Design method of dash device for hard aluminum alloy semi-continuous casting

A water retaining device and a technology of hard aluminum alloy, applied in the field of aluminum alloy semi-continuous casting, can solve problems such as easy cracking, and achieve the effects of suppressing cracks, unique design, and significant economic and social effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

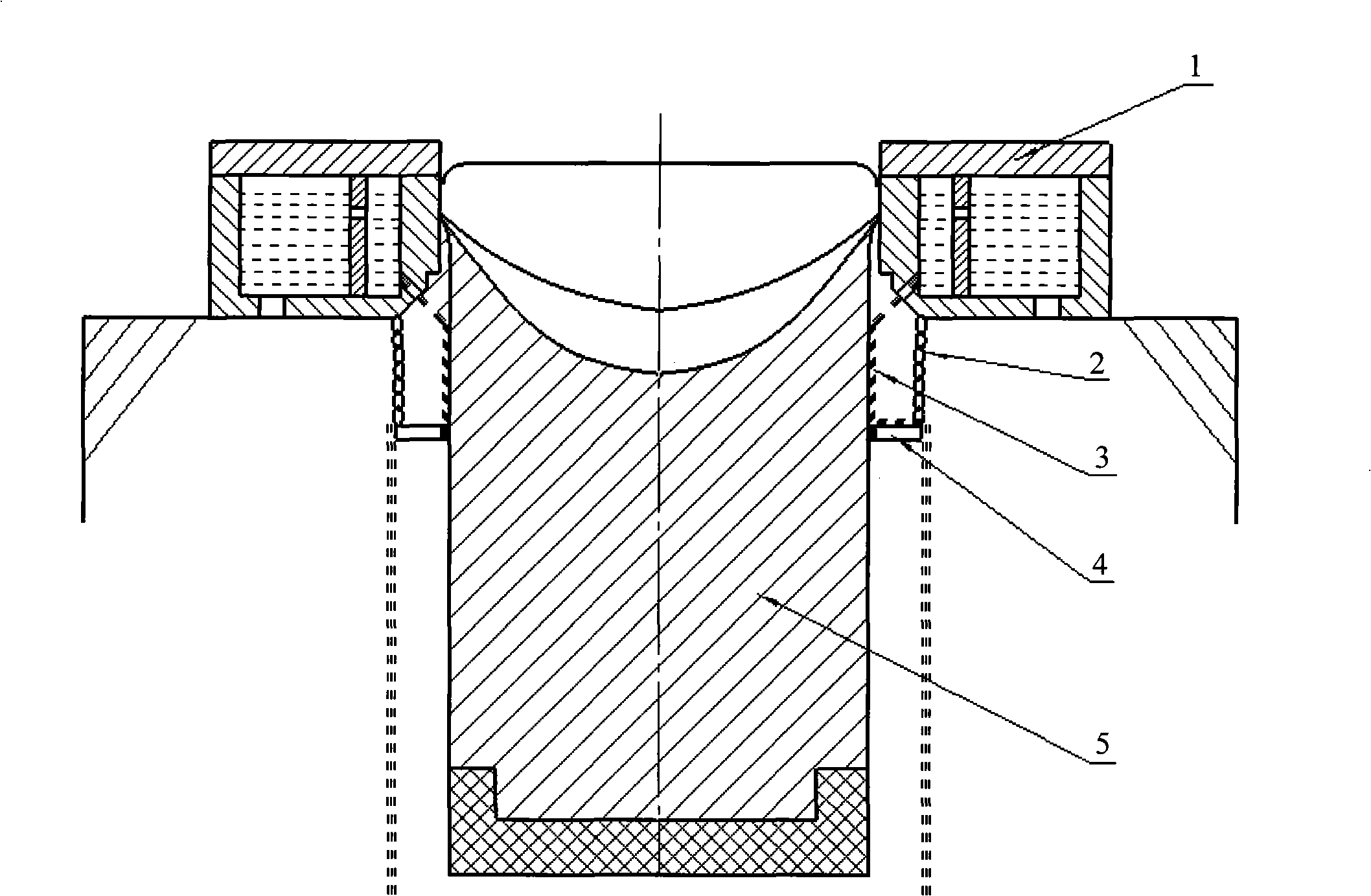

[0019] The invention provides a water retaining device suitable for casting hard aluminum alloy round ingots and flat ingots. The position of the water plate is blocked and shunted, and flows directly into the casting well. During the casting process, the ingot only receives part of the water cooling between the crystallizer and the water baffle, and the lower part of the water baffle realizes natural air cooling. In this way, the cooling intensity of the entire ingot is weakened, while the temperature of the ingot under the water retaining device partially rises, realizing the "self-tempering" effect of the ingot, which can effectively reduce the internal stress of the casting and suppress the cracks of the ingot.

