Forming method of flange ring for automobile tail gas recycling device

A vehicle exhaust, consistent technology, applied in the field of material processing, can solve the problems of low material utilization, low mechanical properties, easy to rust, etc., and achieve the effect of ensuring forming accuracy and surface quality, high material utilization, and good application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to better understand the present invention, the content of the present invention is further illustrated below in conjunction with the examples, but the content of the present invention is not limited to the following examples.

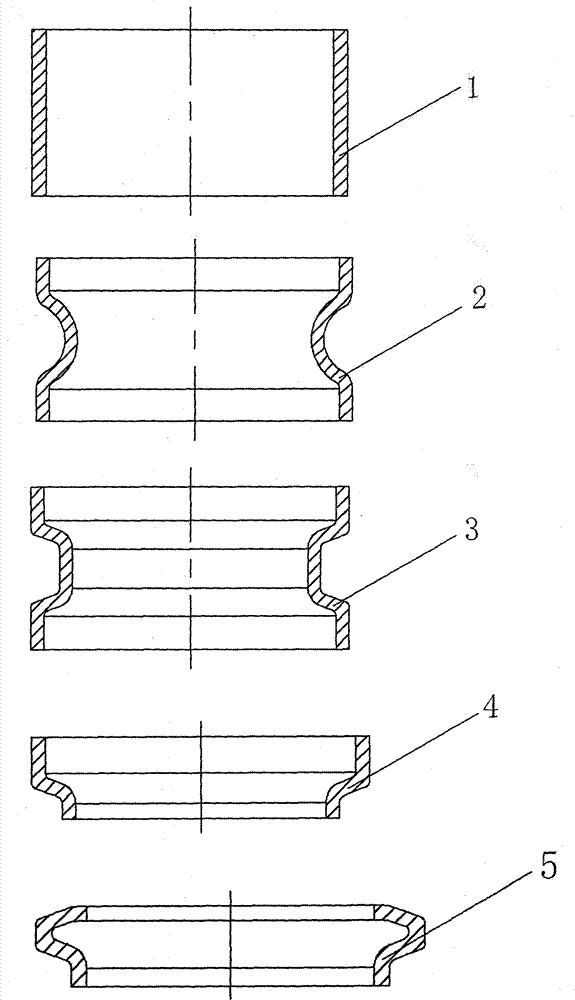

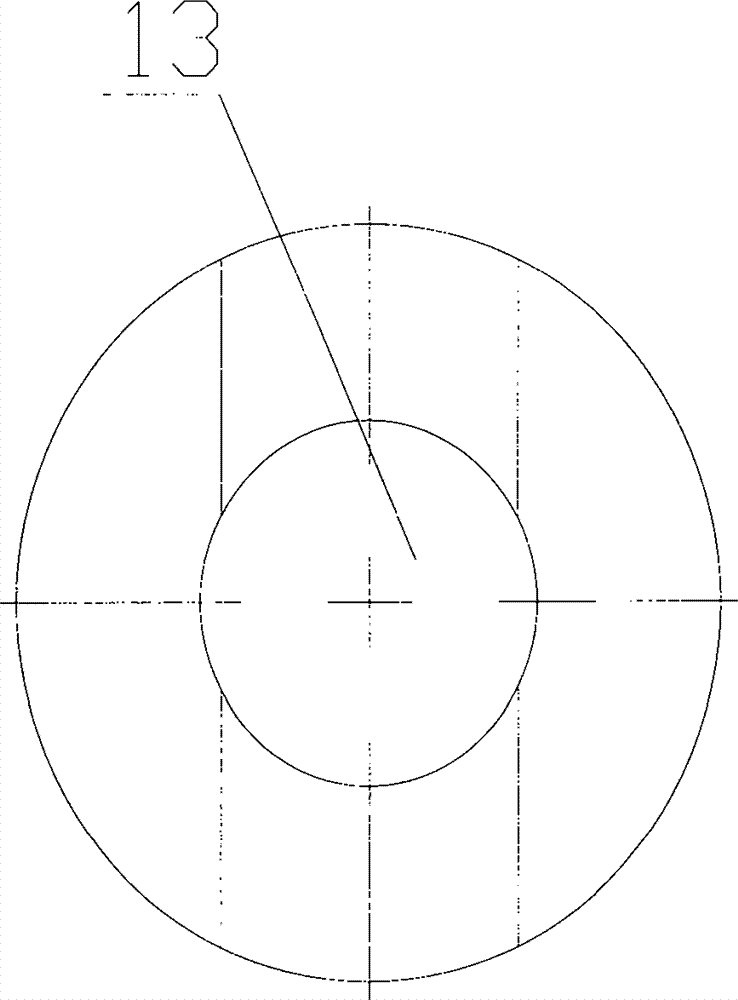

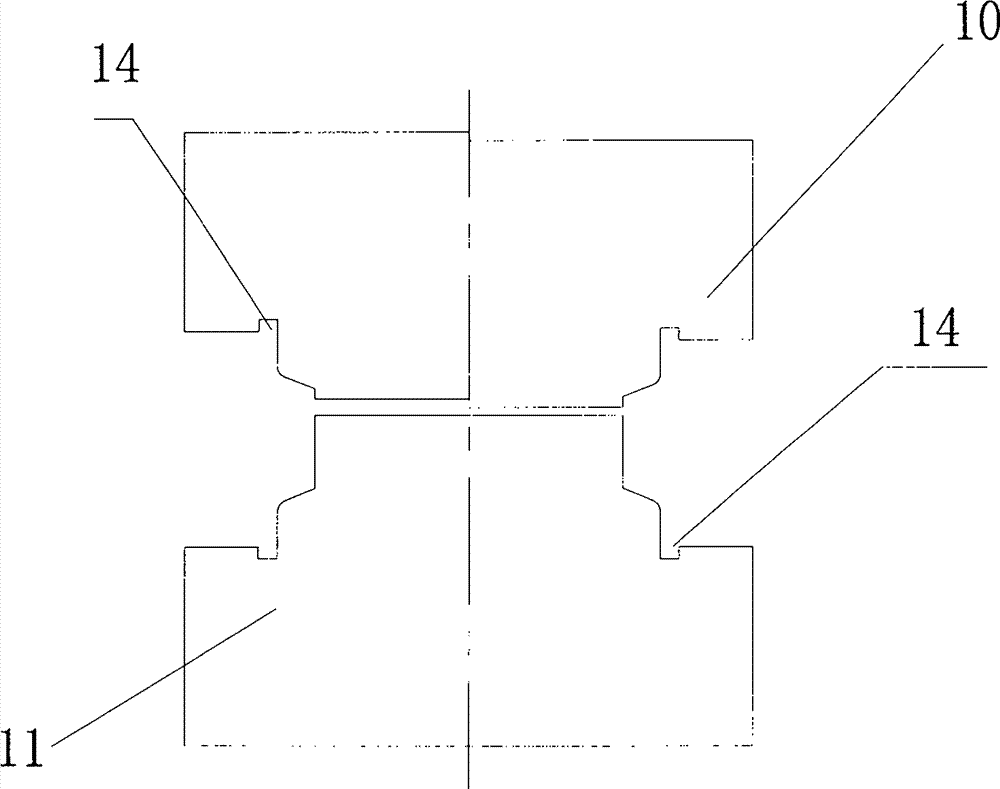

[0029] see Figure 1 ~ Figure 3 , a method for forming a flange ring for an automobile exhaust gas recycling device, which uses a combination of reduced-diameter spinning and shrinking-mouth spinning to directly form a tube blank into a flange ring for an automobile exhaust gas recycling device. The forming method includes the following steps:

[0030] Reduced-diameter spinning step: Considering the symmetry of spinning and improving production efficiency, two parts are formed by one-time reduced-diameter spinning. The shrinking spinning process is divided into two steps, figure 2 Shown is a schematic diagram of the two-pass spinning reduction process. The outer diameter of the initial tube blank is 114mm, the wall thickness is 5mm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com