Patents

Literature

431results about "Container filling without pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

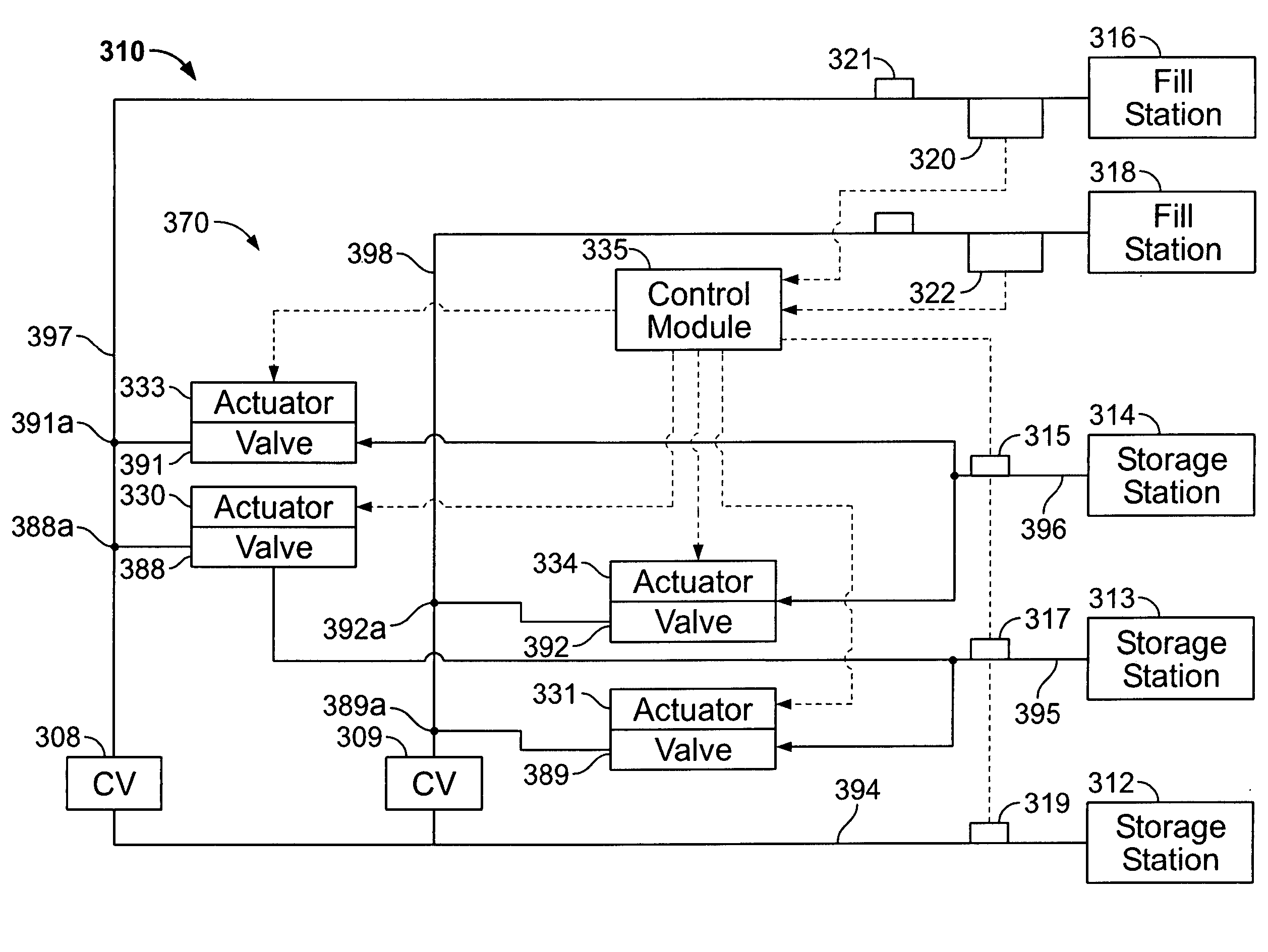

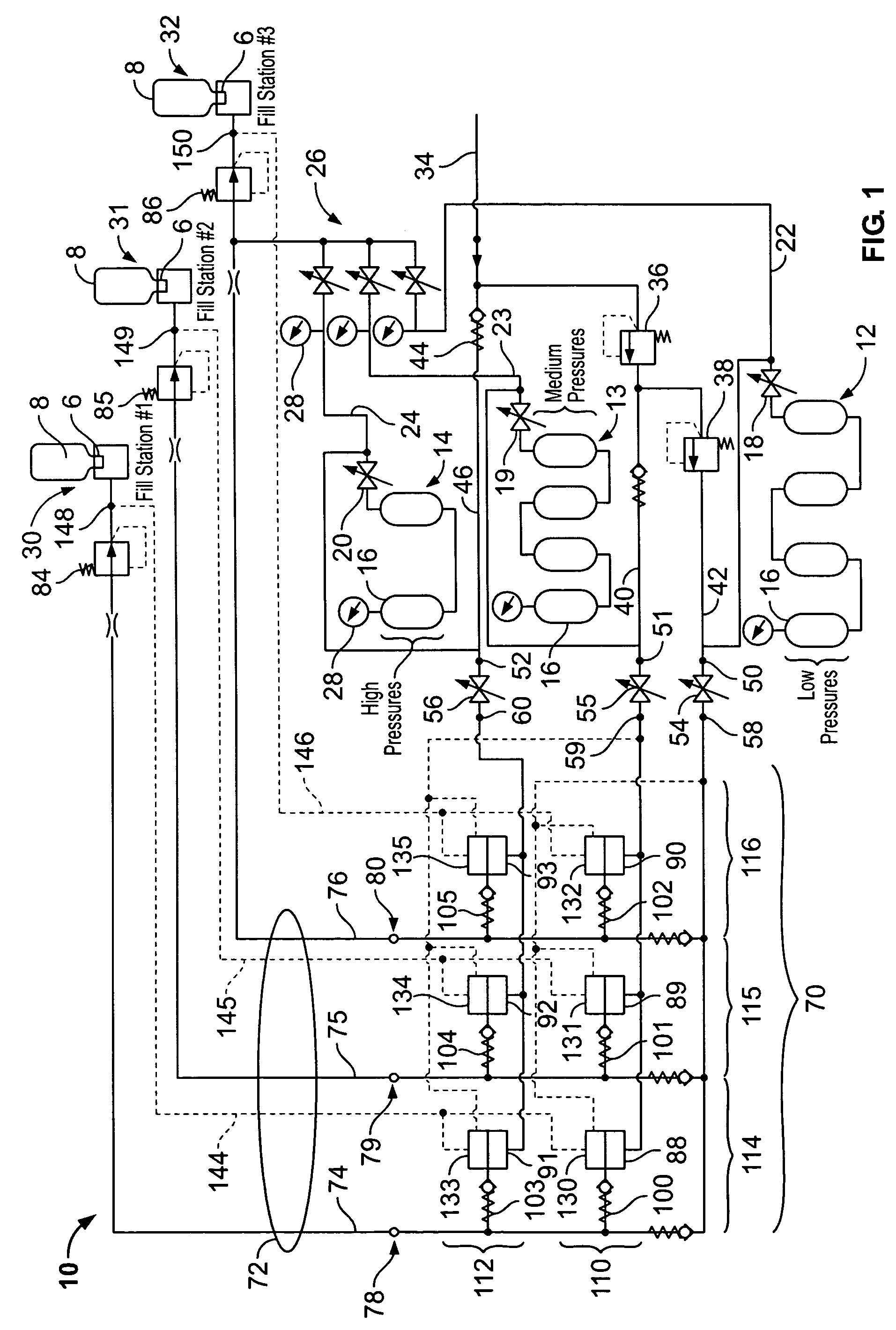

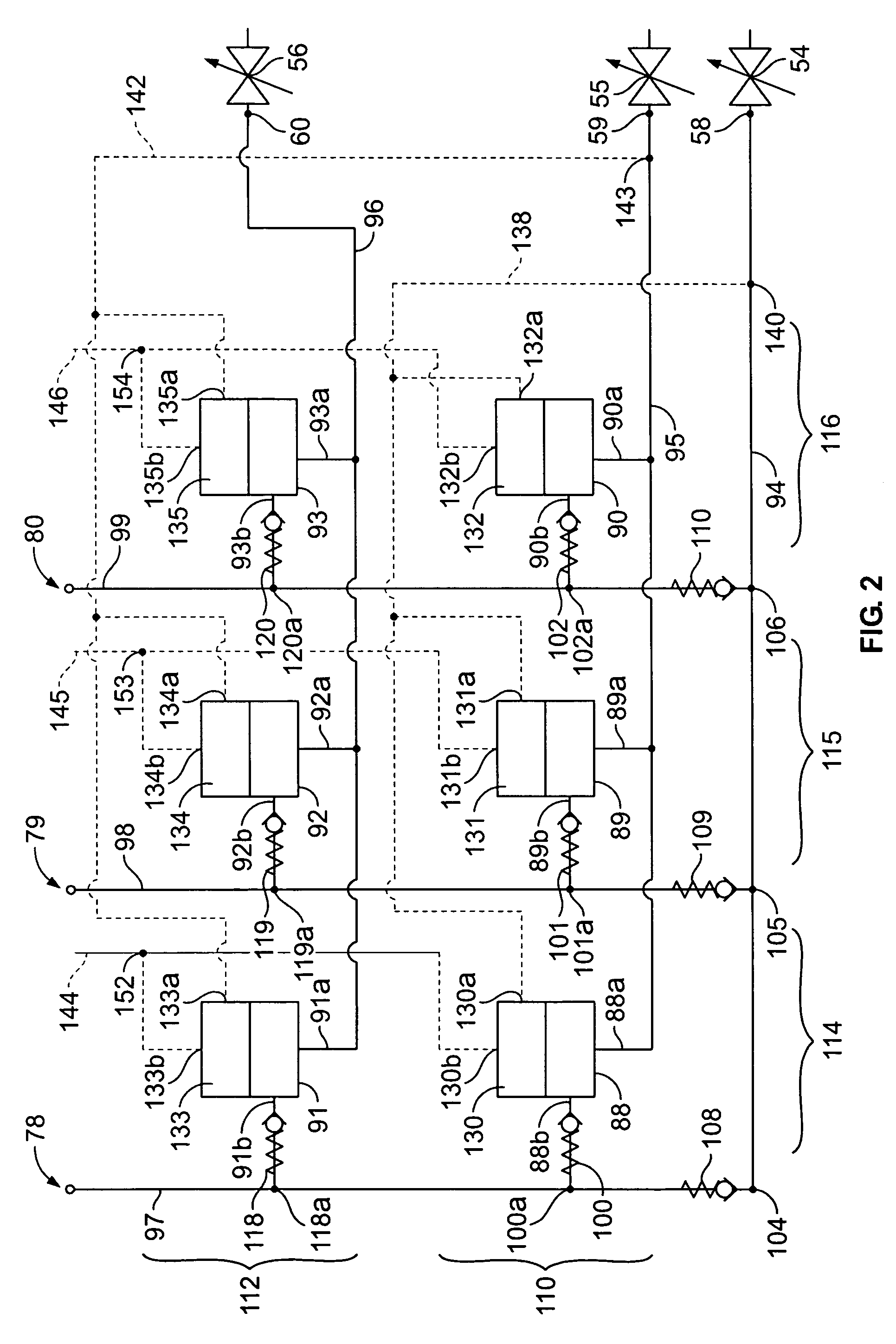

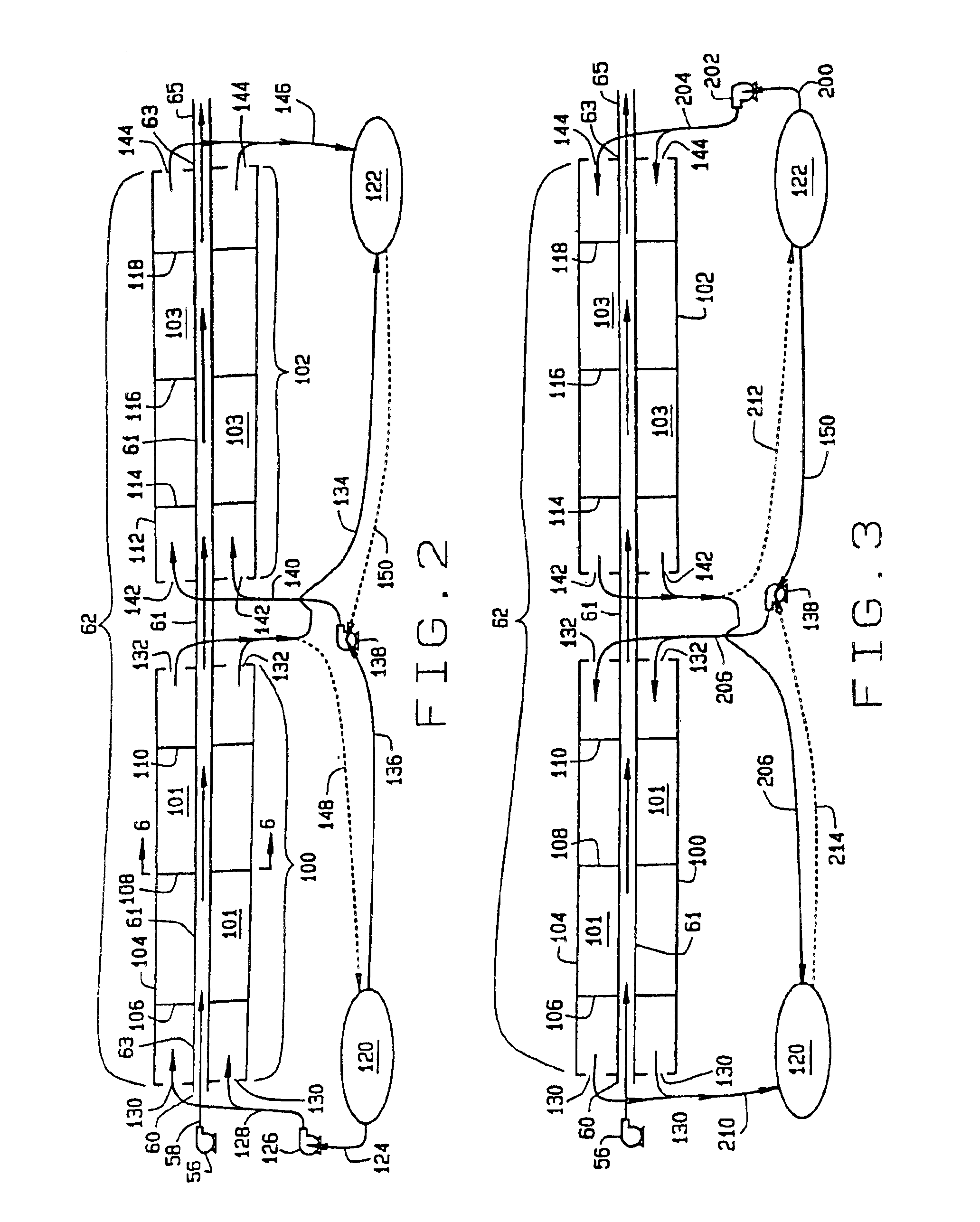

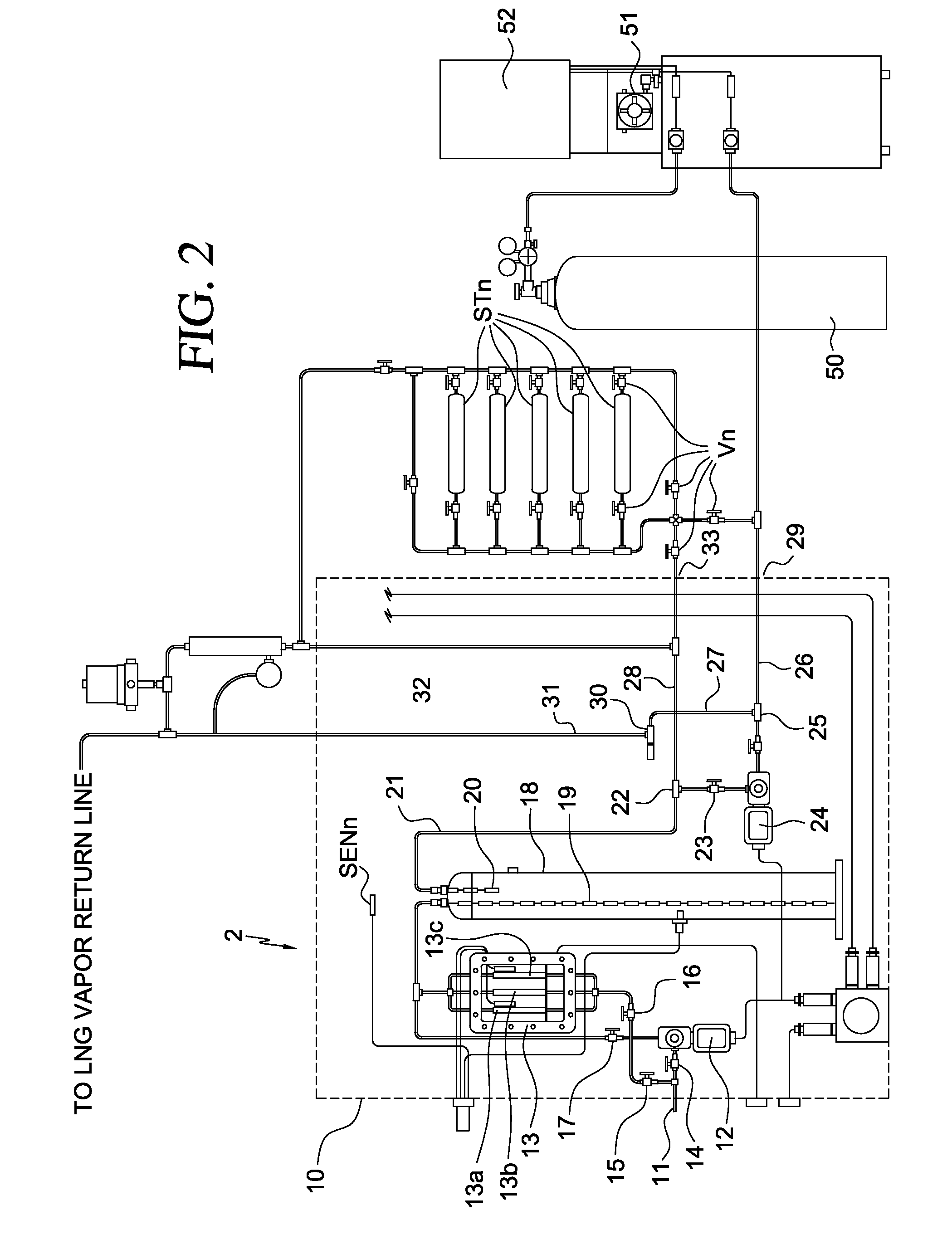

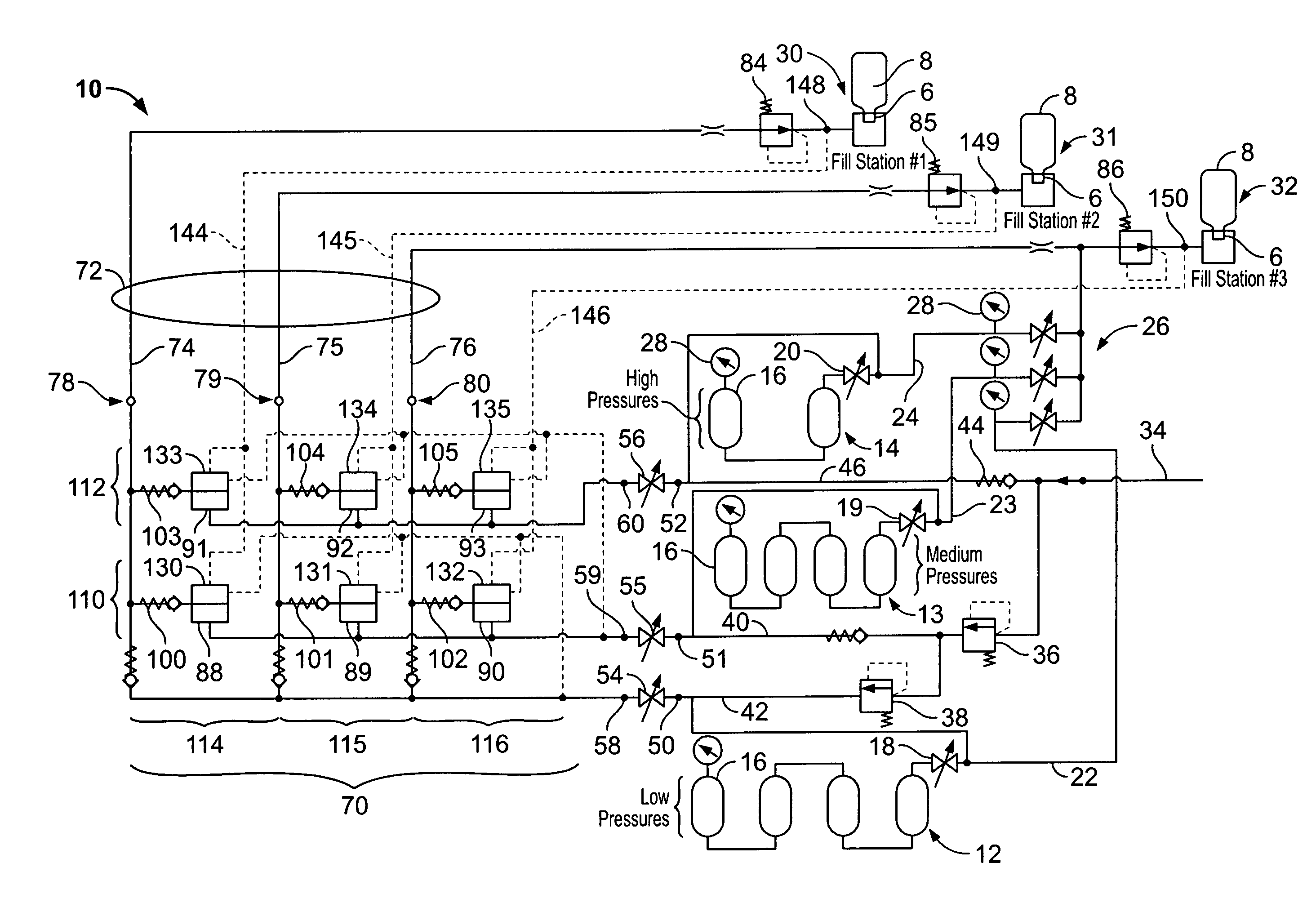

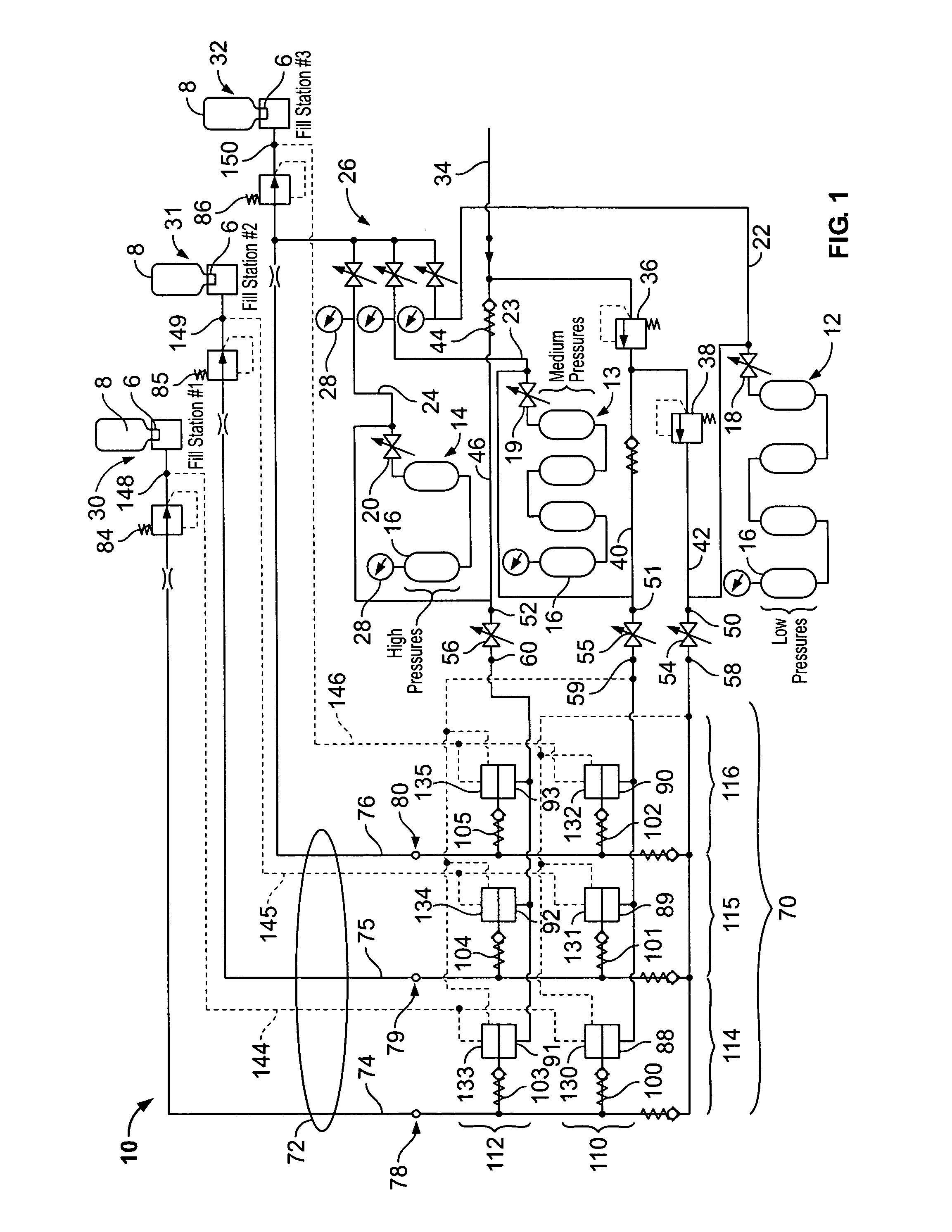

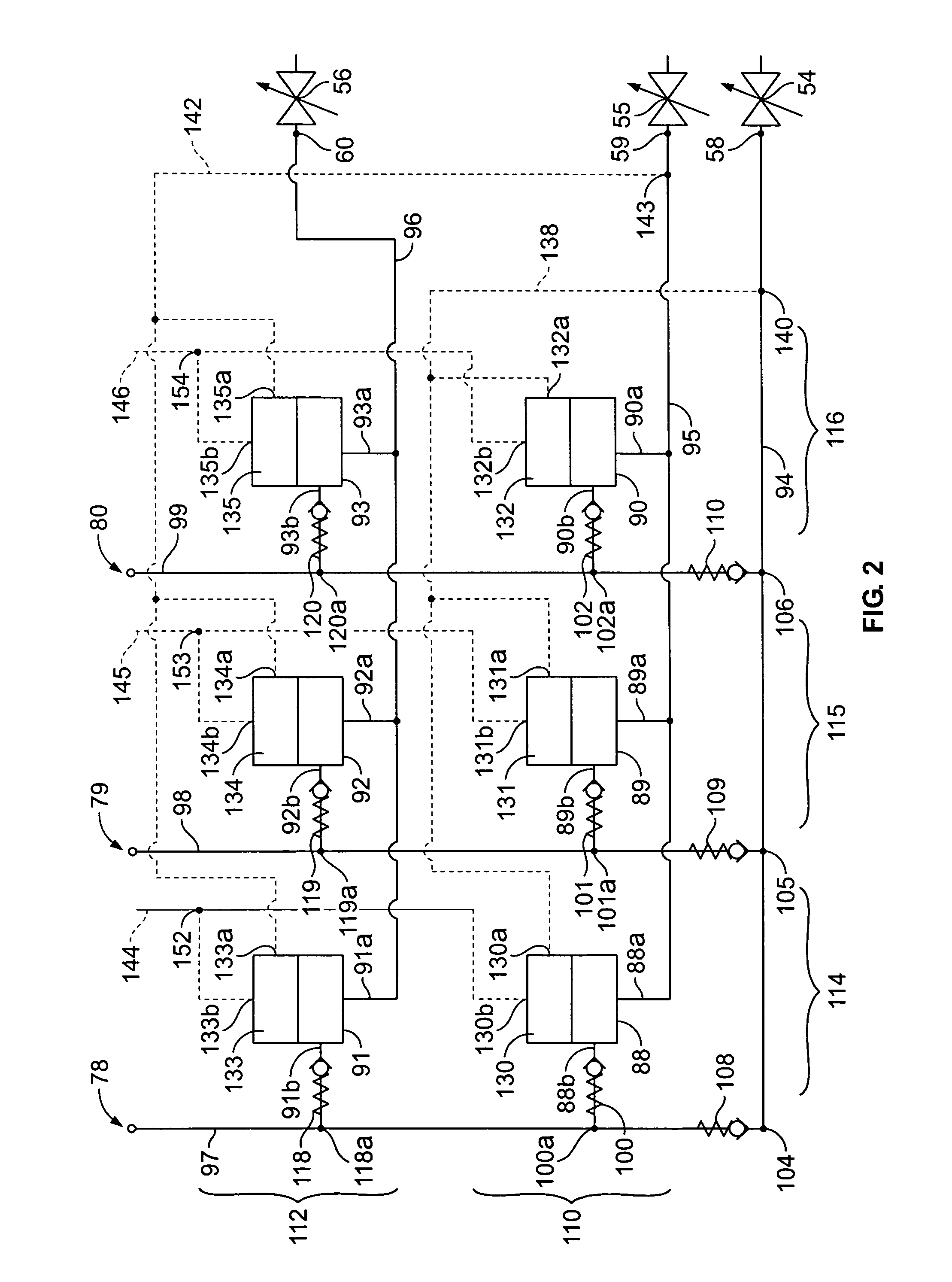

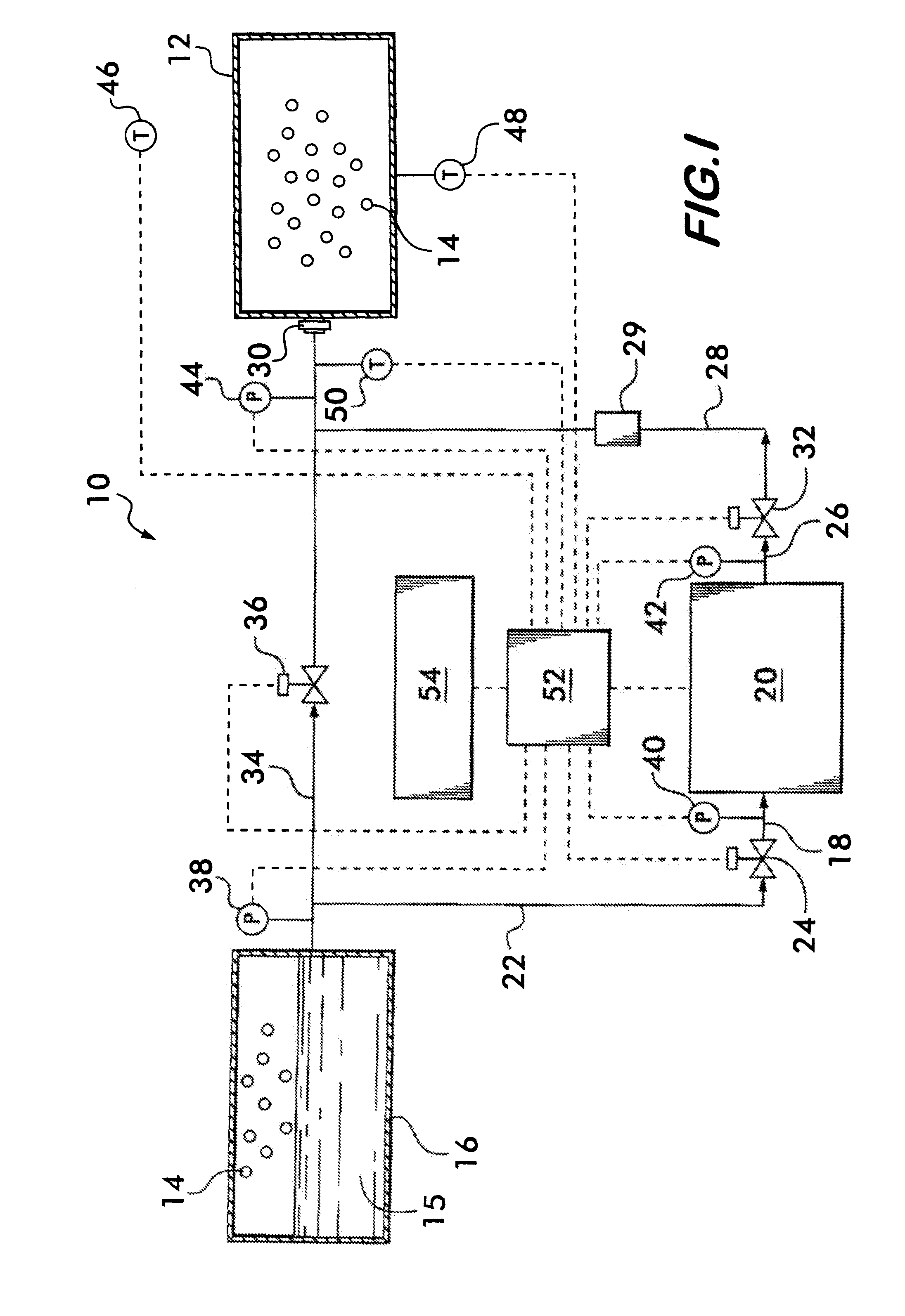

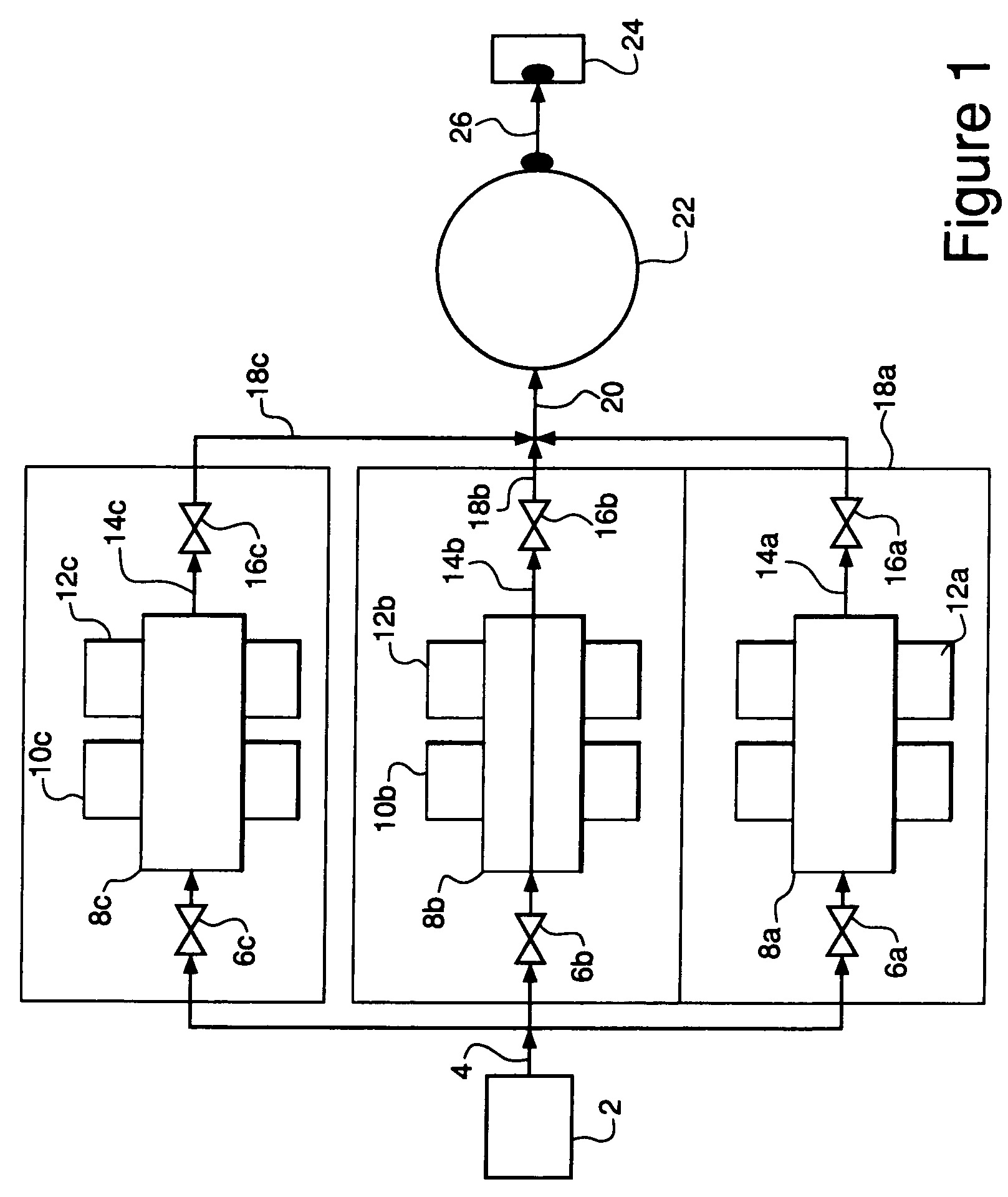

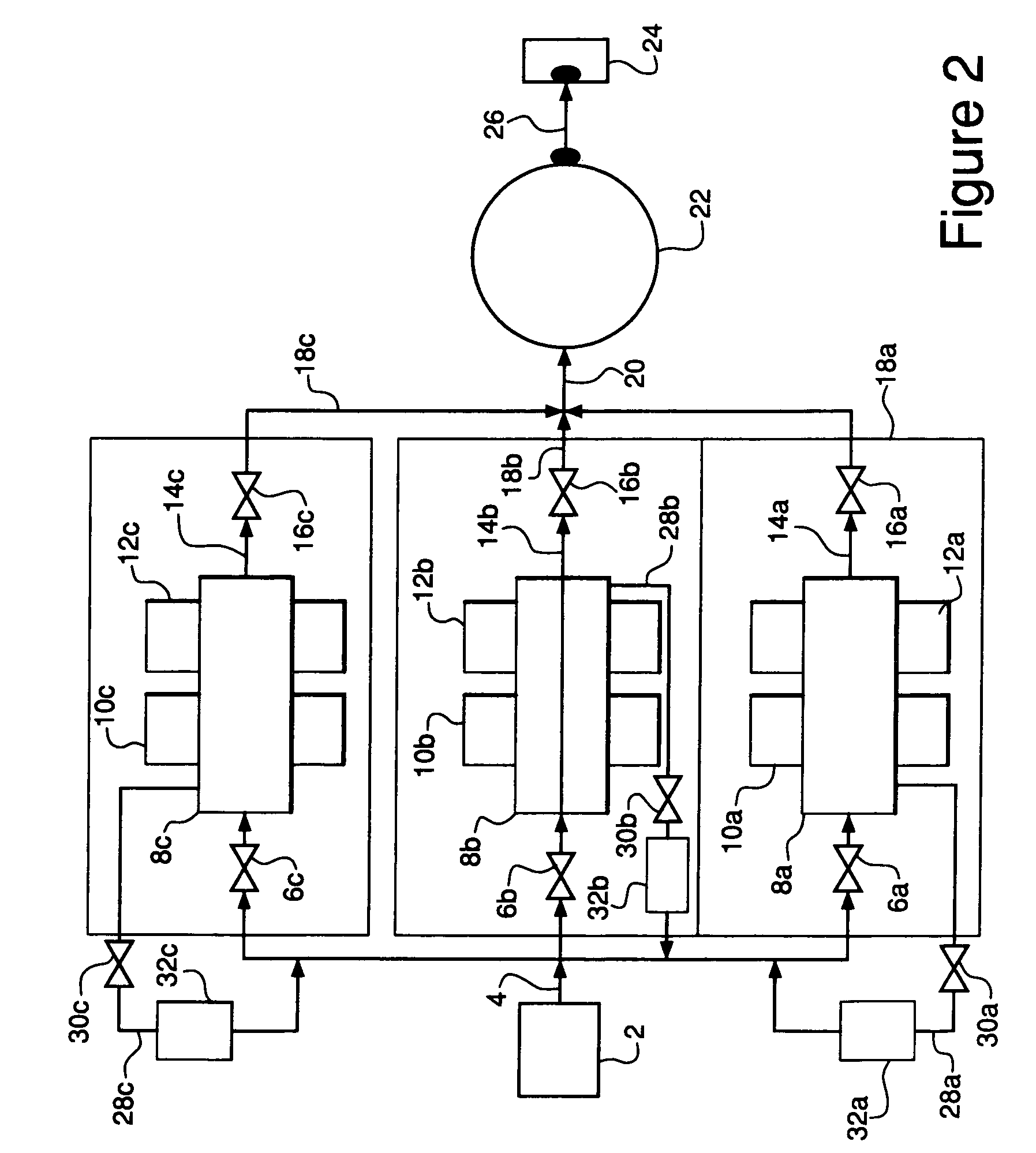

Method and system for independently filling multiple canisters from cascaded storage stations

A canister filling system is provided for independently filling multiple canisters from a common set of storage stations prioritized in a cascaded manner. The system includes first and second fill stations configured to receive and independently fill canisters with pressurized gas. First and second storage stations store gas at corresponding first and second charge pressures, respectively. A supply-chain joins each of the first and second fill stations to both of the first and second storage stations. First and second valve assemblies are provided in the supply-chain to monitor, independent of one another, the canister pressures at the corresponding first and second fill stations. The canister pressures represent the pressure within corresponding canisters. The first and second valve assemblies automatically open and close to permit and prevent discharge of gas from the first and second storage stations, independent of