Structure for connecting heat dissipating fins and case

A technology of heat dissipation fins and connection structure, which is applied in cooling/ventilation/heating transformation, chassis/cabinet/drawer parts, etc., which can solve the problem of unfavorable heat conduction, easy detachment of heat dissipation fins, and high working intensity of workers. and other problems to achieve the effect of realizing automatic production, preventing falling off, and ensuring heat dissipation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

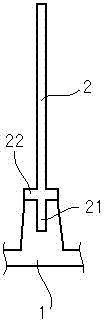

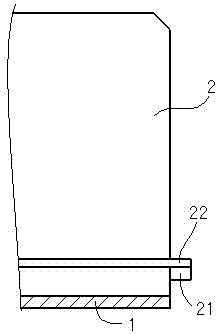

[0026] refer to figure 1 As shown, a connection structure between heat dissipation fins and the housing includes a plurality of heat dissipation fins 2 connected to the heat dissipation housing 1 , and the bottoms 21 of the heat dissipation fins 2 are inlaid and cast in the heat dissipation housing 1 .

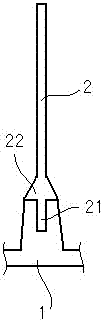

[0027] According to a preferred embodiment of the present invention, an anti-overflow boss 22 is arranged above the bottom 21 of the heat dissipation fin 2 .

[0028] refer to figure 1 As shown, in one embodiment of the present invention, the section of the overflow prevention boss 22 is rectangular.

[0029] refer to figure 2 As shown, in another embodiment of the present invention, the anti-overflow boss 22 has a triangular cross-section, and the right angle side of the triangle is in contact with the heat dissipation housing 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com