Design method of dash device for hard aluminum alloy semi-continuous casting

A water-retaining device and a technology of hard aluminum alloy, which is applied in the field of aluminum alloy semi-continuous casting, can solve problems such as easy cracking, and achieve the effects of reducing internal stress of casting, stable work, and significant economic and social effects.

Active Publication Date: 2010-02-10

CHINALCO MATERIALS APPL RES INST CO LTD

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The present invention aims at the problem that the hard aluminum alloy ingot is easy to crack during the casting process and after the casting is completed, and provides a water retaining device suitable for hard aluminum alloy semi-continuous casting, which can better meet the needs of hard aluminum alloy casting

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

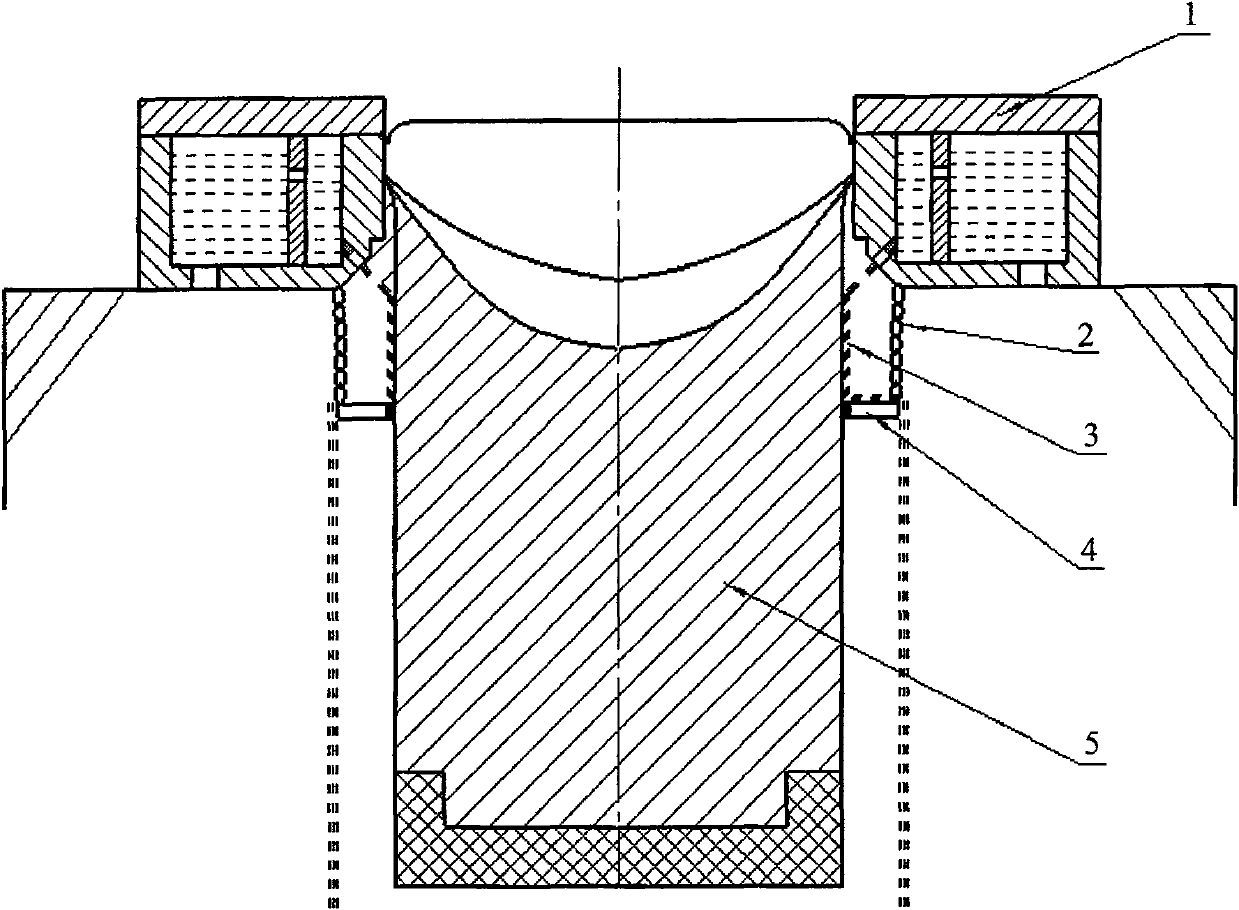

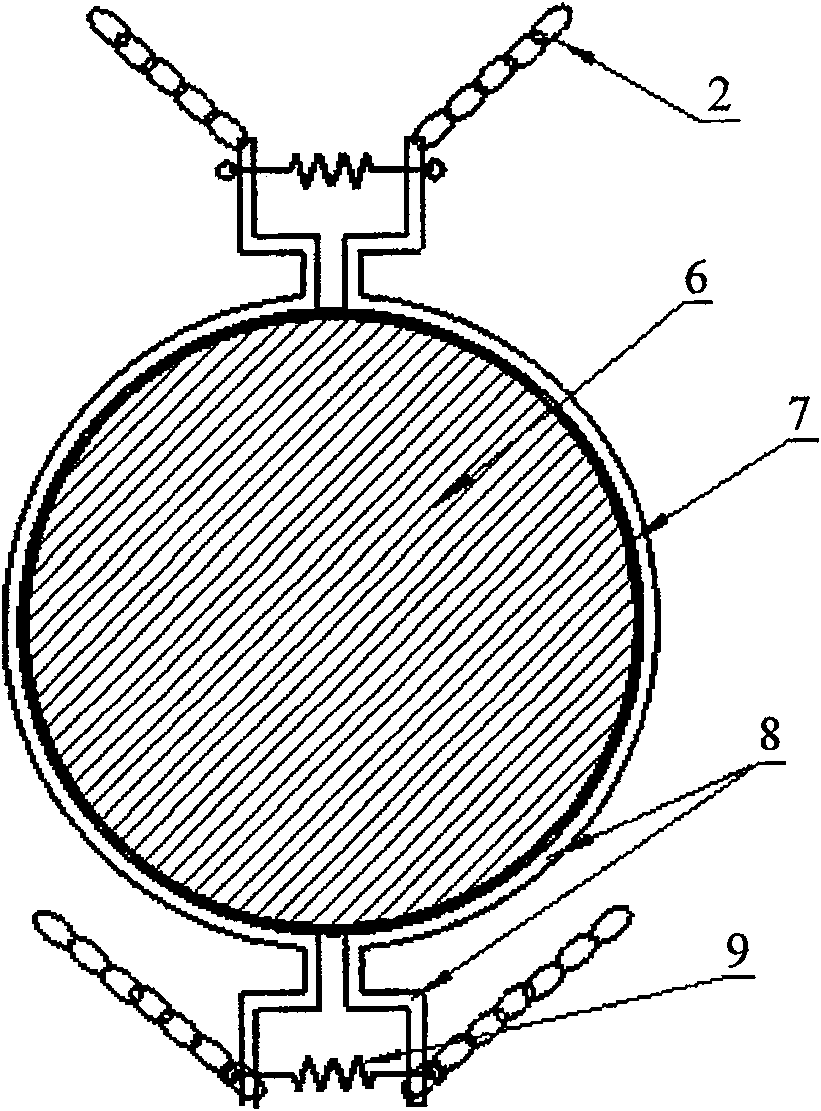

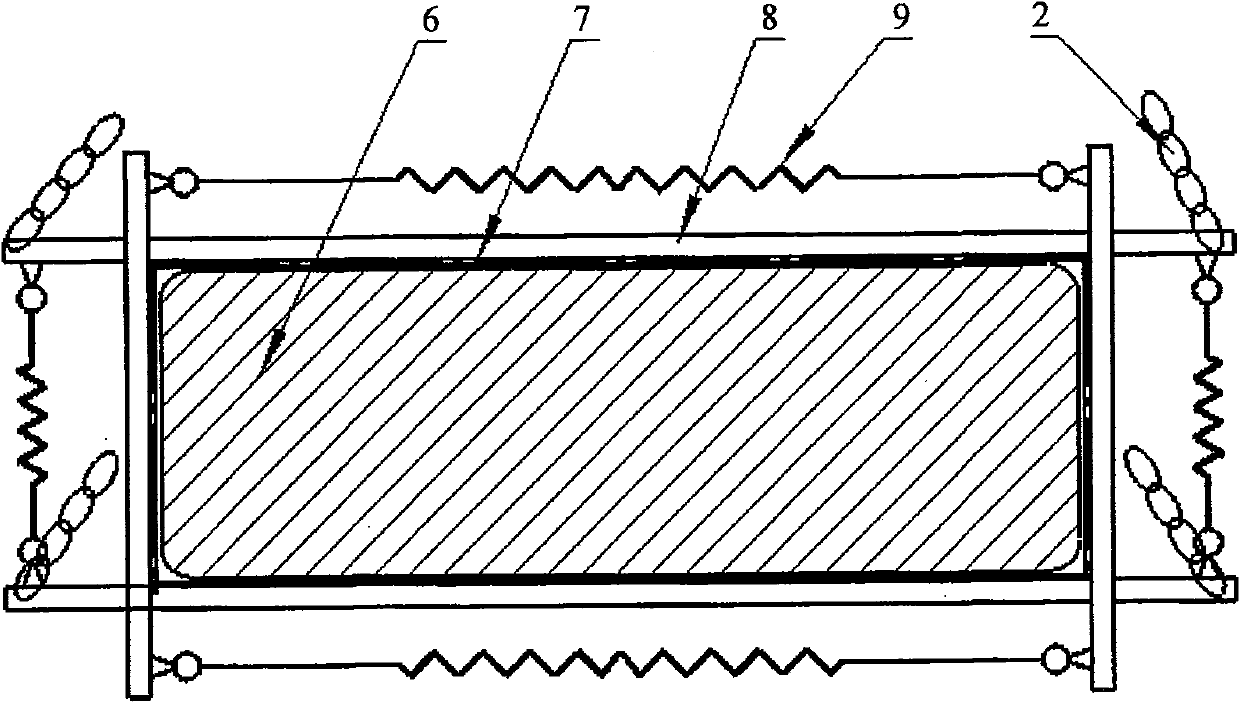

The invention provides a design method of a water blocking device for semi-continuous casting of hard aluminum alloy, the water blocking device comprises a water baffle plate body and springs, a divided structure is