one another, to automatically switch between the first and second storage stations based on the canister pressures. In one embodiment, the valve assembly includes a combination of sequence valves and check valves. Alternatively, the valve assembly may be controlled by electronic sensors and electronic solenoids. The electronic sensors detect the canister pressures and the charge pressures at the storage stations. The electronic solenoids open and close the valves based on the sensed canister pressures.

Owner:SCOTT TECH INC

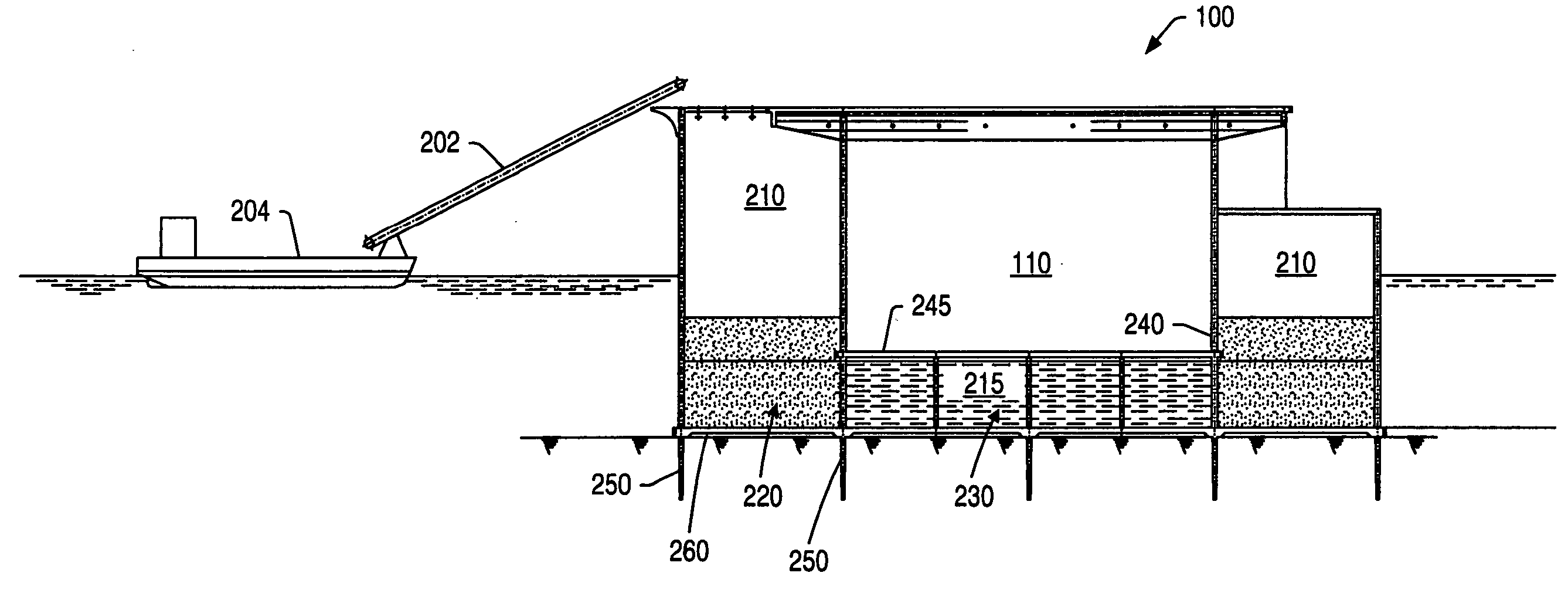

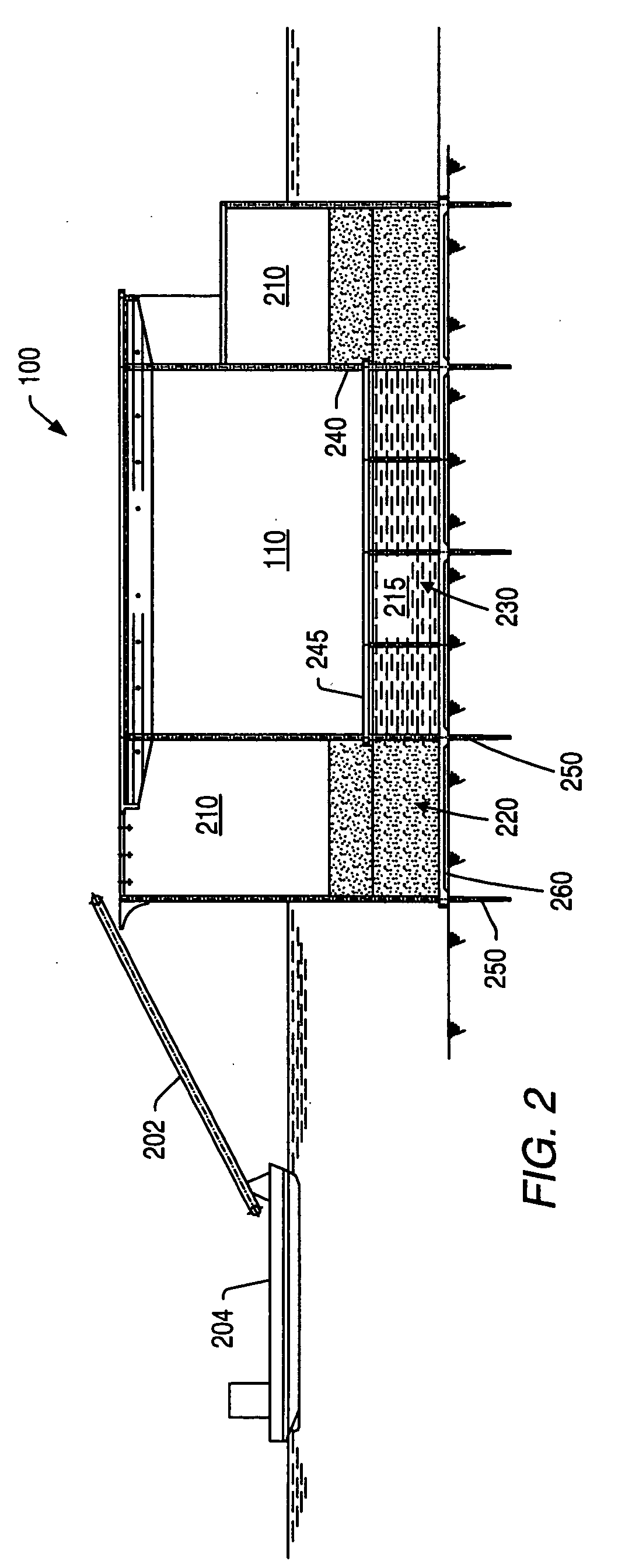

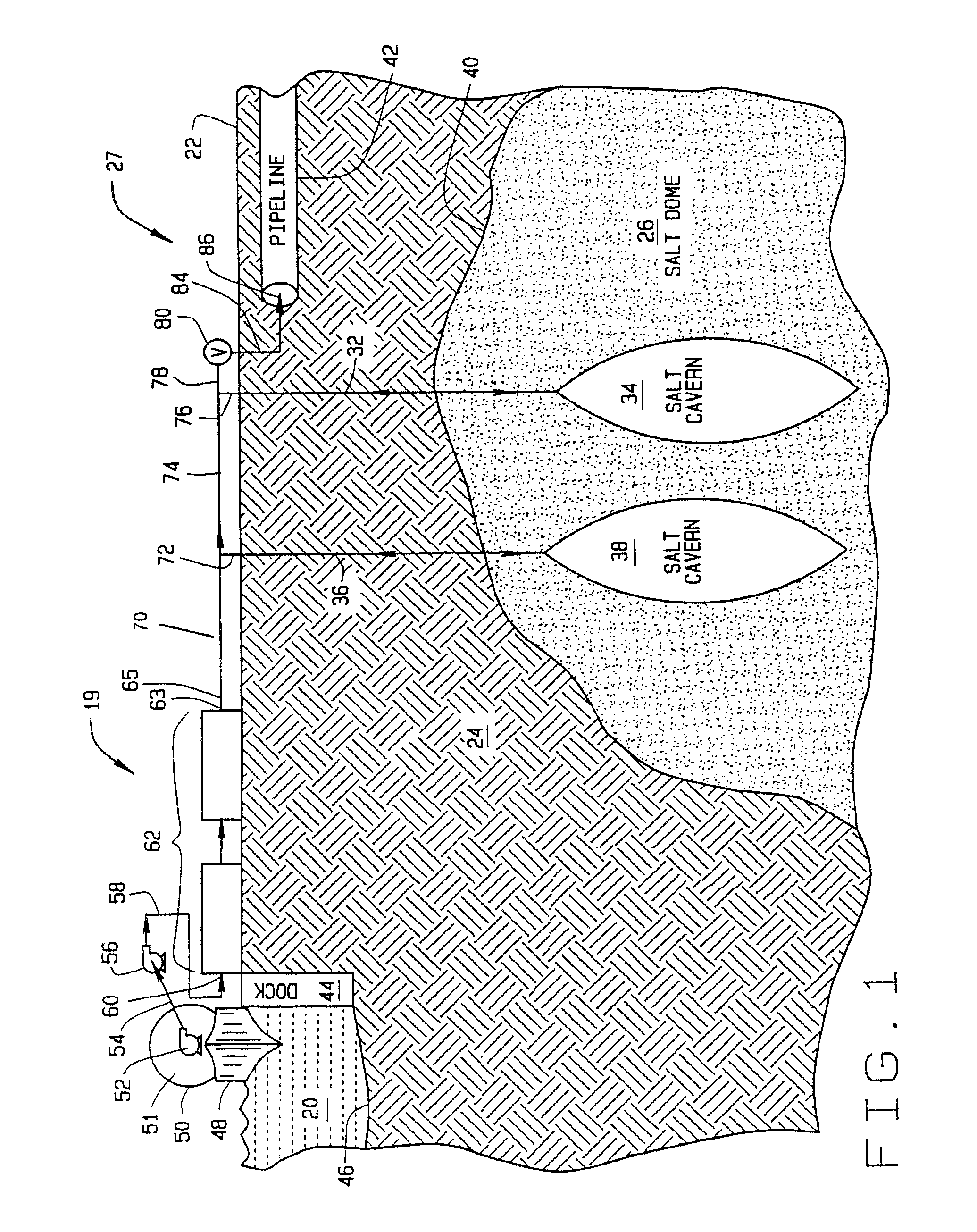

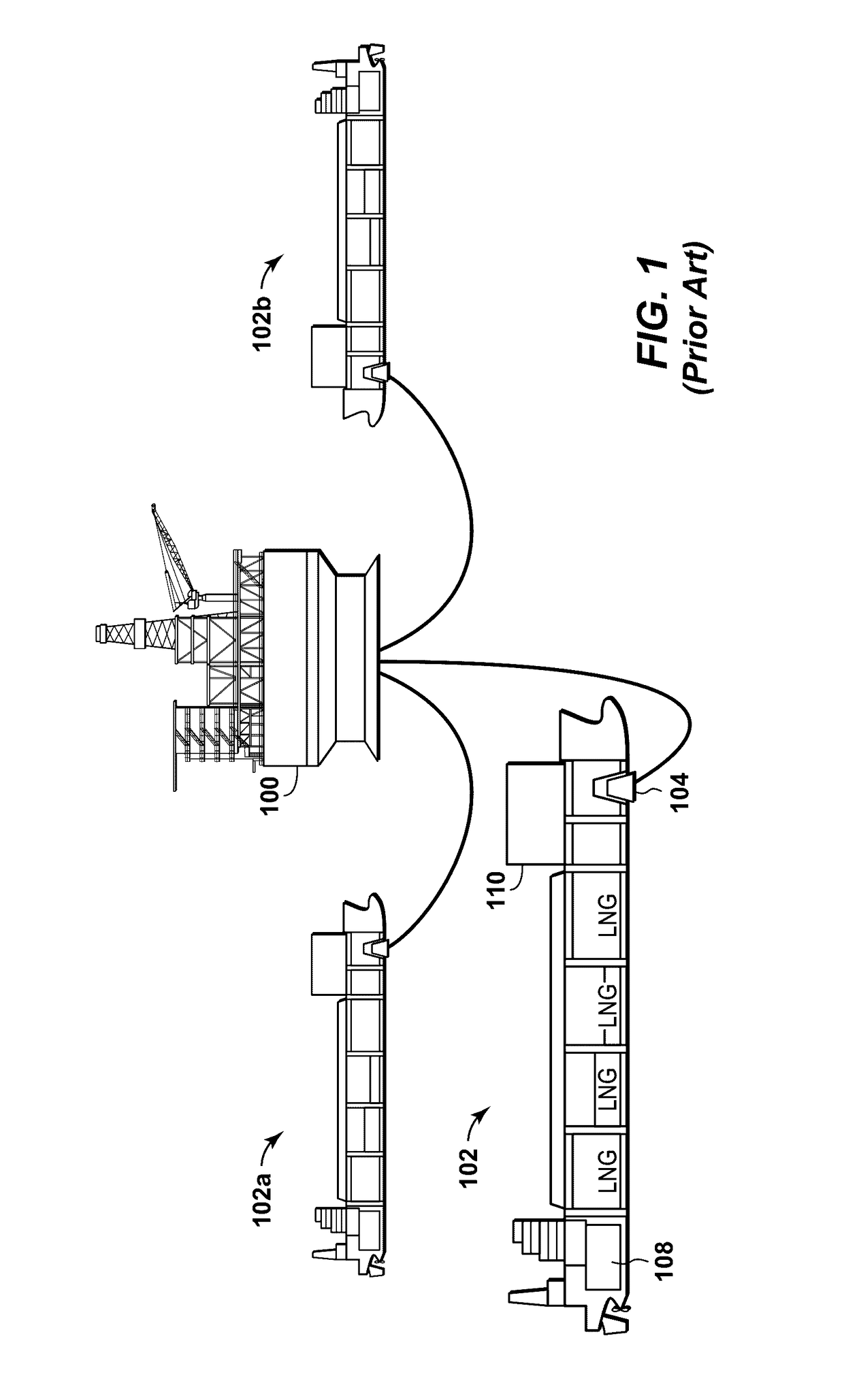

Liquefied natural gas structure

InactiveUS20050115248A1Easy transferProvide protectionGas handling/storage effectsSolid materialMarine engineeringTower

An offshore liquefied natural gas structure may receive, store, and process liquefied natural gas from carriers. A structure may be a gravity base structure. A structure may include a system of ballast storage areas, transfer equipment to offload liquefied natural gas from a carrier, docking equipment to allow direct mooring with carriers, platforms to elevate equipment, water intake systems to provide water to the structure, wave deflectors, and / or projections extending from a bottom of the structure. A portion of the structure may be composed of lightweight concrete. Pipelines may be coupled to the structure to export processed natural gas onshore. Living quarters, flare towers, and export line metering equipment may be included on the structure.

