Flexible display substrate and manufacturing method therefor, and display apparatus

A flexible display, flexible substrate technology, applied in identification devices, climate sustainability, final product manufacturing, etc., can solve problems such as fracture, failure, and performance degradation of flexible display substrates and display devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to enable those skilled in the art to better understand the technical solutions of the embodiments of the present disclosure, the structure and principle of the embodiments of the present disclosure will be described in detail below in conjunction with the accompanying drawings. The scope of protection of the disclosed embodiments.

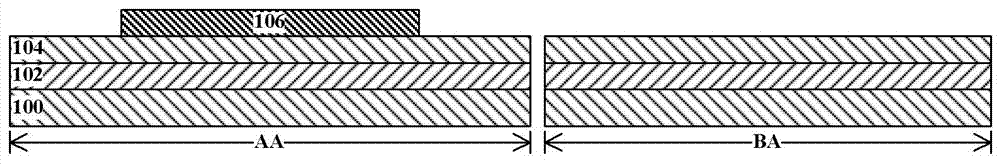

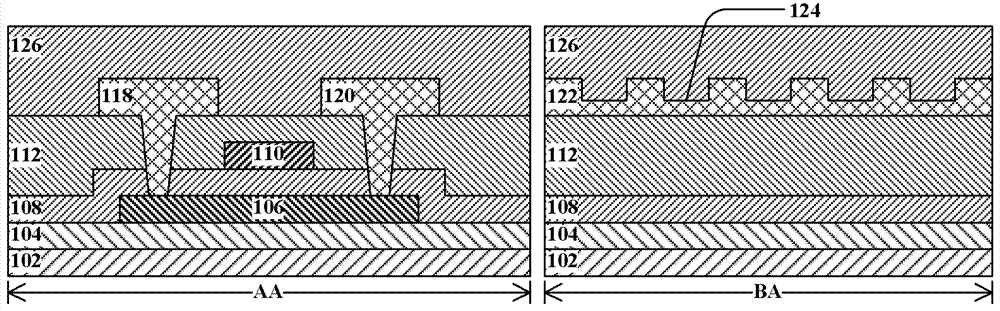

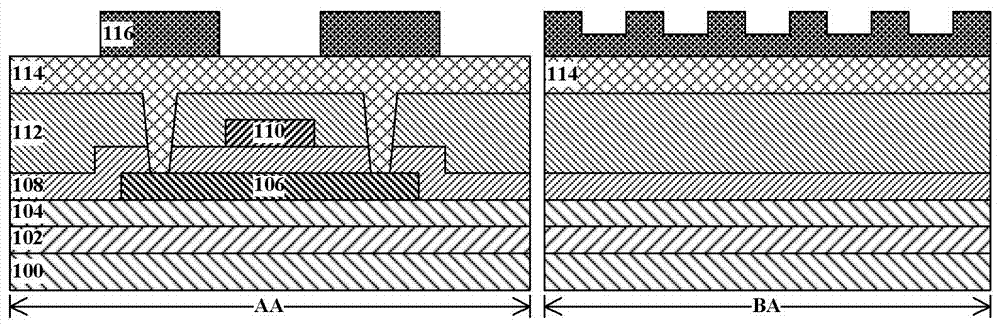

[0029] The components shown in the drawings are marked as follows: AA effective display area; BA bending area; 100 carrier substrate; 102 flexible substrate; 104 buffer layer; 106 active layer; 108 gate insulating layer; 110 gate; 112 interlayer Dielectric layer; 114 source-drain conductive layer; 116 photoresist; 118 source; 120 drain; 122, 1221, 1222, 122m data line; 422 grid line; 424 groove; 126 planarization layer; 510 first electrode; 520 pixel definition layer; 530 functional layer; 540 second electrode; dW width direction of data line; dL length direction of data line.

[0030] The following combination figure 1 A flexibl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com