adopted in the water baffle plate body, all the parts are connected by the springs, the whole water blocking device is suspended under a crystallizer by a hinge or is directly supported on a casting platform, the part of the water baffle plate body which is contacted with the surface of a cast ingot is provided with a polymer material, and the working surface of the water baffle plate body is perpendicular with the surface of the cast ingot or forms a certain angle with the surface of the cast ingot. When in application, the outer surface of the cast ingot is tightly clamped atthe same time of not obstructing the casting process, the secondary cooling water of the semi-continuous casting is blocked and shunted at the position of the water baffle plate, the cast ingot onlyreceives part of the water cooling between the crystallizer and the water baffle plate, the lower part of the water baffle plate is carried out the natural air cooling; the cast ingot is repeatedly heated by a high temperature melt of the core part of the cast ingot, thus realizing the self-tempering effect of the cast ingot, effectively reducing the casting internal stress, preventing the cracksof the cast ingot and being applicable to the application of large-scale industrial production.

Description

technical field The invention relates to a design method of a water retaining device for hard aluminum alloy semi-continuous casting, belonging to the technical field of aluminum alloy semi-continuous casting. Background technique Ultra-high-strength aluminum alloys usually refer to aluminum alloys with a tensile strength exceeding 500 MPa, mainly Al-Zn-Mg-Cu series aluminum alloys. Ultra-high-strength aluminum alloys are widely used in aerospace and aviation fields due to their high specific strength and hardness, good corrosion resistance and high toughness. They are the main structural materials of spacecraft such as launch vehicles, spacecraft and space stations. . High alloying is the main means to improve the strength of hard aluminum alloys. In hard aluminum alloys represented by Al-Zn-Mg-Cu series, increasing the content of alloying elements such as Zn, Mg, and Cu is the main measure to improve the strength of aluminum alloy materials. . In the 1950s, the United ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B22D11/124

Inventor 韩逸乐永康吴文祥陈琦翁文凭郭世杰

Owner CHINALCO MATERIALS APPL RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com