Owner:SHELL OIL CO

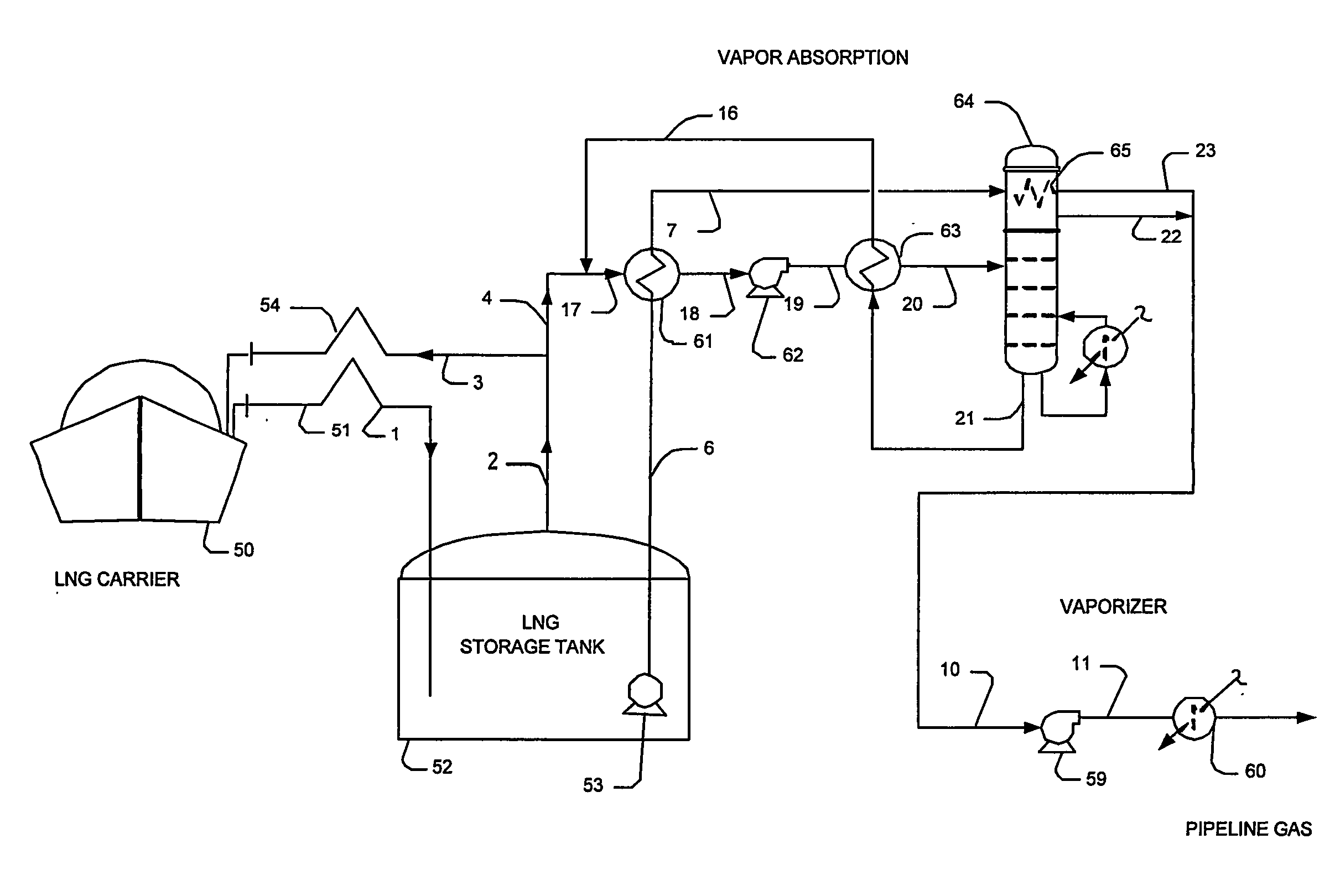

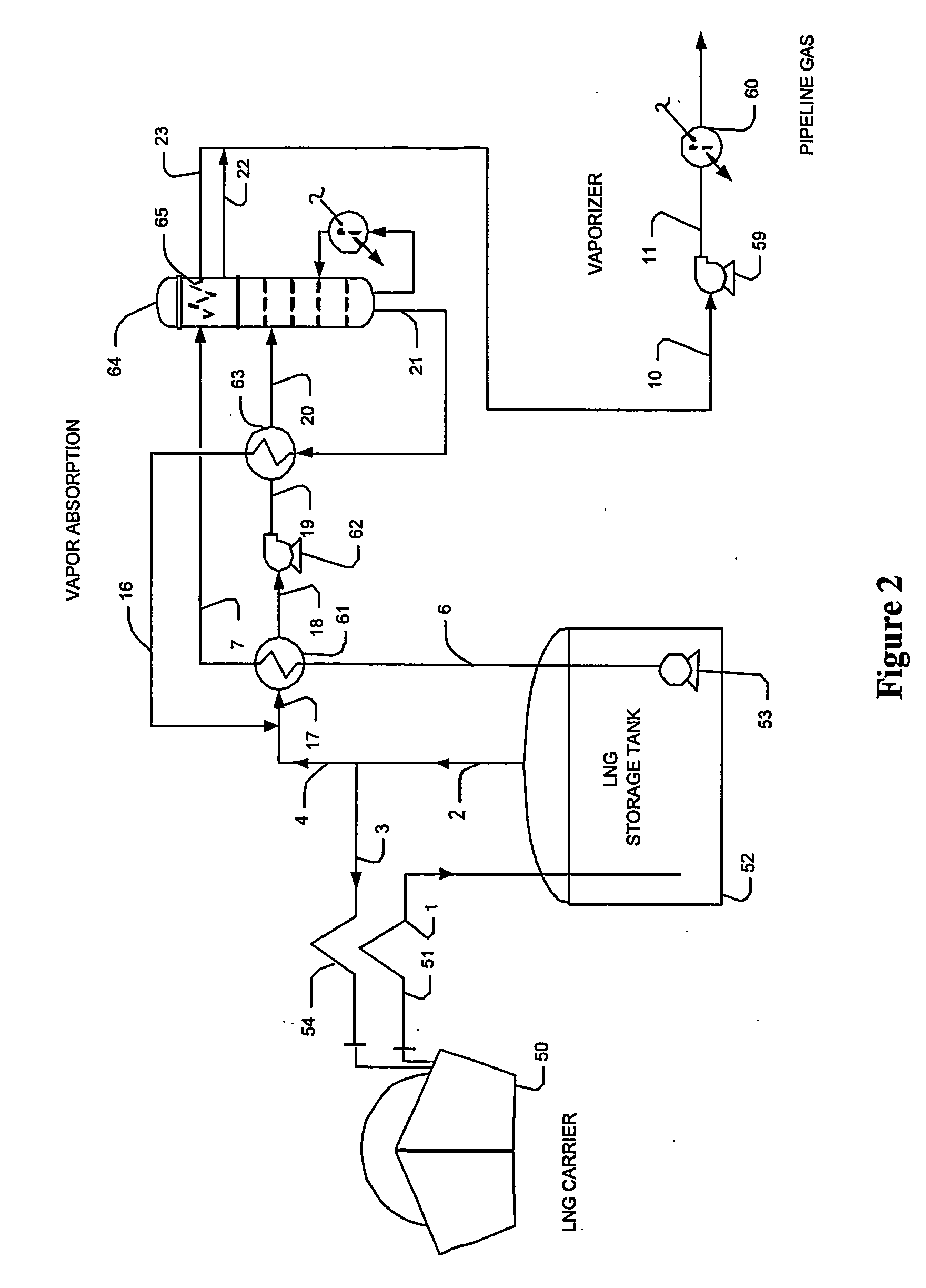

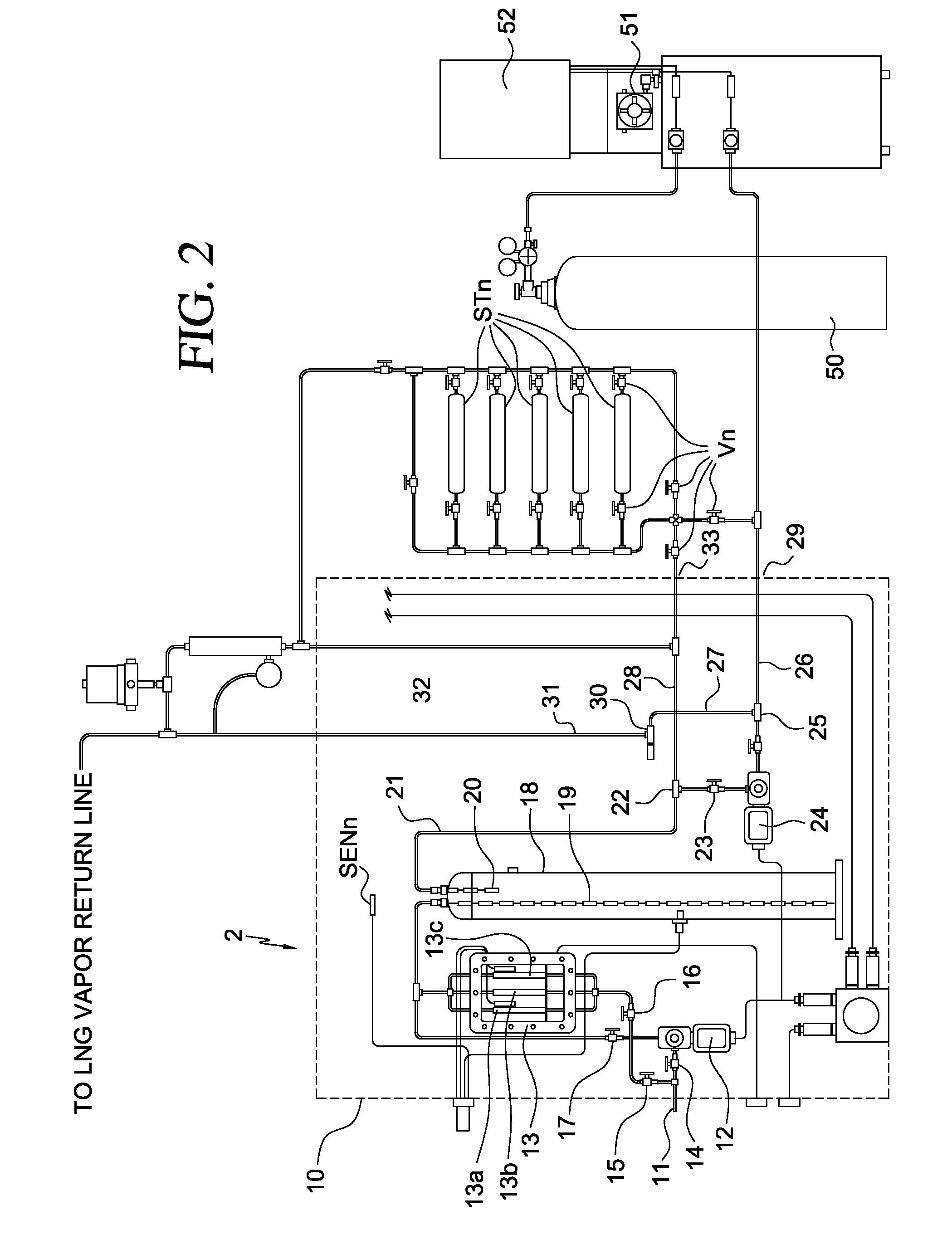

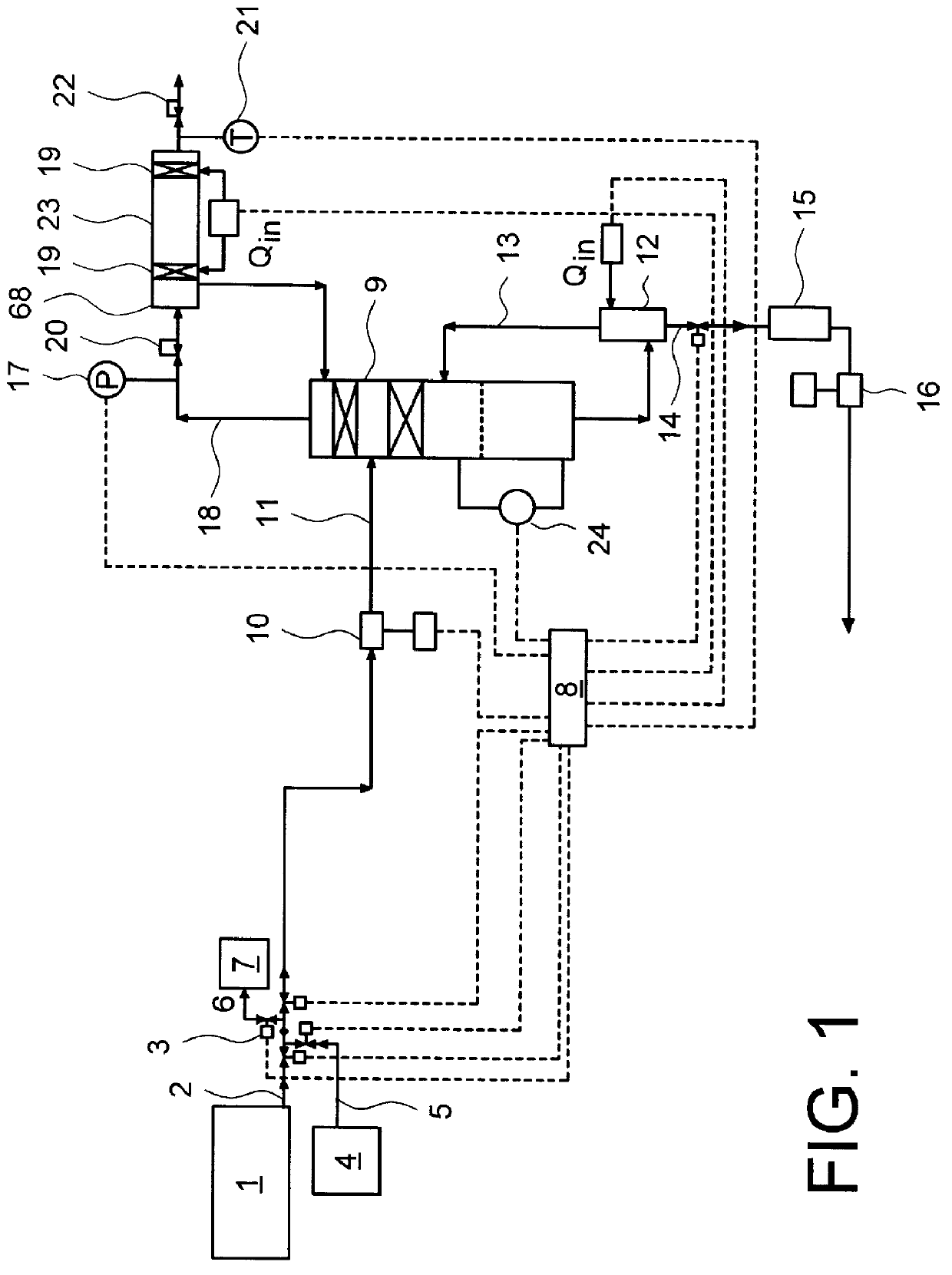

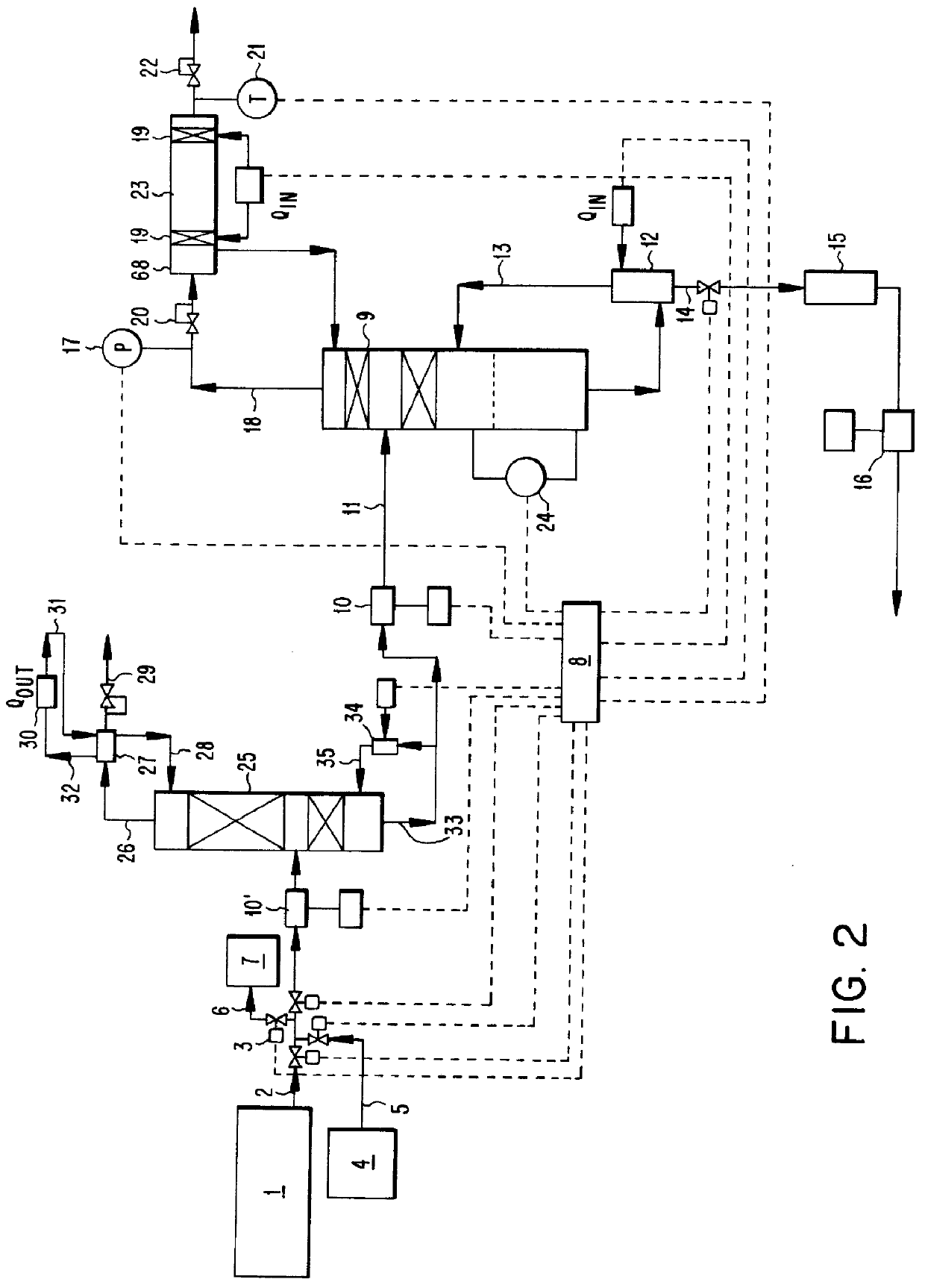

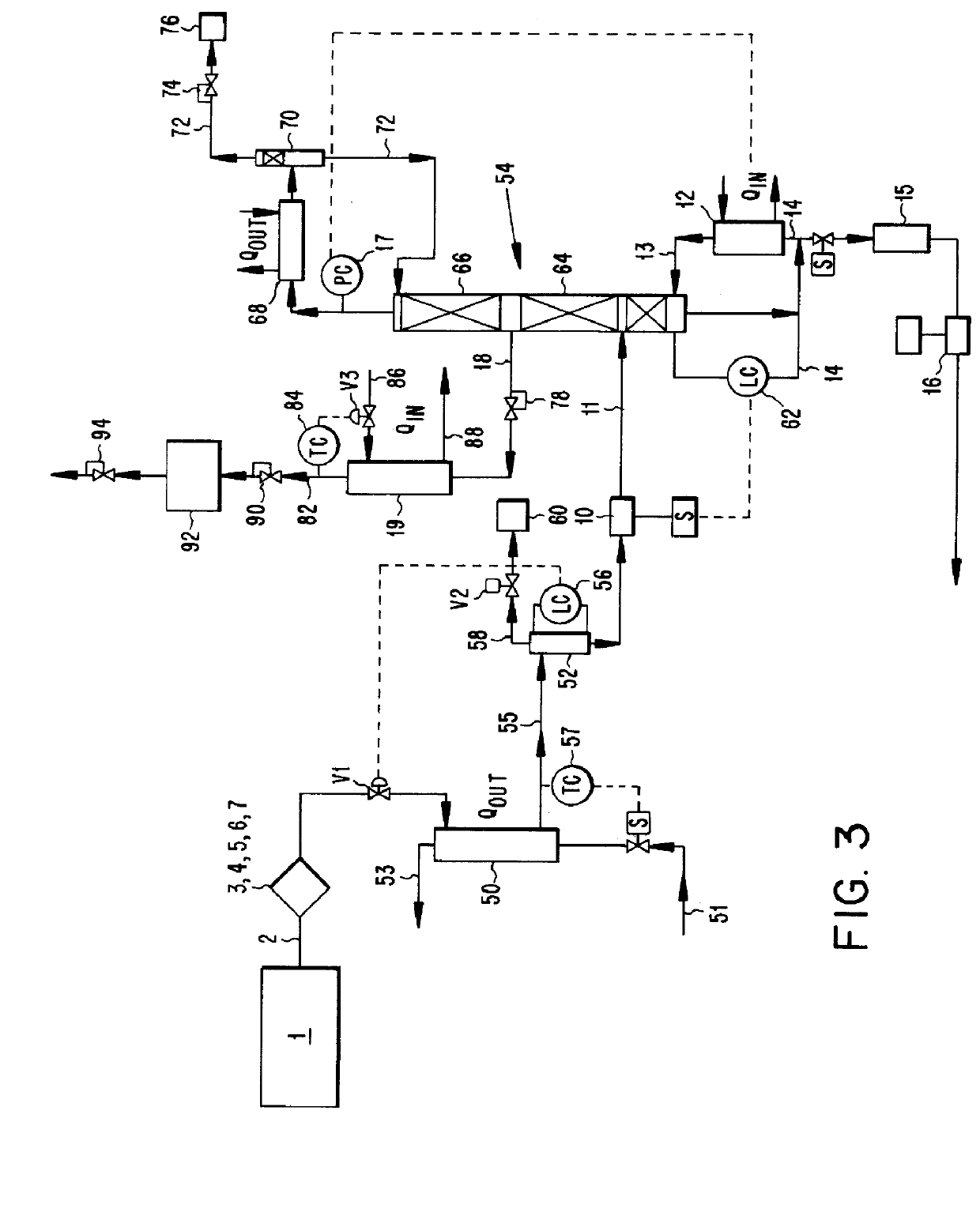

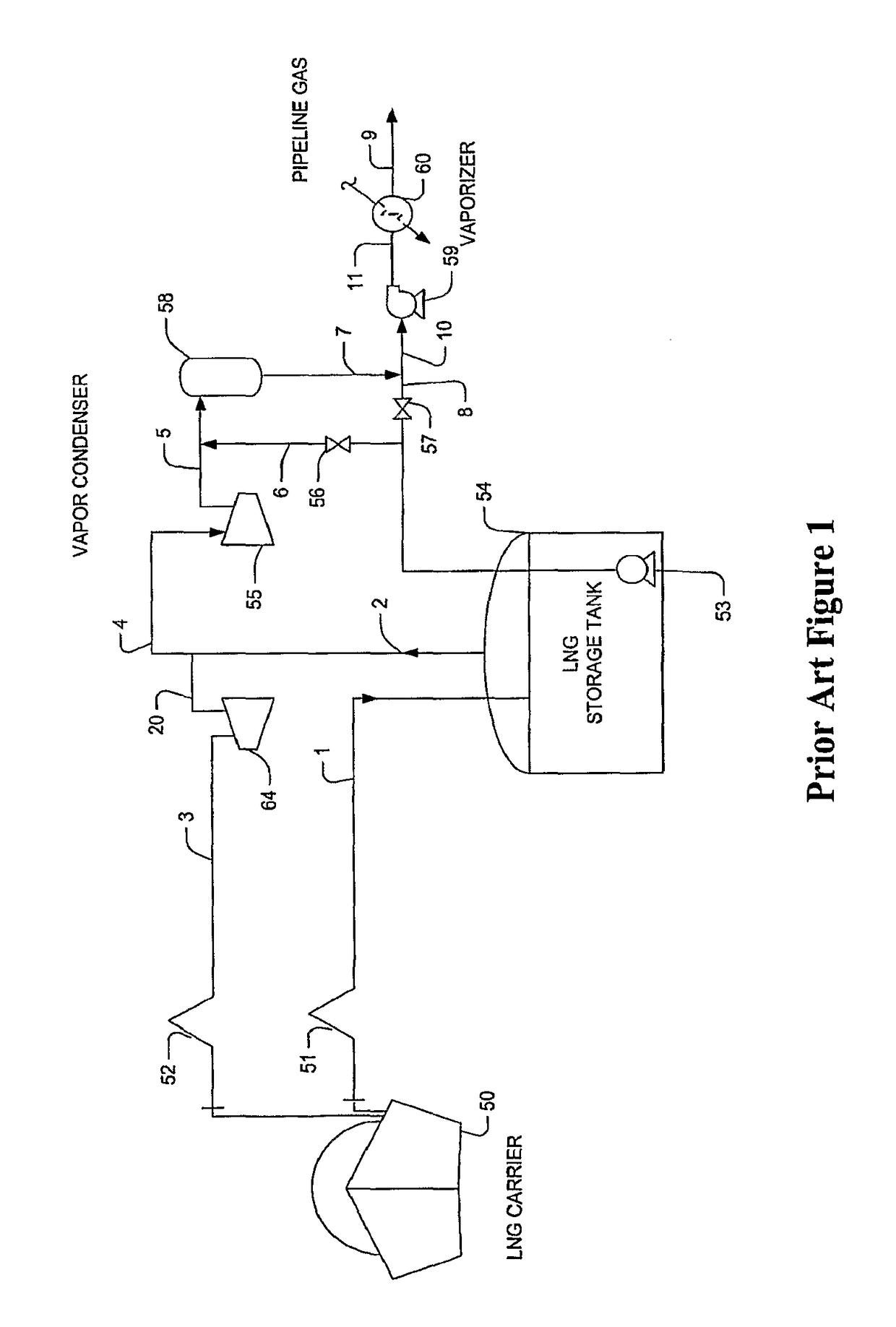

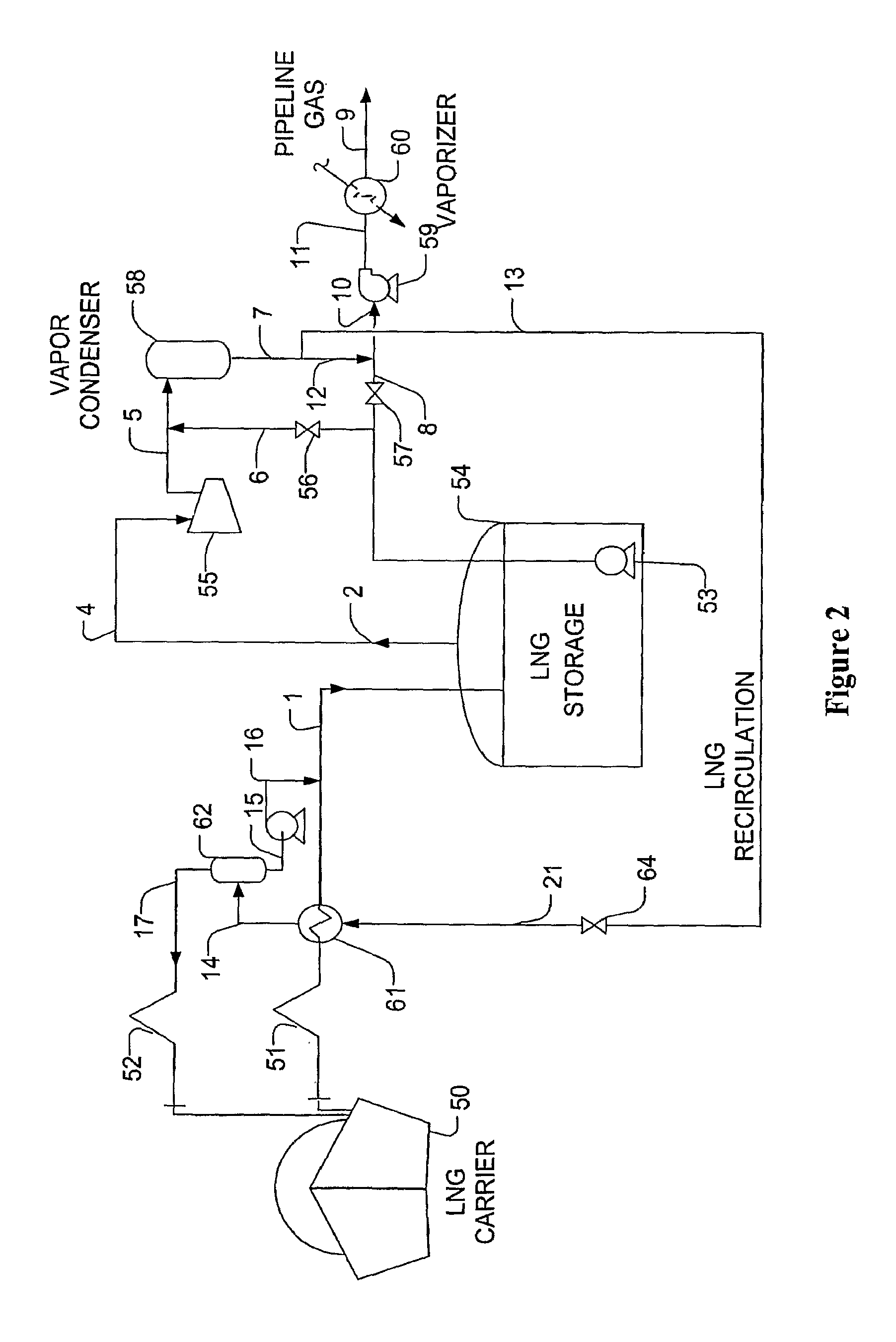

Lng vapor handling configurations and methods

InactiveUS20070125122A1Easy to condenseSolidificationLiquefactionProcess engineeringComponents of crude oil

LNG vapor from an LNG storage vessel is absorbed using C3 and heavier components provided by a fractionator that receives a mixture of LNG vapors and the C3 and heavier components as fractionator feed. In such configurations, refrigeration content of the LNG liquid from the LNG storage vessel is advantageously used to condense the LNG vapor after separation. Where desired, a portion of the LNG liquid may also be used as fractionator feed to produce LPG as a bottom product.

Owner:FLUOR TECH CORP

Container chemical guard

InactiveUS6520218B1Packaging by pressurising/gasifyingSolid materialInterior spaceCompound (substance)

Owner:ENTEGRIS INC

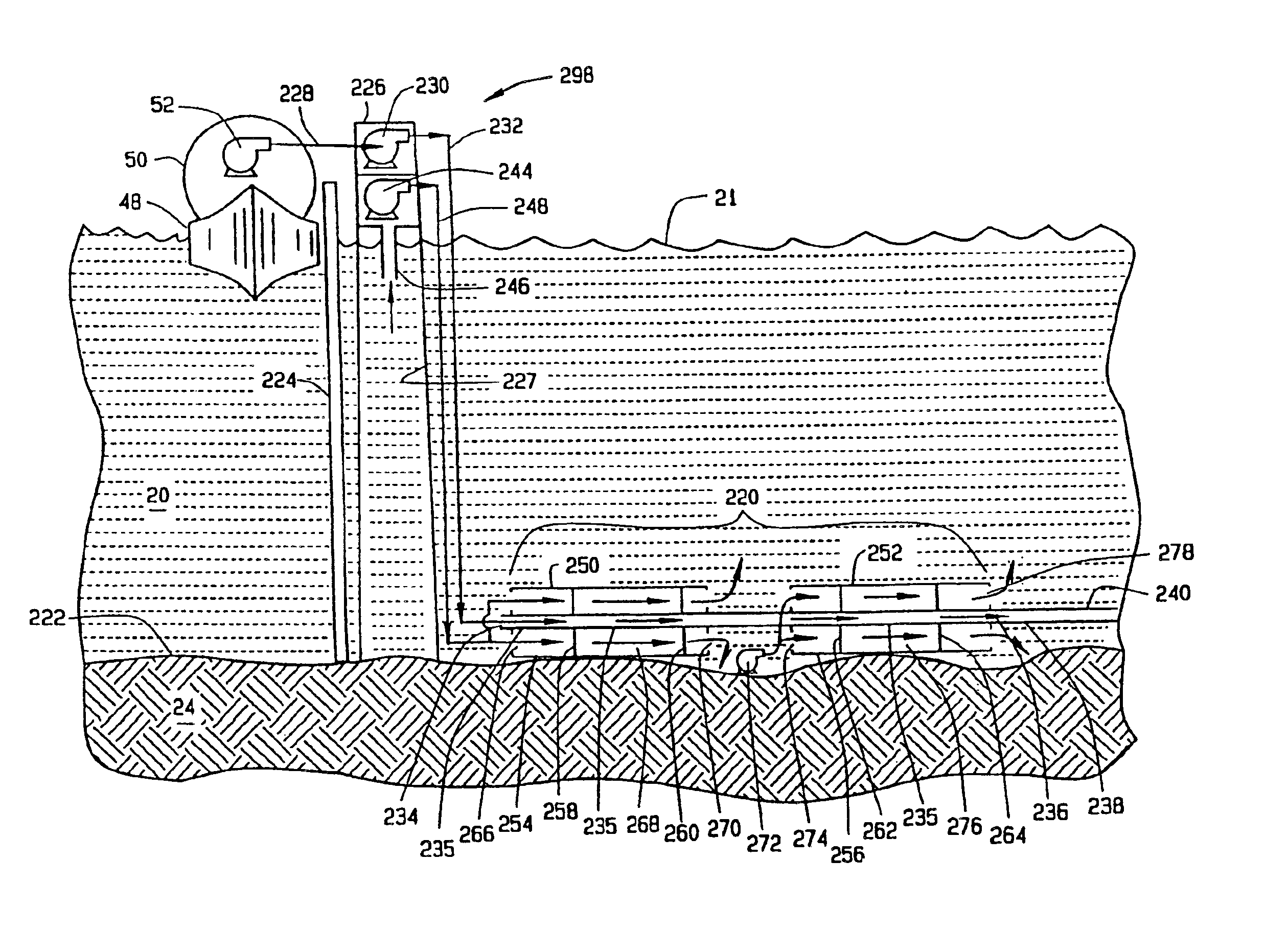

Method and apparatus for warming and storage of cold fluids

InactiveUS6848502B2Gas handling applicationsGas handling/storage effectsProcess engineeringHigh pressure

Stranded natural gas is sometimes liquefied and sent to other countries that can use the gas in a transport ship. Conventional receiving terminals use large cryogenic storage tanks to hold the liquefied natural gas (LNG) after it has been offloaded from the ship. The present invention eliminates the need for the conventional cryogenic storage tanks and instead uses uncompensated salt caverns to store the product. The present invention can use a special heat exchanger, referred to as a Bishop Process heat exchanger, to warm the LNG prior to storage in the salt caverns or the invention can use conventional vaporizing systems some of which may be reinforced and strengthened to accommodate higher operating pressures. In one embodiment, the LNG is pumped to higher pressures and converted to dense phase natural gas prior to being transferred into the heat exchanger and the uncompensated salt caverns.

Owner:CONVERSION GAS IMPORTS

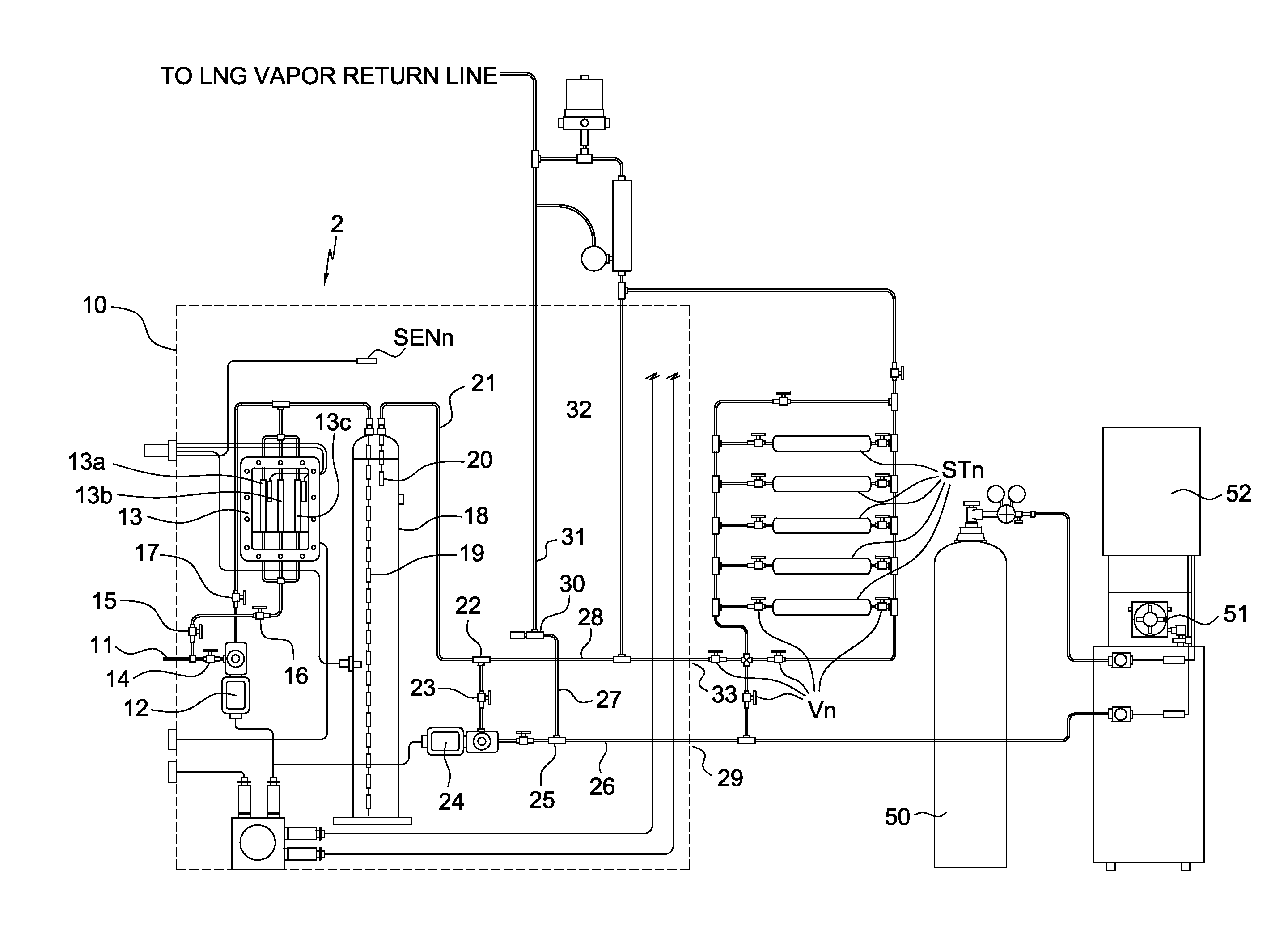

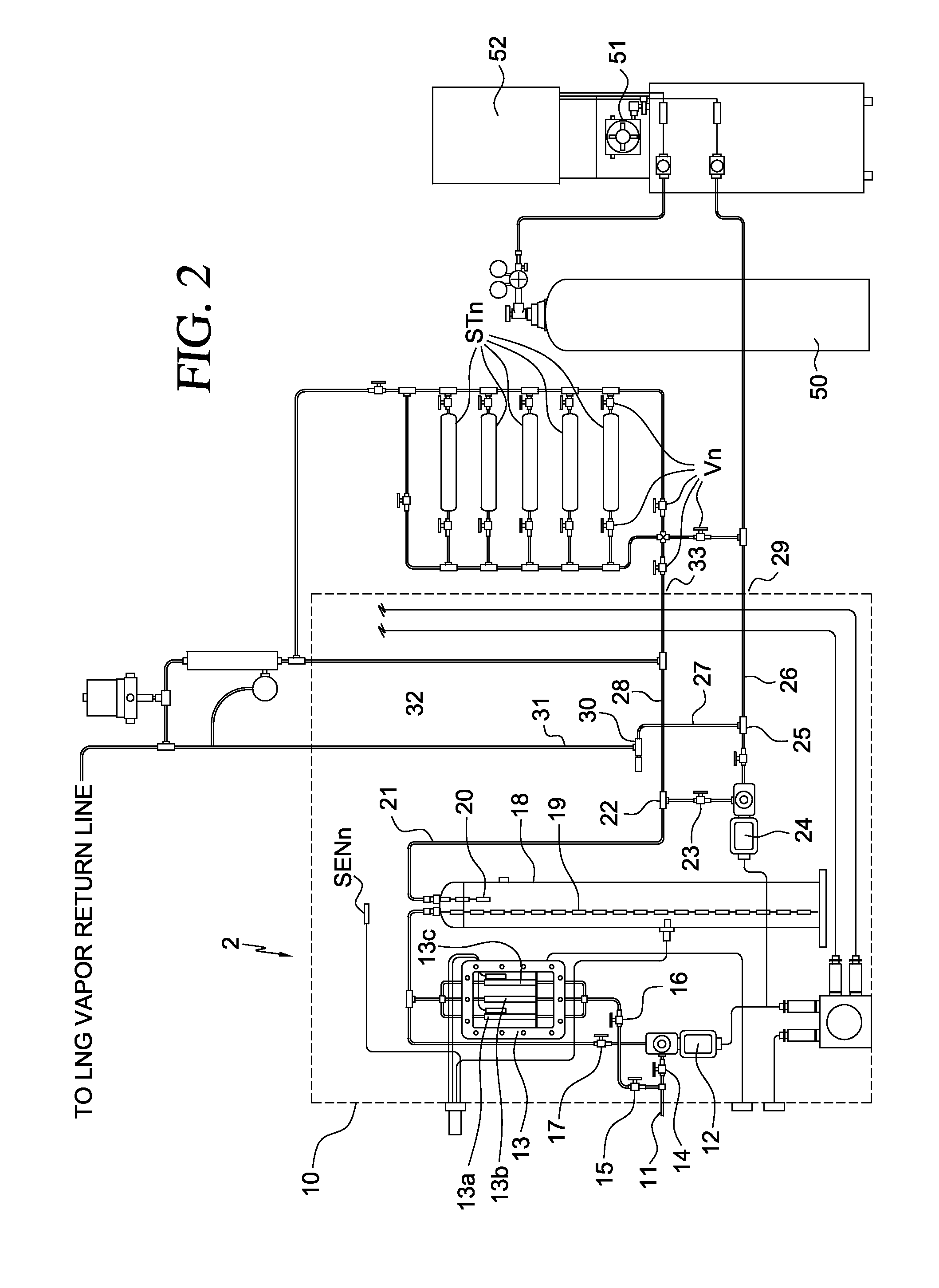

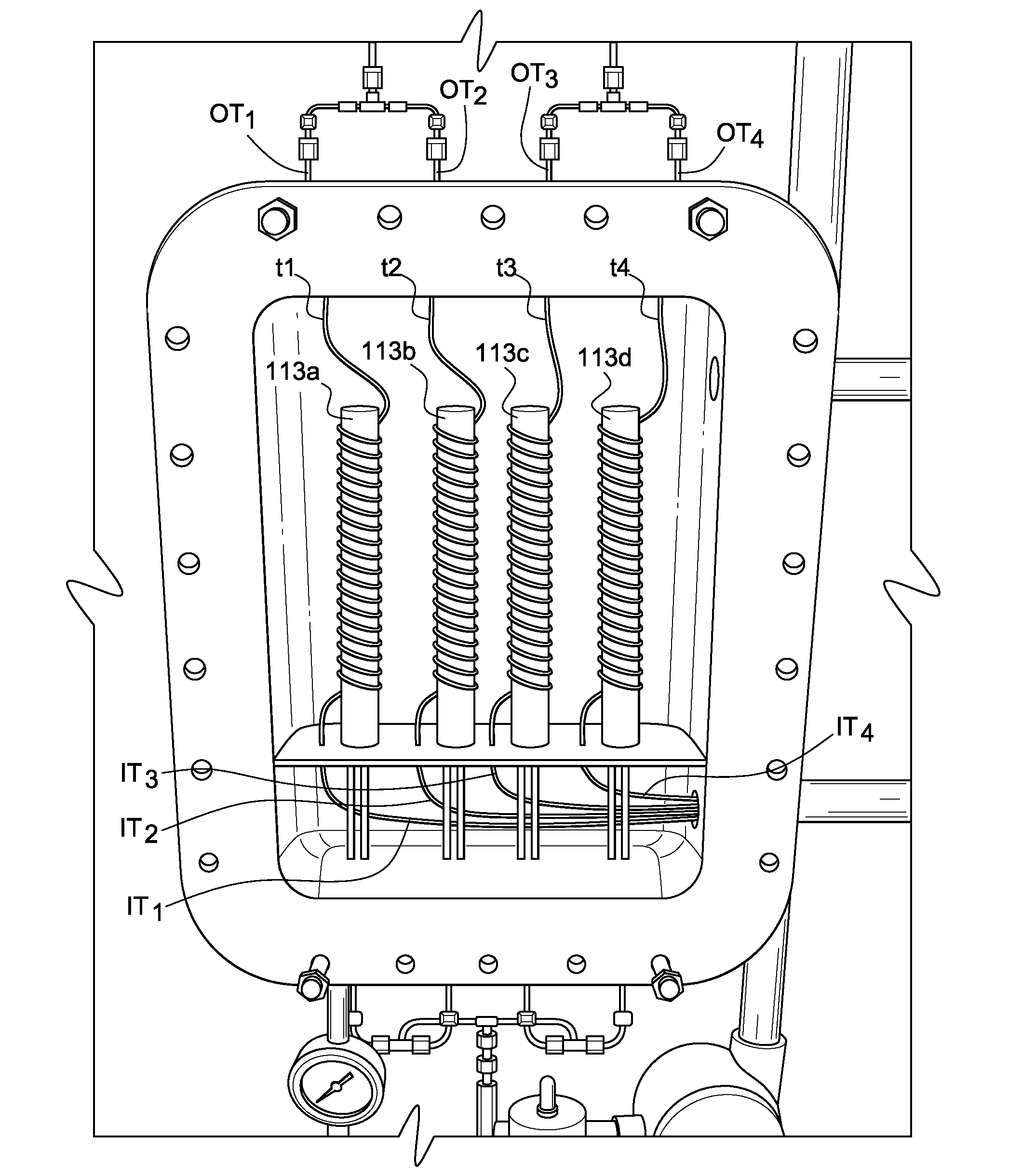

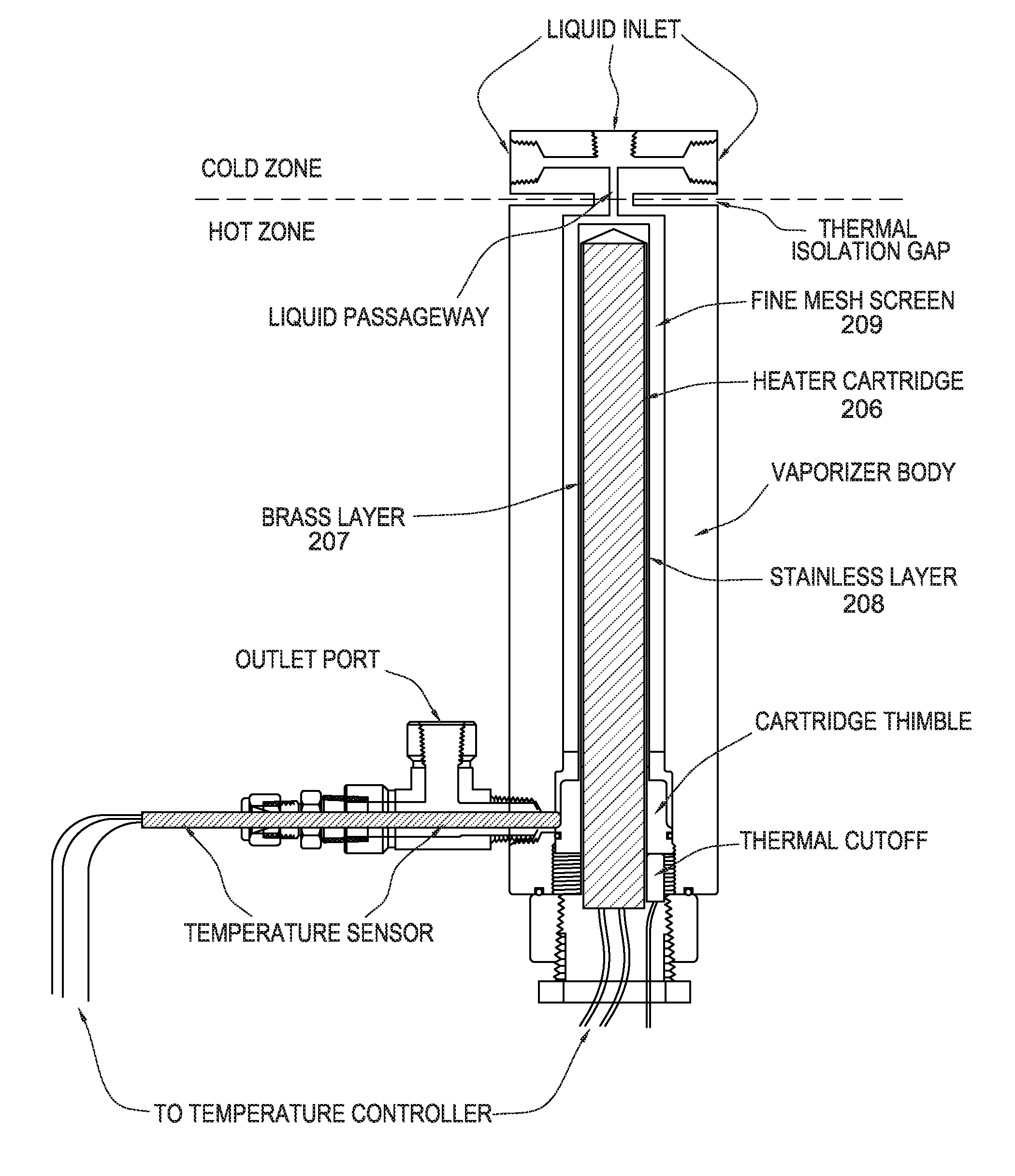

Liquid gas vaporization and measurement system and method

ActiveUS7484404B2Efficiently and accurately sampling and measuringEfficiently flash vaporizeComponent separationGas handling applicationsMass storageMeasuring instrument

A liquid gas vaporization and measurement system, and associated method, for efficiently vaporizing a continuous sample of liquid gas, such as liquid natural gas (LNG), and accurately determining the constituent components of the gas. A constant flow of liquid gas sampled from a mass storage device is maintained in a vaporizing device. Within the vaporizing device the liquid gas is flash vaporized within heated narrow tubing. The liquid gas is converted to vapor very quickly as it enters one or more independently operating vaporizer stages within the vaporizing device. The vapor gas is provided to a measuring instrument such as a chromatograph and the individual constituent components and the BTU value of the gas are determined to an accuracy of within + / −0.5 mole percent and 1 BTU, respectively.

