Turning fixture of cast steel sleeve for lathe

A technology of cast steel sleeves and fixtures, applied in clamping, manufacturing tools, supports, etc., can solve problems affecting product quality and yield, inconvenient use, complex fixture structure, etc., achieve small maintenance, easy disassembly and maintenance , Calibration convenient and accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

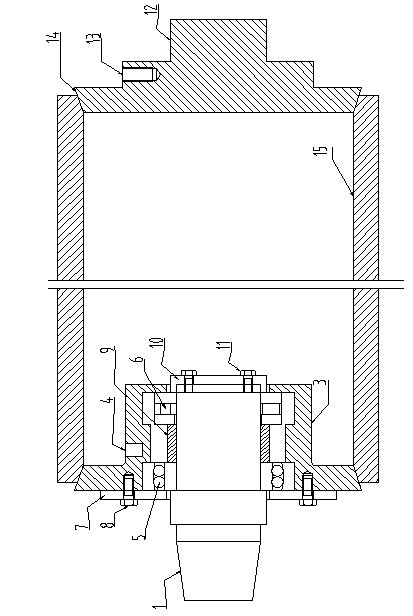

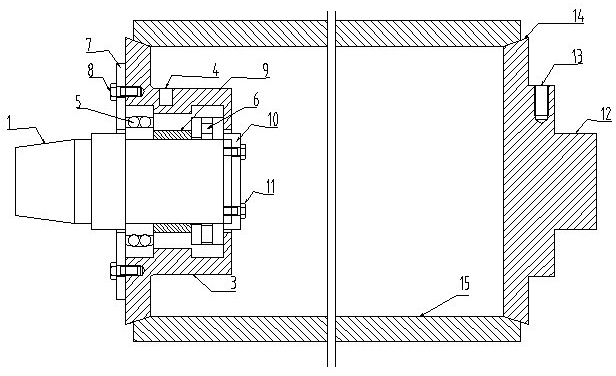

[0017] Such as figure 1 The cast steel sleeve turning fixture for lathes shown includes a bed end fixture and a bed end fixture. The bed end fixture includes a hollow sleeve positioning block 3 and a tapered shaft 1. The positioning edge of the hollow sleeve positioning block 3 is inclined Shaped, hollow sleeve positioning block 3 is provided with lifting ring screw hole 4, which plays a lifting role in the process of loading and unloading the fixture. The row ball bearing 5 and the thrust cylindrical bearing 6 are partly located in the hollow sleeve positioning block 3, and the taper shaft 1 between the double row ball bearing 5 and the thrust cylindrical bearing 6 is provided with a bearing spacer 9, and the hollow sleeve positioning block 3 and The double-row ball bearings 5 are fixed by the bearing gland 7, the bearing gland 7 is fixed on the hollow sleeve positioning block 3 by the bolt 8, and the bearing adjustment gland is arranged between the thrust cylindrical beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com