Ingot-casting area water cooling technique during aluminum alloy semi-continuous casting

An aluminum alloy, semi-continuous technology, applied in the field of aluminum alloy semi-continuous casting, can solve the problems of poor casting of hard/super-hard aluminum alloys, improve ingot plasticity, reduce casting internal stress, and achieve significant economic and social effects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

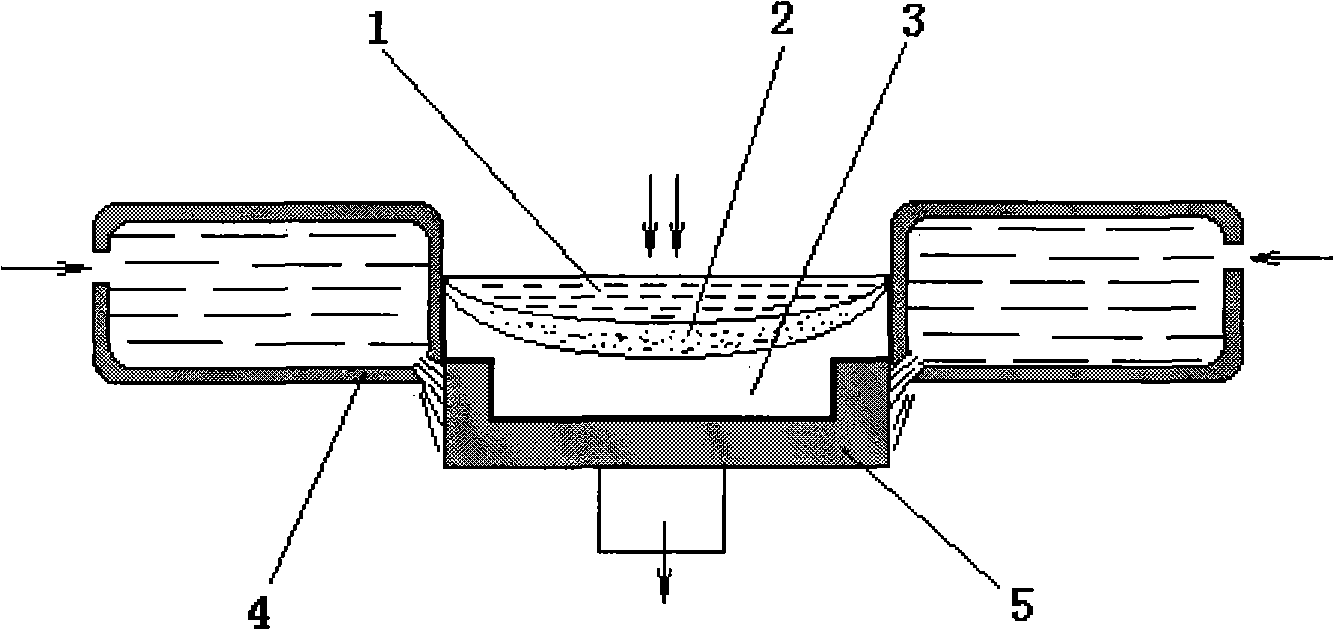

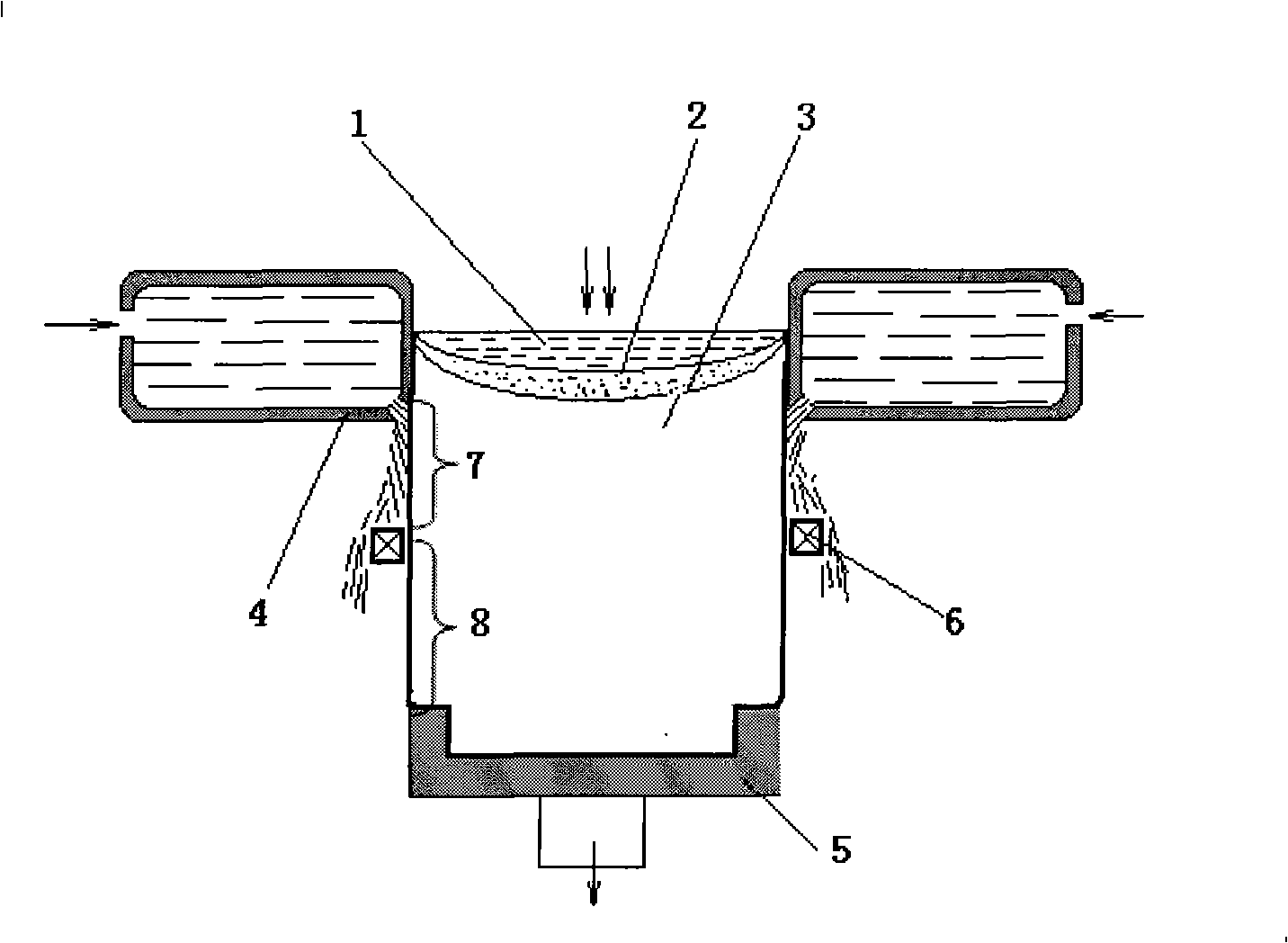

[0020] Aiming at the phenomenon of cracking of hard / superhard aluminum alloy ingots during casting, a regional water cooling process for casting ingots in aluminum alloy semi-continuous casting is provided.

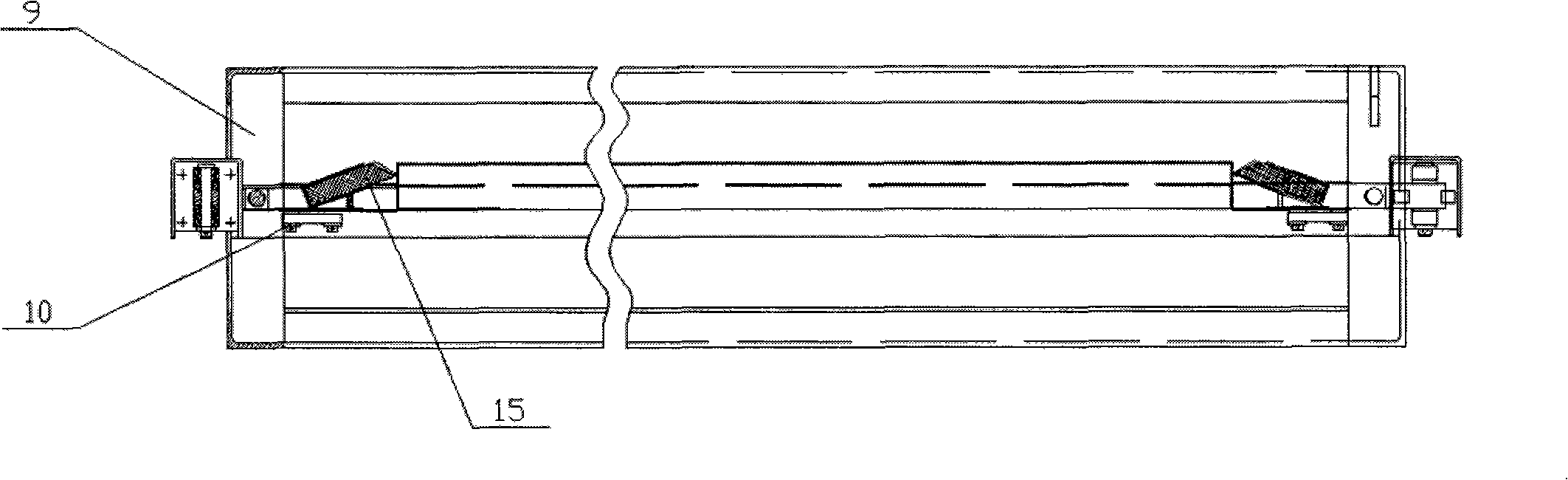

[0021] Such as figure 2 As shown, a zone cooling device 6 is set below the crystallizer 4, and the distance between the zone cooling device 6 and the lower edge of the crystallizer 4 is 100-1000 mm, as Figure 3-5 , the water-cooling device 6 in this area mainly includes a bracket 9, a main splint 12, a secondary splint 13, a connecting rod 10, a cylinder 14 and a wiper 15, and the bracket 9 plays a role in supporting the whole device. A plurality of positioning holes or guide grooves, a support rod 11 is pierced in the positioning holes or guide grooves, two main splints 12 are sleeved on the support rods 11, one main splint at the front and rear, and a cylinder 14 is arranged between the two main splints 12 , each main splint 12 is connected to a secondary splint 13 t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com