Owner:MUSTANG SAMPLING

Liquid Gas Vaporization and Measurement System and Method

ActiveUS20090151427A1Efficiently flash vaporizeEfficiently and accurately sampling and measuringSpace heating and ventilationGas handling applicationsMass storageMeasuring instrument

A liquid gas vaporization and measurement system, and associated method, for efficiently vaporizing a continuous sample of liquid gas, such as liquid natural gas (LNG), and accurately determining the constituent components of the gas. A constant flow of liquid gas sampled from a mass storage device is maintained in a vaporizing device. Within the vaporizing device the liquid gas is flash vaporized within heated narrow tubing. The liquid gas is converted to vapor very quickly as it enters one or more independently operating vaporizer stages within the vaporizing device. The vapor gas is provided to a measuring instrument such as a chromatograph and the individual constituent components and the BTU value of the gas are determined to an accuracy of within + / −0.5 mole percent and 1 BTU, respectively.

Owner:MUSTANG SAMPLING

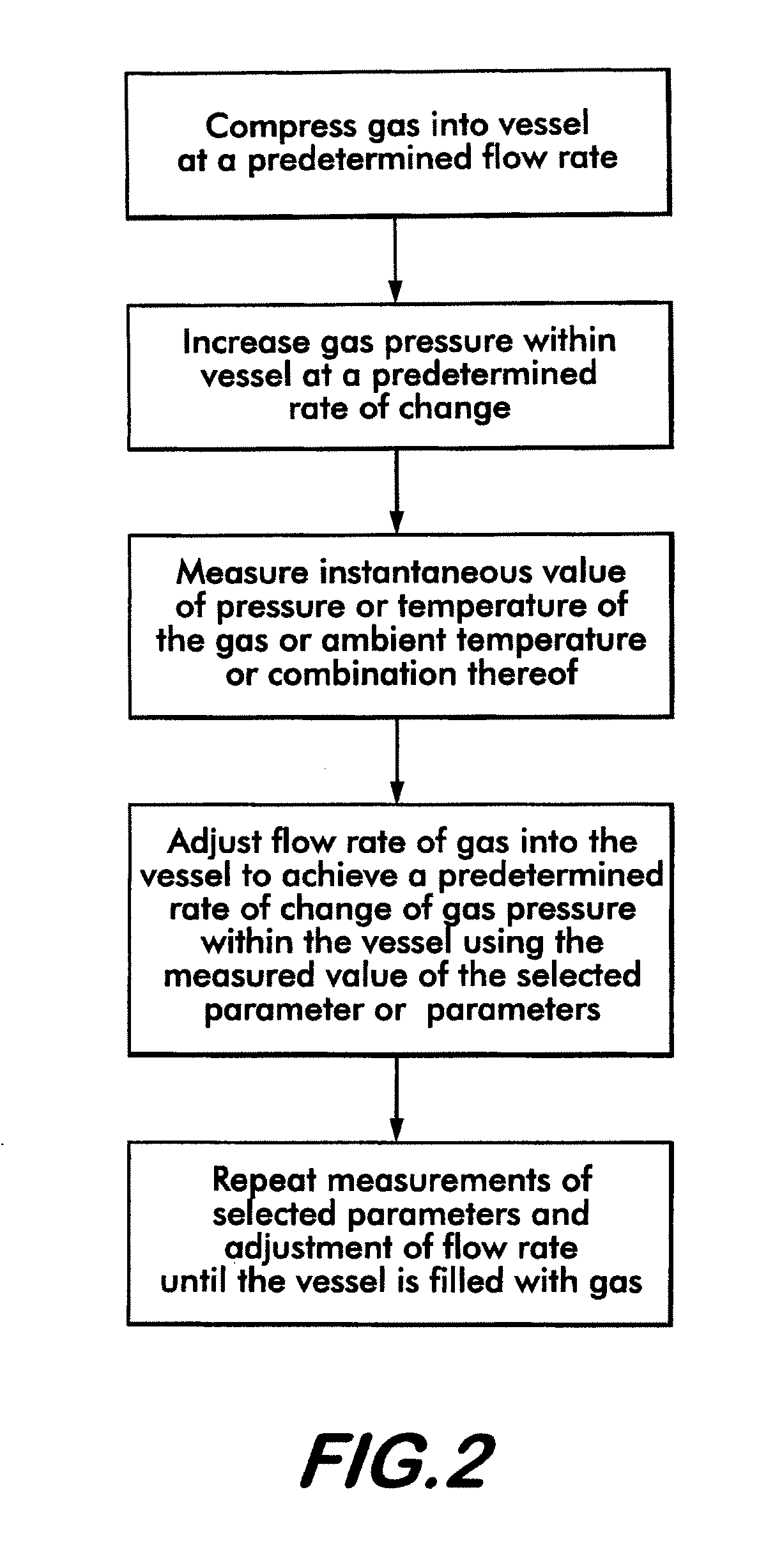

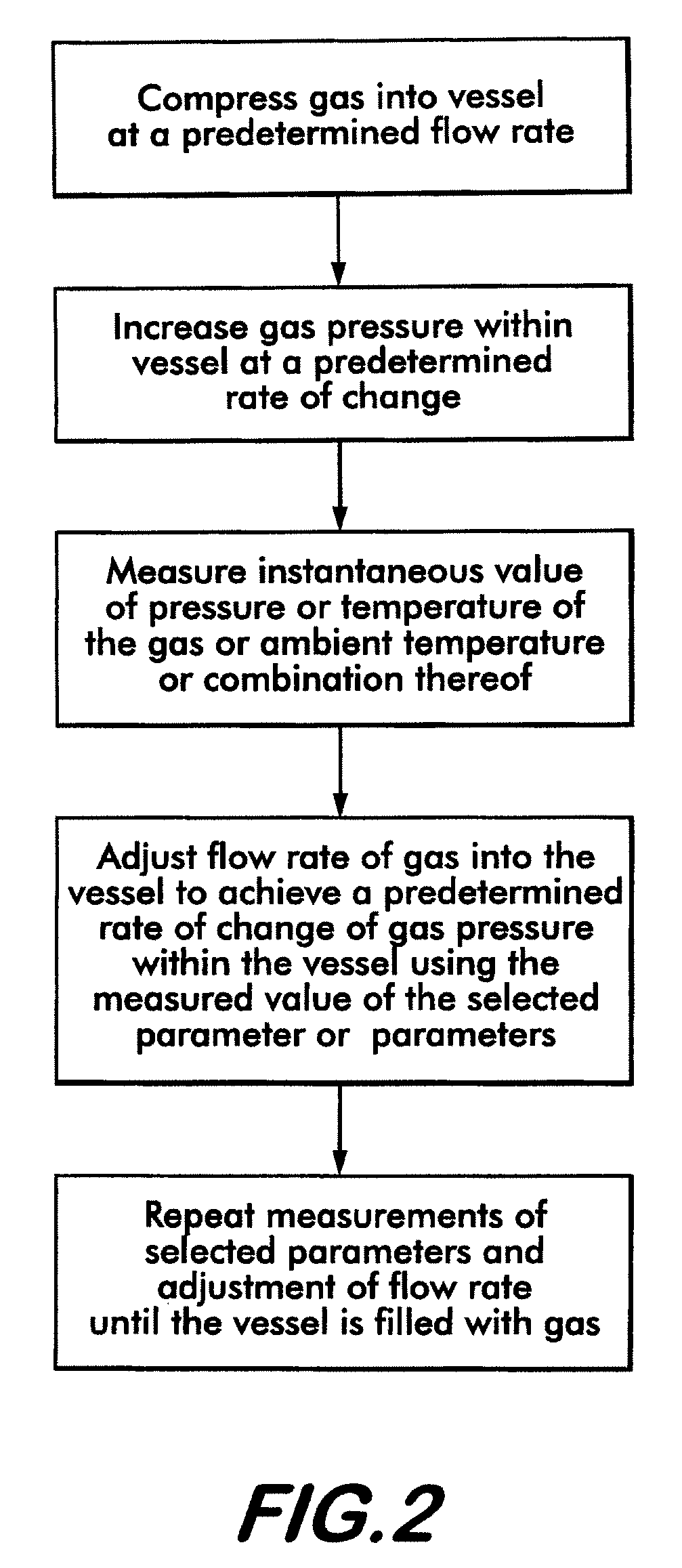

Compressor Fill Method And Apparatus

A method an apparatus for filling a vessel with compressed gas is disclosed. Gas is compressed into the vessel at a predetermined flow rate using a variable speed pump or compressor. The flow rate is adjusted to increase the gas pressure at a predetermined rate of change. The flow rate is adjusted based upon the instantaneous value of a measured parameter such as gas temperature or pressure or ambient temperature. The parameter is measured by a transducer and the value is fed back to a controller which adjusts the speed of the compressor or pump to produce the flow rate needed to achieve the predetermined pressure rate of change.

Owner:AIR PROD & CHEM INC

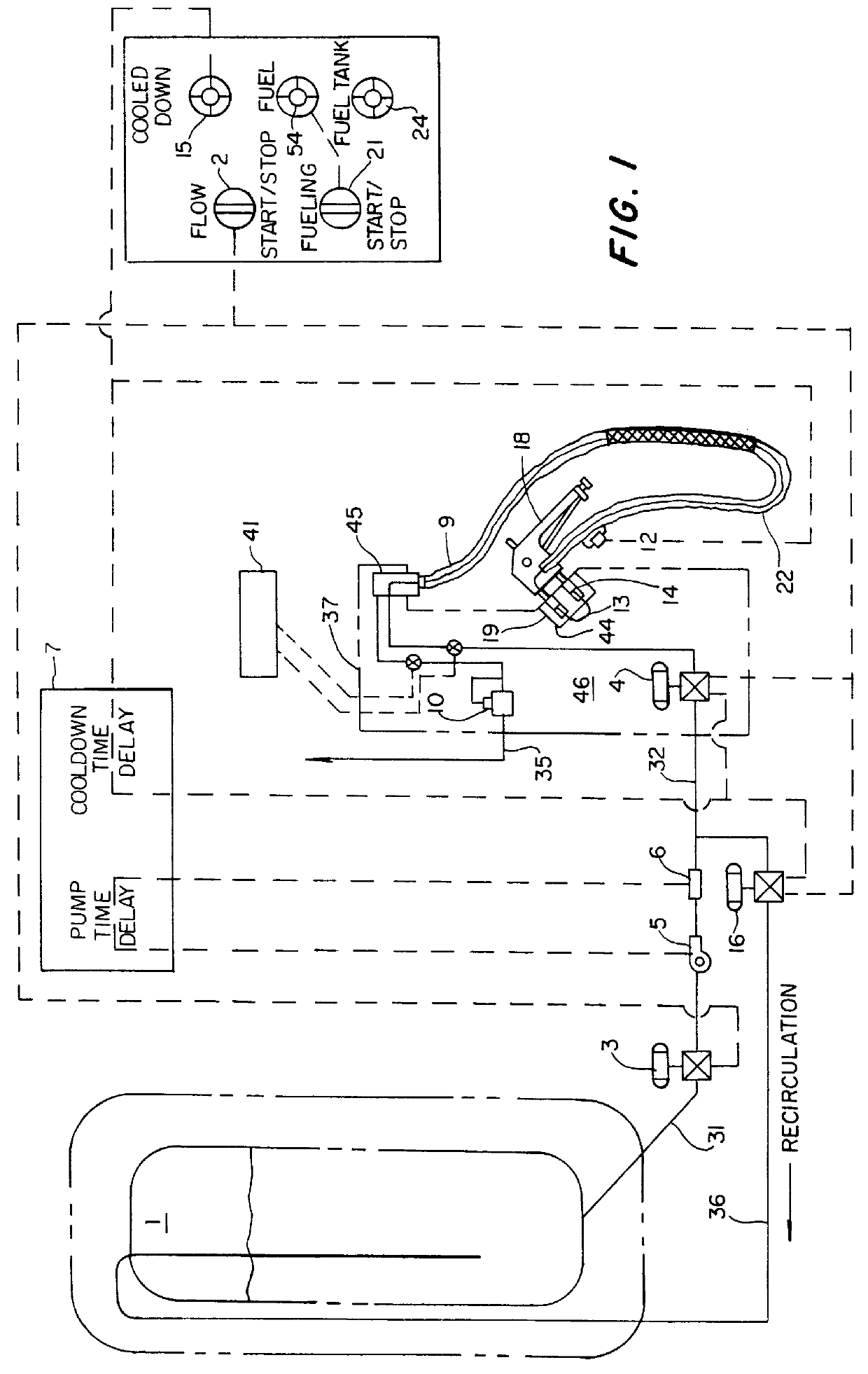

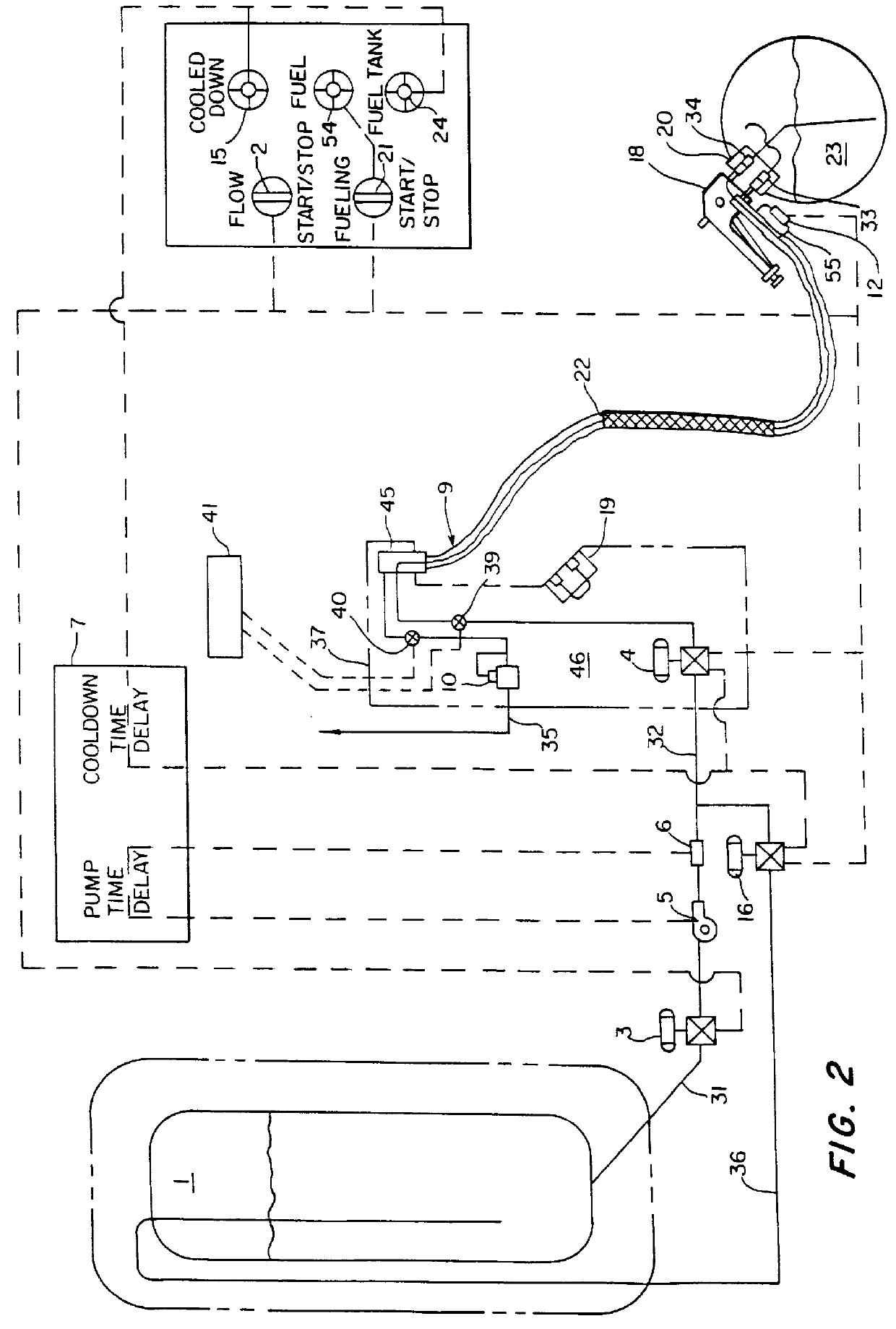

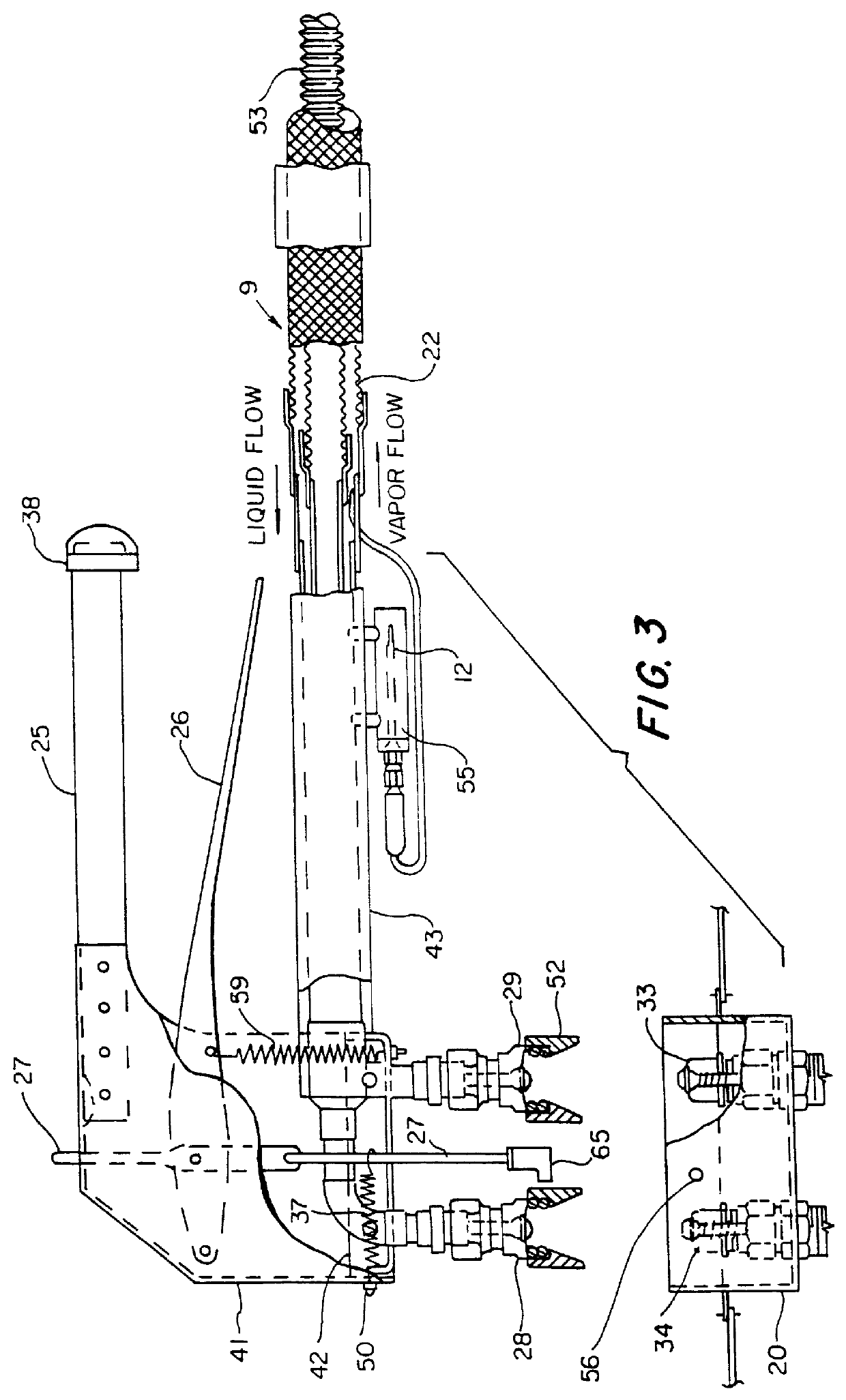

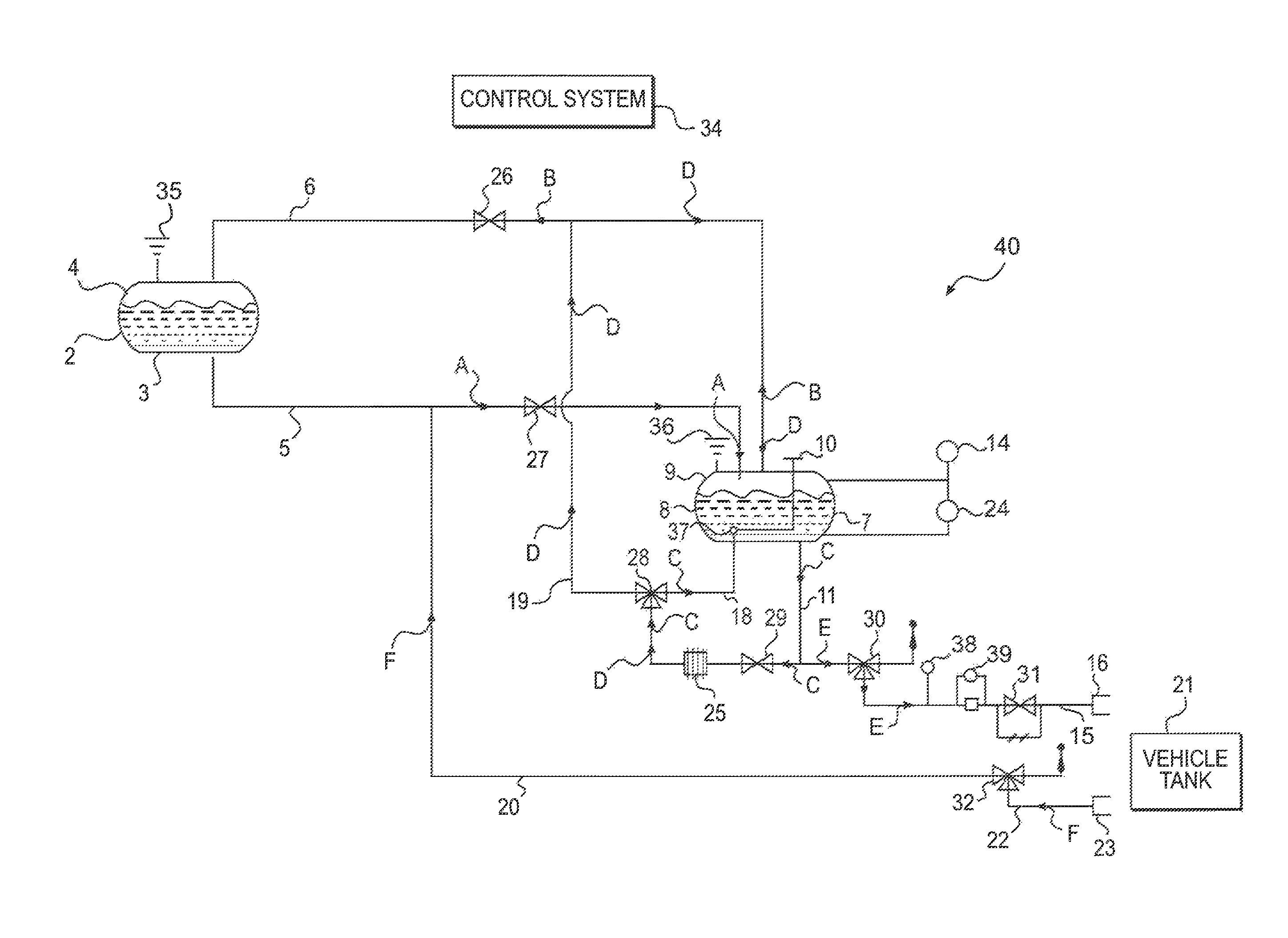

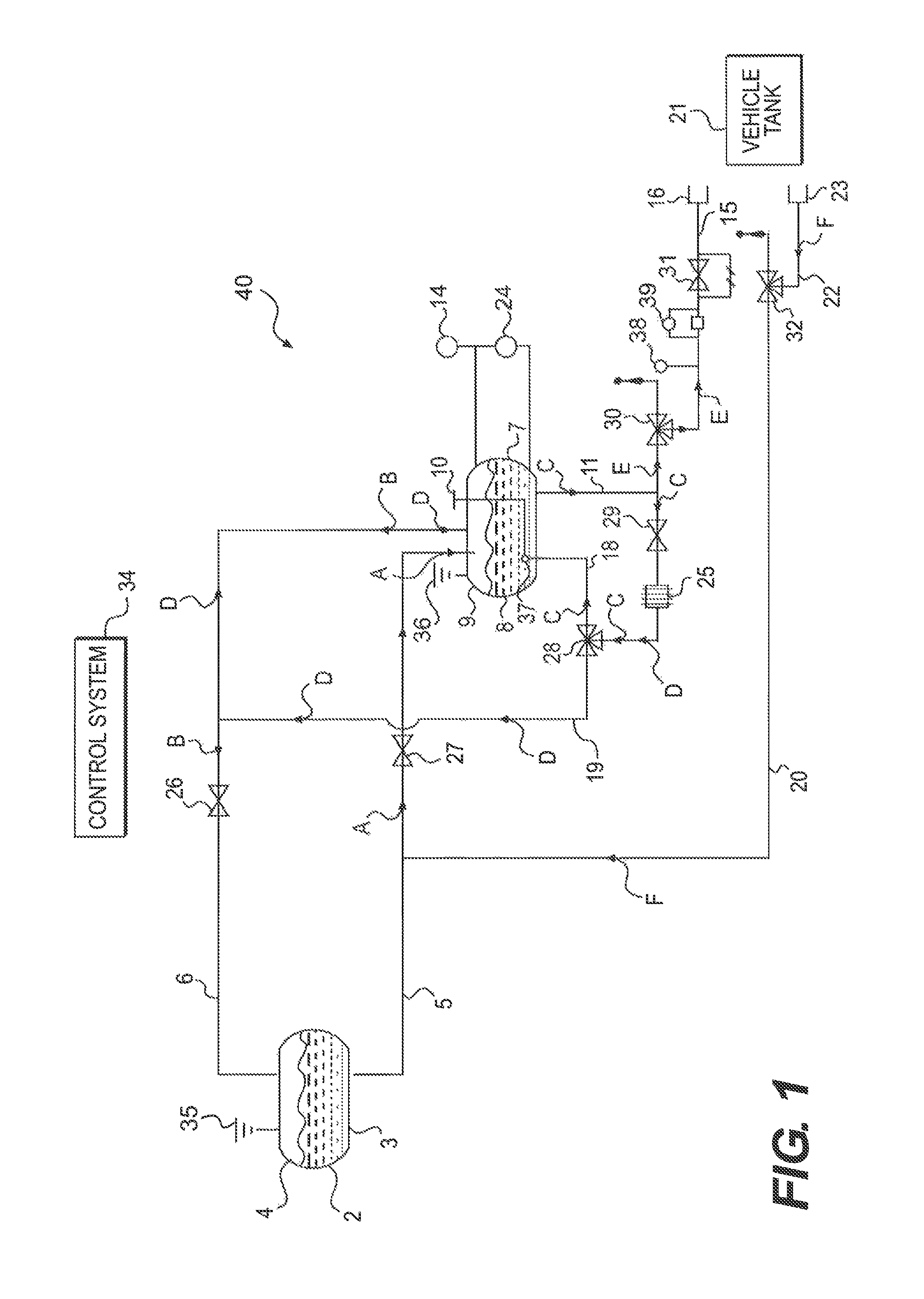

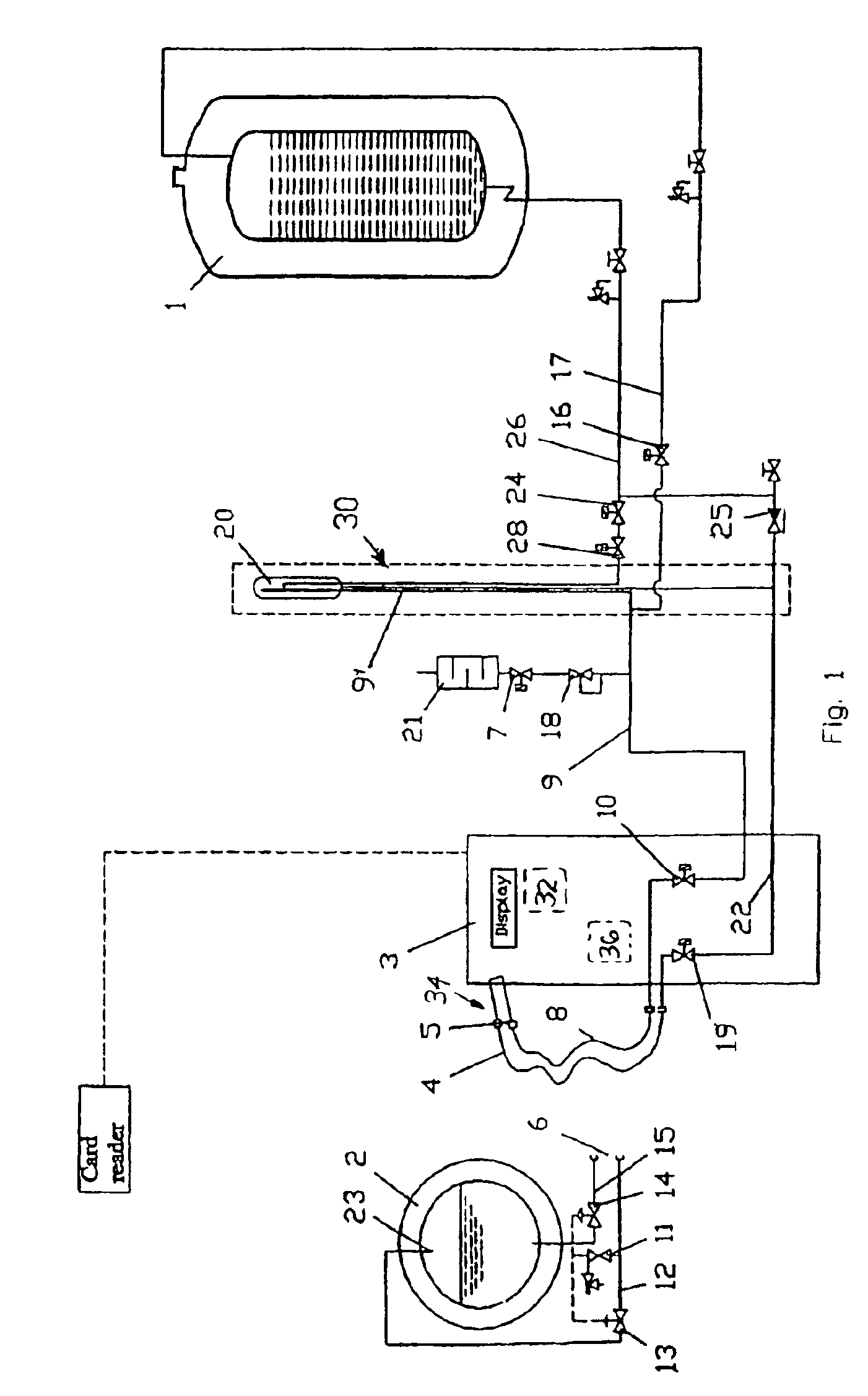

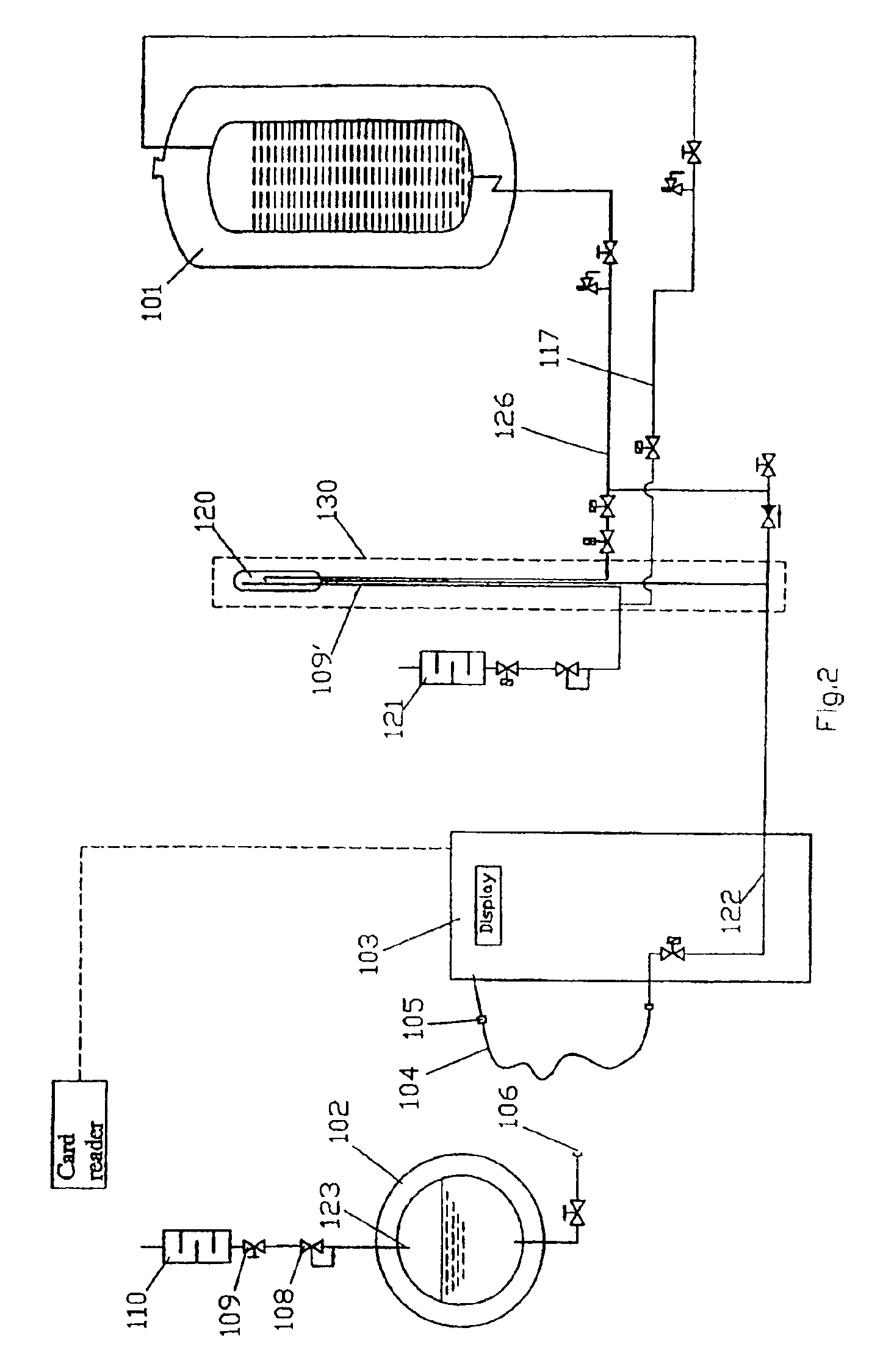

Apparatus and method of metering and transfer of cryogenic liquids

InactiveUS6142191AReliable transmissionDiscomfort and injuryGas handling applicationsGas handling/storage effectsMotor driveTime delays

An apparatus and method for efficiently metering and transferring a cryogenic liquid, such as liquefied natural gas, from a storage vessel to, for example, a vehicle fuel tank. The apparatus incorporates a programmable controller, a motor-driven pump and a network of conduits with motor-operated valves and liquid sensors for effecting a priming of the pump with liquid free of vapor and a cool-down of the flow passages prior to a transfer operation for ensuring that a vapor-free liquid is delivered. A pair of flow meters, one for liquid and the other for returned vapor, allows a reliable determination of the amount of liquid delivered to-and remaining in-a receiving vessel. The apparatus employs a delivery nozzle with quick-disconnect valved fittings and a delivery nozzle incorporating features which allow it to be handled by an operator without the use of heavy gloves. The method of transferring a cryogenic liquid employs an operating sequence with programmed time delays for ensuring that the liquid pump is properly primed and that the transfer apparatus is cooled down before liquid transfer begins.

