Intermediate transcriptional body

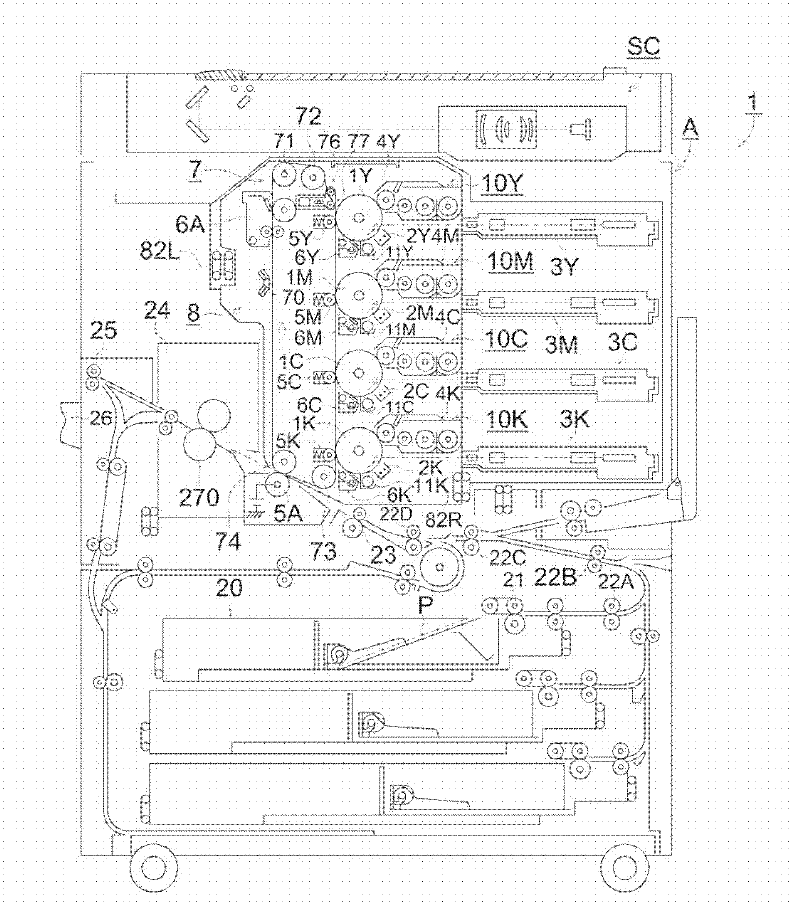

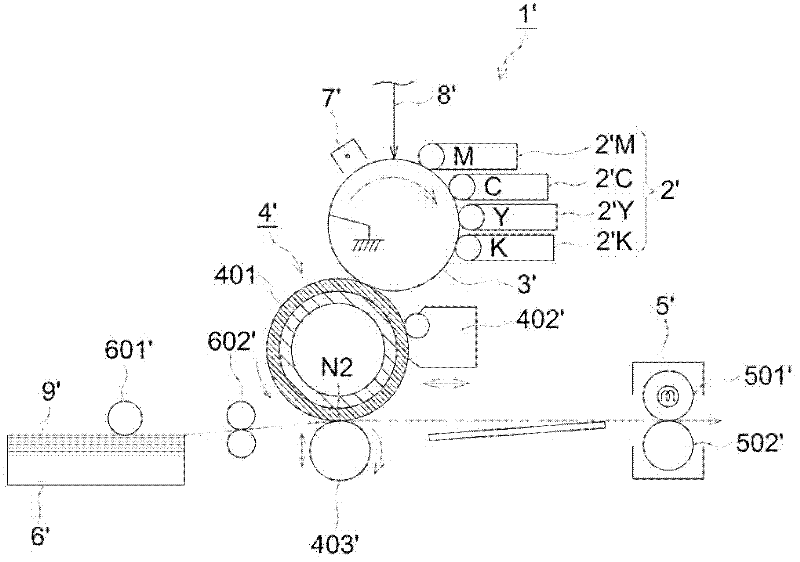

An intermediate transfer body, image technology, applied in the direction of electrography, optics, instruments, etc., can solve the problems of hollowing and consolidation of text and images, and achieve the effect of inhibiting scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

