Selective laser melting forming and post-treatment method for thin-wall interlayer cooling structure

A laser selective melting and cooling structure technology, which is applied in the field of additive manufacturing, can solve the problems of complex structure and process flow, bulging, pressure bulging, etc., achieve uniform polishing of the length-to-diameter ratio flow channel, ensure the forming quality, and ensure the structural strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention is described in conjunction with accompanying drawing.

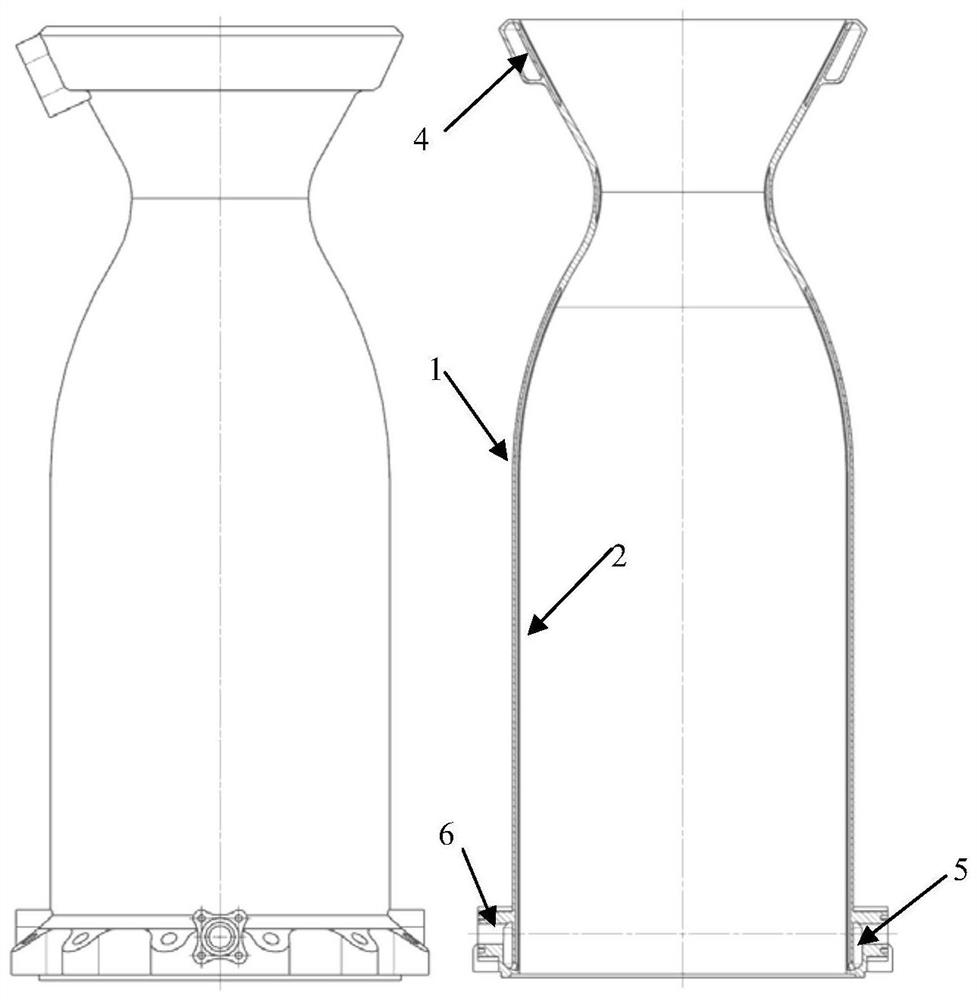

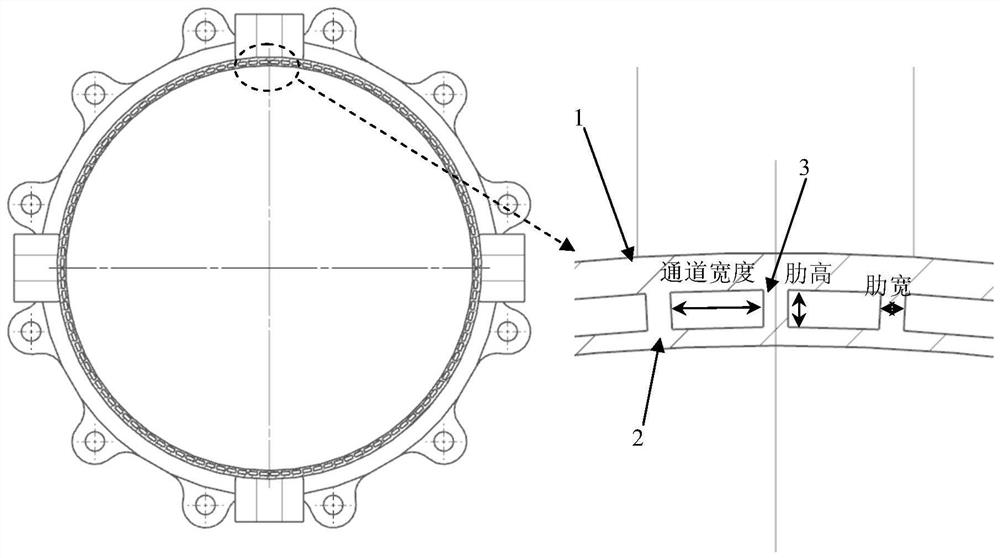

[0045] Such as figure 1 ,2 As shown, the thin-wall interlayer cooling structure of the present invention includes an inner wall 2, an outer wall 1, a rib wall 3, an outlet collecting