Owner:CRYOGENIC FUELS

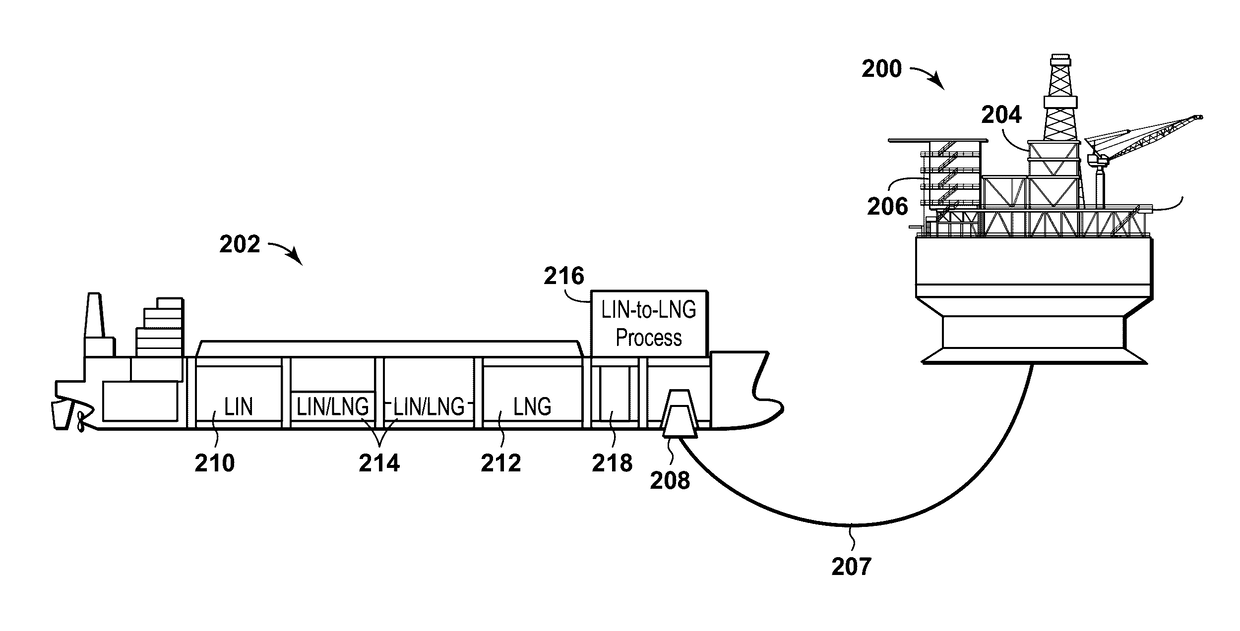

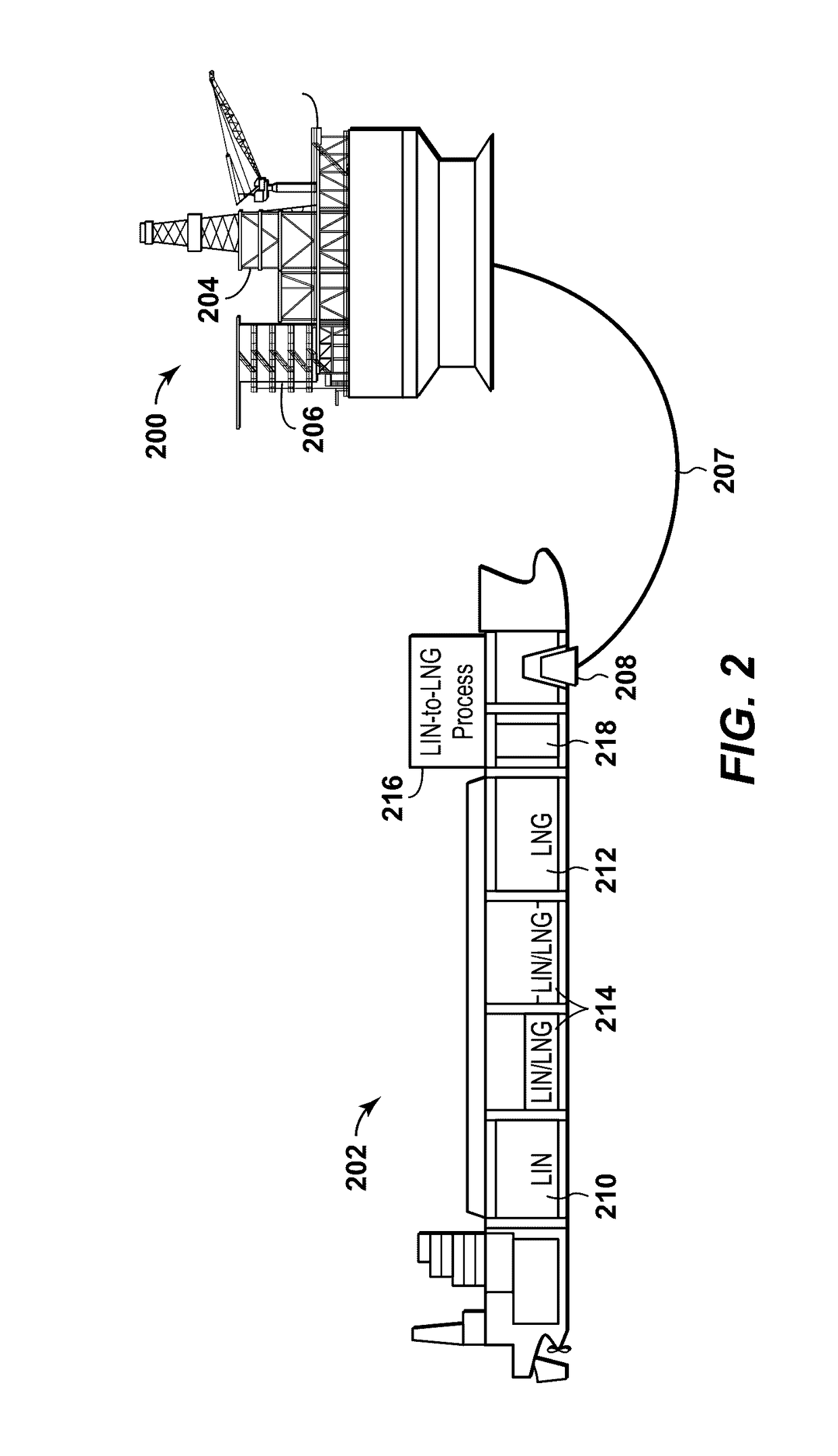

Method of Natural Gas Liquefaction on LNG Carriers Storing Liquid Nitrogen

A method for producing liquefied natural gas (LNG). A natural gas stream is transported to a liquefaction vessel. The natural gas stream is liquefied on the liquefaction vessel using at least one heat exchanger that exchanges heat between the natural gas stream and a liquid nitrogen stream to at least partially vaporize the liquefied nitrogen stream, thereby forming a warmed nitrogen gas stream and an at least partially condensed natural gas stream comprising LNG. The liquefaction vessel includes at least one tank that only stores liquid nitrogen and at least one tank that only stores LNG.

Owner:EXXONMOBIL UPSTREAM RES CO

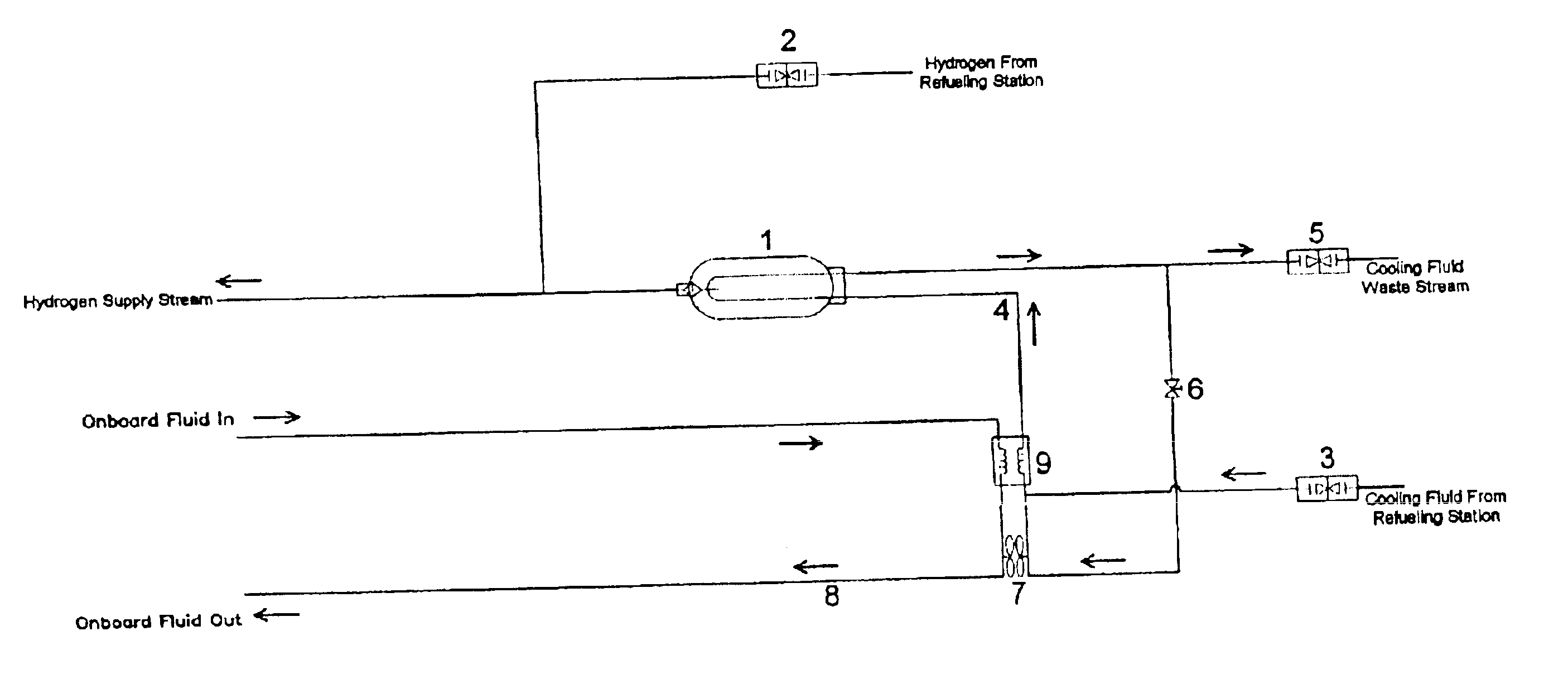

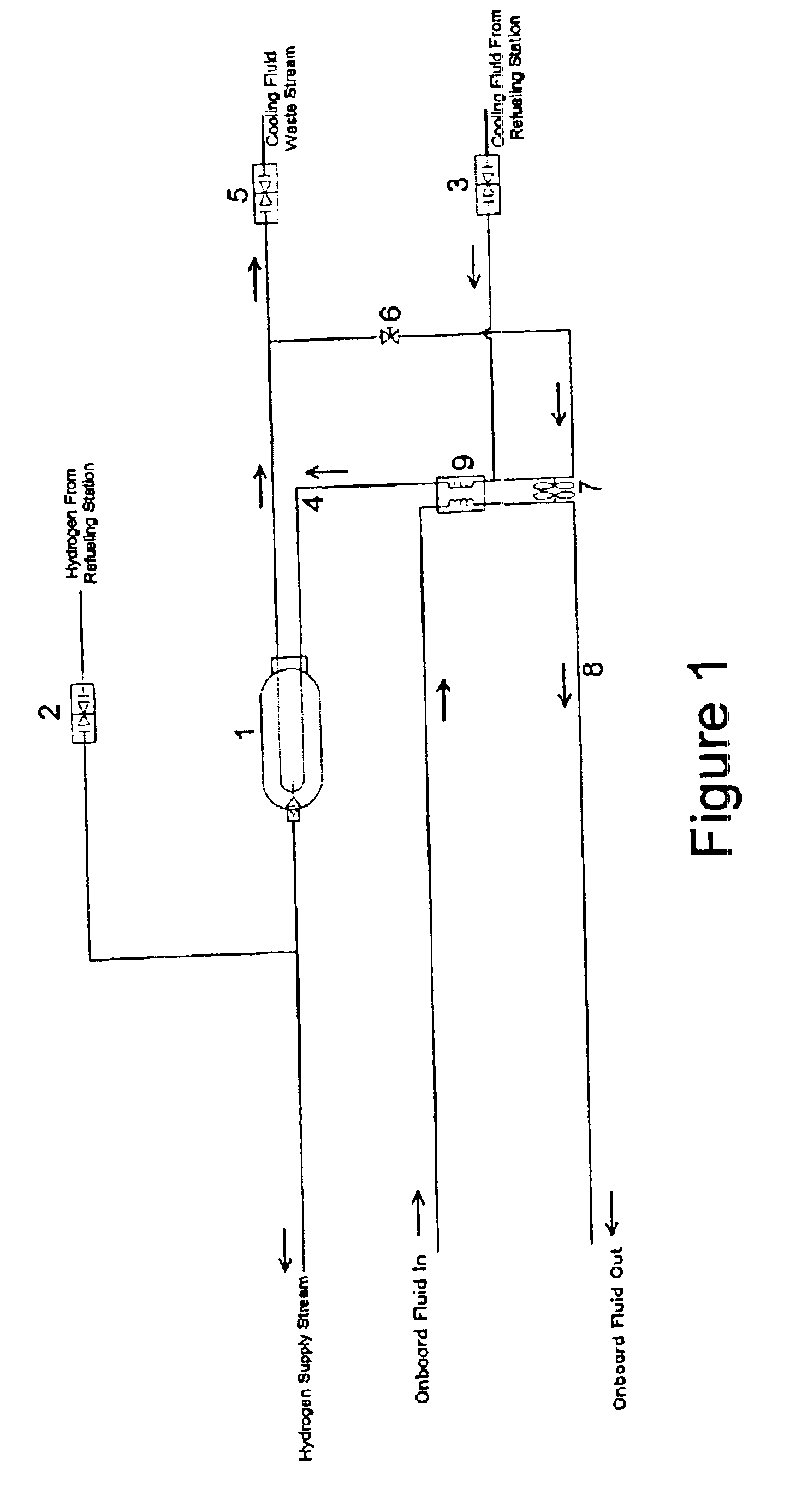

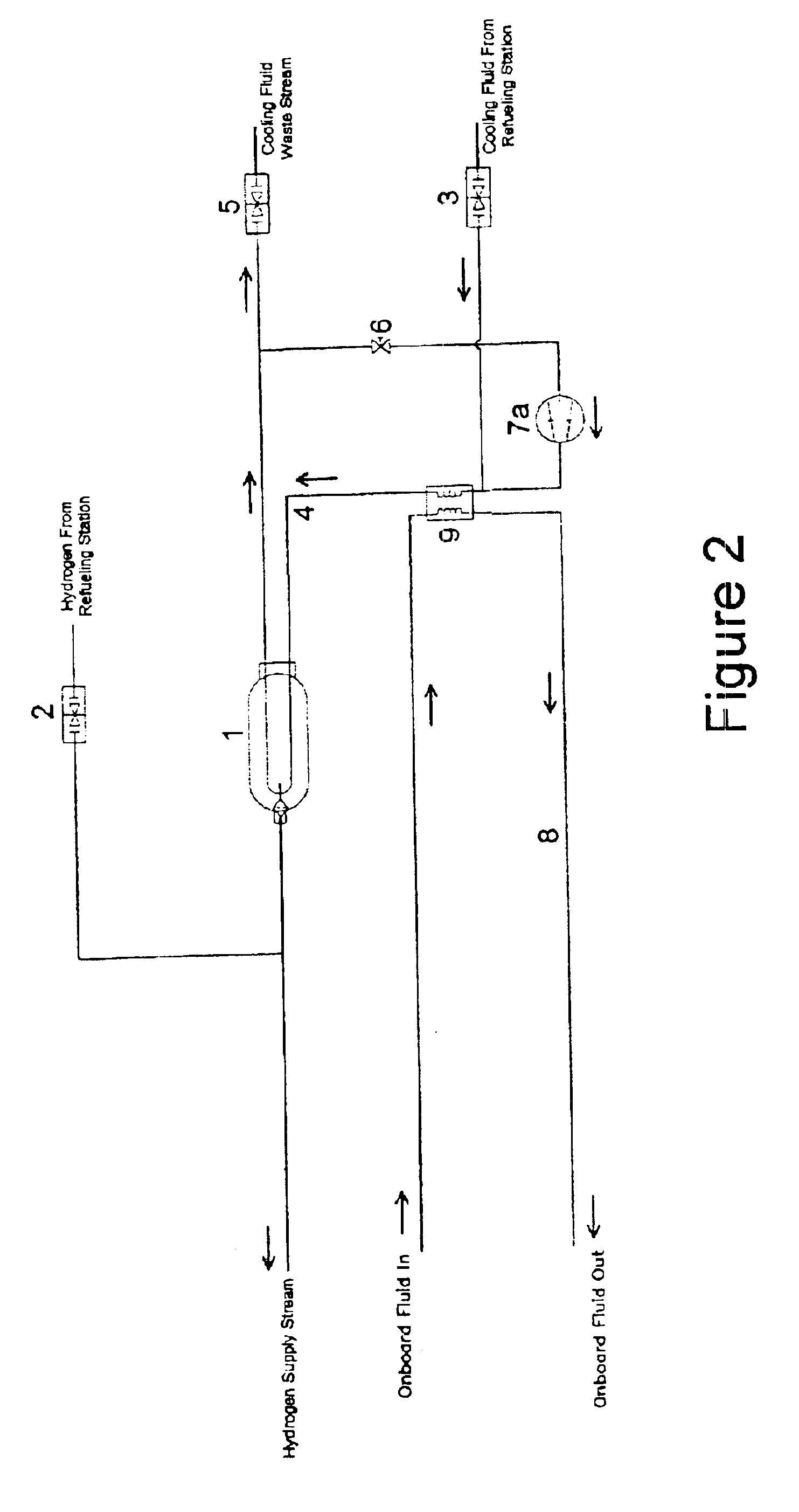

Onboard hydrogen storage unit with heat transfer system for use in a hydrogen powered vehicle

InactiveUS6860923B2Remove heatReversible hydrogen uptakeGas handling applicationsProcess engineeringHydrogen desorption

An onboard hydrogen storage unit with heat transfer system for a hydrogen powered vehicle. The system includes a hydrogen storage vessel containing a hydrogen storage alloy configured to receive a stream of hydrogen and provide hydrogen for use in powering a vehicle. During refueling a cooling / heating loop is used to remove the heat of hydride formation from the hydrogen storage alloy and during operation of the vehicle the heating / cooling loop is used to supply heat to the hydrogen storage alloy to aid in hydrogen desorption.

Owner:VODIK LABS LLC

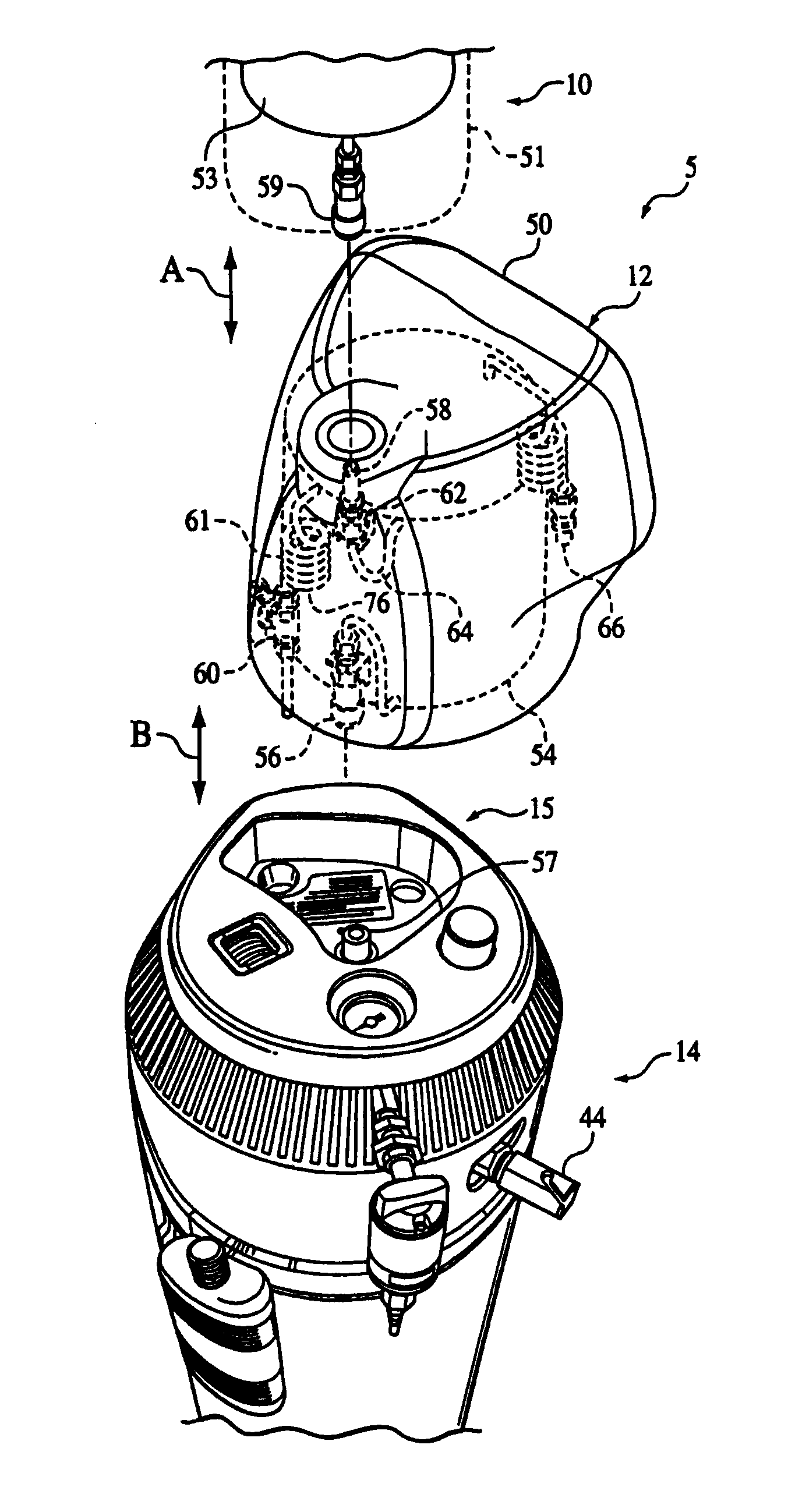

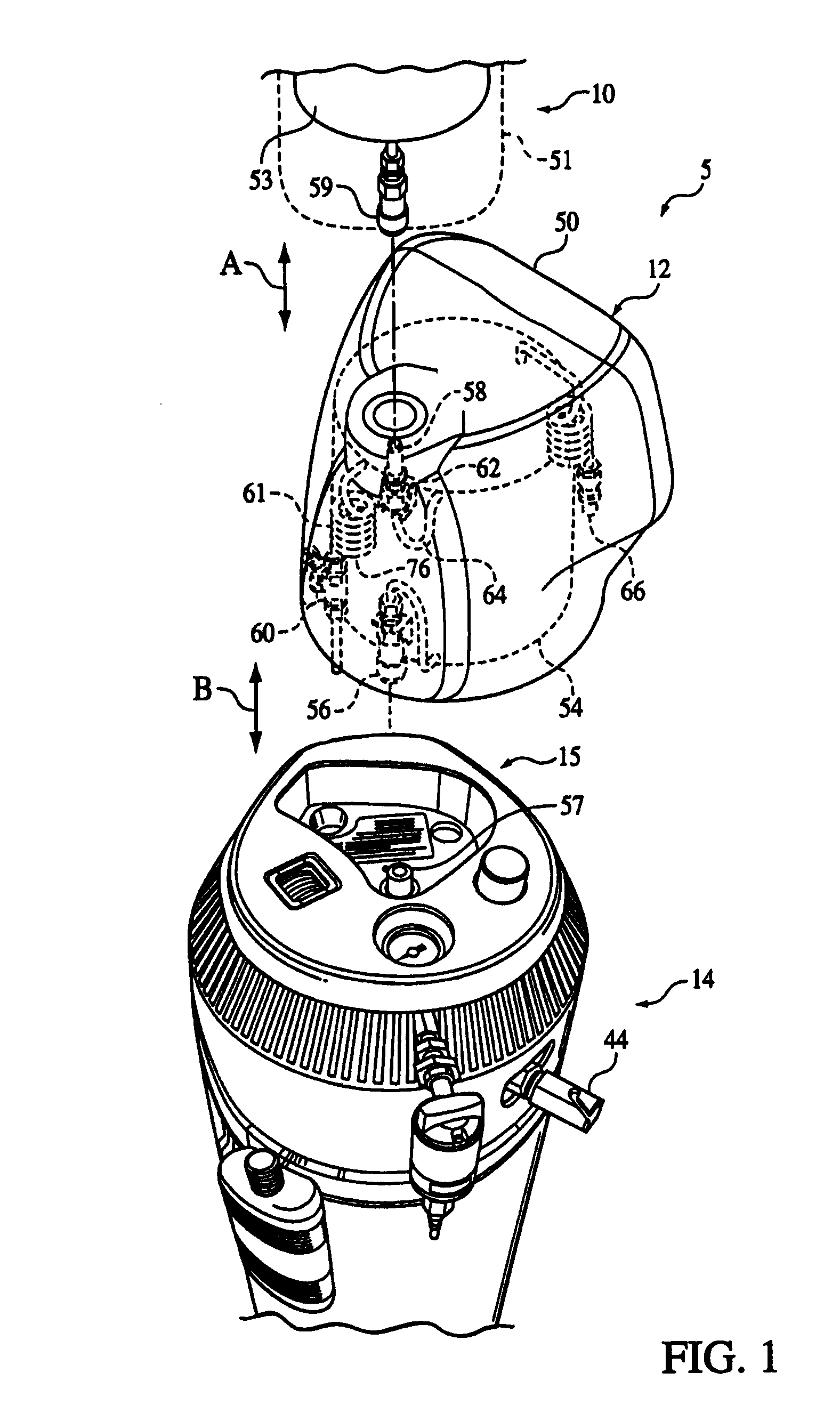

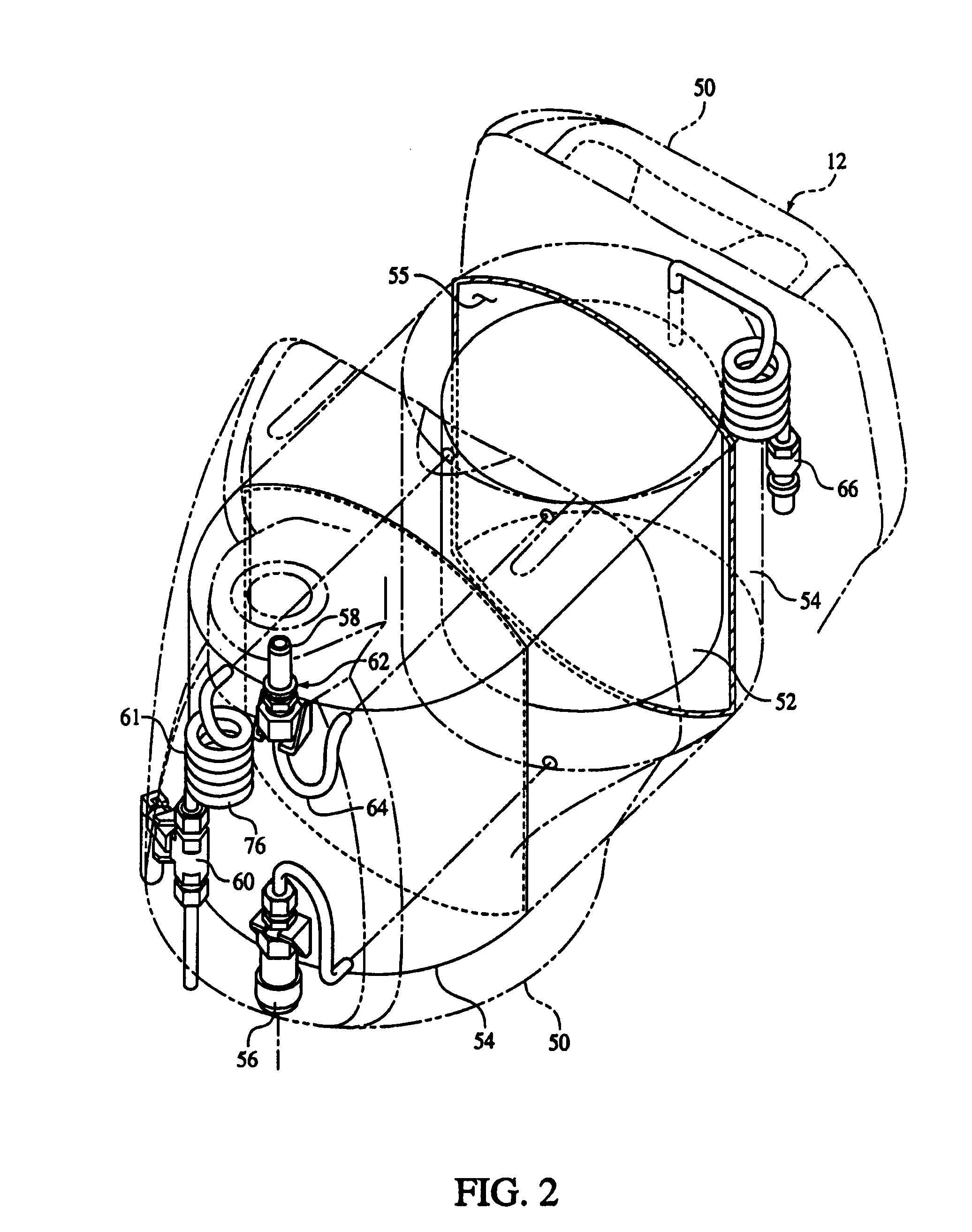

Portable liquid oxygen delivery system

InactiveUS7721733B2Sufficiently lightweight for portabilitySufficiently lightweightSurgeryMedical devicesEngineeringLiquid oxygen

A portable liquid oxygen medical delivery system including a portable liquid oxygen delivery apparatus and a portable liquid oxygen recharger. The portable liquid oxygen delivery apparatus contains an initial quantity of liquid oxygen. The liquid oxygen delivery apparatus is sufficiently lightweight for portability by an ambulatory patient and has a fill port for receiving liquid oxygen. The liquid oxygen recharger stores a supplemental quantity of liquid oxygen and is also sufficiently lightweight for portability by an ambulatory individual. The liquid oxygen recharger has an interface for interfacing the liquid oxygen recharger with the portable liquid oxygen delivery apparatus for delivering the supplemental quantity of liquid oxygen to the portable liquid oxygen delivery apparatus.

