Axletree steel and heat treatment method thereof

A heat treatment method and technology for axle steel, applied in heat treatment furnaces, heat treatment equipment, shafts, etc., can solve problems such as grain size fluctuations, material mixed crystals, grain size mixed crystals, etc., to suppress cracks and prolong service life Longevity and the effect of ensuring driving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

[0057] Table 5 shows the components of the axle steels of Examples 1-6. The mechanical properties of the axle steels of Examples 1-6 are shown in Table 6.

[0058] The heat treatment methods of Examples 1-6 are: primary normalizing: temperature 830°C, holding time 5 hours, then air cooling to room temperature; primary tempering: temperature 610°C, holding time 5 hours, then air cooling to room temperature.

[0059]Table 5 Embodiment 1-6 Composition of axle steel (surplus is iron and other unavoidable elements)

[0060]

[0061] Table 6 The mechanical properties of steel for axles in embodiment 1-6

[0062]

[0063] Note: where impact AKU 2 all three measurements

[0064] Comparing Table 2 and Table 6, it can be seen that the mechanical properties of the axle steel provided by the present invention are much higher than that of the existing LZ50 steel, and the tensile strength and yield strength are about 13% higher than that of the LZ50 steel.

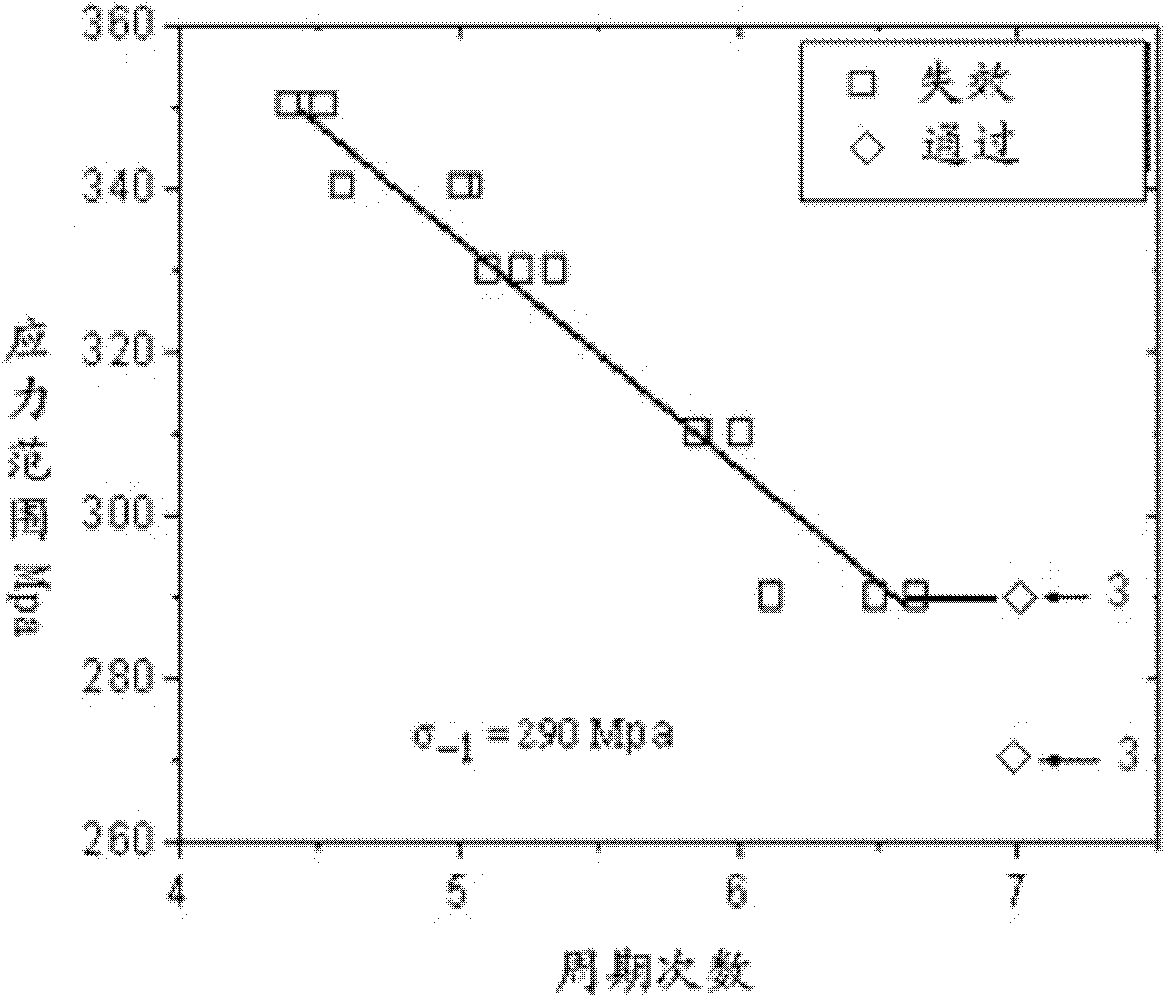

[0065] In addition, ra...

