Laser cladding lateral powder feed processing head

A technology of lateral powder feeding and laser cladding, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems that are difficult to achieve, achieve uniform distribution of beam energy, improve powder utilization efficiency and forming quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] This embodiment is aimed at an embodiment in which the powder nozzle can perform both self-rotation and revolution. The present invention will be further described in detail with reference to the drawings and specific embodiments below.

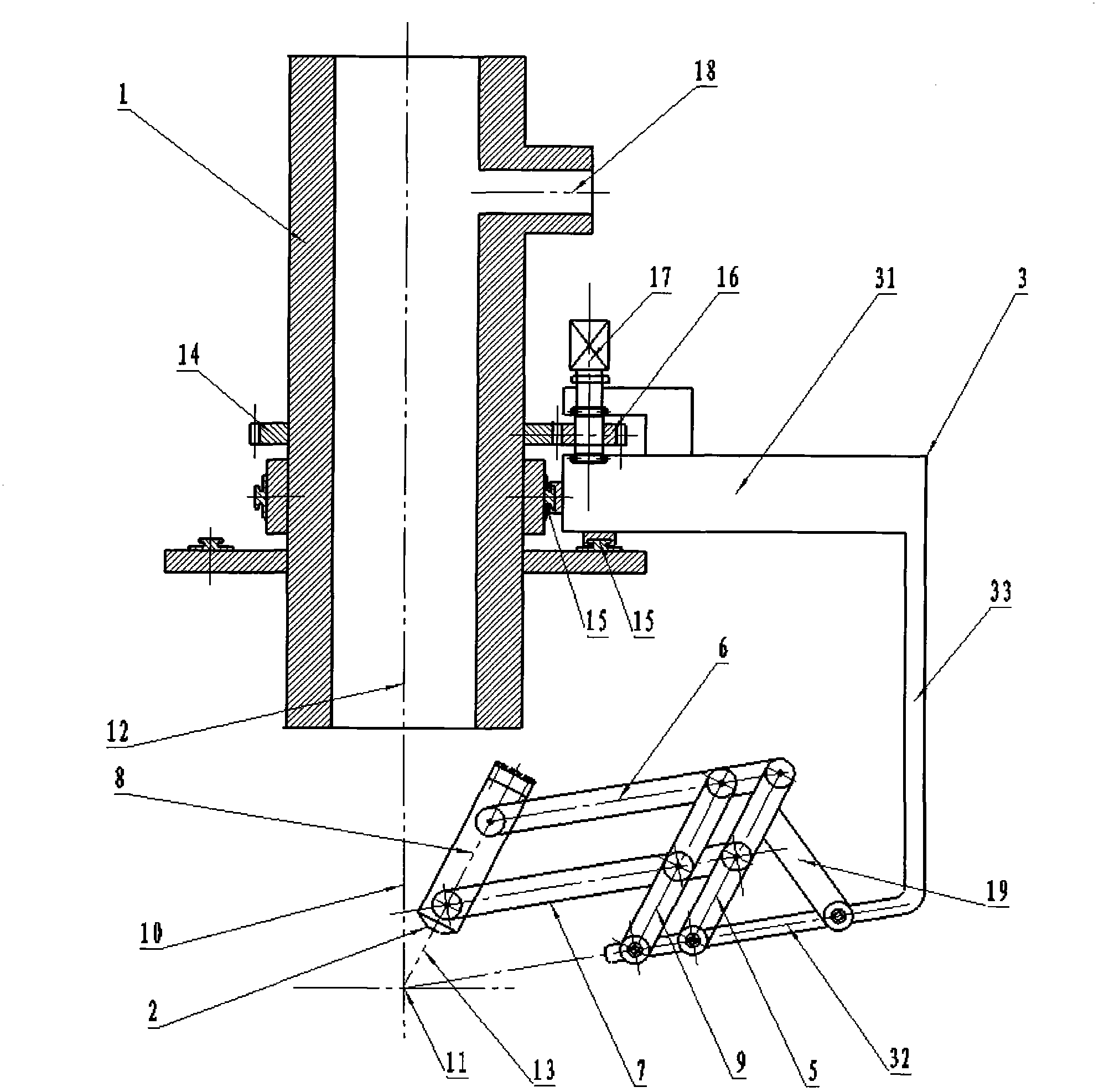

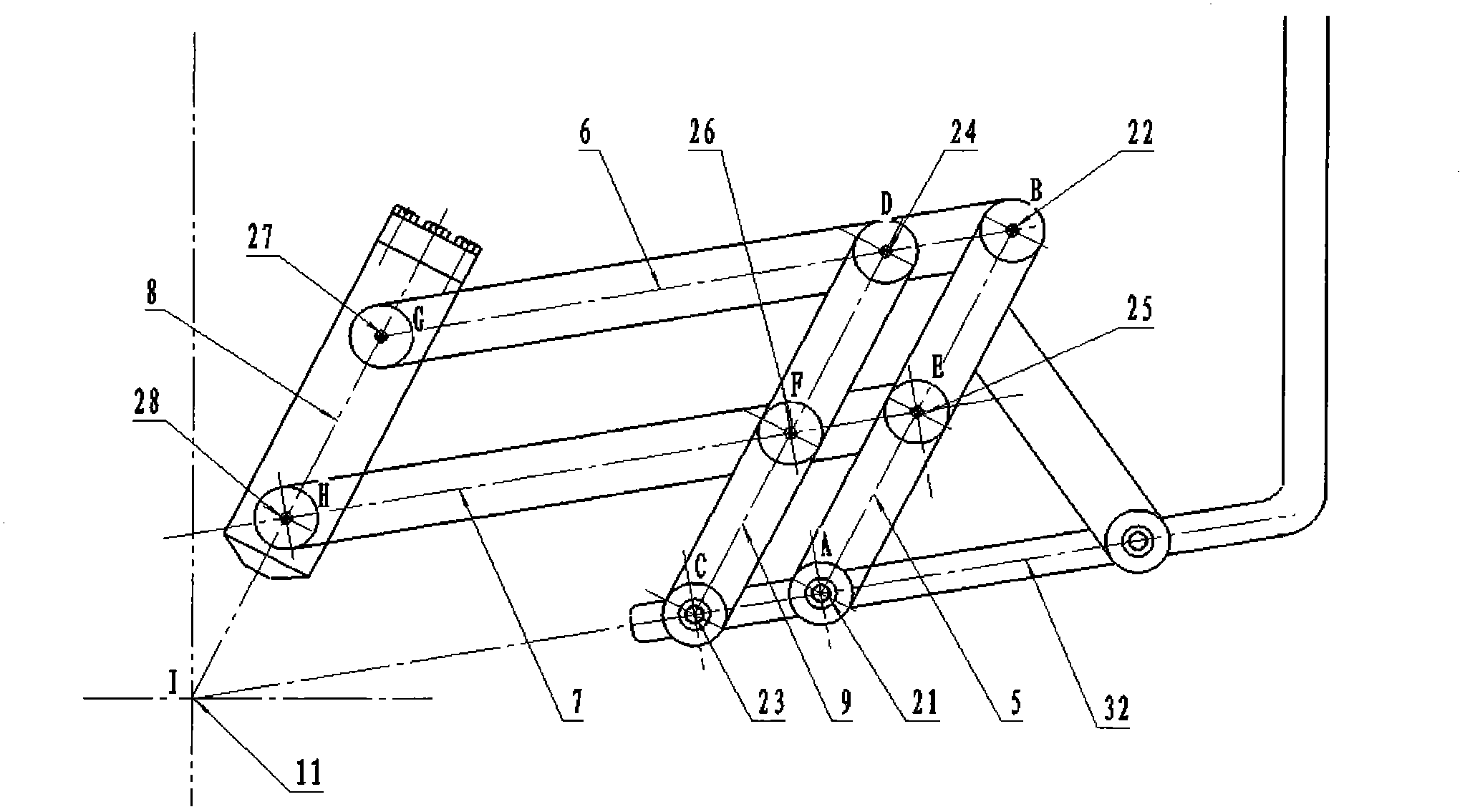

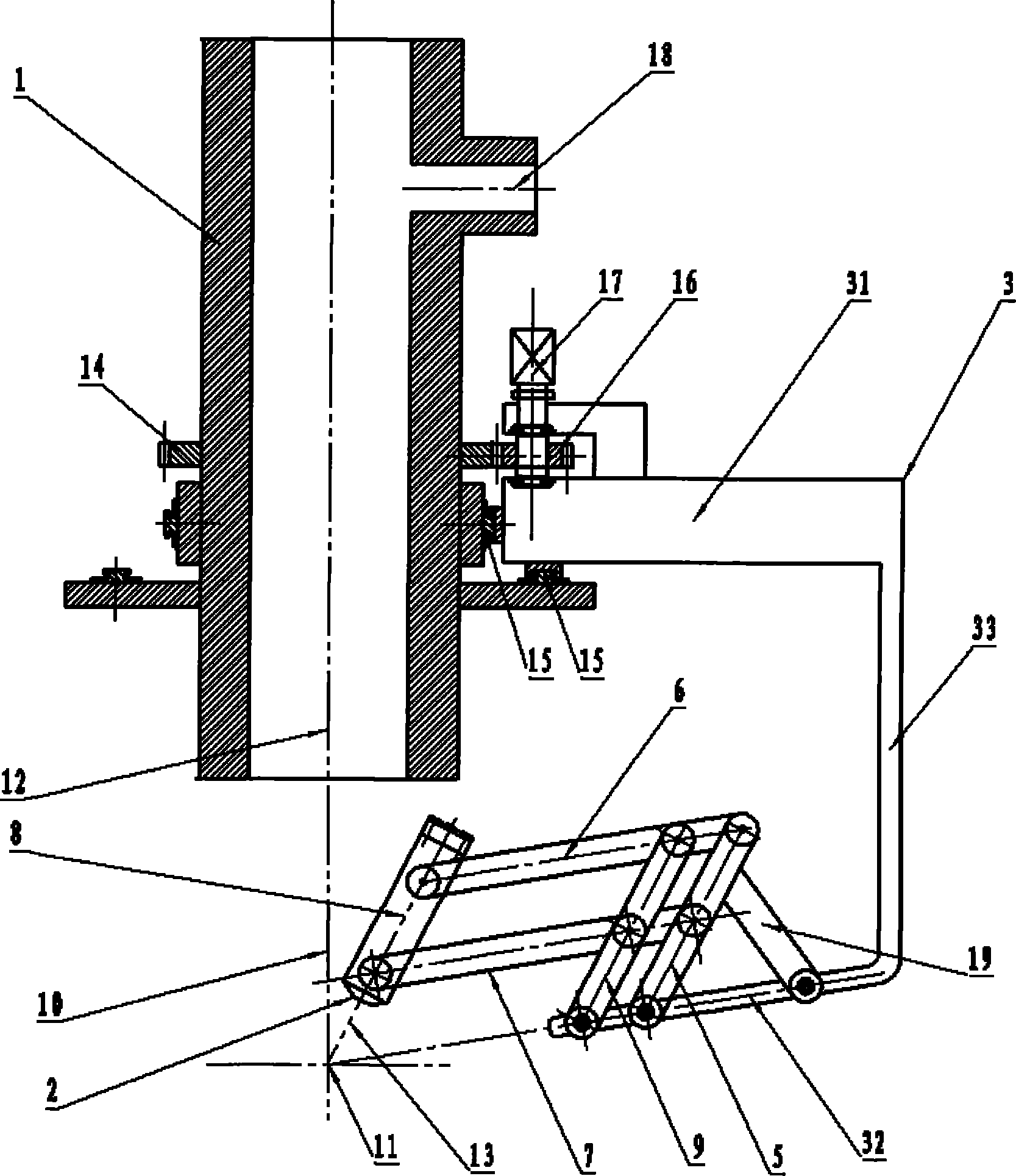

[0025] Such as figure 1 , 2 As shown, the present invention provides a laser cladding side powder feeding processing head, including a laser cylinder 1, a powder nozzle 2 and a powder nozzle clamping mechanism.

[0026] Described laser tube 1 is a hollow cylindrical structure, and laser tube 1 is provided with a laser entrance 18 and a laser exit port 12, and the light guide path (not shown) is installed in the laser tube 1, and the light guide path makes from The laser beam incident on the side of the laser entrance 18 is transformed into a focused focused laser beam 10 that exits vertically downwards and is output.

[0027] The powder nozzle clamping mechanism includes a support arm 3 and a parallel linkage mechanism. The support a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com