A high-performance composite roll laser injection forming manufacturing and repair method and equipment

A spray forming and composite roll technology, which is applied in the field of laser technology, can solve problems such as spalling, cracking of the working layer, and restrictions on the large-scale application of composite rolls, so as to prolong the service life, save the time for powder replacement, and improve the light absorption rate. and processing speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

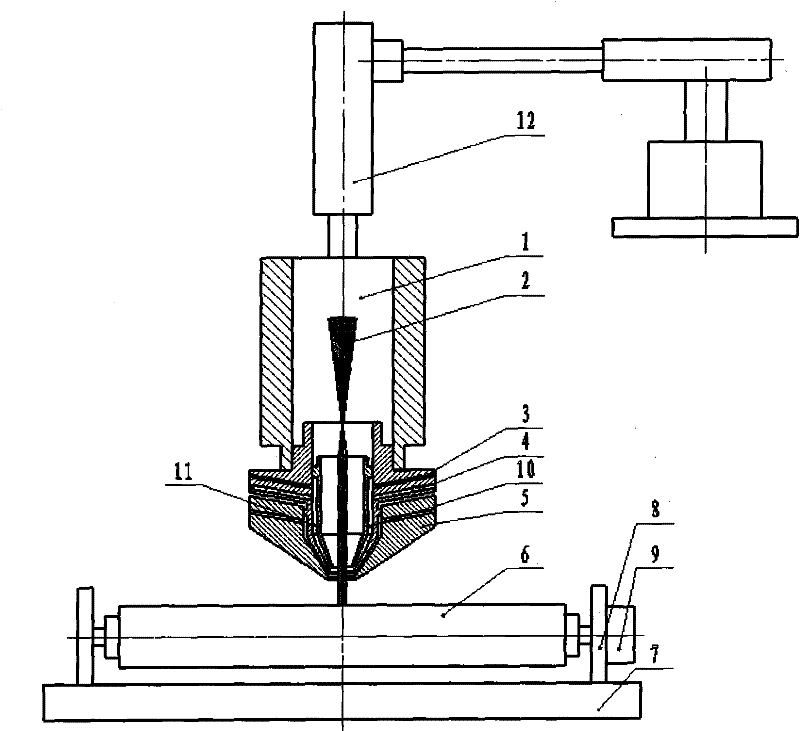

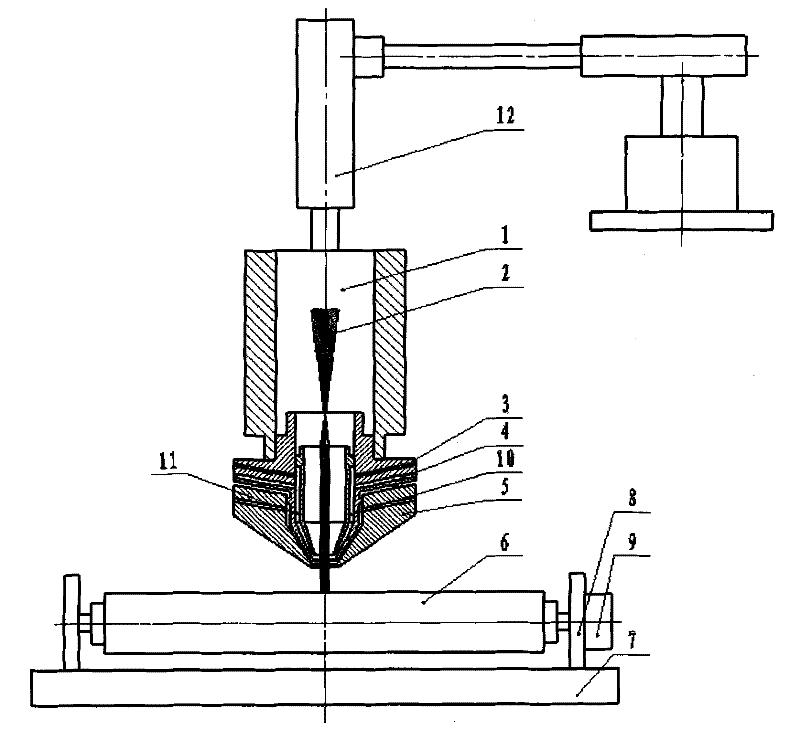

[0029] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0030] A method and equipment for manufacturing and repairing a high-performance composite roll by laser spray forming, which uses laser spray forming to manufacture the transition layer and the working layer of the roll, and is characterized in that the specific method steps are as follows:

[0031] A) remove the oil stain on the surface of the roll core, and polish it with sandpaper to further remove its oil stain;

[0032] B) The powder of the working layer material and the powder of the roll core are respectively loaded into the powder feeding system, and the intermediate transition layer of the direct metal manufacturing roll is started by la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com