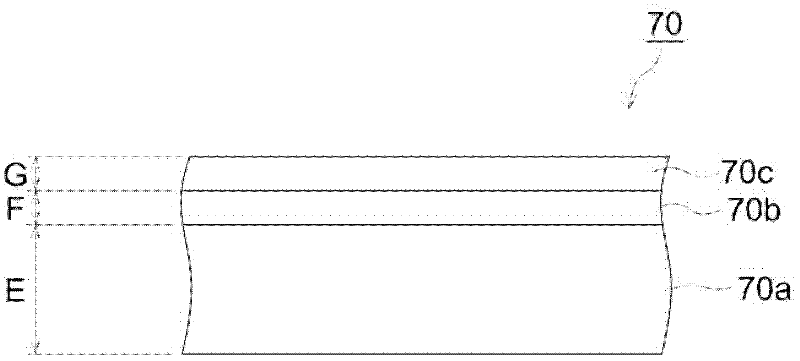

[0172] (Prepare the ring-shaped substrate)

[0173] A 100 μm-thick, endless belt-shaped substrate containing a conductive substance and made of polyimide (PI) was prepared. As the conductive substance added to the resin material, carbon black can be used. As carbon black, neutral or acidic carbon black can be used. The amount of conductive material used varies depending on the type of conductive material used, but as long as the amount of conductive material added makes the volume resistance value and surface resistance value of the intermediate transfer body reach the specified range, usually, relative to the resin For 100 parts by mass of the material, the amount of the conductive material used is 10 parts by mass to 20 parts by mass, preferably 10 parts by mass to 16 parts by mass. The modulus of elasticity of the matrix is 5 GPa.

[0174] (making elastic layer)

[0175] On the outer periphery of the prepared endless belt-shaped substrate, an elastic layer whose elast...

Embodiment 2

[0228] (Prepare the ring-shaped substrate)

[0229] The same endless belt-shaped substrate as in Example 1 was prepared.

[0230] (Preparation of intermediate transfer body)

[0231] On the prepared annular belt-shaped substrate, change the ratio of the hardness of the surface layer to the hardness of the elastic layer, the hardness of the surface layer, the modulus of elasticity of the surface layer, and the thickness of the surface layer as shown in Table 3 to make a substrate with / elastic layer / surface layer, thus obtaining sample Nos. 201 to 225.

[0232] The hardness and elastic modulus of the surface layer represent values measured by the same method as in Example 1. The thickness of the surface layer represents the value measured by the same method as in Example 1. The thickness and hardness of the elastic layer represent values measured by the same method as in Example 1.

[0233] (making elastic layer)

[0234] On the outer periphery of the prepared endless ...

Embodiment 3

[0264] (Prepare the ring-shaped substrate)

[0265] The same endless belt-shaped substrate as in Example 1 was prepared.

[0266] (making elastic layer)

[0267] By the same method, the same elastic layer as the endless belt-shaped base No. 1-3 formed to the elastic layer produced in Example 1 was formed on the prepared endless belt-shaped base, thereby obtaining an endless belt-shaped base. However, nitrile rubber was used as a material, and the film thickness of the elastic layer was 150 μm and the modulus of elasticity was 50 MPa.

[0268] (Preparation of intermediate transfer body)

[0269]When forming the surface layer on the elastic layer formed to the endless belt-shaped base of the elastic layer, as shown in Table 5, the surface layer is made of two layers, the lower layer and the upper layer, and the hardness and elastic modulus of the lower layer are changed. The intermediate transfer body was prepared under the condition of the hardness, elastic modulus, and thic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com