Self-coupling ultrasonic detection probe device

A technology for detecting probes and ultrasonic waves, applied in measuring devices, material analysis using sound waves/ultrasonic waves/infrasonic waves, instruments, etc., can solve problems such as inconvenient operation, low efficiency, and impact on detection accuracy, and avoid uneven force , good coupling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions of the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention.

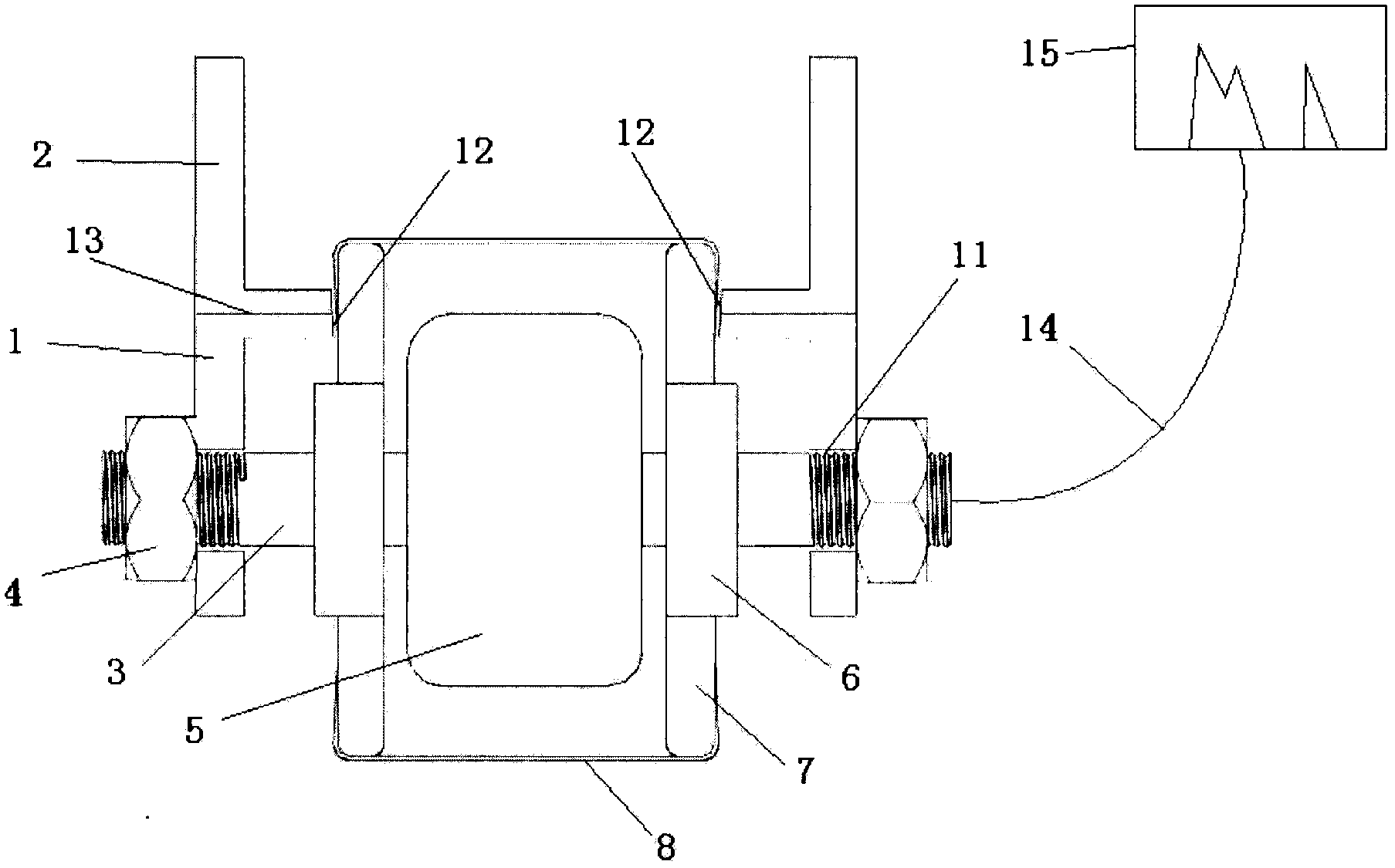

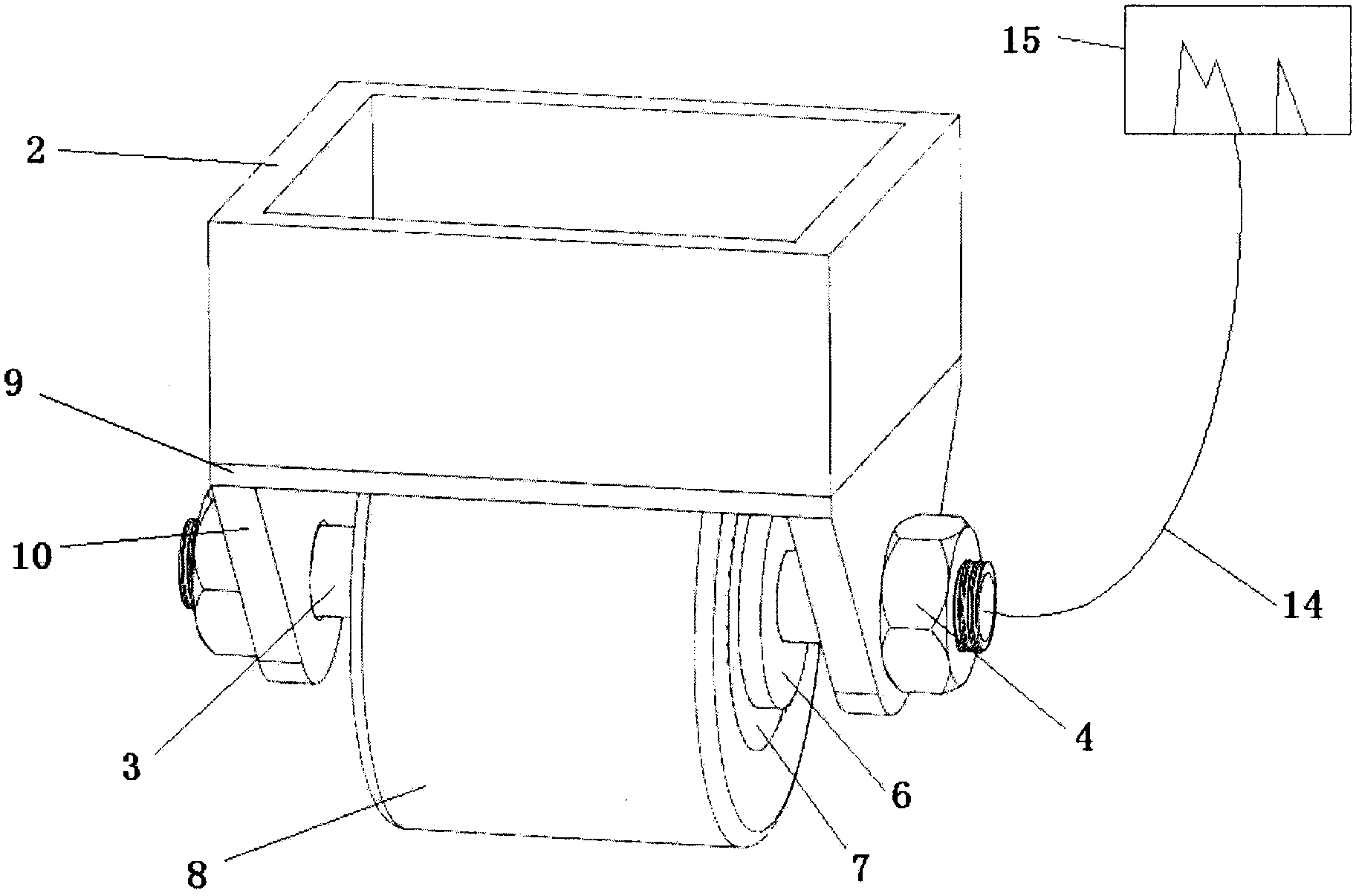

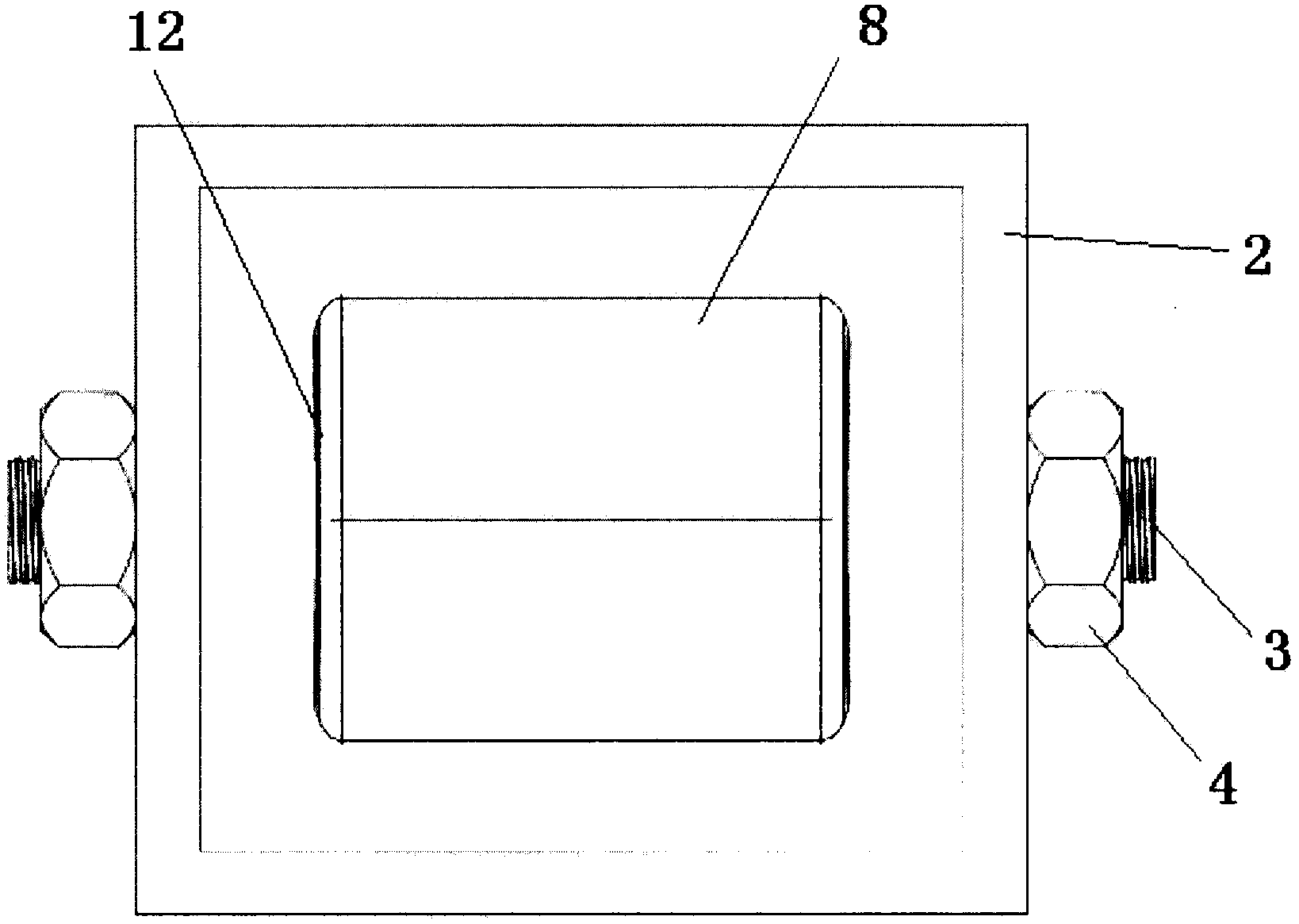

[0016] Such as Figure 1~3 Shown: a self-coupling ultrasonic detection probe device disclosed in the present invention, including a support member, a rolling member and a detection device, the support member includes a bracket 1, a water tank 2, a hollow shaft 3 and a nut 4, and the rolling member includes Probe 5, sealed bearing 6, circular plate 7 and rubber film 8.

[0017] Wherein, the bracket 1 has a mounting plate 9, and the two ends of the mounting plate 9 extend vertically downward with a triangular support plate 10, the water tank 2 is installed on the upper surface of the mounting plate 9, and the support plate 10 is provided with a through hole 11 , the hollow shaft 3 passes through the through hole 11, and both ends are fastened by nuts 4, the bottom of the water tank 2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com