Method for forming uniformly-variable-height component through laser

A technology of laser forming and parts, which is applied in the direction of improving energy efficiency, process efficiency, and additive manufacturing. It can solve problems such as the inability to realize arbitrary materials, heavy tasks, and huge data volumes, so as to improve complexity and forming efficiency, and eliminate The effect of step effect, stability and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0030]A method for laser forming uniformly heightened parts shown in a preferred embodiment of the present invention includes steps S1 to S5. In the method of laser forming uniform heightened parts, laser cladding nozzles are used to achieve accumulation.

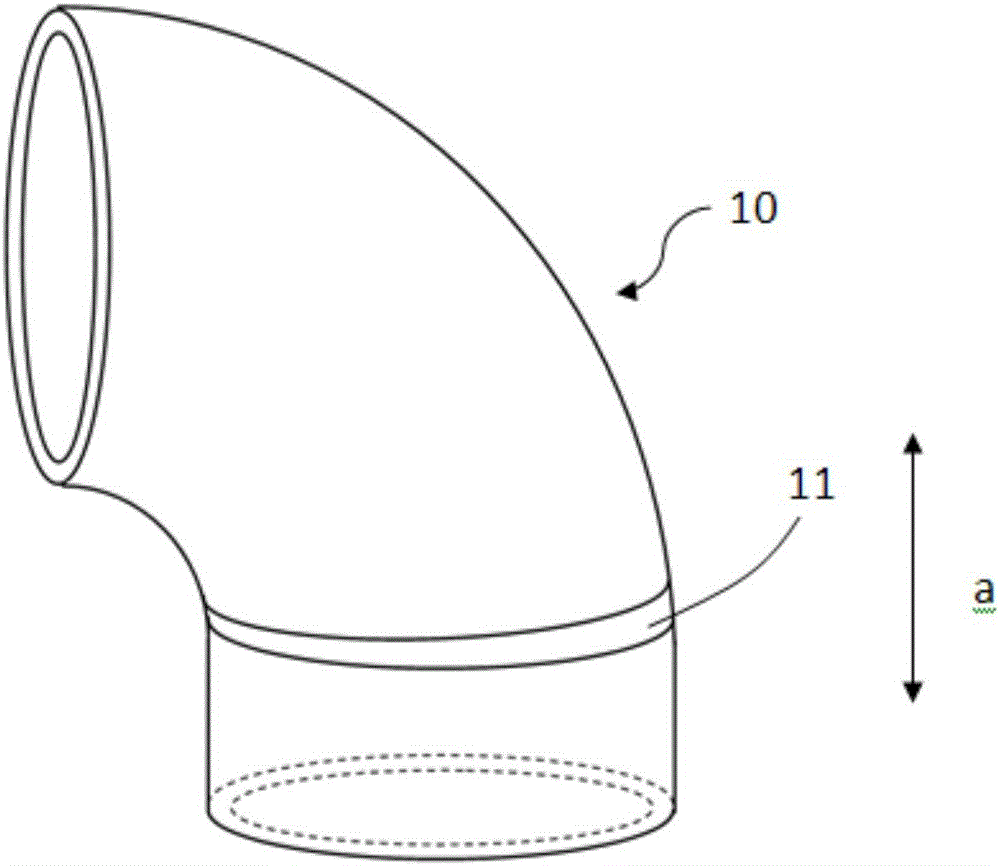

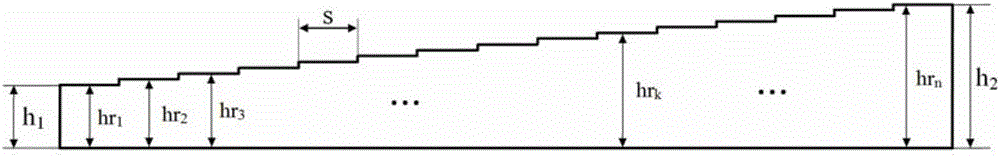

[0031] S1: Tangentially stratify the CAD model of complex structural parts along the normal direction of the outer contour curve to determine several cladding layers. The upper and lower surfaces of each cladding layer are not parallel, so that the cladding layer of each layer is not parallel. Everywhere is high and low. For example, Fig. 1 is a CAD model of the structure of a metal elbow 10. Since the laser cladding ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com