Owner:RIC INVESTMENTS LLC

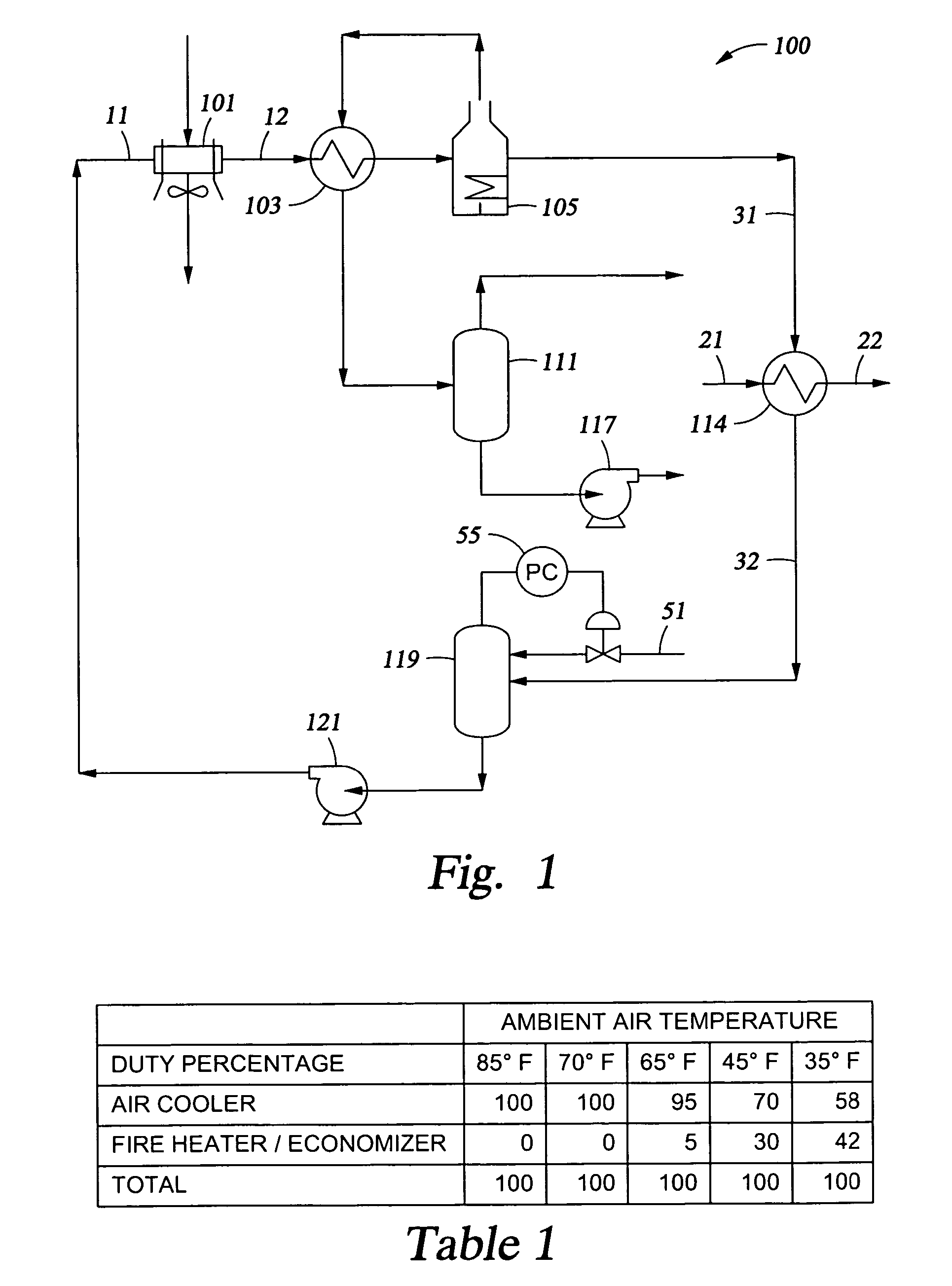

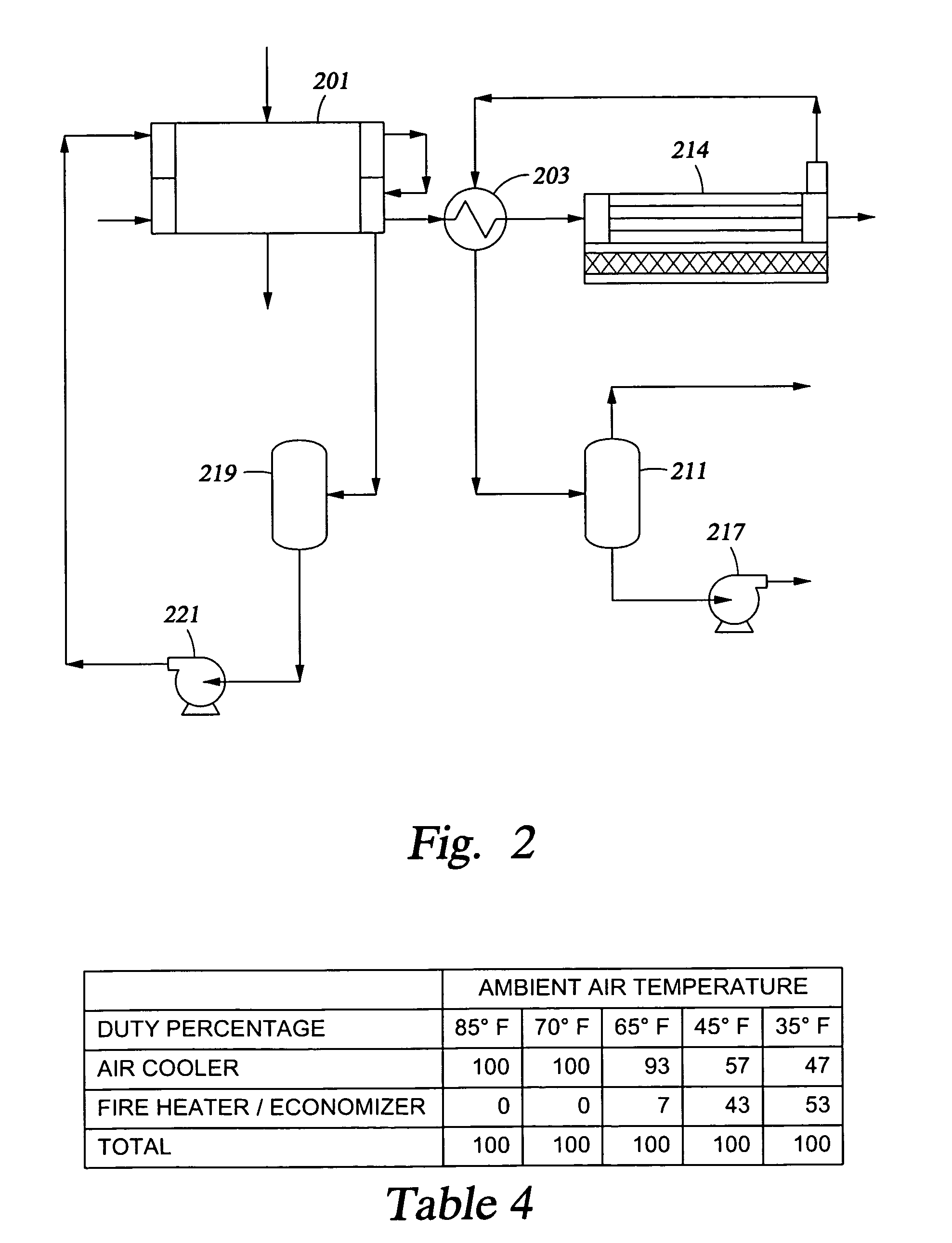

Apparatus and methods for converting a cryogenic fluid into gas

InactiveUS7155917B2Gas handling applicationsGas handling/storage effectsEngineeringHeat transfer fluid

Method and apparatus for vaporizing cryogenic fluids in which an intermediate heat transfer fluid is first heated across a heat transfer surface with ambient air, and then the heat transfer surface provides heat to vaporize the cryogenic fluid.

Owner:MUSTANG ENG

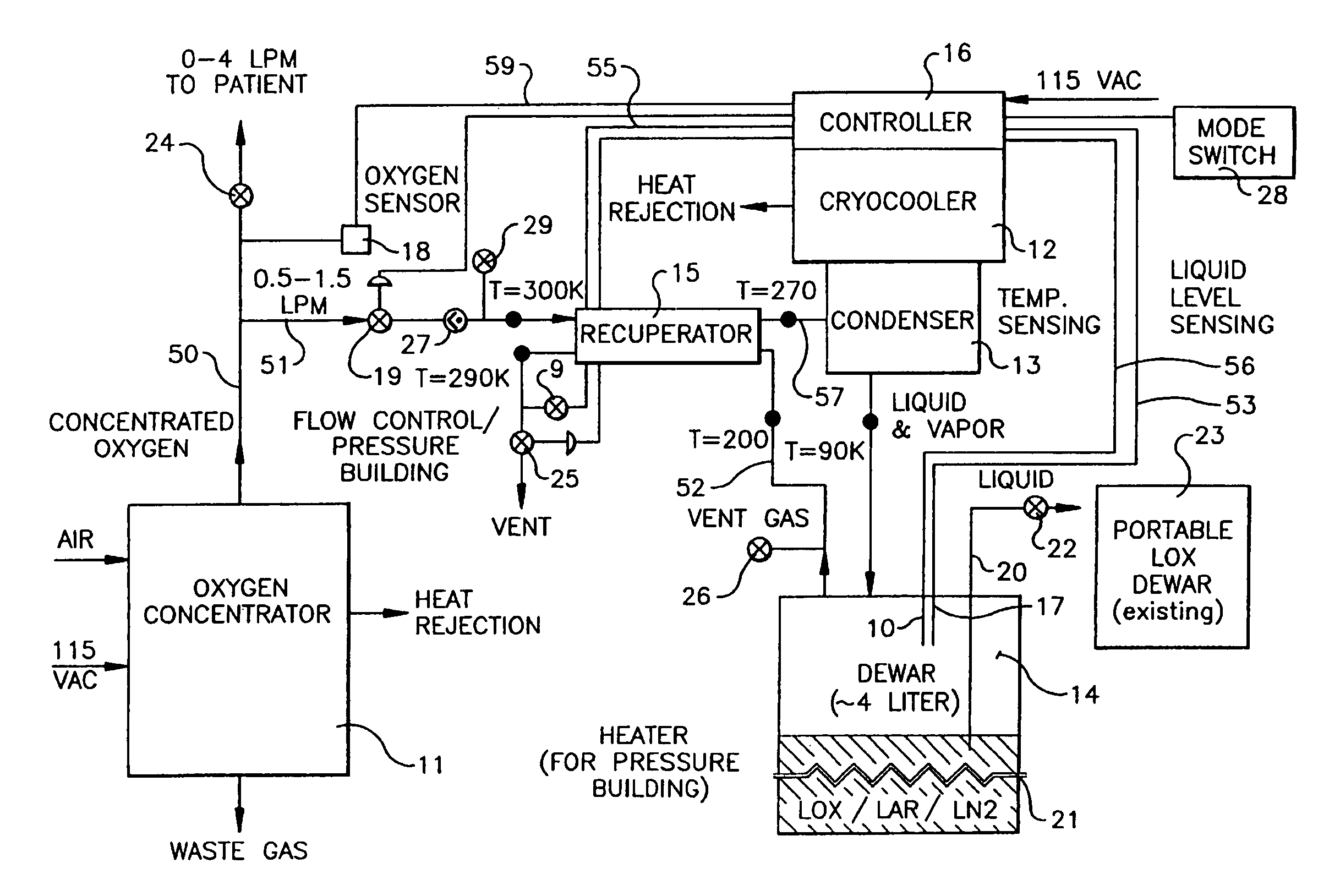

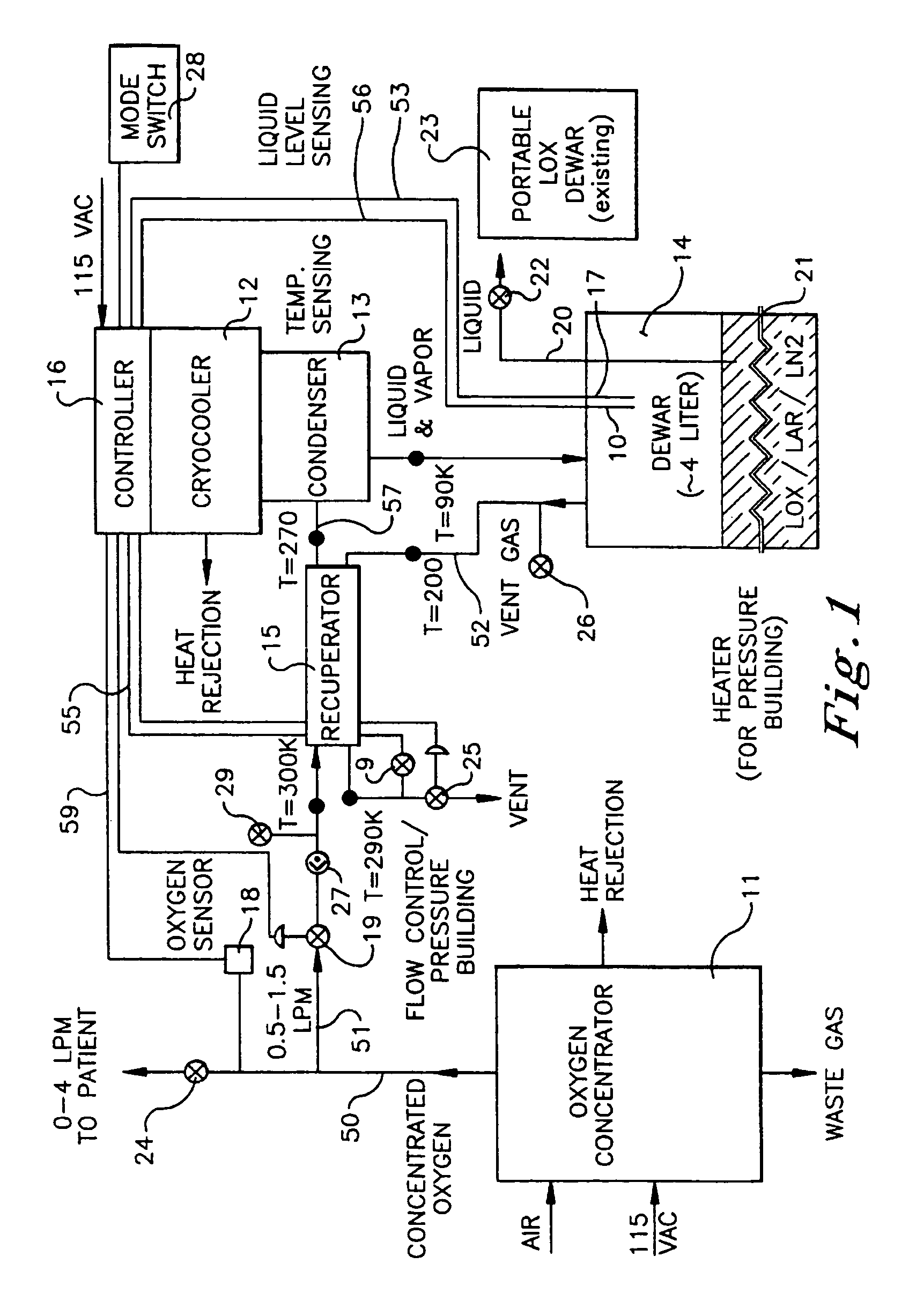

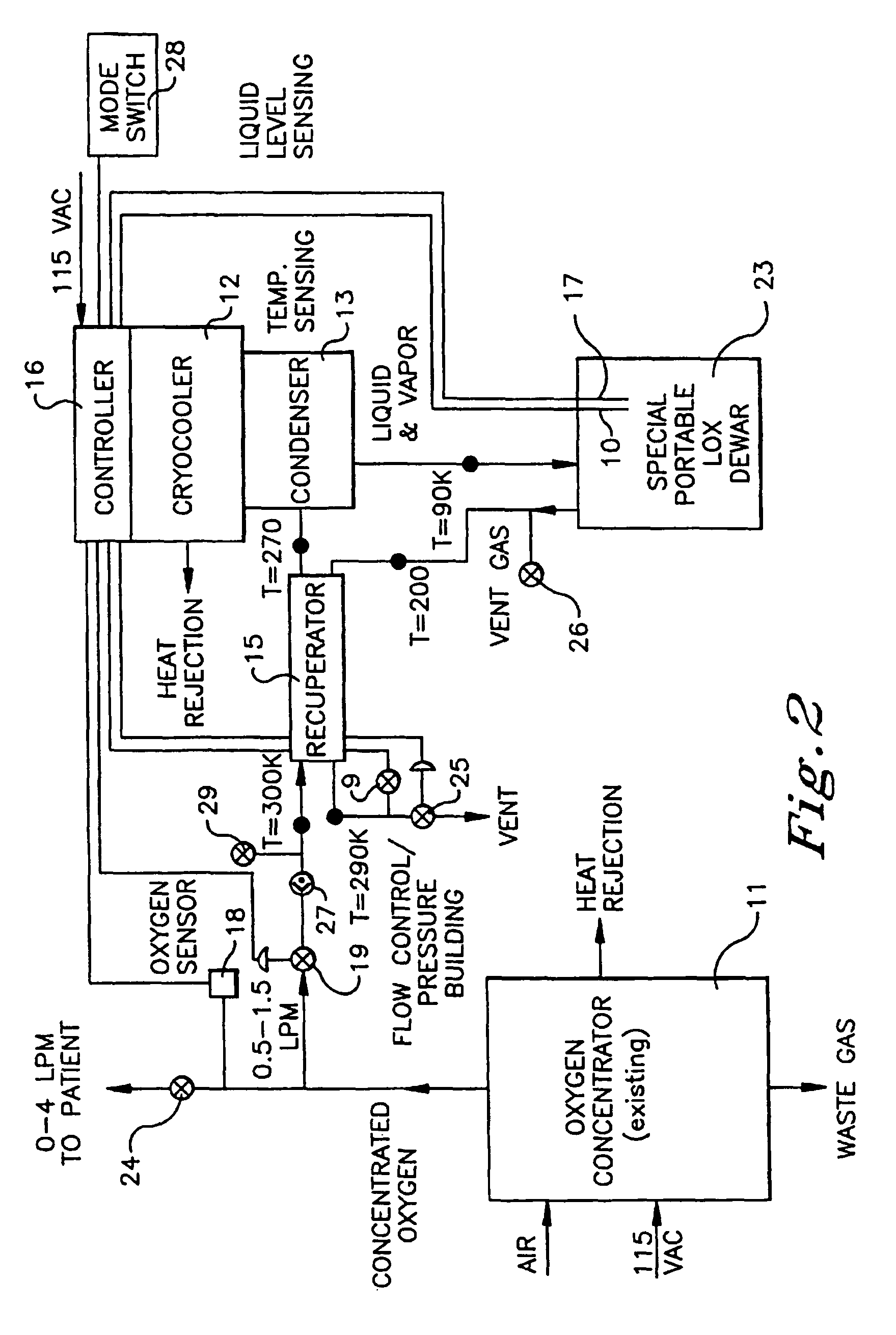

Methods and apparatus to generate liquid ambulatory oxygen from an oxygen concentrator

InactiveUSRE43398E1Increase condensation rateIncrease the areaLiquefactionOther heat production devicesAmbulatory systemCryocooler

Owner:RESPIRONICS

Liquid gas vaporization and measurement system and method

ActiveUS8056399B2Efficiently and accurately sampling and measuringEfficiently flash vaporizeSpace heating and ventilationGas handling applicationsMass storageMeasuring instrument

A liquid gas vaporization and measurement system, and associated method, for efficiently vaporizing a continuous sample of liquid gas, such as liquid natural gas (LNG), and accurately determining the constituent components of the gas. A constant flow of liquid gas sampled from a mass storage device is maintained in a vaporizing device. Within the vaporizing device the liquid gas is flash vaporized within heated narrow tubing. The liquid gas is converted to vapor very quickly as it enters one or more independently operating vaporizer stages within the vaporizing device. The vapor gas is provided to a measuring instrument such as a chromatograph and the individual constituent components and the BTU value of the gas are determined to an accuracy of within + / −0.5 mole percent and 1 BTU, respectively.

Owner:MUSTANG SAMPLING

System and method for delivery of a vapor phase product to a point of use

Provided are a novel system and method for delivery of a vapor phase product to a point of use, as well as a novel on-site chemical distribution system and method. The system for delivery of a vapor phase product includes a storage vessel containing a liquid chemical under its own vapor pressure, a column connected to receive the chemical in liquified state from the storage vessel, wherein the chemical is fractionated into a contaminated liquid heavy fraction and a purified light vapor fraction and a conduit connected to the column for removing the purified light vapor fraction therefrom. The system is connected to the point of use for introducing the purified vapor fraction thereto. Particular applicability is found in semiconductor manufacturing in the delivery of electronic specialty gases to one or more semiconductor processing tools.

Owner:AIR LIQUIDE AMERICA INC

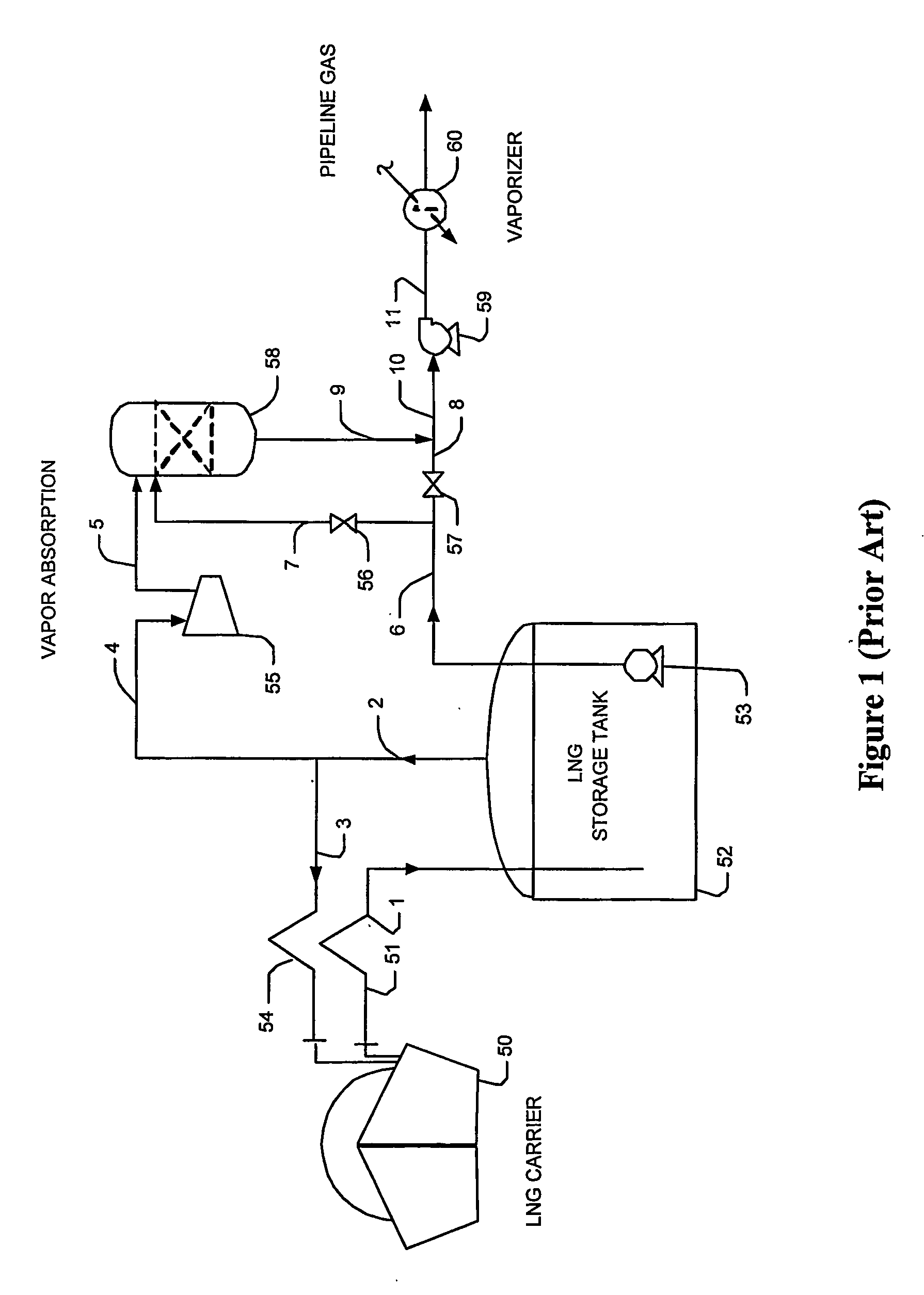

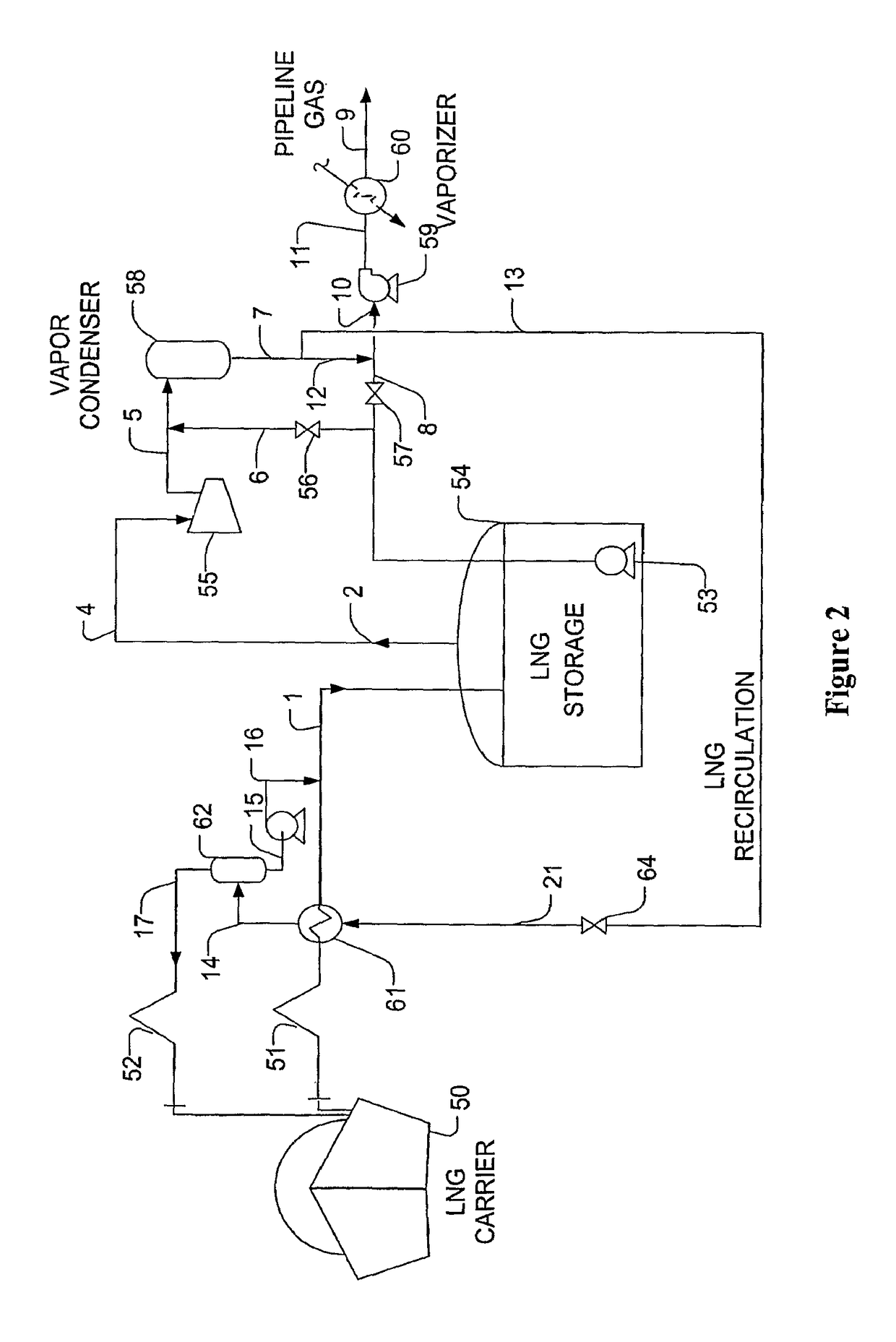

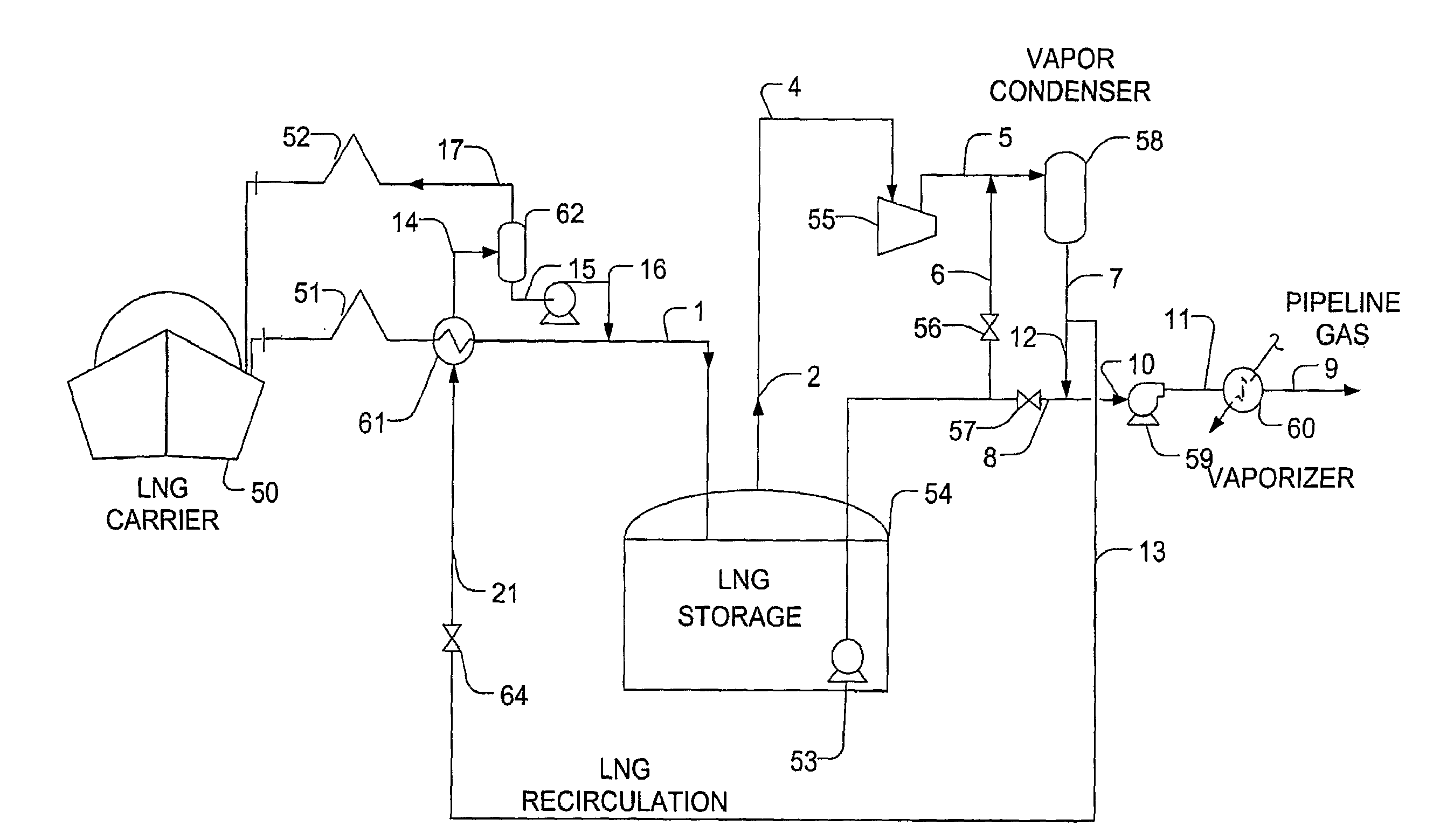

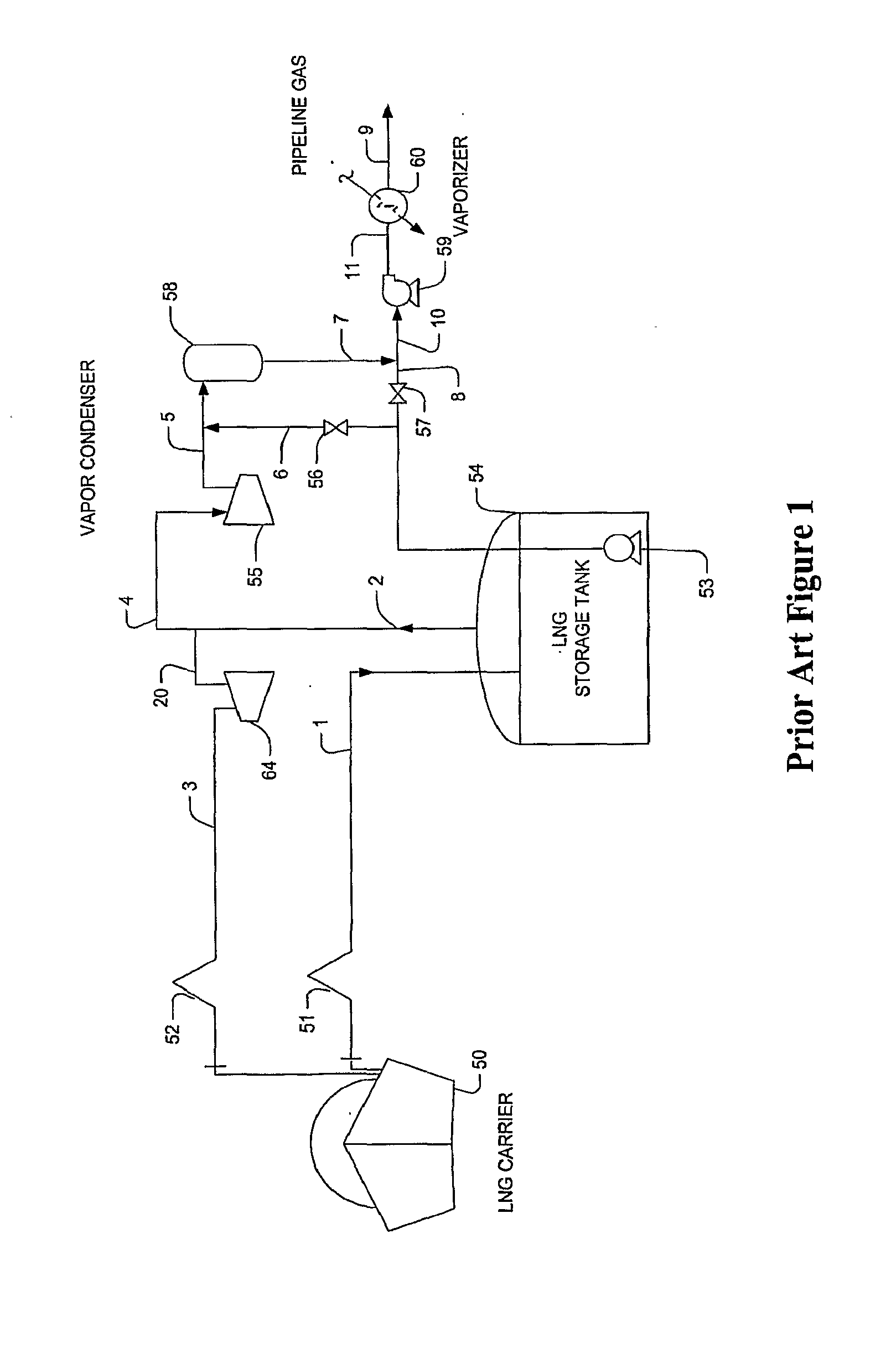

LNG vapor handling configurations and methods

InactiveUS8117852B2Reduce boil-off volumeEliminate needSolidificationLiquefactionProcess engineeringRefrigeration

LNG from a carrier is unloaded to an LNG storage tank in configurations and methods in which expansion of compressed and condensed boil-off vapors from the LNG storage tank provide refrigeration to subcool the LNG that is being unloaded. Most advantageously, such configuration and methods reduce the amount of boil-off vapors and eliminate the need for a vapor return line and associated compressor.

