The Method of Detecting the Vacuum Degree Inside the Accelerometer by Frequency Sweeping of the Servo Circuit

A technology of accelerometer and vacuum degree, which is applied in the testing/calibration of speed/acceleration/shock measurement equipment, speed/acceleration/shock measurement, vacuum gauge, etc. It can solve the problems of the external dimension change of the accelerometer and achieve simple and easy operation Easy, accurate calibration and detection, and good promotional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

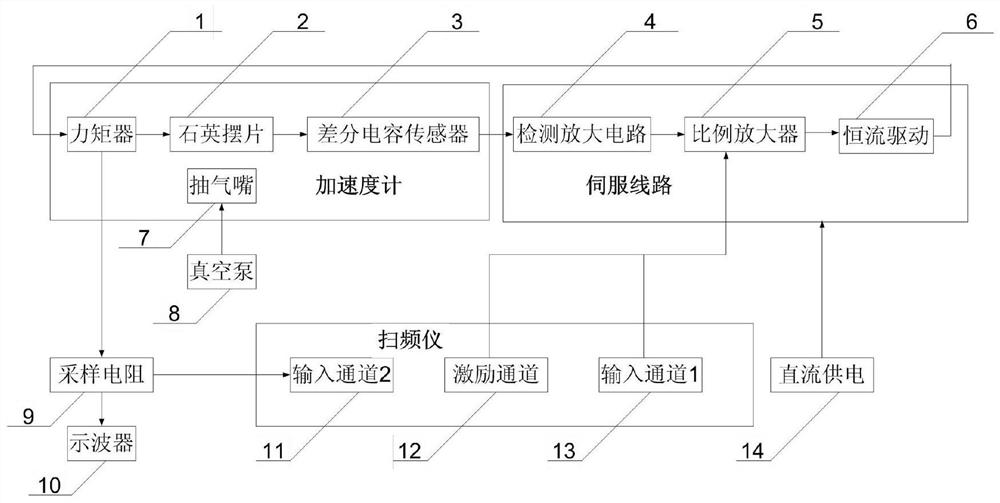

[0024] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

[0025] The invention relates to a method for detecting the internal vacuum degree of a quartz flexible accelerometer used for a gravity gradiometer, which is a simple method for detecting the internal vacuum degree of the accelerometer through a closed-loop frequency sweep of a servo circuit, which can be used for detecting the internal vacuum degree of inertial components such as accelerometers, and can The convenient and accurate calibration and detection of the vacuum degree inside the accelerometer is realized.

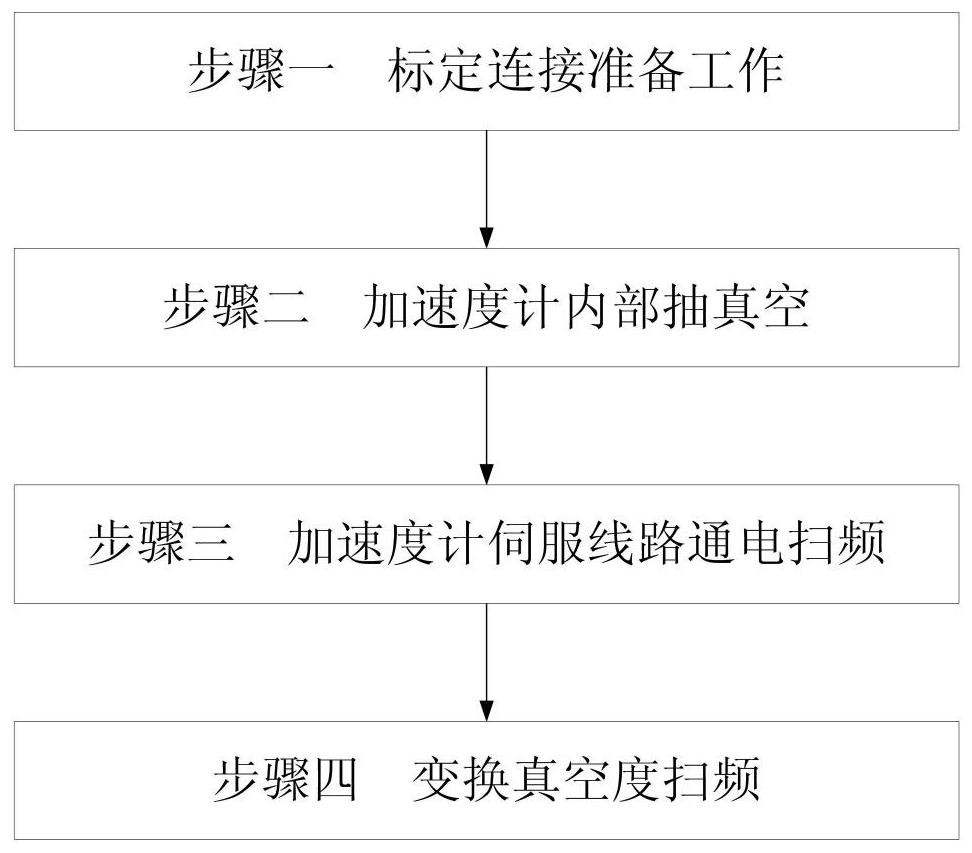

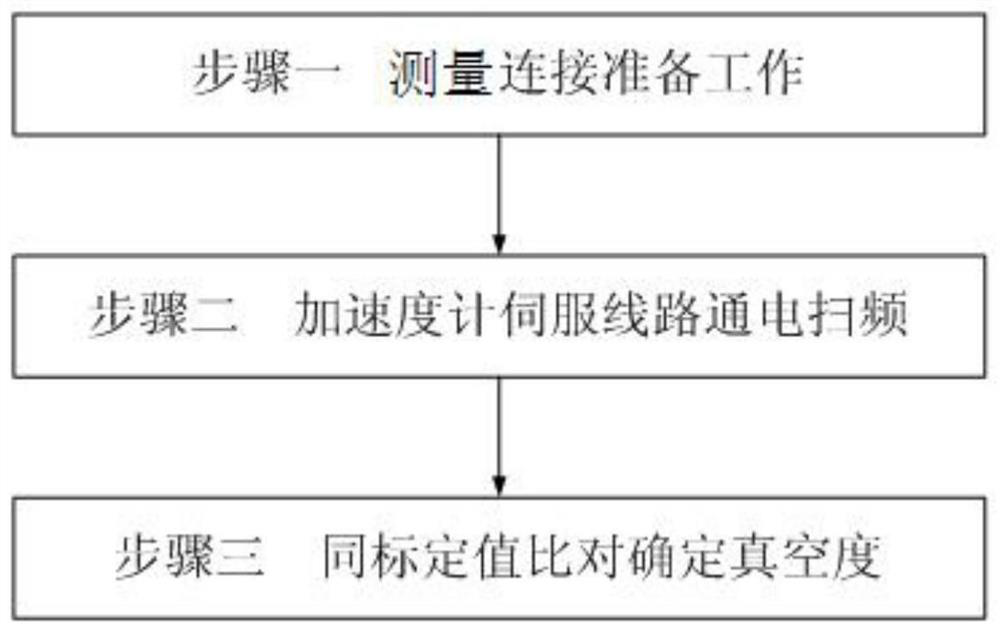

[0026] A method of detecting the vacuum degree inside the accelerometer by sweeping the frequency of the servo circuit, such as figure 1 and figure 2 shown, including the following steps:

[0027] Step 1. Before vacuum sealing, calibrate the vacuum degree of the accelerometer through the closed-loop frequency sweep method inside the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com