Embodiment 7-13

[0067] The production process route of axle steel: electric furnace or converter steelmaking (eccentric bottom tapping circuit) → LF (ladle refining furnace) + VD (vacuum refining furnace) refining → pouring ingot → hot rolling steel → ingot heating → rolling → slow Cold → (sampling for heat treatment and inspection) → cleaning → inspection → packaging, storage, and delivery.

[0068] The composition of the billet is shown in Table 7. In Examples 7-13, a sample of 200×200×200 mm was taken from the billet, the processes of different heat treatment conditions were controlled, and its mechanical properties under different heat treatment conditions were tested. Table 8 shows the test results of the mechanical properties of steel slabs in Examples 7-13.

[0069] The composition of table 7 embodiment 7-13 billet (surplus is iron and other unavoidable elements)

[0070]

[0071] Examples 7-13 The heat treatment method of steel for axles is as follows: put the steel billet 200×200...

Embodiment 13

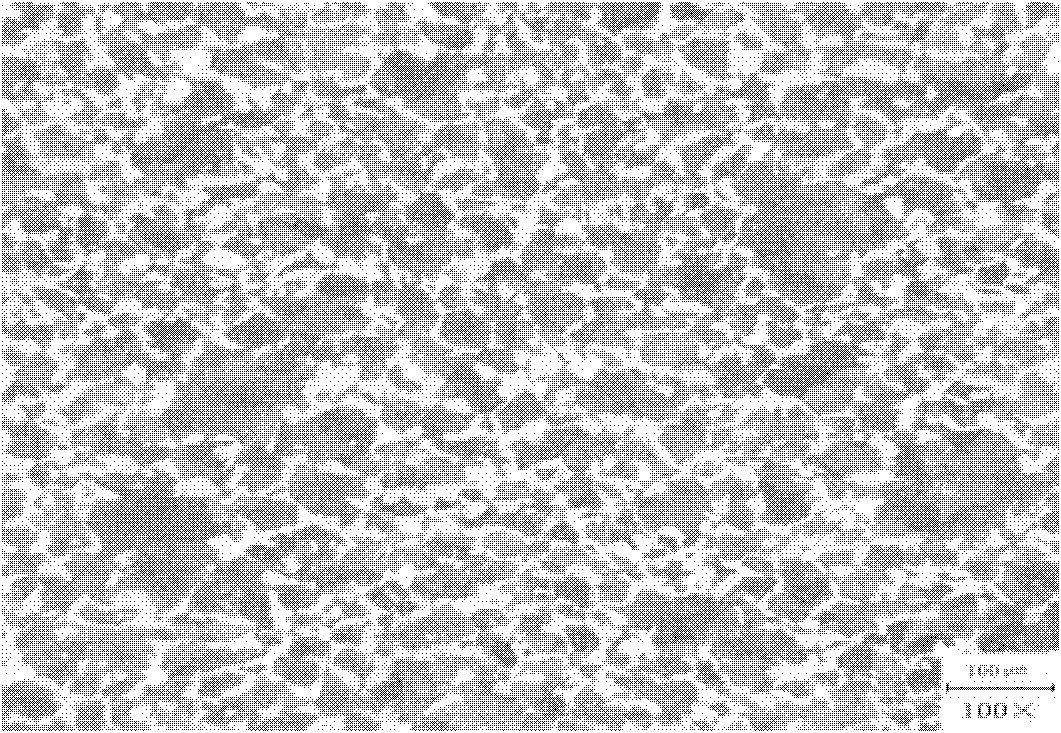

[0076] In the process of forging the axle steel described in Example 13 into an axle, it undergoes final forging at a high temperature of 900° C., and the grain size reaches 7-8 grades without mixed crystals. The mechanical safety of the steel is higher than that of LZ50 steel. Such as Figure 6 As shown, the grain size is grade 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com