System and method for extracting and testing cave secondary carbonate fluid inclusion water

A technology of secondary carbonate and fluid inclusions, which is applied in the preparation, sampling, and measurement devices of test samples, can solve problems affecting test analysis results, access to test instruments, test analysis, etc., to improve extraction efficiency, High test accuracy and guaranteed stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below with reference to the drawings and specific embodiments. It should be noted that the present invention is not limited to the following specific embodiments, and all equivalent transformations made on the basis of the technical solution of the present application fall within the protection scope of the present invention.

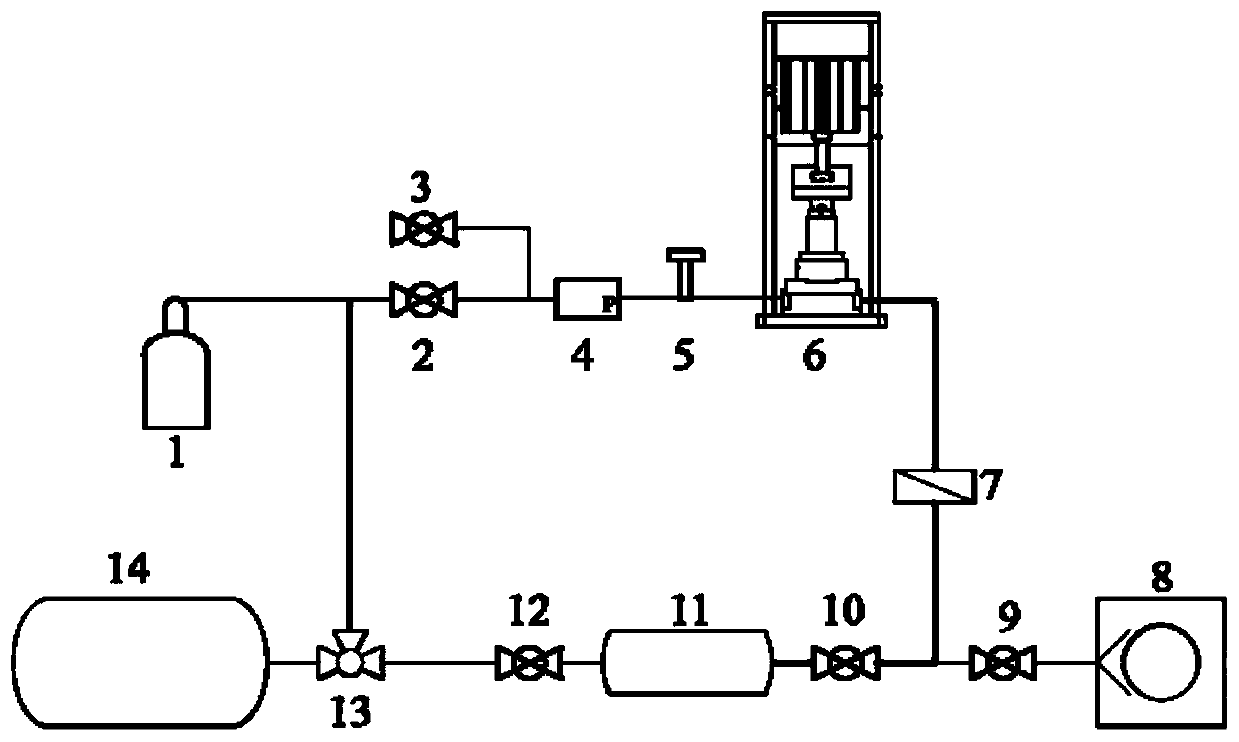

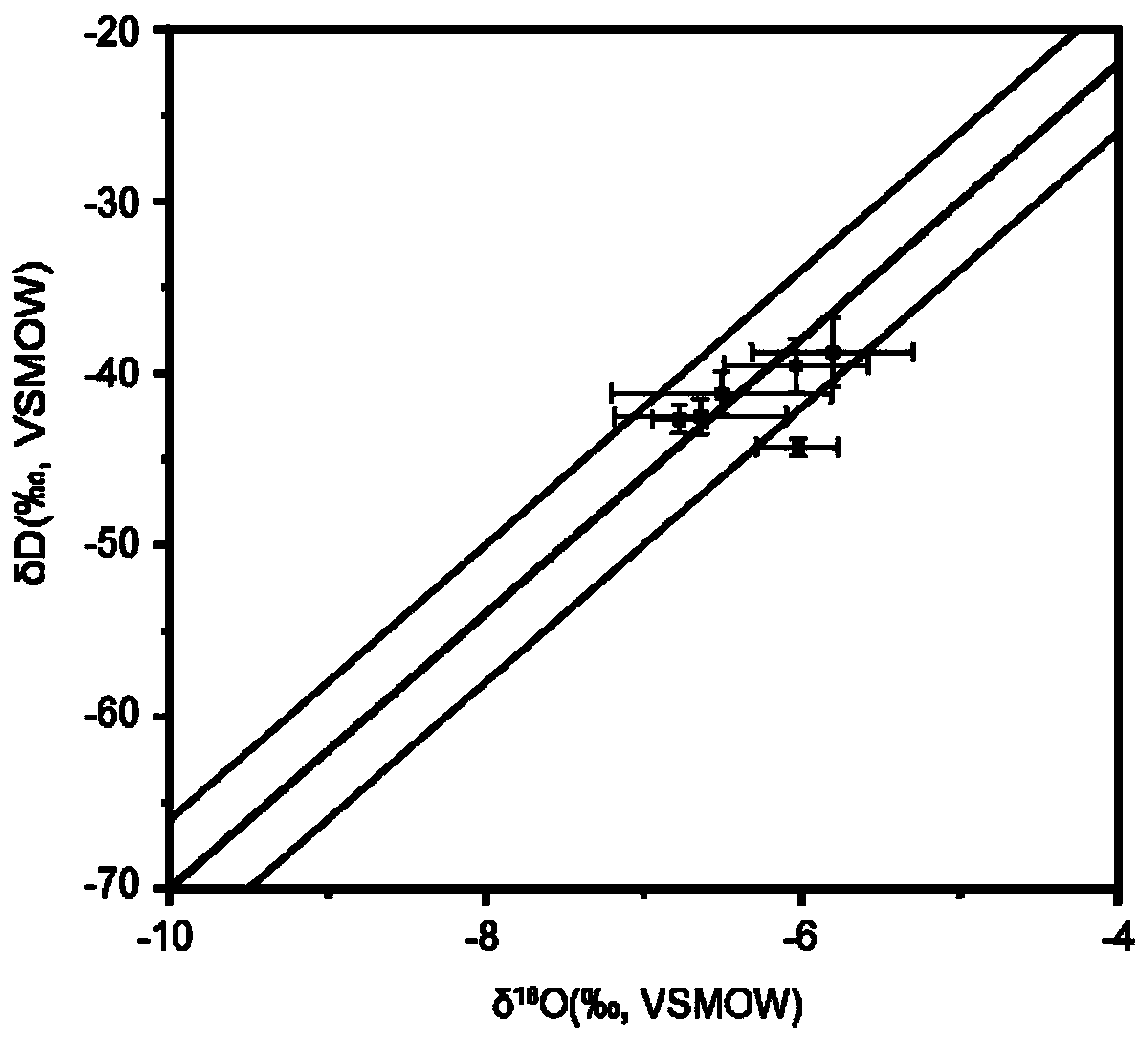

[0030] The system of the present invention is divided into two main parts, one part is a cave secondary carbonate fluid inclusion formed by connecting valves, pressure gauge 4, injection port 5, crushing grinder 6, vacuum pump 8 and buffer bottle 11 The second part of the water extraction device is a water isotope analyzer 14 that performs hydrogen and oxygen isotope testing on the inclusion water.

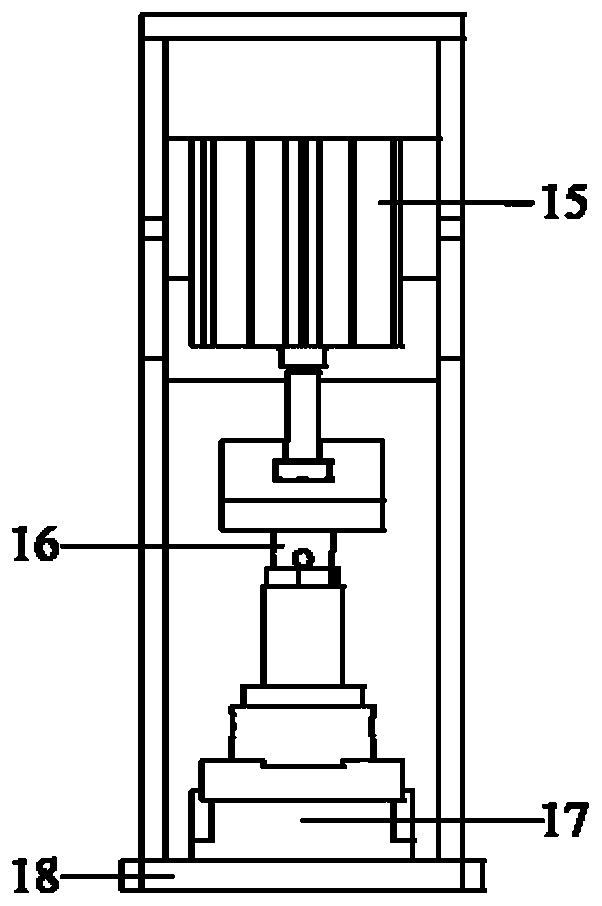

[0031] Such as figure 1 As shown, a system for extracting and testing cave secondary carbonate fluid inclusion water includes a carrier gas storage device 1, a pressure gauge 4, an injection port 5, a crus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com