Combined structure of cooling fins and shell body

A heat dissipation fin and combined structure technology, which is applied in the direction of cooling/ventilation/heating transformation, electrical equipment shell/cabinet/drawer, electrical components, etc., can solve the problem of easy falling off of heat dissipation fins, high work intensity of workers, and unfavorable heat conduction and other problems to achieve the effect of preventing falling off, ensuring heat dissipation capacity, and preventing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

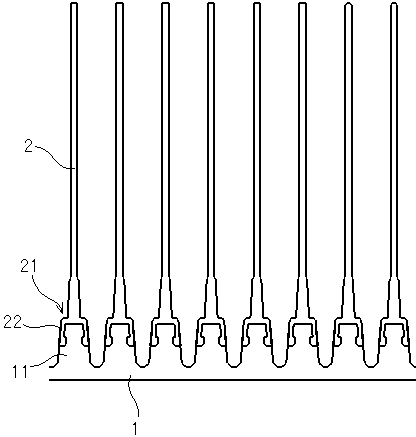

[0027] refer to figure 1 As shown, a combined structure of a heat dissipation fin and a housing includes a heat dissipation housing 1 and a heat dissipation fin 2. A plurality of elongated bosses 11 are uniformly arranged on the heat dissipation housing 1. The heat dissipation fins 2 The bottom 21 of the bottom 21 is insert-cast on the boss 11 of the heat dissipation housing 1 . The bottom 21 of the heat dissipation fin 2 is hollow and open, with skirts 22 on both sides. The bottom of the skirt 22 is folded inward, and the boss 11 is inlaid and cast in the skirt 22 .

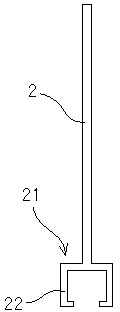

[0028] refer to figure 2 As shown, in Embodiment 1, the hollow structure inside the skirt 22 is rectangular.

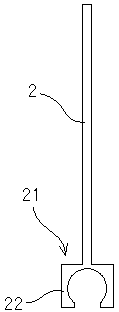

[0029] refer to image 3 As shown, in Embodiment 2, the hollow structure inside the skirt 22 is circular.

[0030] refer to Figure 4 As shown, in Embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com