ring 4 and an inlet collecting ring 5, and the rib wall 3 is located between the inner wall 2 and the outer wall 1 to form an interlayer together The channel is a variable cross-section flow channel, and the minimum channel size is 1mm×1mm. The cooling liquid enters into the body through the four inlets 6 of the inlet collecting ring 5, and flows in the cooling channel to cool the sandwich structure.

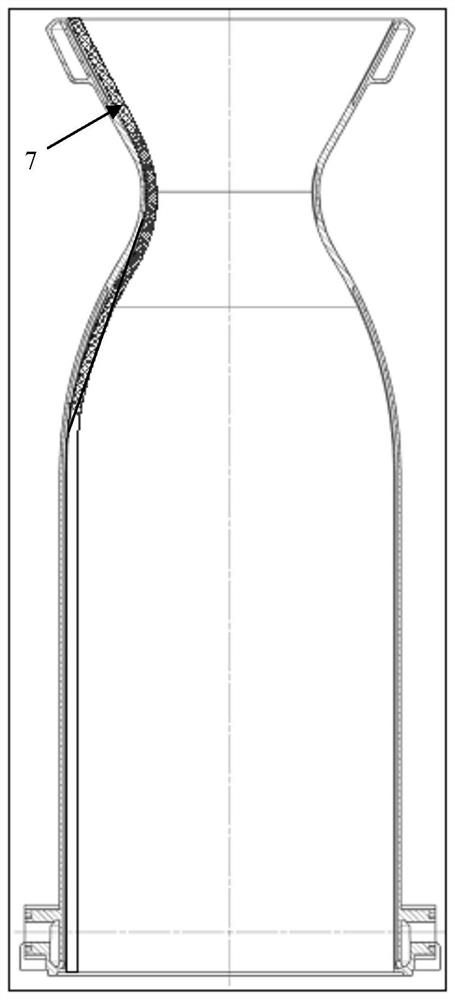

[0046] In order to effectively prevent interlayer cooling from the structural cavitation and improve work reliability, the optimal forming scheme is integral forming while ensuring the dimensional accuracy and surface quality requirements of the complex flow path. Based on this, this application proposes a thin-wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com