Liquefied natural gas sampling and continuous collecting device

A liquefied natural gas and collection device technology, applied in the field of liquefied natural gas sampling and continuous collection devices, can solve problems such as friction jamming of moving parts, sample mixed filling, non-uniform sample injection, etc., to prevent early gasification and prevent cold and heat Convection, to ensure the effect of heat insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

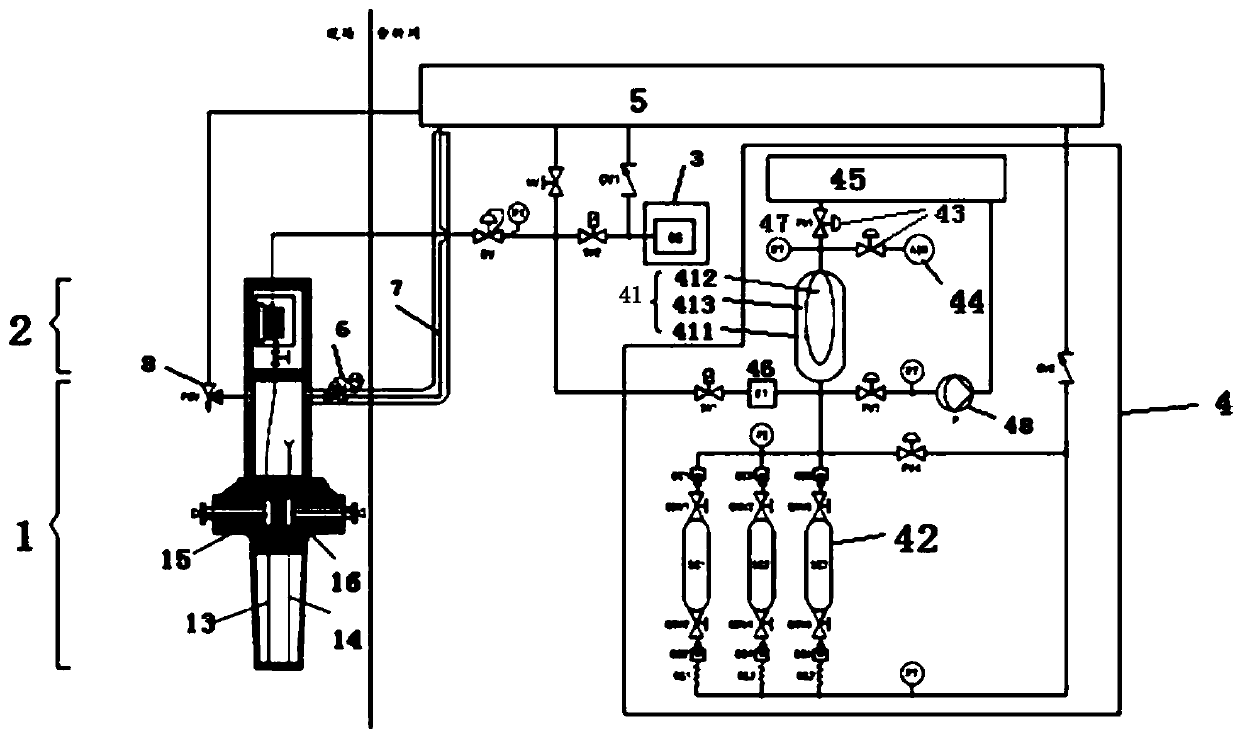

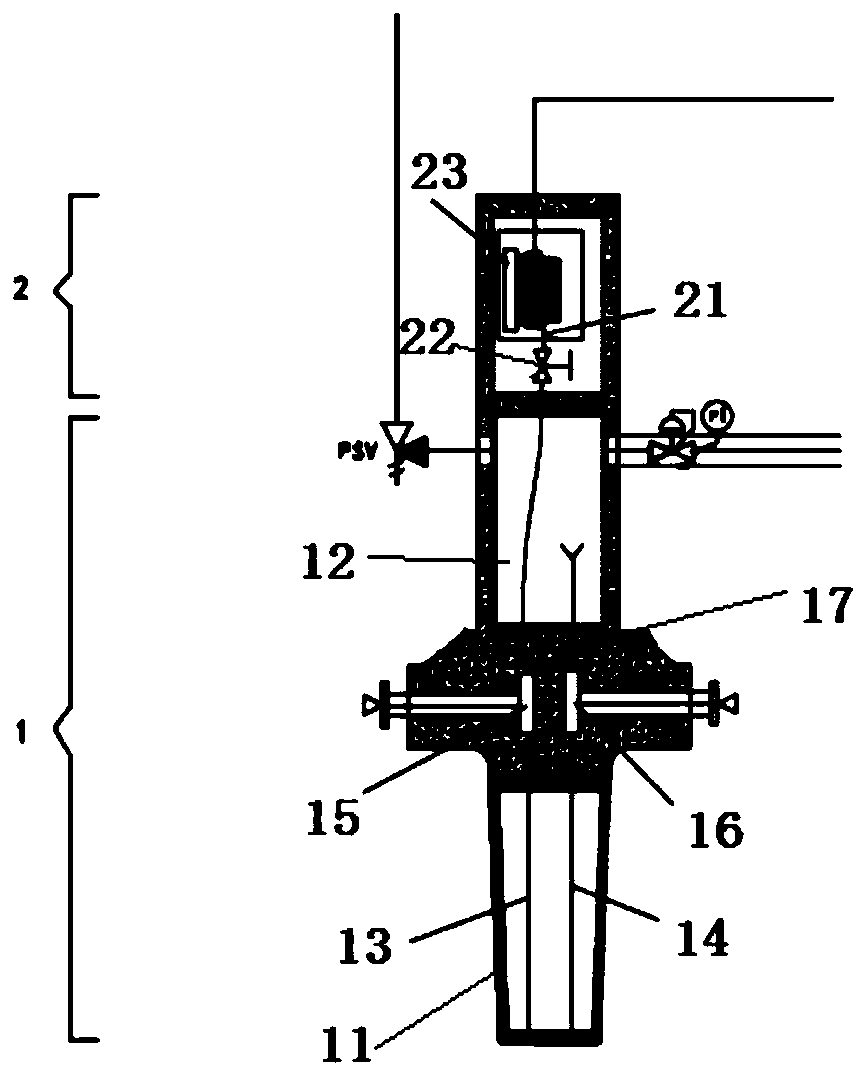

[0036] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, so as to better understand the purpose, features and advantages of the present invention. It should be understood that the embodiments shown in the drawings are