Lifting type sheet metal part punching device

A sheet metal parts, lift-type technology, applied in the field of lift-type sheet metal punching devices, can solve the problem of inability to achieve high-quality, high-efficiency punching, uneven force on the punched parts, easy damage to the cut edge, etc. problems, to avoid uneven stress, solve the limited expansion length, and ensure product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

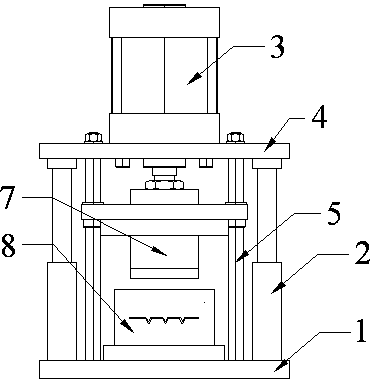

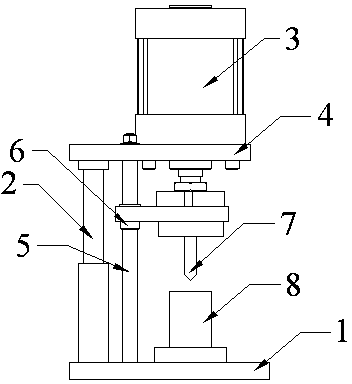

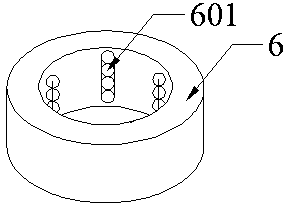

[0027] Such as figure 1 , figure 2 as well as image 3 As shown, a lift-type sheet metal punching device includes a base plate 1, a punch 8 and a die 9, and also includes a telescopic looper 2, a cylinder 3, a guide rod 5, a guide sleeve 6, and a punch seat 7, and the cylinder 3 is located on the top plate 4, the piston of the cylinder 3 is connected to the middle part of the punch seat 7; the telescopic looper 2 and the guide rod 5 are fixed on the side of the bottom plate 1 away from the feed port; the top of the telescopic looper 2 is fixed on the top plate 4 the lower surface; the guide rod 5 passes through the top plate 4 and is fixed with a nut; the guide sleeve 6 is set on the guide rod 5 and is connected with the two ends of the punch seat 7; the guide sleeve 6 is also provided with a ball 601; the punch 8 is fixed on Below the punch seat 7, and the shape of the lower end surface is conical.

[0028] In addition, there are two telescopic loopers 2, which are distr...

Embodiment 2

[0031] Same as embodiment 1, the difference is that the taper angle of the tapered portion of the lower end surface of the punch 8 is 40°, which reduces the contact area and better realizes punching under the premise of ensuring that the die is not damaged.

Embodiment 3

[0033] Same as embodiment 1, the difference is that there are 4 guide rods to ensure more stable and reliable work of the punching tool and to obtain better quality sheet metal parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com