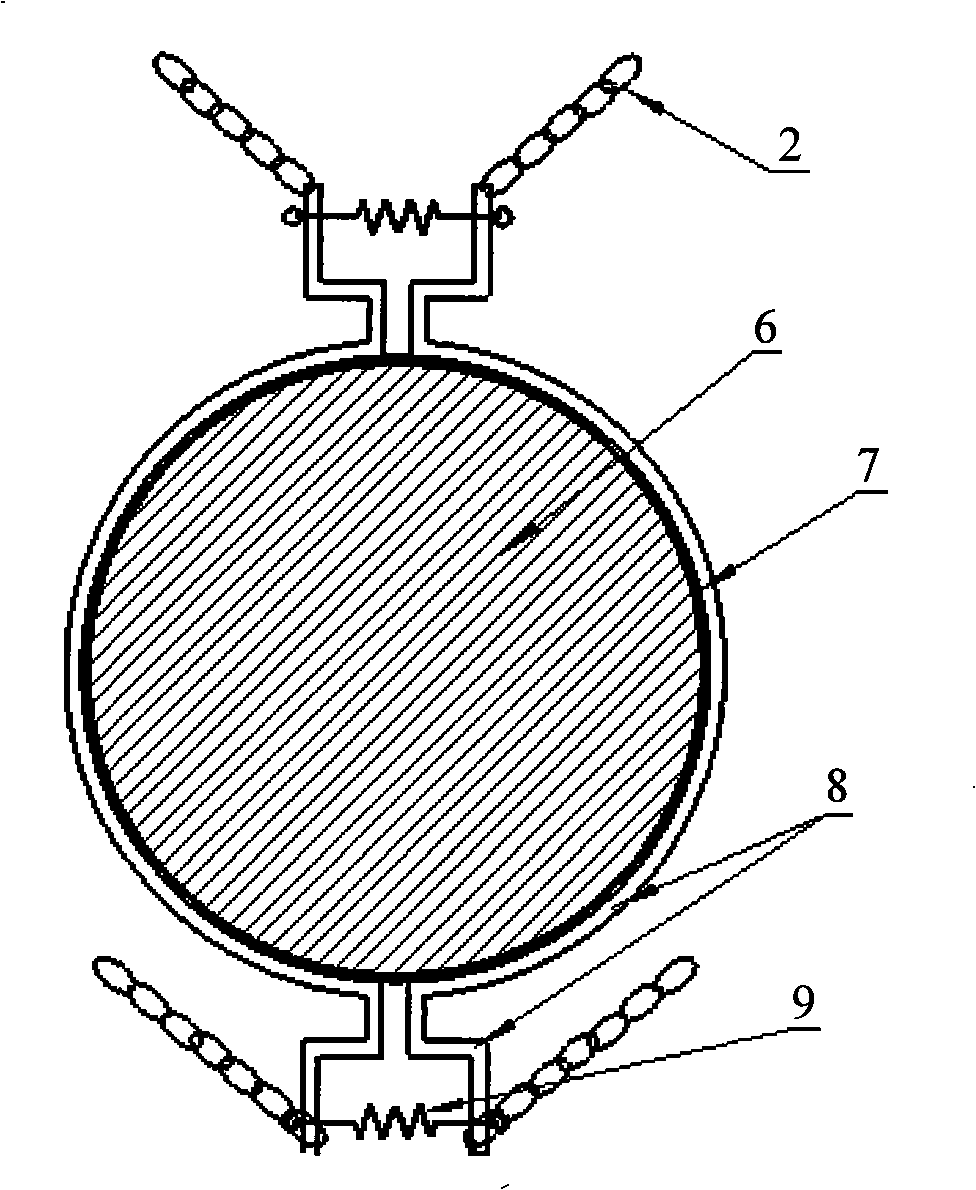

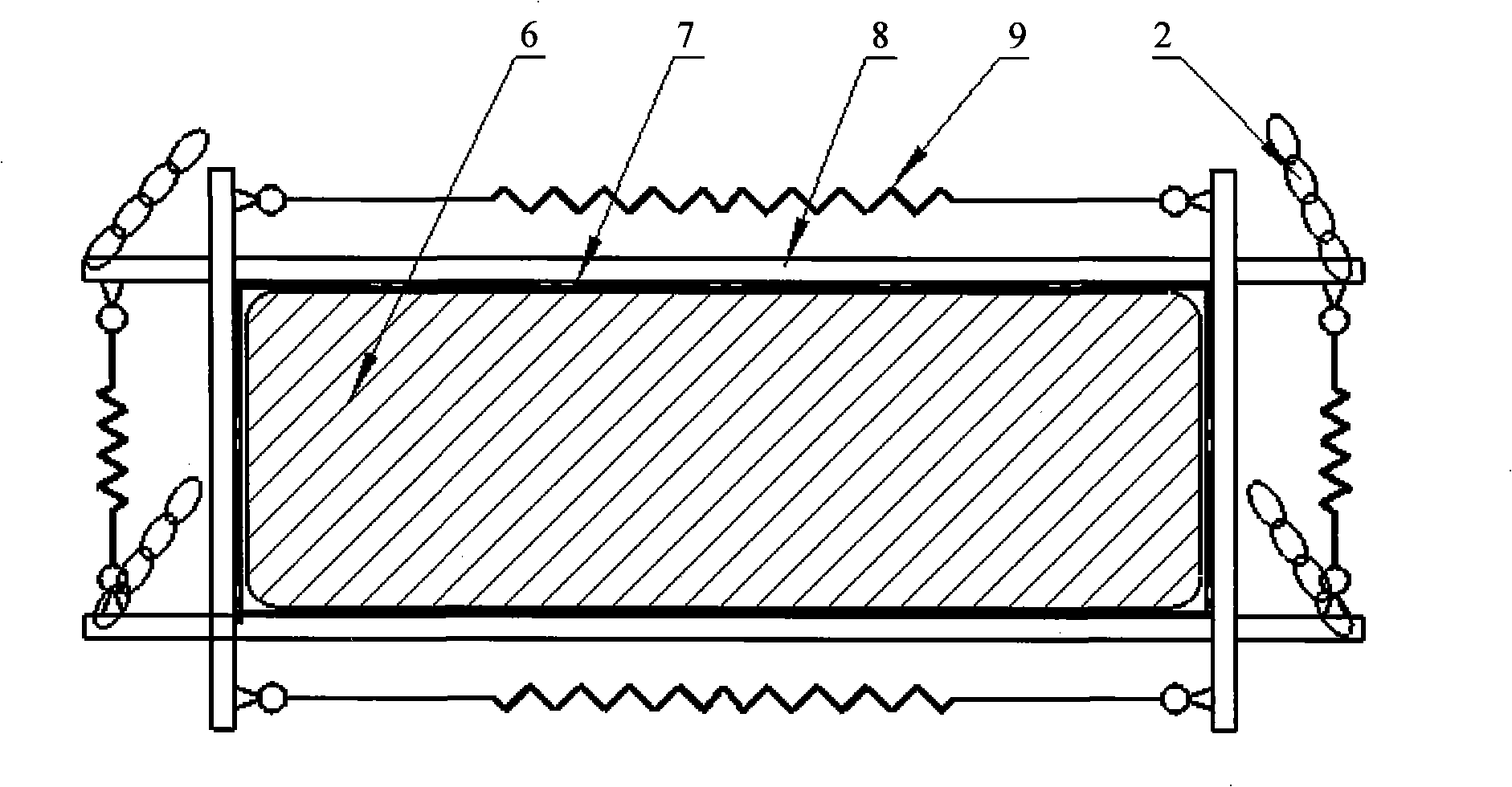

[0020] Such as figure 2 , image 3 As shown, the water retaining device is designed into the required shape and size according to the specifications of the round ingot and the flat ingot. The water retaining device 4 includes the water retaining plate body 8 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com