not intended to limit the scope of the present invention, but only to illustrate the essence of the technical solutions of the present invention.

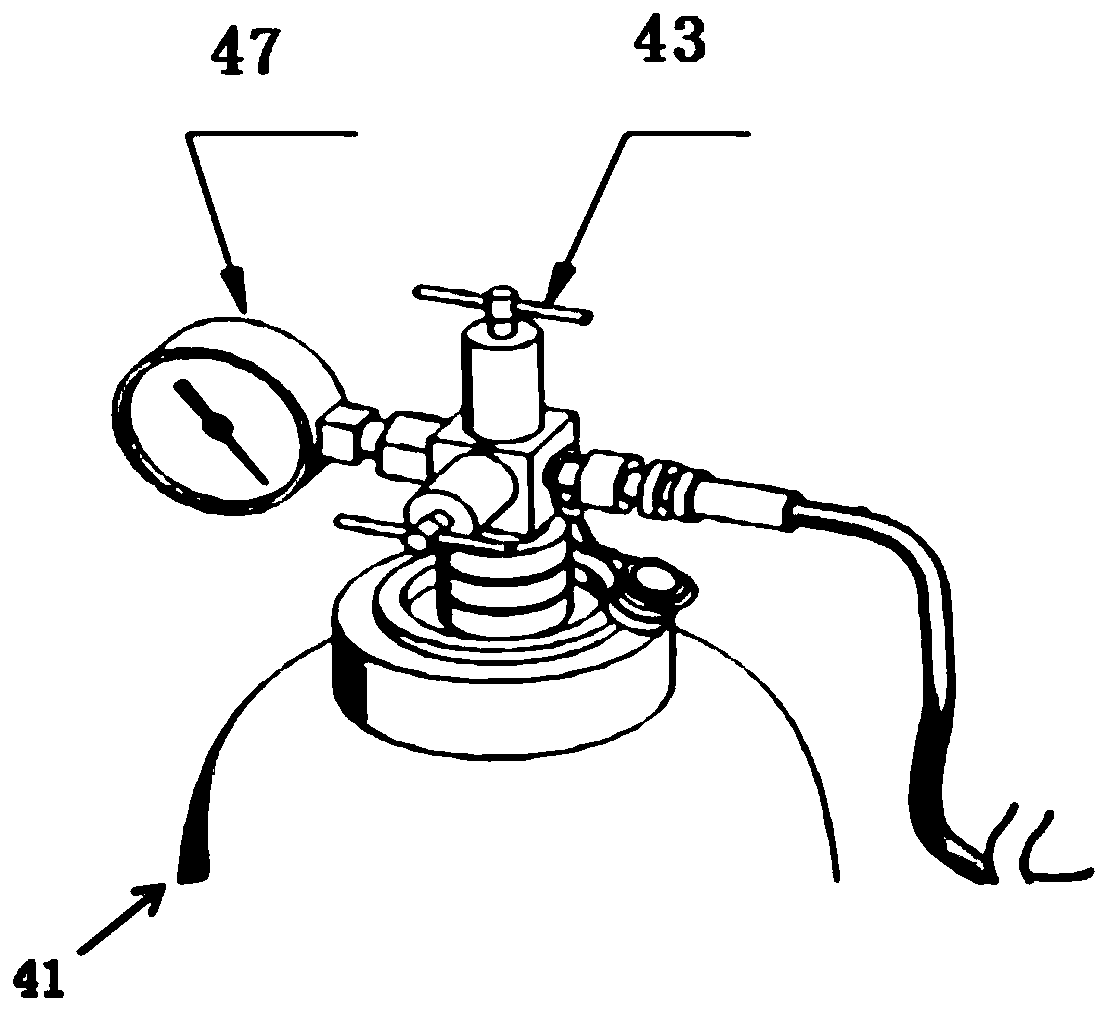

[0037] Such as figure 1As shown, the embodiment of the present invention provides a kind of liquefied natural gas sampling and continuous collection device, comprises: sampling system 1, comprises LNG sampling probe 11, forms airtight cryogenic cavity 12 at the front end of LNG sampling probe 11; Sampling pipeline 13, It is installed in the LNG sampling probe 11; the LNG filling pipeline 14 is installed in the LNG sampling probe 11 and communicated with the closed cryogenic chamber 12;

[0038] Gasification system 2, one end of the sampling p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com