Adjustable reverse-deformation welding jig for titanium alloy

A welding fixture and anti-deformation technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of not providing titanium alloy welding back protection, the effect is not very ideal, etc., to ensure the back forming quality, The effect of reducing welding deformation and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

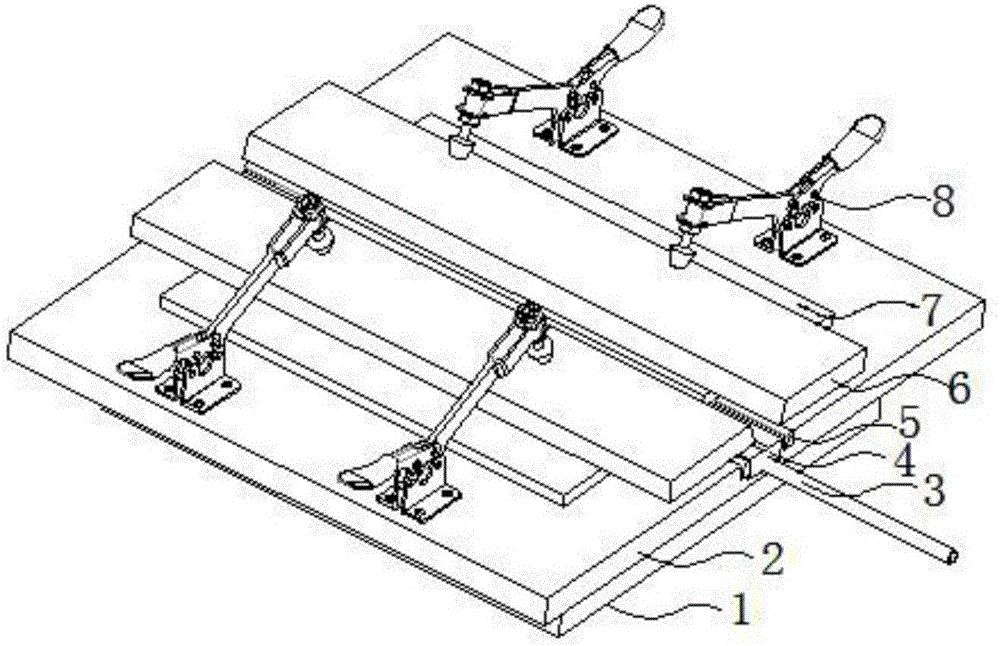

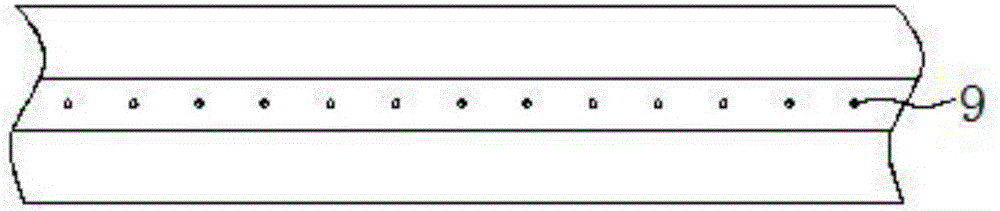

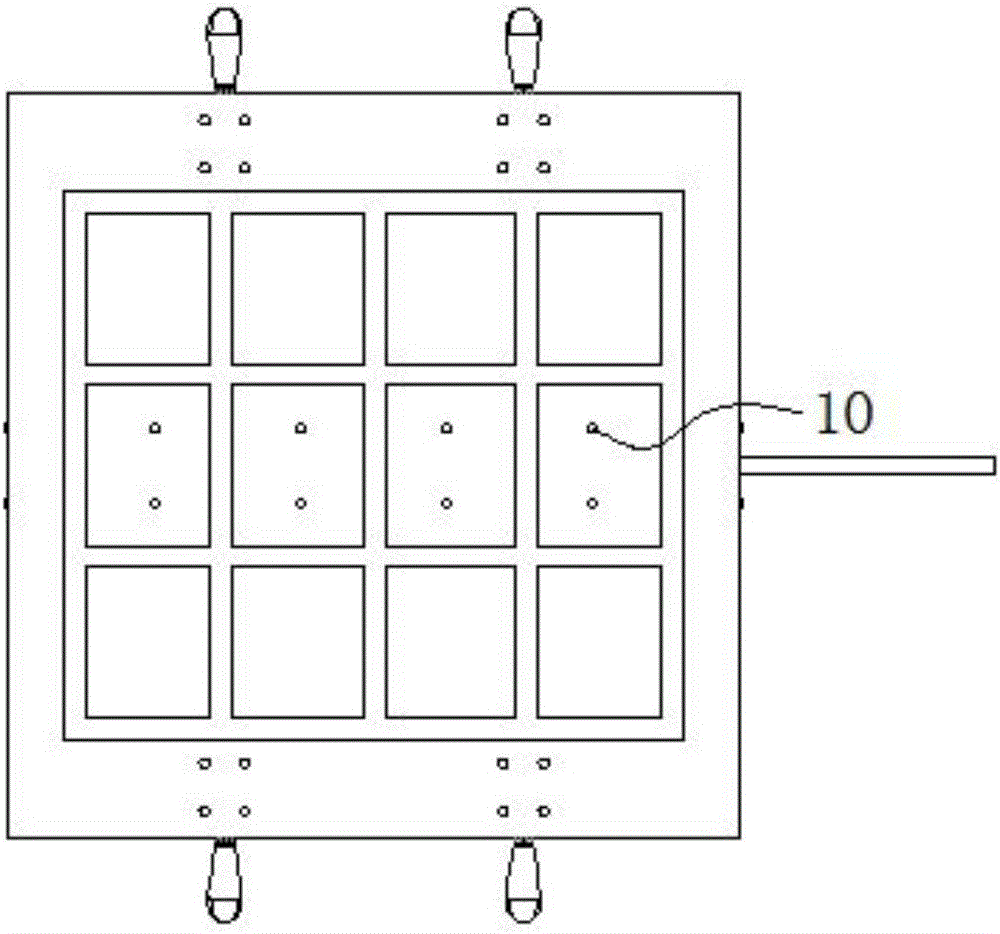

[0022] Such as Figure 1 to Figure 4 As shown, a welding fixture for adjustable anti-deformation of titanium alloys of the present invention includes a base 1 and a clamping platform 2 on the base 1, a first square groove is opened in the middle of the clamping platform 2, and the The back liner 4 is fixed in the first square groove, and the back liner 4 has a row of ventilation holes 9 for providing back protection. The back liner 4 is connected with the ventilation pipe 3, and the ventilation hole is passed through the ventilation pipe 3. 9 Conveying the protective gas, the back liner 4 is provided with a circular groove 11 to ensure the quality of the back side forming, and the reverse side liner 4 is placed on both sides of the anti-deformation pad 5, and a row of threads is provided under the anti-deformation pad 5 The thimble 10 and the threaded thimble 10 are located on the base, the titanium alloy test plate 7 is placed on the clamping platform 2, the left pressure pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com