Hollow grid flow adjusting cover machining process method

A processing technology and fairing technology, which is applied in the field of hollow grid fairing processing technology to achieve high processing efficiency, good quality stability of parts, high-quality, high-efficiency and low-cost processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

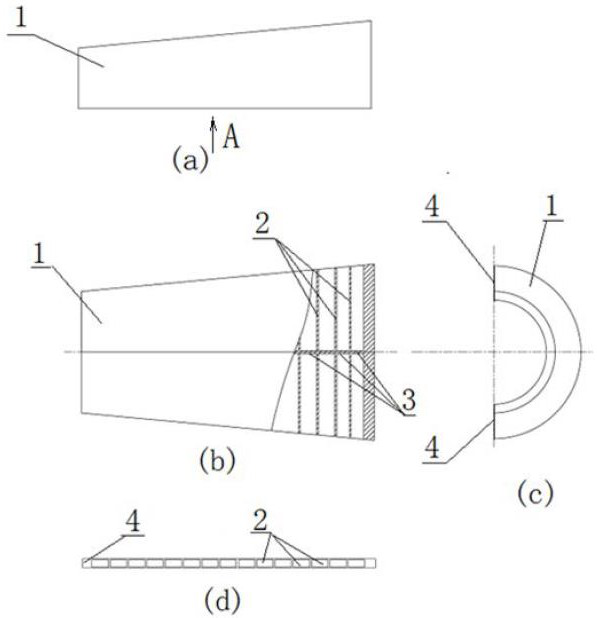

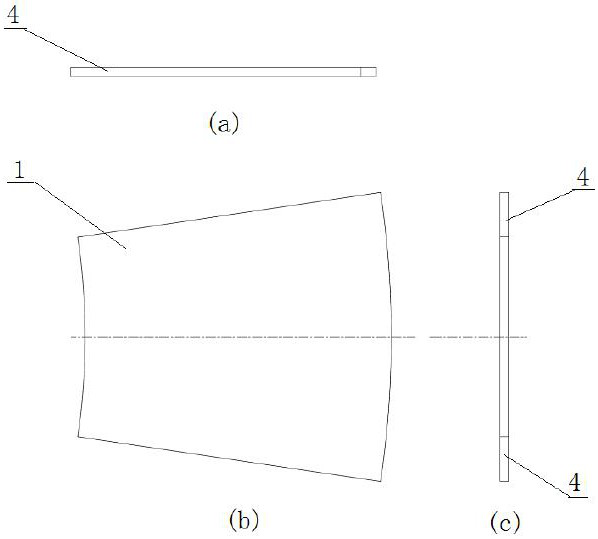

[0036] The part blank of the present invention selects deformed aluminum alloy, as 2A12, technological process: Milling thickness and shape; gun drilling deep holes; sheet metal forming; Electrically machined ring grid.

[0037] In the selection of blank materials, the selected materials are deformed aluminum alloy sheet 2A12, etc., which have high strength and elongation.

[0038] The first step, milling thickness and shape: In this process, a face milling cutter is used on a milling machine to process the maximum envelope thickness of the part in the thickness direction, and the tolerance is 1 / 5 to 1 of the final symmetry accuracy of the surface / 3, using an end mill to process the peripheral dimensions to the fan-shaped contour dimensions of the part.

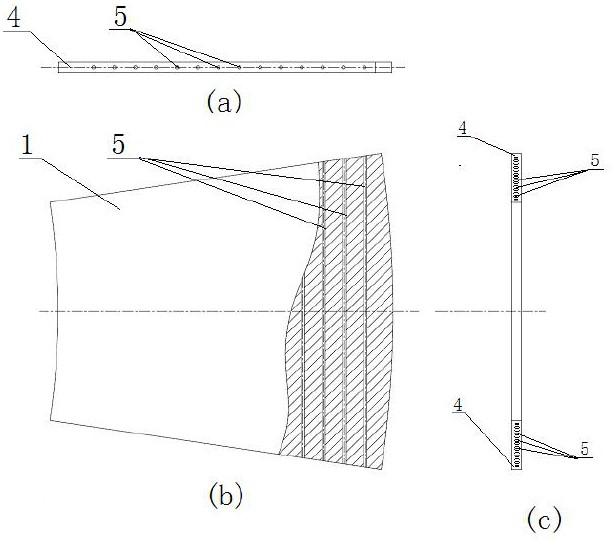

[0039] The second step, gun drilling to process deep holes: This process uses a gun drill commonly used in gun barrel processing as a deep hole processing tool. The maximum processing depth-to-diameter ratio can exce...

Embodiment 2

[0043] A fairing has a semi-conical surface structure, and there are 15 rectangular grids on the central plane with symmetrical thickness to form a rectangular hollow grid structure. 24mm, 30mm from the big end, 50mm spacing, 5mm thick vertical ribs in the middle of the fairing cone and between grooves.

[0044] process flow Milling thickness and shape; gun drilling deep holes; sheet metal forming; Electrically machined ring grid.

[0045] The rough material is made of deformed aluminum alloy sheet 2A12, with a size of 850mm×800mm×30mm.

[0046] The first step, milling thickness and shape: use a Ø32 face milling cutter on a common milling machine to mill the thickness to mm, using a Ø10 end mill to make the peripheral shape into a fan-shaped profile, the length is 800mm, the radius of the arc at the small end is 1950mm, the radius of the arc at the large end is 2753mm, and the angle is 17°.

[0047] The second step, gun drilling deep holes: on the gun drilling machi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com