Owner:FLUOR TECH CORP

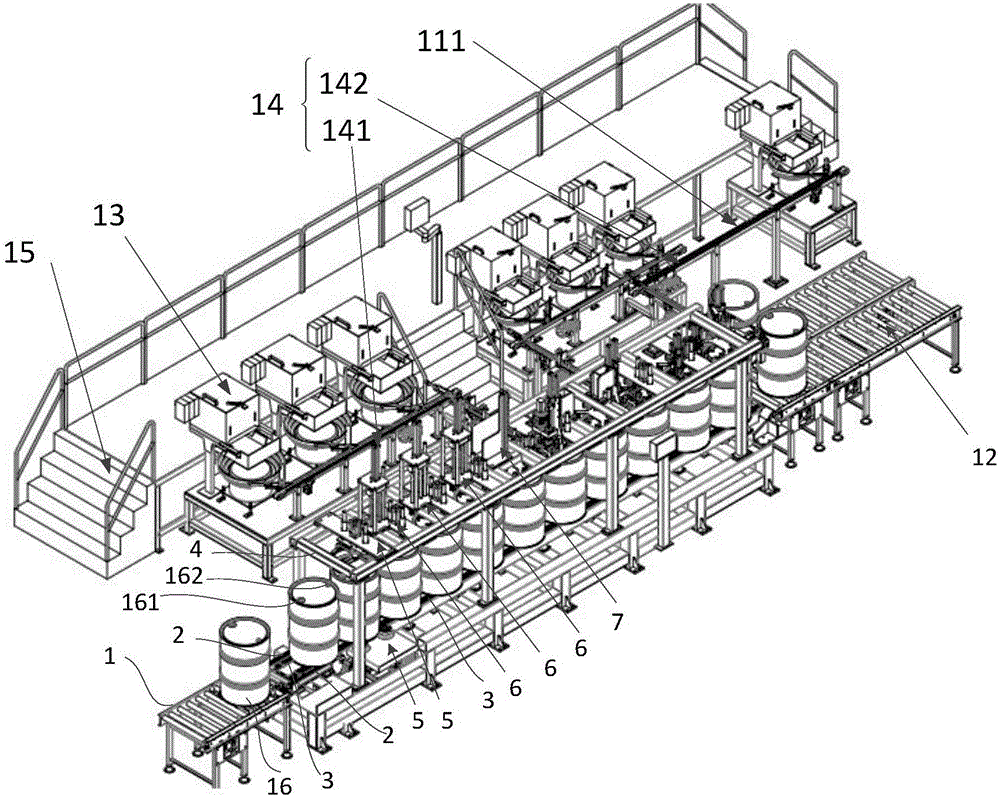

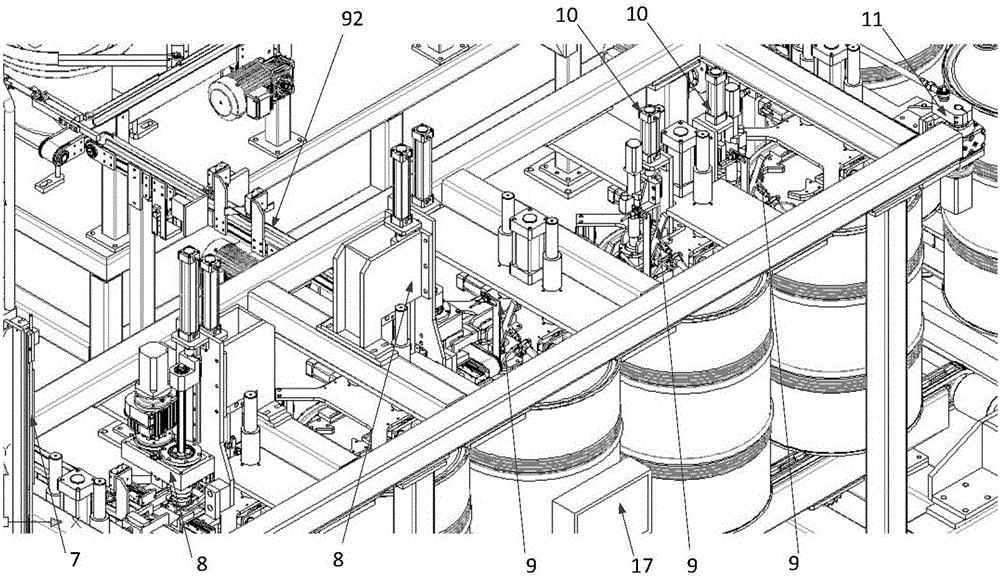

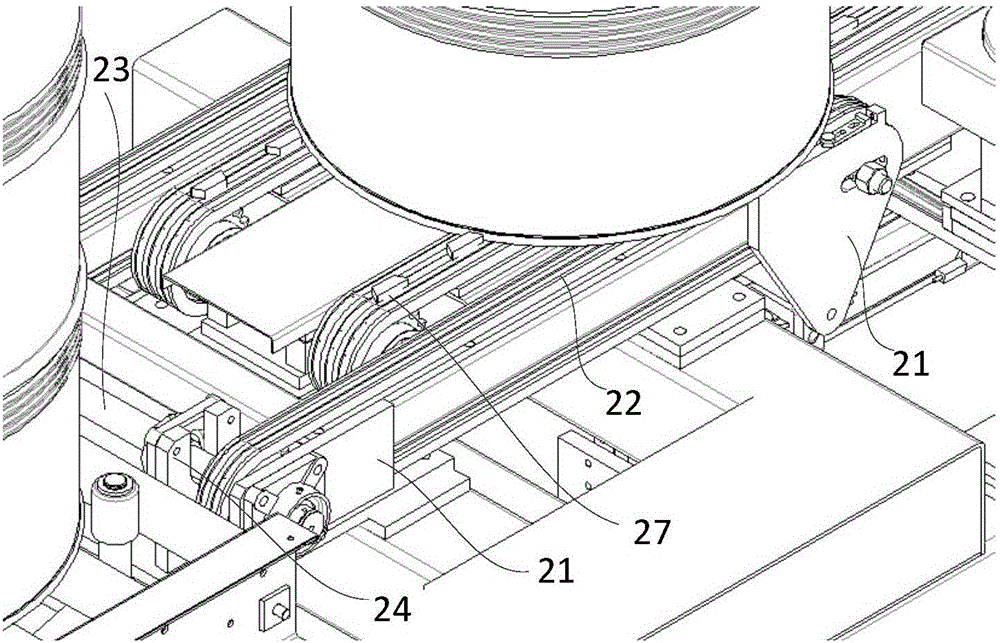

Automatic inflation cover tightening system

ActiveCN105836686ARealize automatic fillingEasy to installClosing machinesCapsControl systemEngineering

The invention provides an automatic inflation cover tightening system. The automatic inflation cover tightening system comprises a barrel body conveying system for conveying barrel bodies, a main machine frame and a control system connected with the barrel body conveying system, and further comprises large opening and small opening positioning devices, dry air injection devices, an inert gas injection device, a barrel cover conveying device, barrel cover pre-tightening devices, barrel cover tightening mechanisms, a sealing cover mechanism and an outlet conveyor. Each dry air injection device comprises a first injection device body and a second lifting pressing device used for pressing barrel bodies downwards. The barrel cover pre-tightening devices are used for pre-tightening barrel covers. The barrel cover tightening mechanisms are used for tightening barrel covers and each comprise a tightening gun unit for tightening barrel covers and a second vertical lifting mechanism for driving the tightening gun unit to move. The sealing cover mechanism comprises a sealing cover taking mechanism, a sealing cover conveyor connected with the control system, and a second lifting pressing device. The outlet conveyor is connected with the control system and arranged at an outlet of the automatic inflation cover tightening system. The automatic inflation cover tightening system provided by the invention relieves the manual labor intensity, improves production efficiency and can lower production cost and management cost for enterprises.

Owner:SHANGHAI JISHENG AUTOMATIC MACHINERY SYST

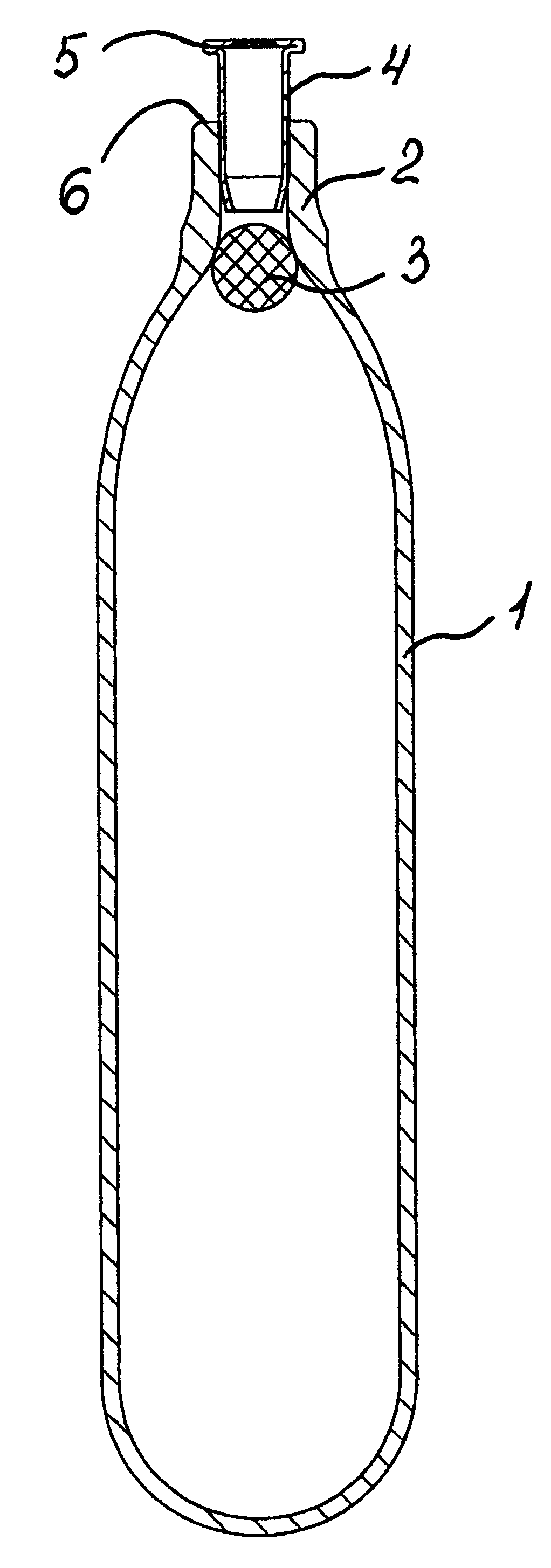

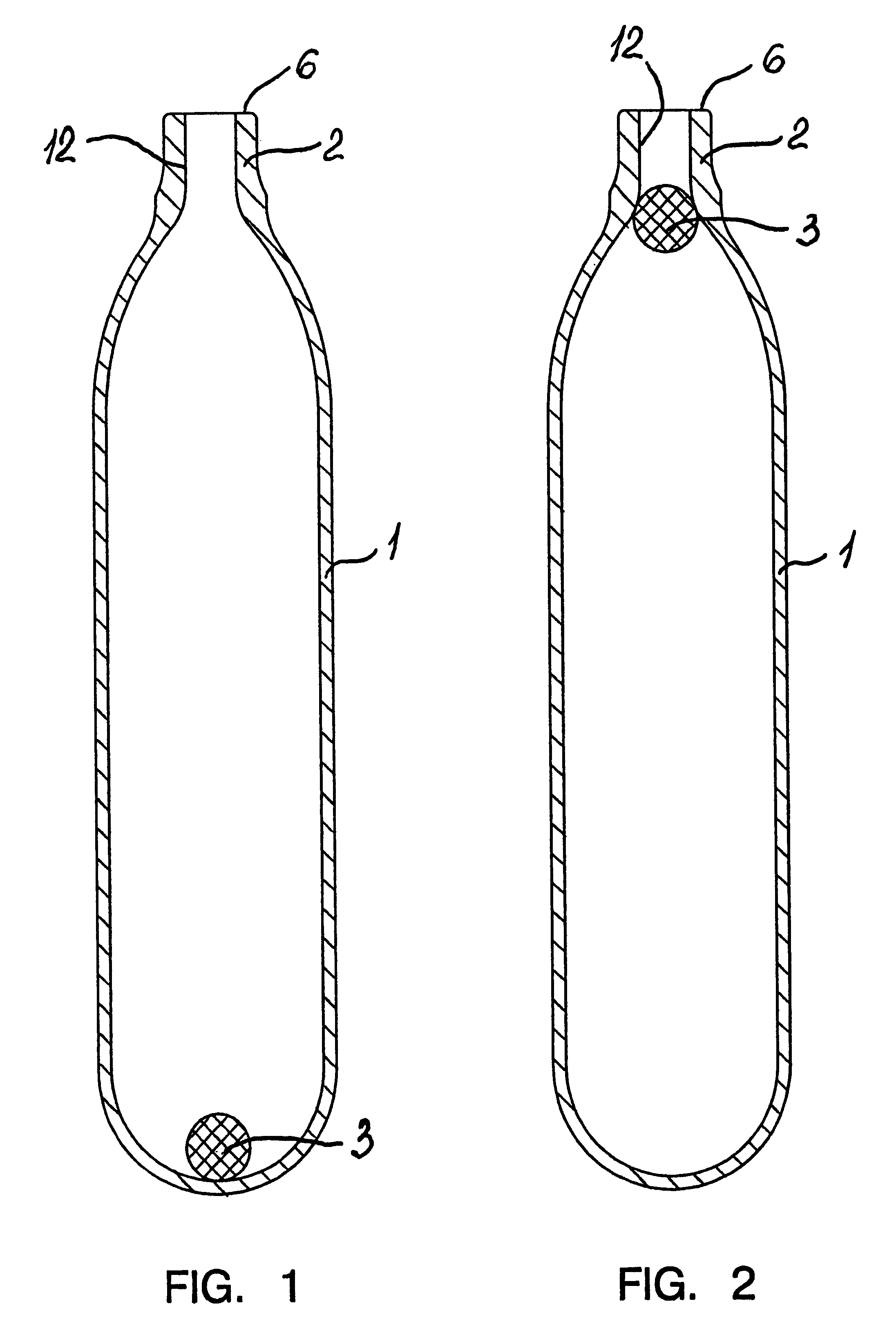

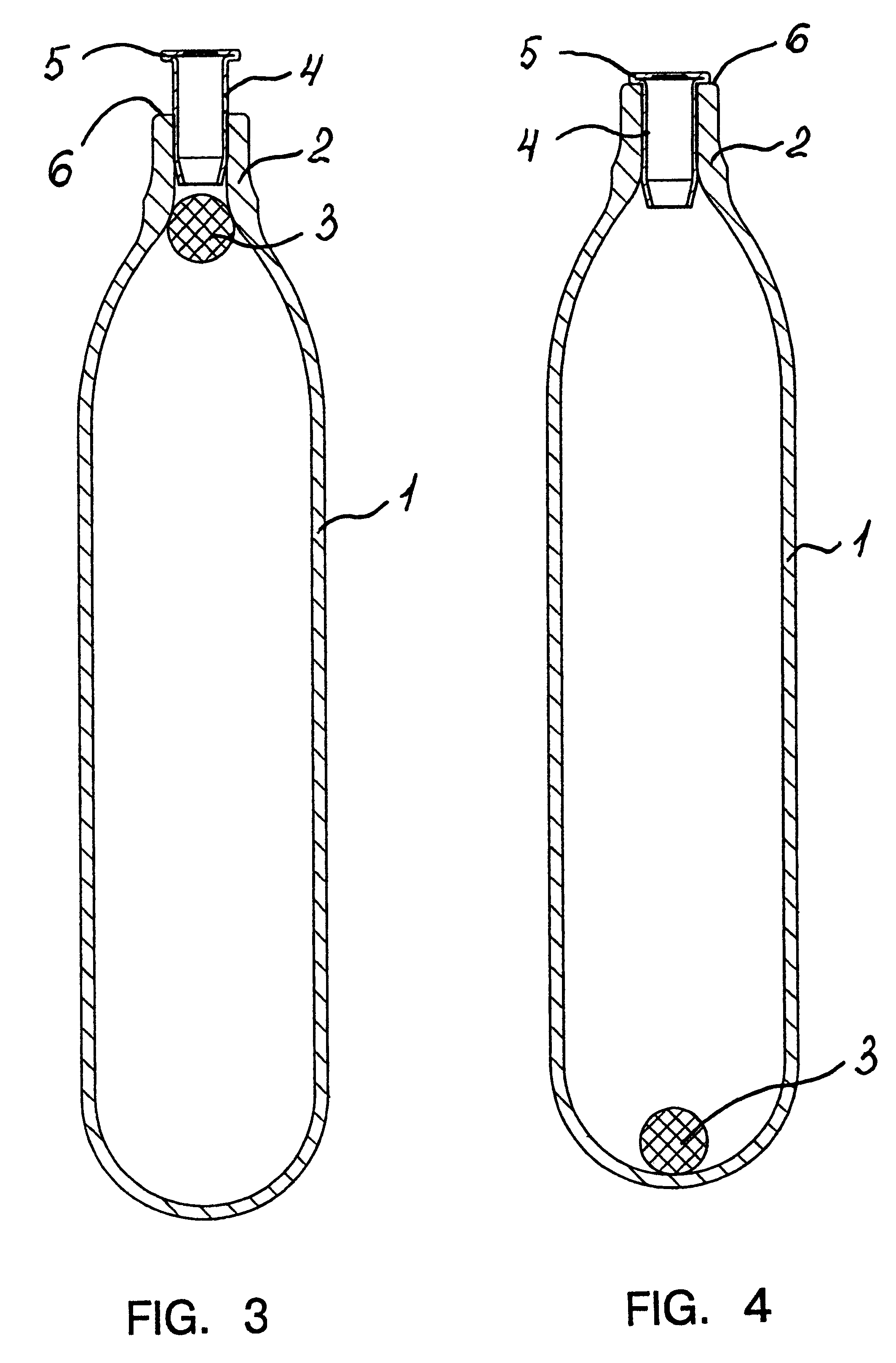

Gas cylinder and a method for filling the same

InactiveUS6378570B1Simple requirementsReduce manufacturing costGas handling applicationsSolid materialGas cylinderLiquid gas

A gas cartridge comprises a body 1 with a neck 2. A movable valve made as a ball 3 is disposed inside the body 1. A cap 4 is installed in the neck. The end of the cap 4 can be chamfered or expanded. The ball 3 can be manufactured from an elastic, resilient material, from an elastic, resilient material with a metallic powdered filler or be fully metallic in an elastic, resilient envelope. A method of charging the gas cartridge comprises placing a movable valve inside the body of the cartridge, turning the cartridge with its neck downward and charging the cartridge with a liquefied gas under a pressure, reducing the charging pressure with simultaneous closing of the neck by the movable valve, closing the neck with a cap, pressing-in the cap and welding the flange of the cap to the face of the neck of the cartridge.

