Newly-added steel girder and original reinforced concrete column hoop connecting joint and connecting method thereof

A technology for reinforced concrete columns and connecting nodes, which is used in construction, building maintenance, building construction, etc., can solve the problems of large restrictions on the construction of connecting nodes, difficulty in forming fixed perforations, and weak seismic resistance of the connecting part, so as to reduce damage and disturbance. , convenient construction, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

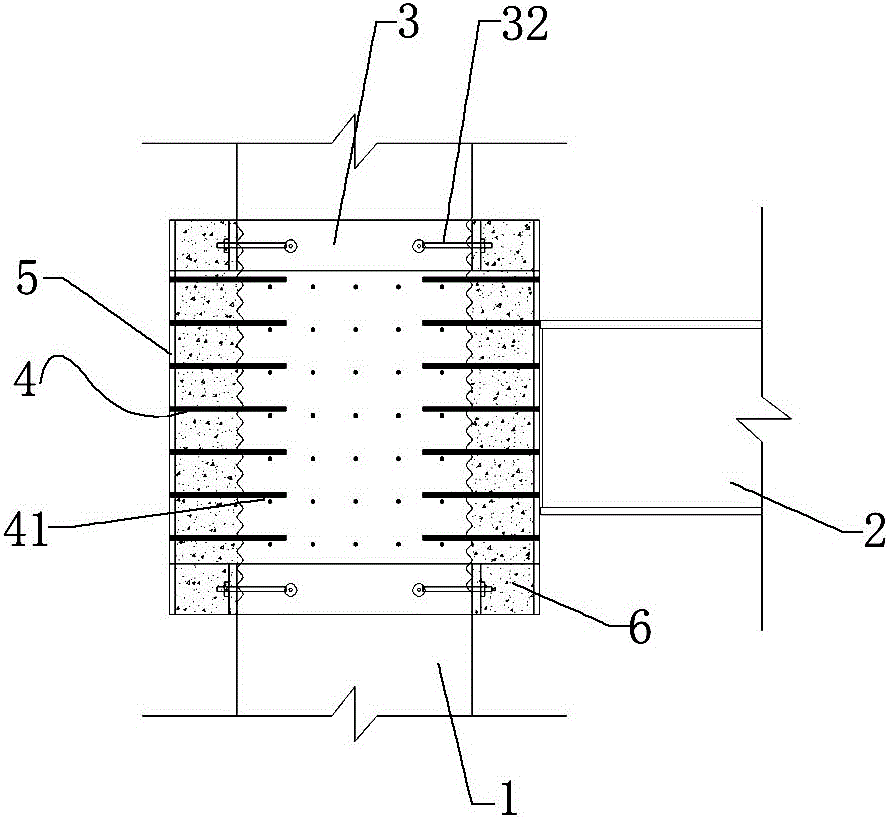

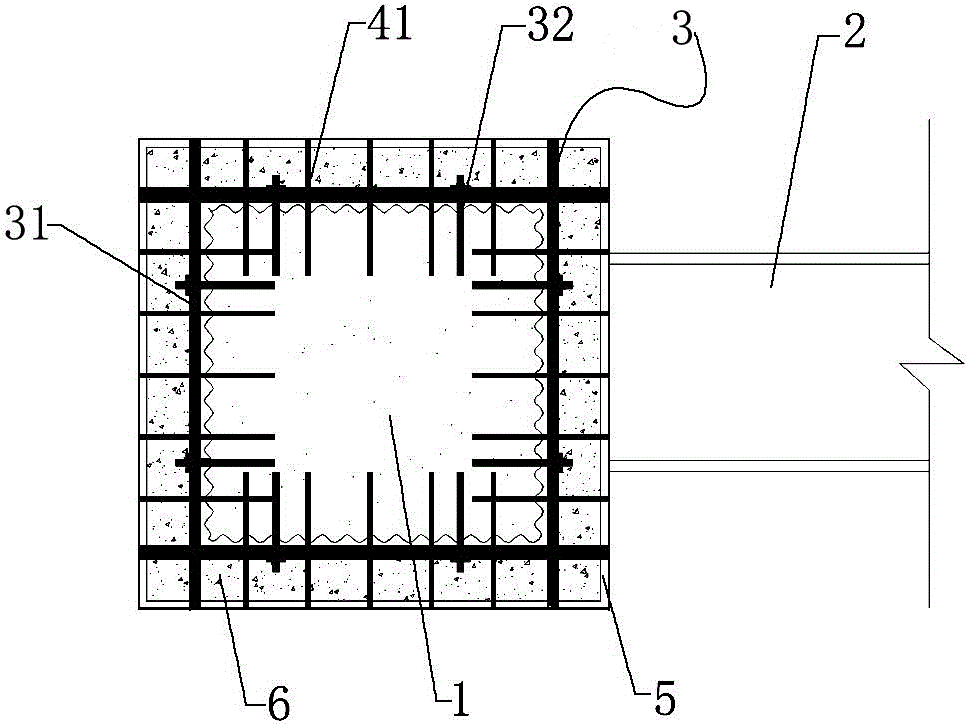

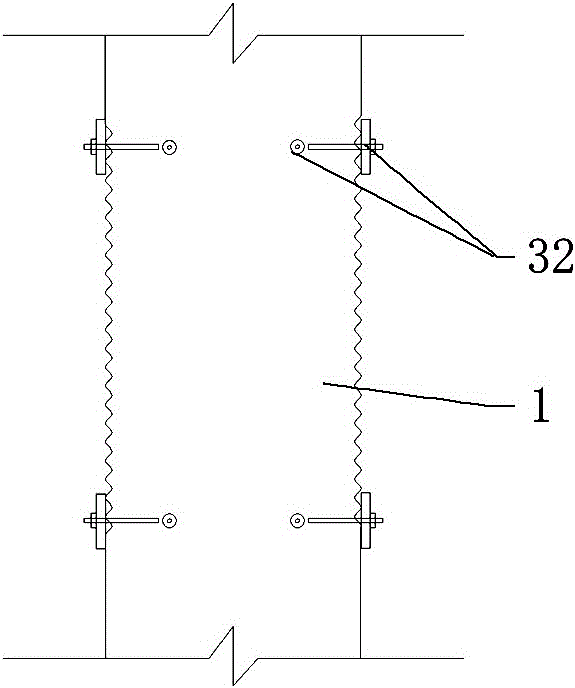

[0039] like figure 1 and figure 2 As shown, the hoop connection node between the newly added steel beam and the original reinforced concrete column in the present invention includes the original reinforced concrete column 1, the newly added steel beam 2 and the connection part arranged on the original reinforced concrete column 1 and connected with the newly added steel beam 2 The connecting member includes the inner hoop 3 fixed on the outer periphery of the original reinforced concrete column 1, the steel skeleton 4 implanted in the connection part, the outer hoop 5 fixed on the outer periphery of the steel skeleton 4, and the outer hoop 5 poured on the side of the original reinforced concrete column 1 The inner hoop concrete structure 6 between the walls; the number of inner hoops 3 is 2, which are respectively sleeved on the upper end and the lower end of the connection part. The inner hoop 3 is a well-shaped frame, which is formed by inserting and enclosing four steel st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com