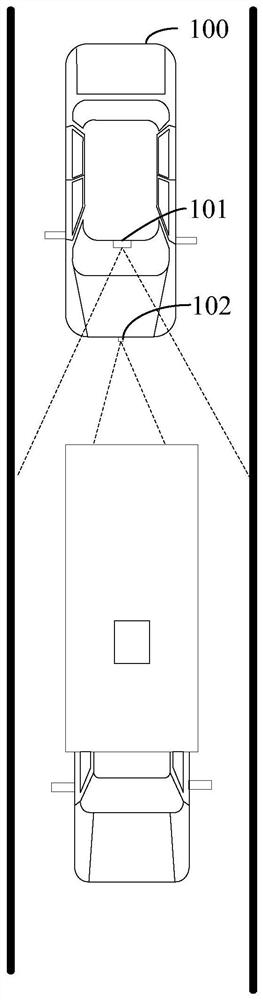

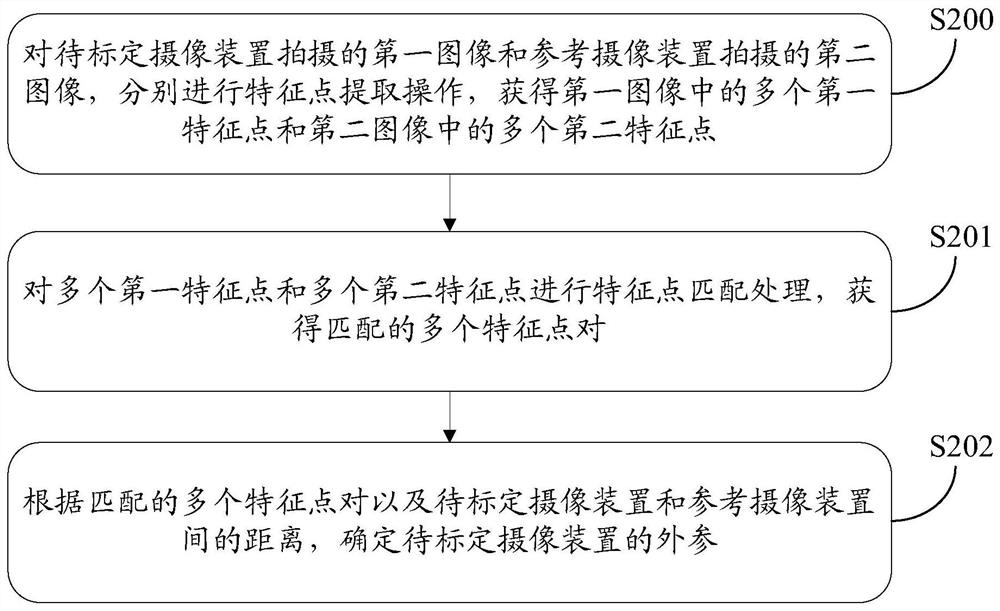

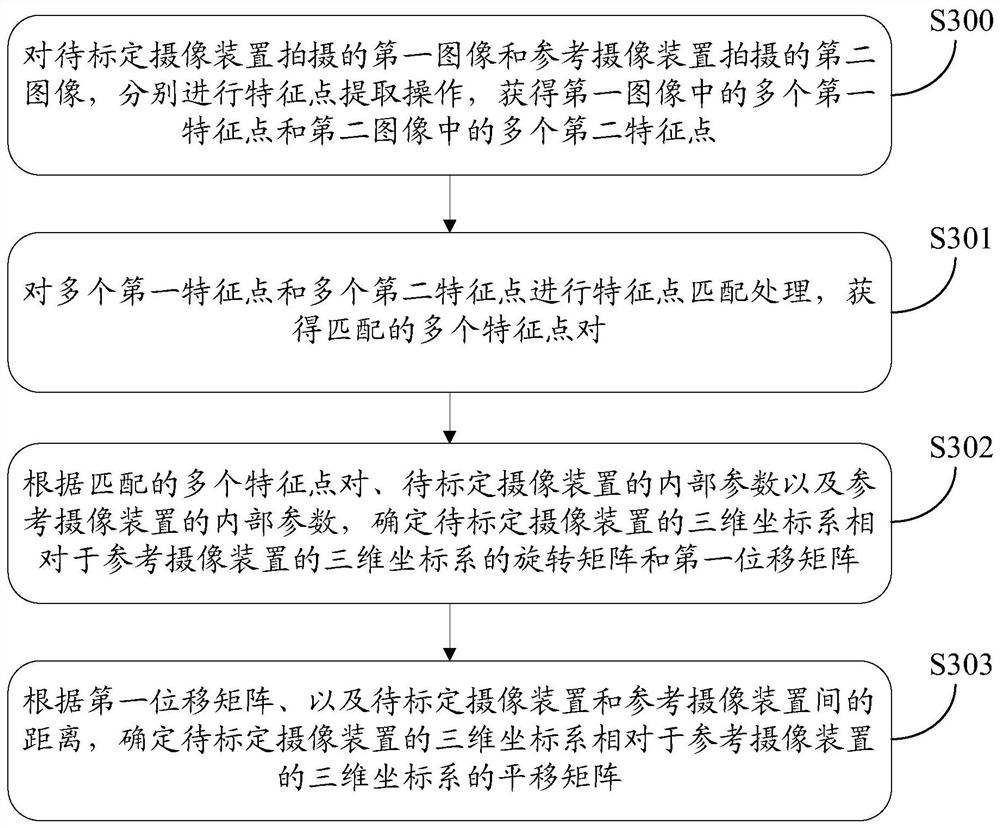

Parameter calibration method and device of camera device, medium and electronic equipment

PendingCN113628283AEasy and accurate calibrationImprove securityImage analysisCharacter and pattern recognitionComputer graphics (images)Engineering

The invention discloses a parameter calibration method and device of a camera device, a medium and electronic equipment, wherein the method comprises the steps: respectively carrying out the feature point extraction operation of a first image shot by a to-be-calibrated camera device and a second image shot by a reference camera device, obtaining a plurality of first feature points in the first image and a plurality of second feature points in the second image; performing feature point matching processing on the plurality of first feature points and the plurality of second feature points to obtain a plurality of matched feature point pairs; and determining external parameters of the to-be-calibrated camera device according to the plurality of matched feature point pairs and the distance between the to-be-calibrated camera device and the reference camera device. According to the technical scheme provided by the invention, the external parameters of the camera device can be conveniently and accurately recalibrated. For smart driving application, the safety of vehicle driving can be improved.

Owner:HORIZON JOURNEY (HANGZHOU) ARTIFICIAL INTELLIGENCE TECH CO LTD

Method for calibrating camera by utilizing concentric circles

InactiveCN101783018BEasy and accurate calibrationRealize CalibrationImage analysisAutonomous Navigation SystemImaging processing

The invention discloses a method for calibrating camera by utilizing concentric circles, and belongs to the technical field of image processing, which comprises the following steps: pasting white paper on a horizontally even panel to prepare a calibration object; acquiring three initial images; fitting according to an elliptical point set to obtain an elliptical image matrix; and obtaining a projection equation of a circle by adopting projective transformation, calculating circle center projection of two concentric circles according to a correlation of a projection equation of the concentric circles, and obtaining a symmetrical matrix according to the circle center projection so as to obtain an internal parameter matrix of the camera and complete the internal parameter calibration of the camera. The method avoids an error caused by a mode that the internal parameters of the camera are determined by calculating imaginary circular points, and a linear method is adopted to simply, conveniently and accurately calibrate all the internal parameters of the camera (including a principal point position, an aspect ratio and an obliquity factor). The method is suitable for vision-based autonomous navigation system and non-contact industrial detection.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com