Owner:ZAKRYTOE AKTSIONERNOE OBSHCHESTVO GRP ANICS

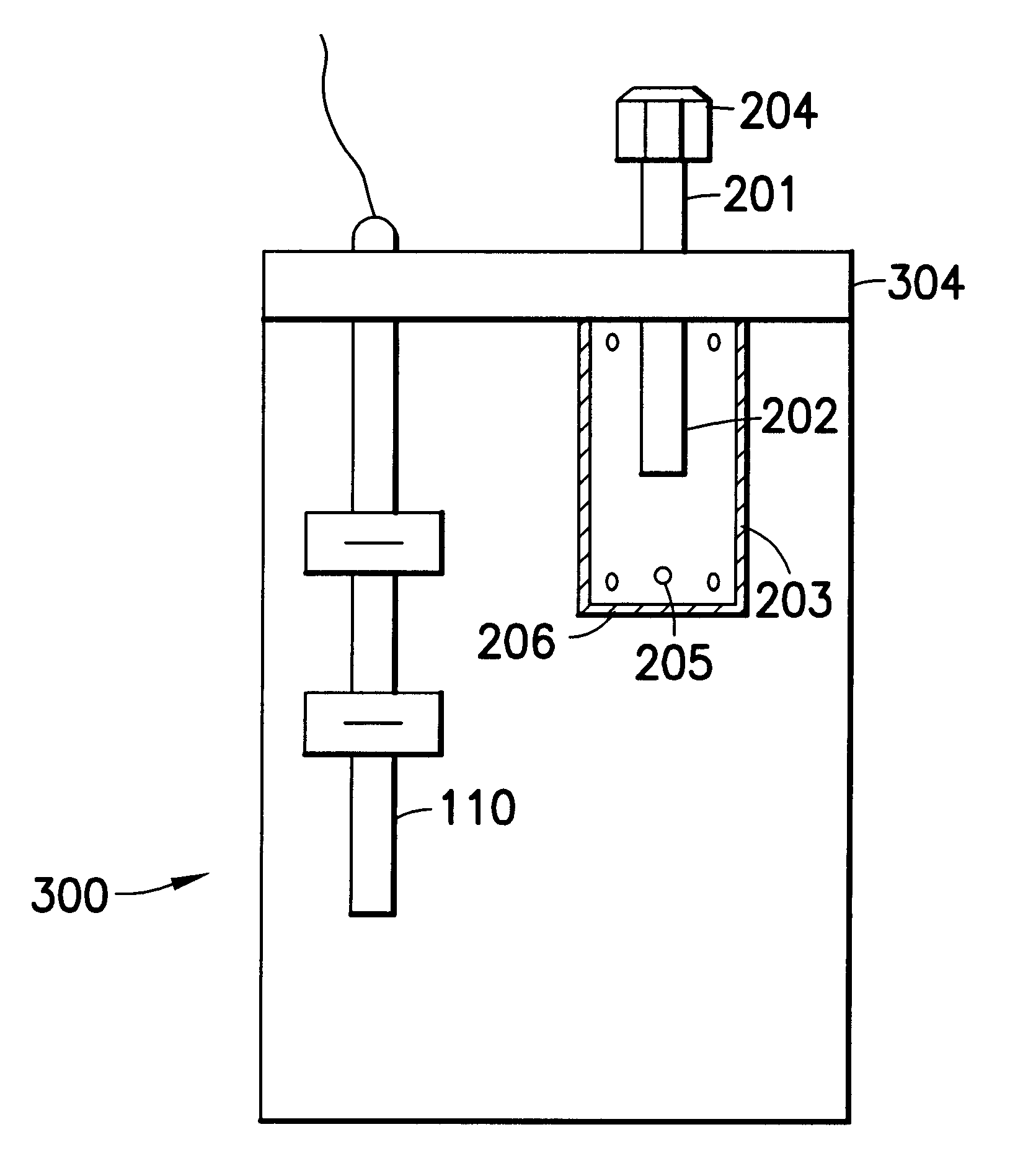

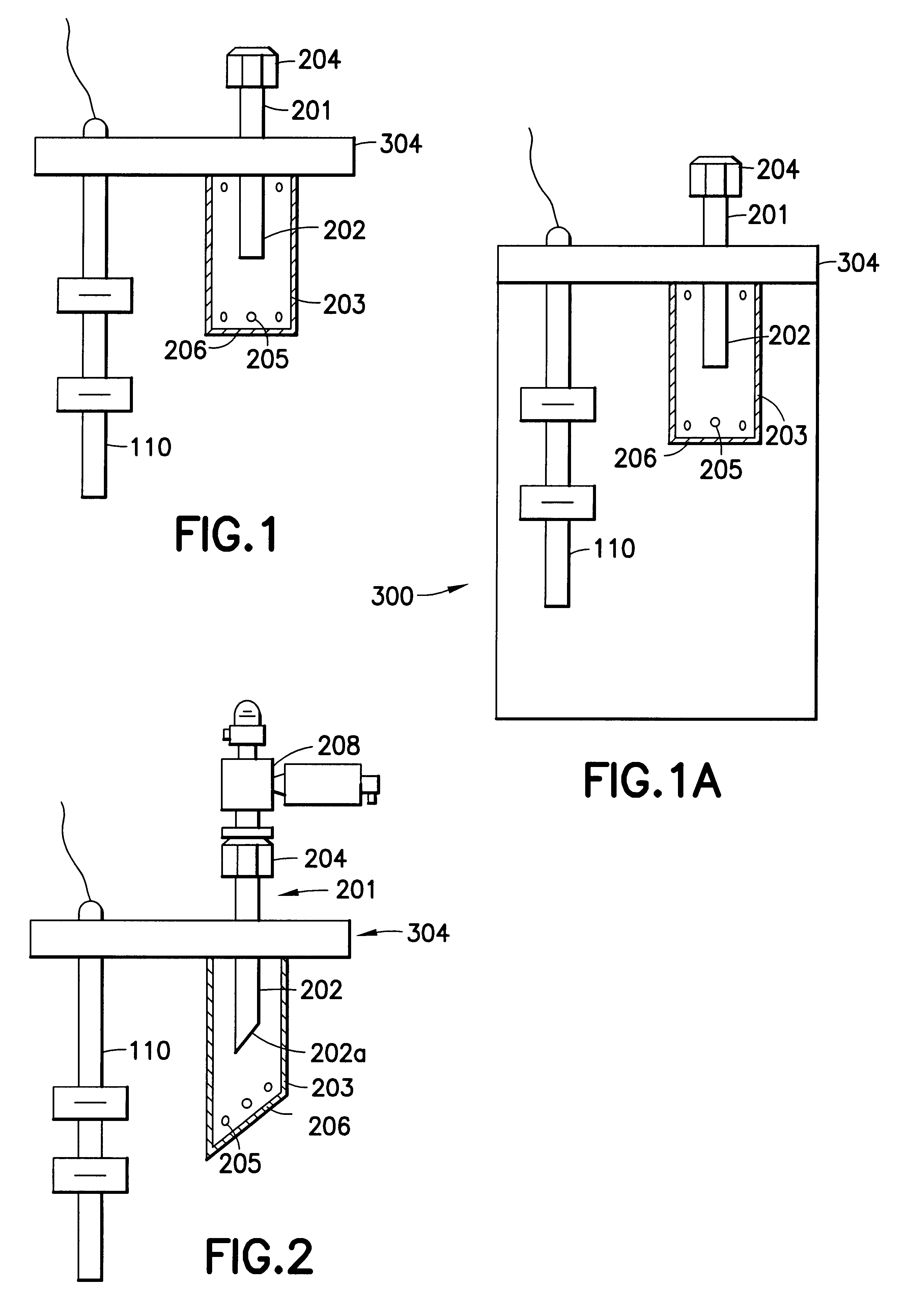

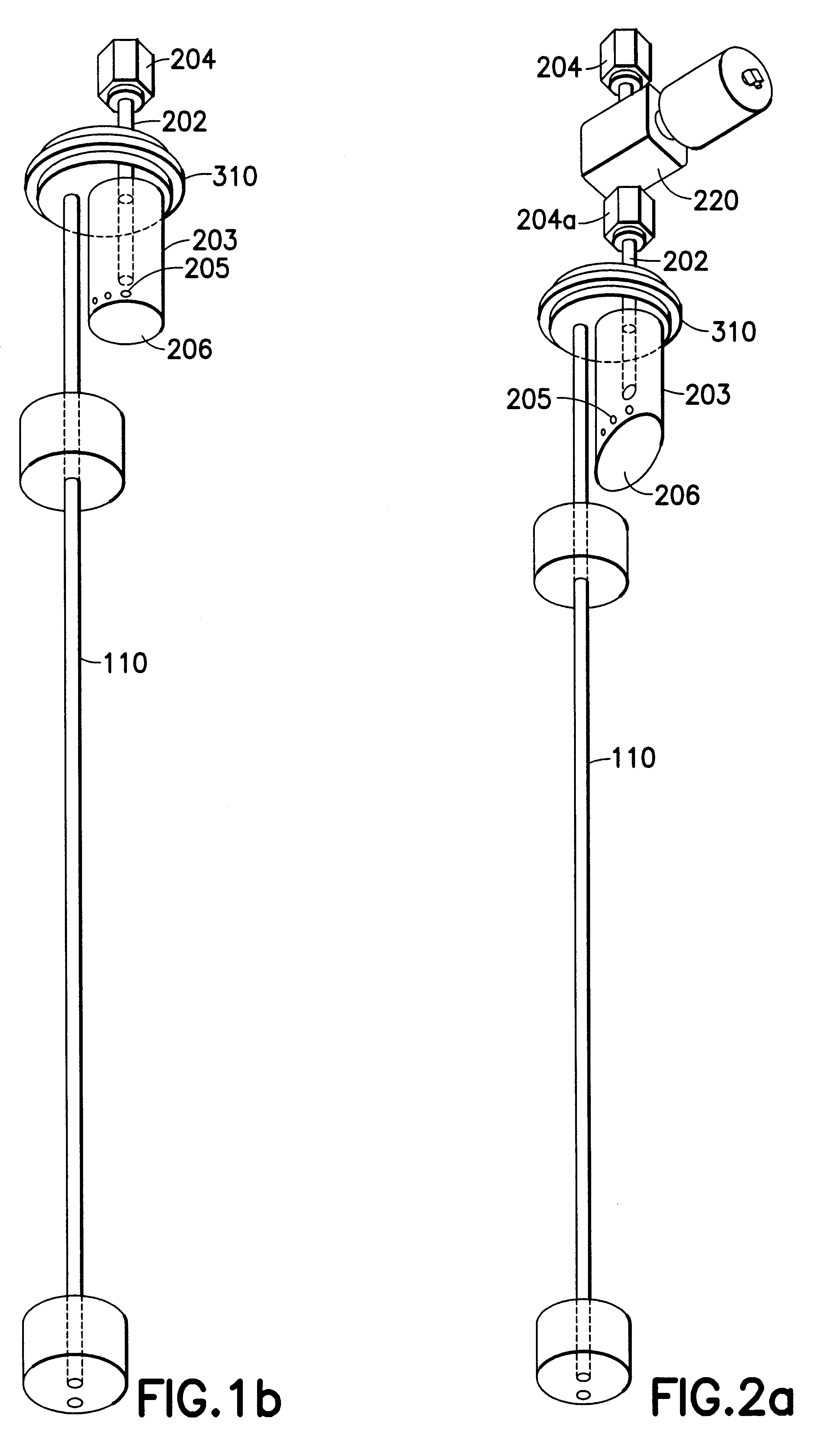

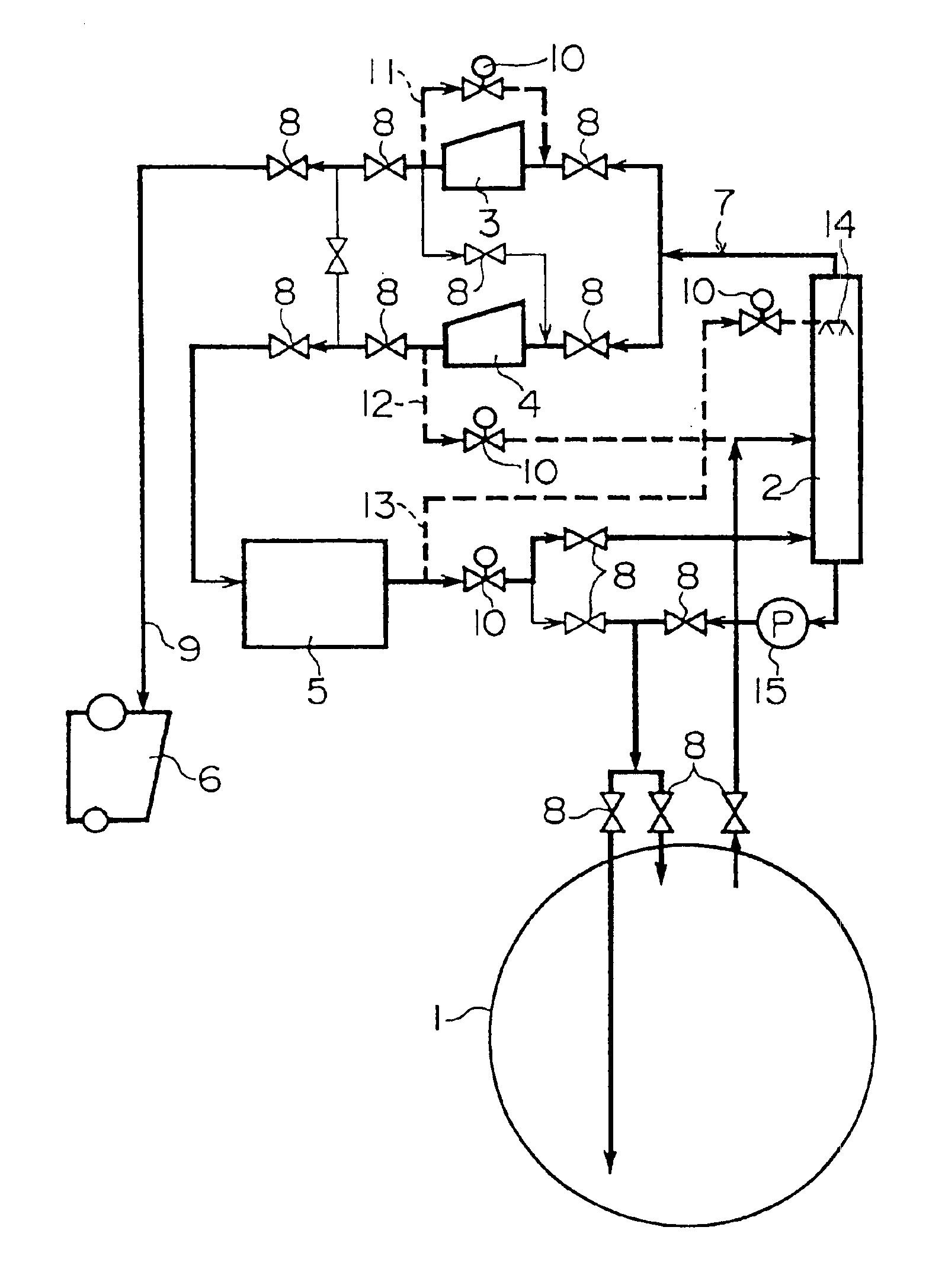

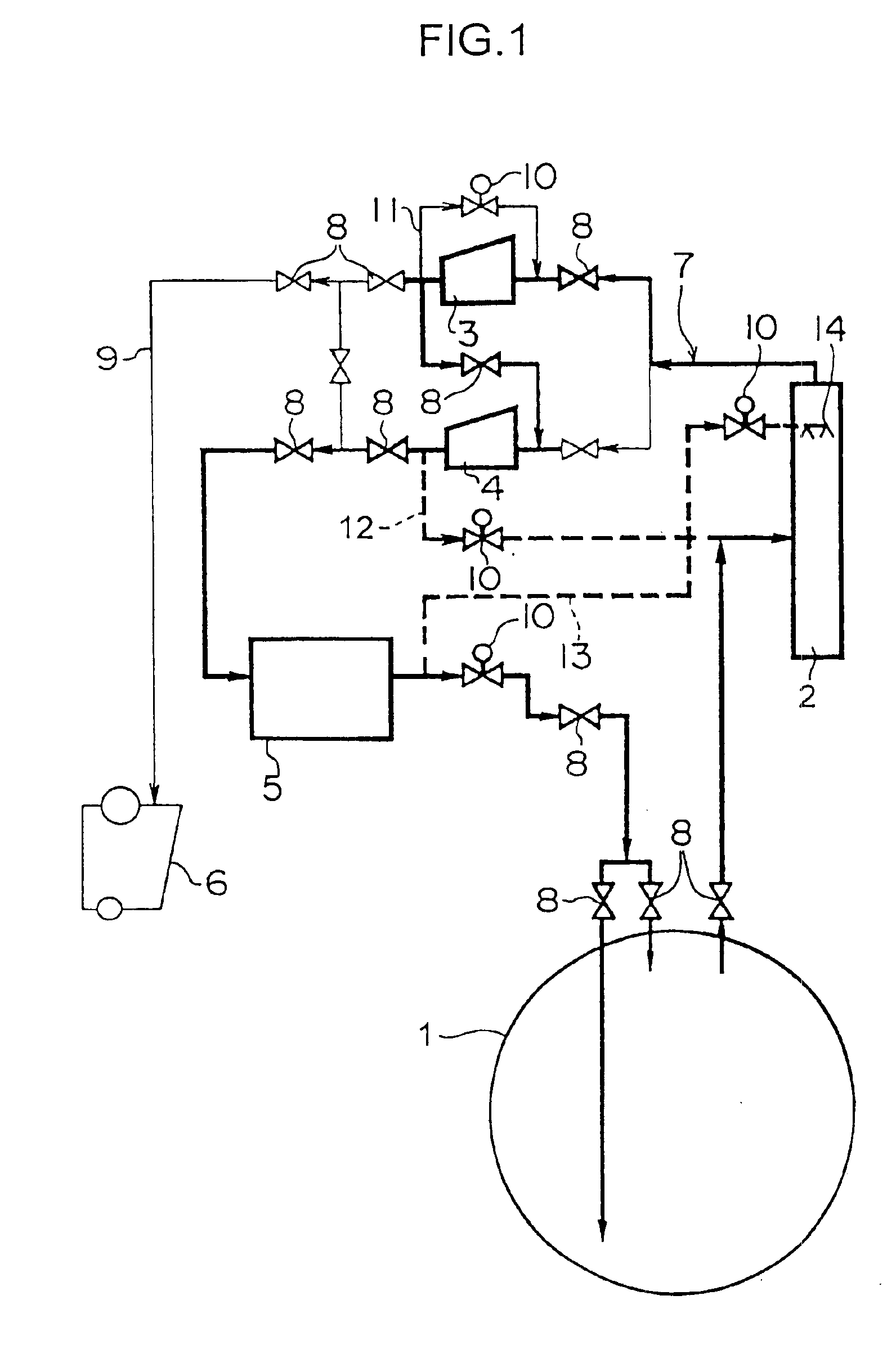

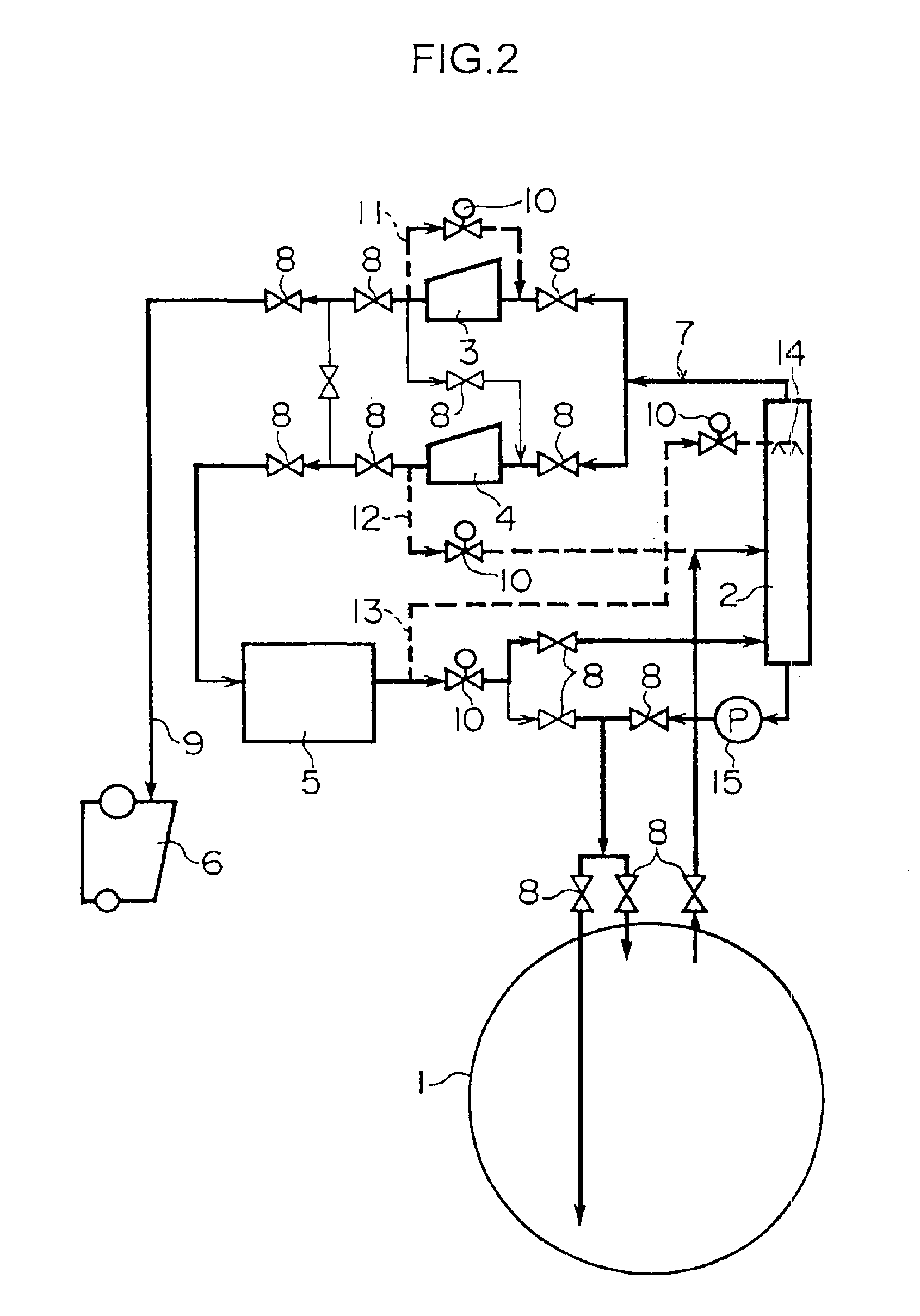

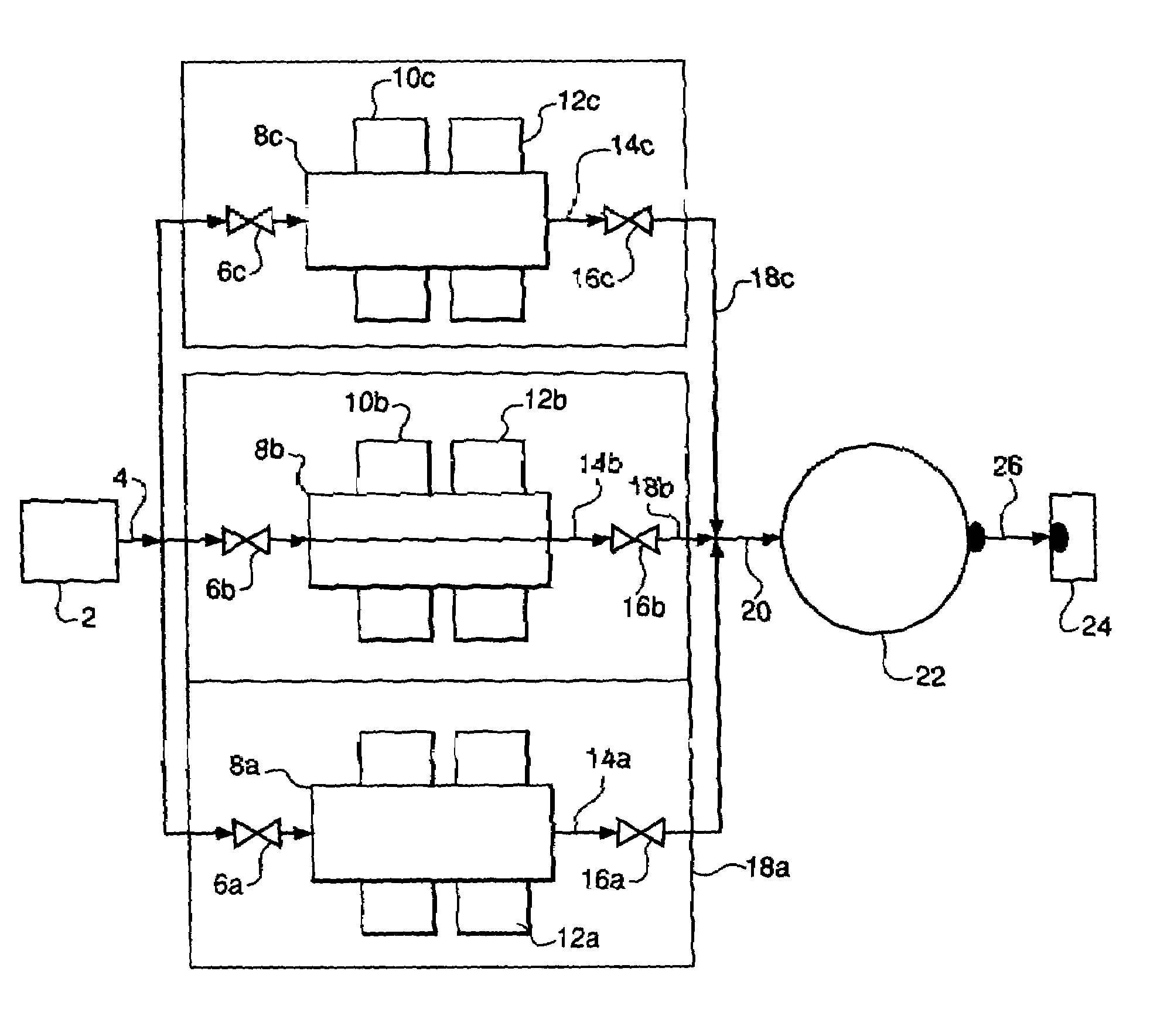

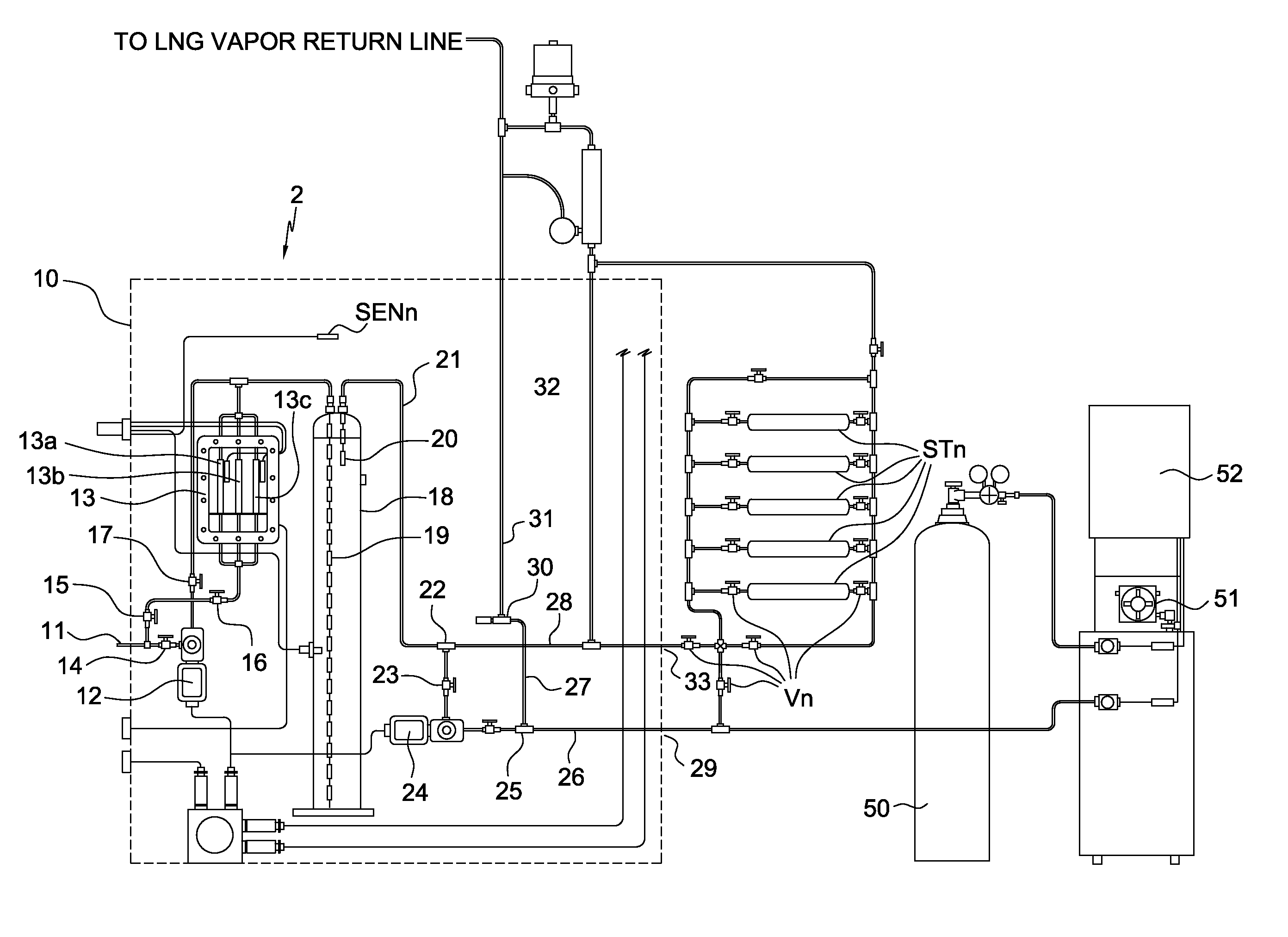

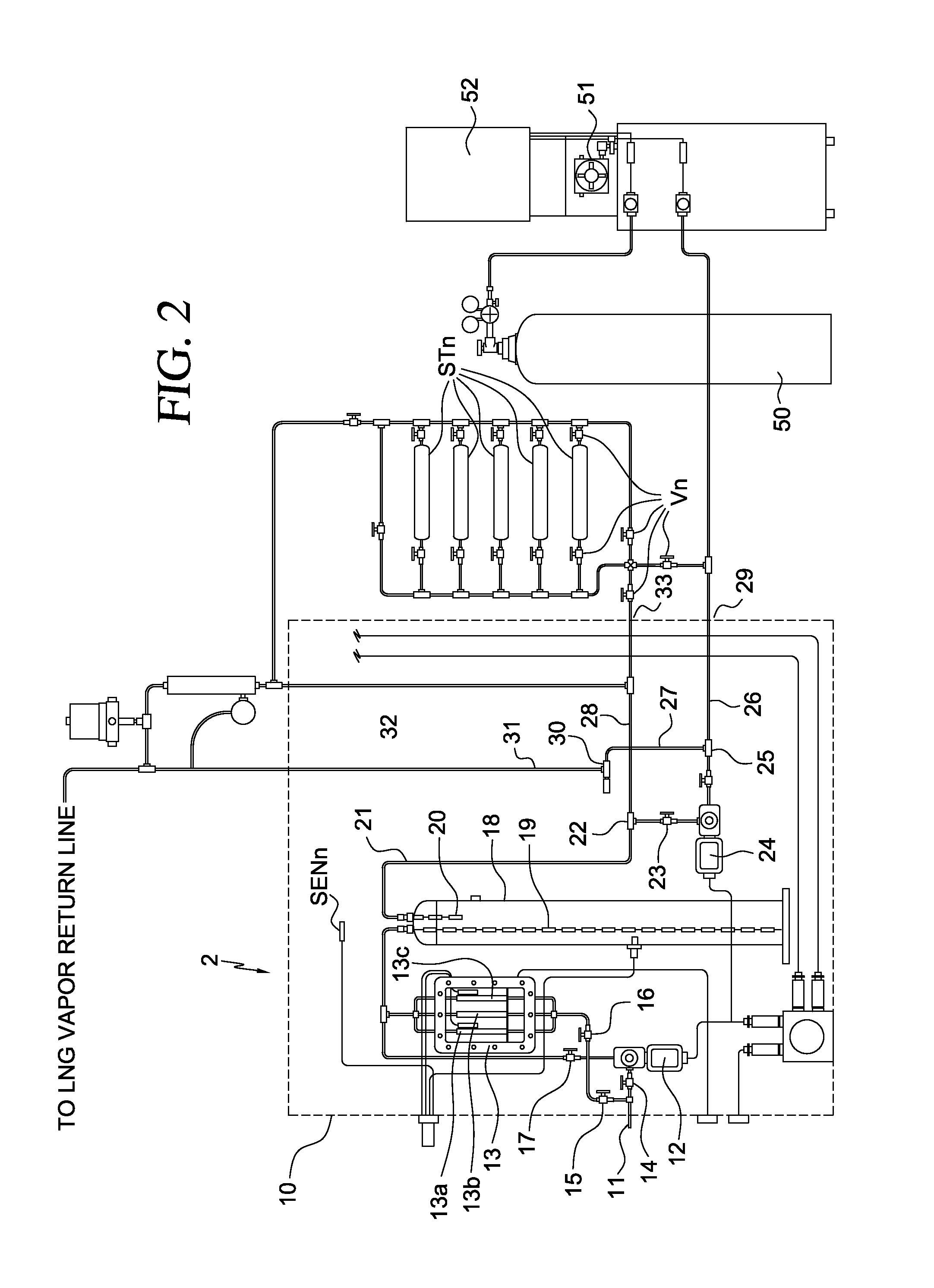

Method and system for independently filling multiple canisters from cascaded storage stations

A canister filling system is provided for independently filling multiple canisters from a common set of storage stations prioritized in a cascaded manner. The system includes first and second fill stations configured to receive and independently fill canisters with pressurized gas. First and second storage stations store gas at corresponding first and second charge pressures, respectively. A supply-chain joins each of the first and second fill stations to both of the first and second storage stations. First and second valve assemblies are provided in the supply-chain to monitor, independent of one another, the canister pressures at the corresponding first and second fill stations. The canister pressures represent the pressure within corresponding canisters. The first and second valve assemblies automatically open and close to permit and prevent discharge of gas from the first and second storage stations, independent of one another, to automatically switch between the first and second storage stations based on the canister pressures. In one embodiment, the valve assembly includes a combination of sequence valves and check valves. Alternatively, the valve assembly may be controlled by electronic sensors and electronic solenoids. The electronic sensors detect the canister pressures and the charge pressures at the storage stations. The electronic solenoids open and close the valves based on the sensed canister pressures.

Owner:SCOTT TECH INC

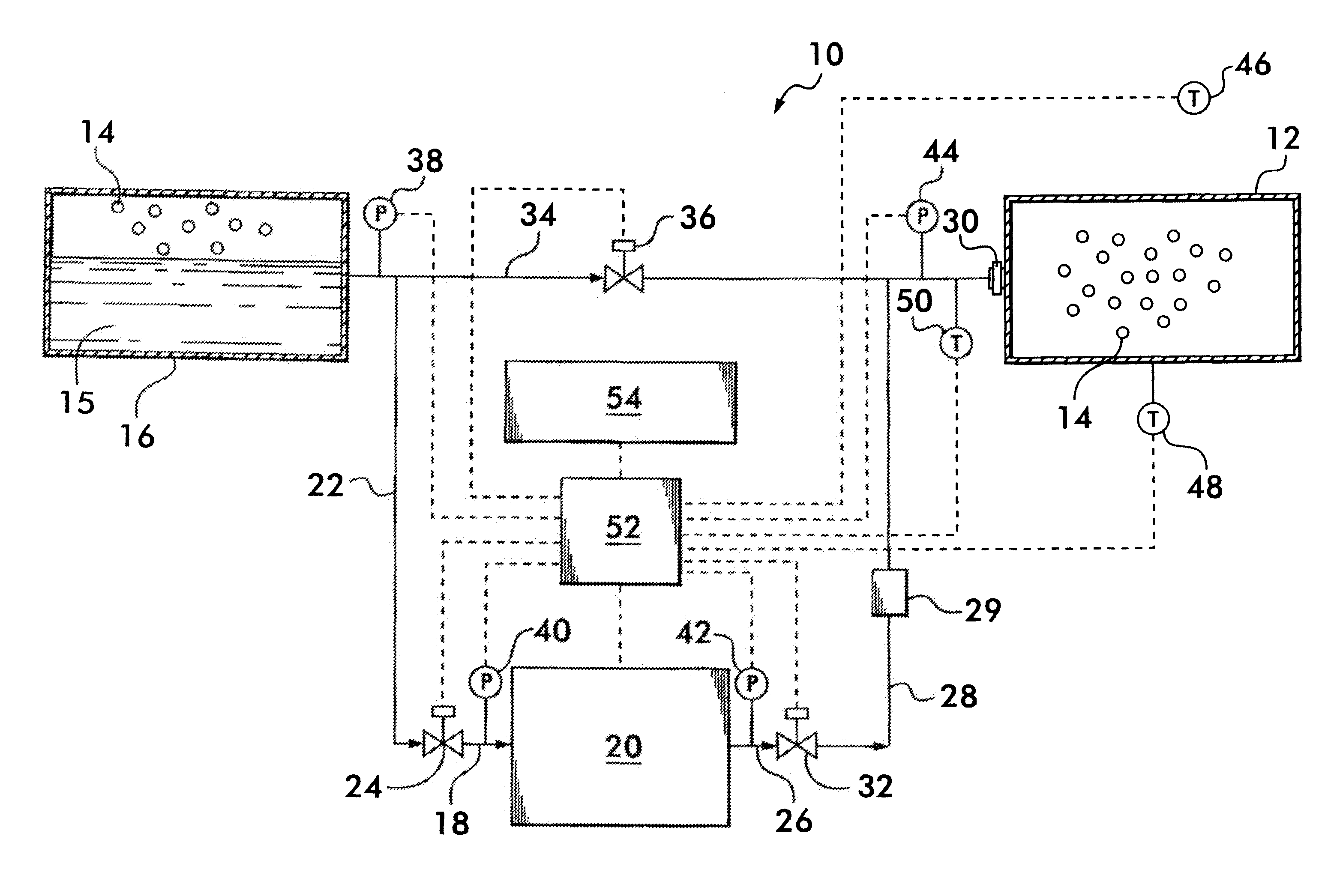

Compressor fill method and apparatus

A method an apparatus for filling a vessel with compressed gas is disclosed. Gas is compressed into the vessel at a predetermined flow rate using a variable speed pump or compressor. The flow rate is adjusted to increase the gas pressure at a predetermined rate of change. The flow rate is adjusted based upon the instantaneous value of a measured parameter such as gas temperature or pressure or ambient temperature. The parameter is measured by a transducer and the value is fed back to a controller which adjusts the speed of the compressor or pump to produce the flow rate needed to achieve the predetermined pressure rate of change.

Owner:AIR PROD & CHEM INC

LNG Vapor Handling Configurations And Methods

InactiveUS20090217676A1Reduce boil-off volumeEliminate needSolidificationLiquefactionProcess engineeringRefrigeration

LNG from a carrier is unloaded to an LNG storage tank in configurations and methods in which expansion of compressed and condensed boil-off vapors from the LNG storage tank provide refrigeration to subcool the LNG that is being unloaded. Most advantageously, such configuration and methods reduce the amount of boil-off vapors and eliminate the need for a vapor return line and associated compressor.

Owner:FLUOR TECH CORP

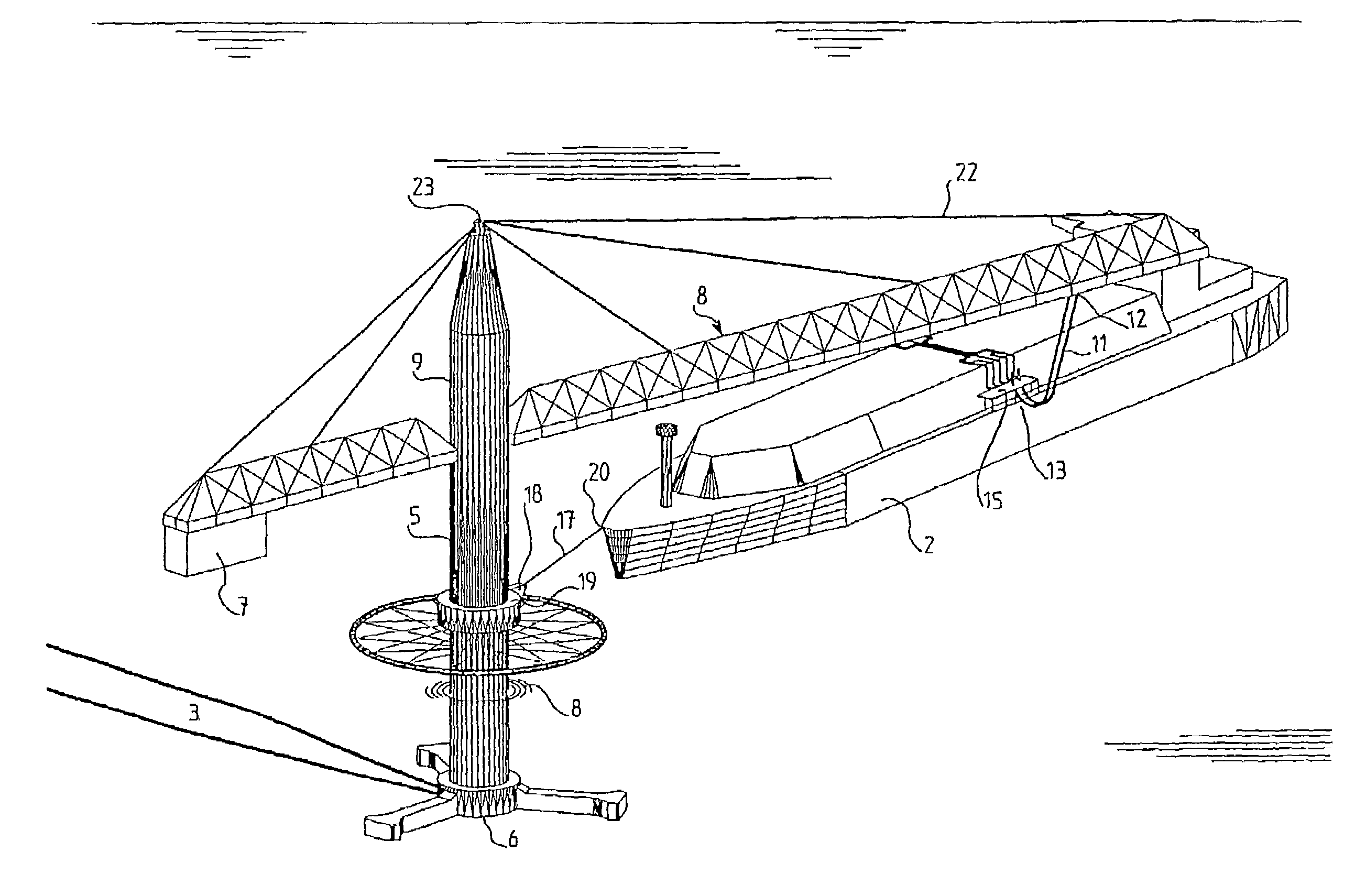

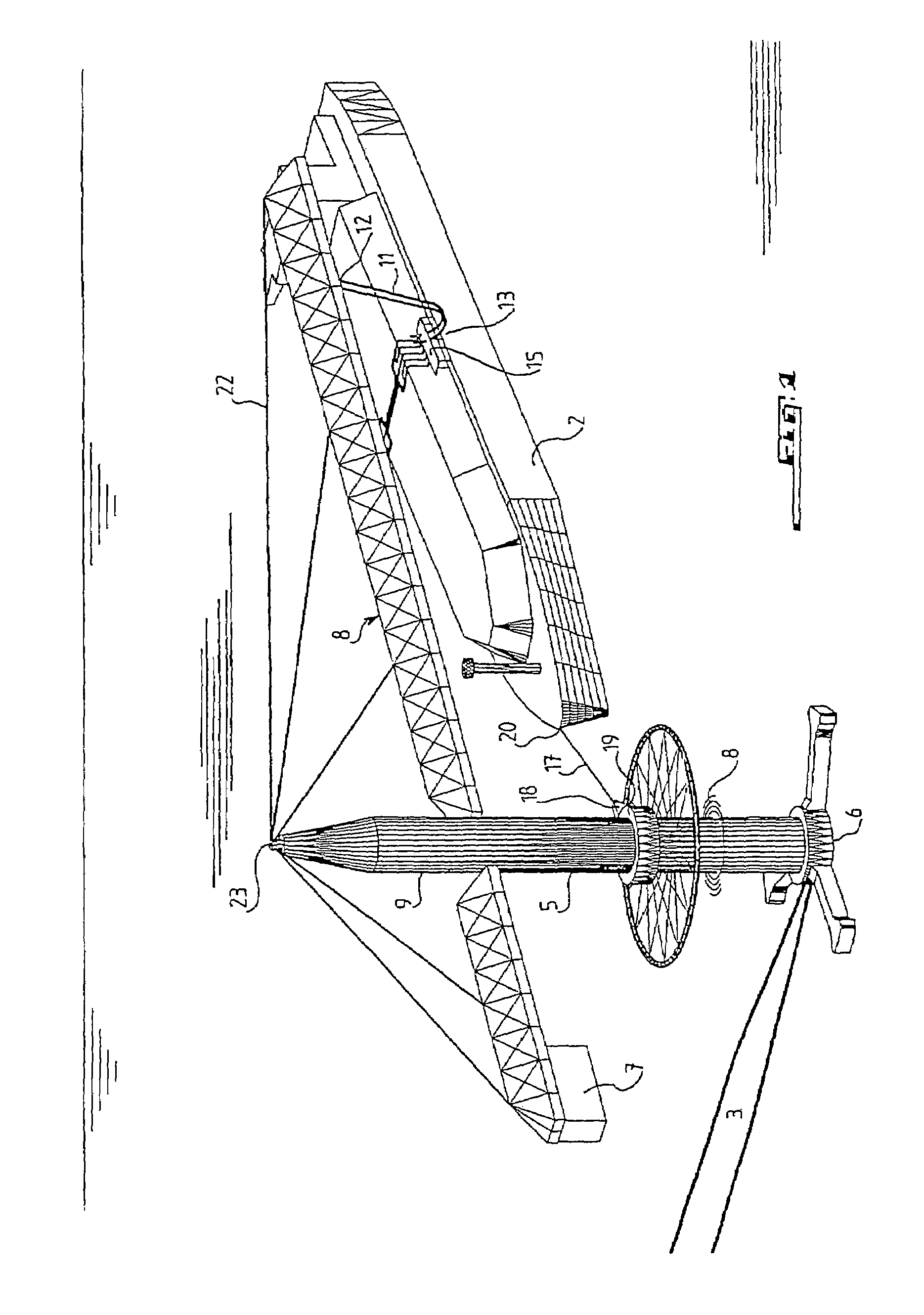

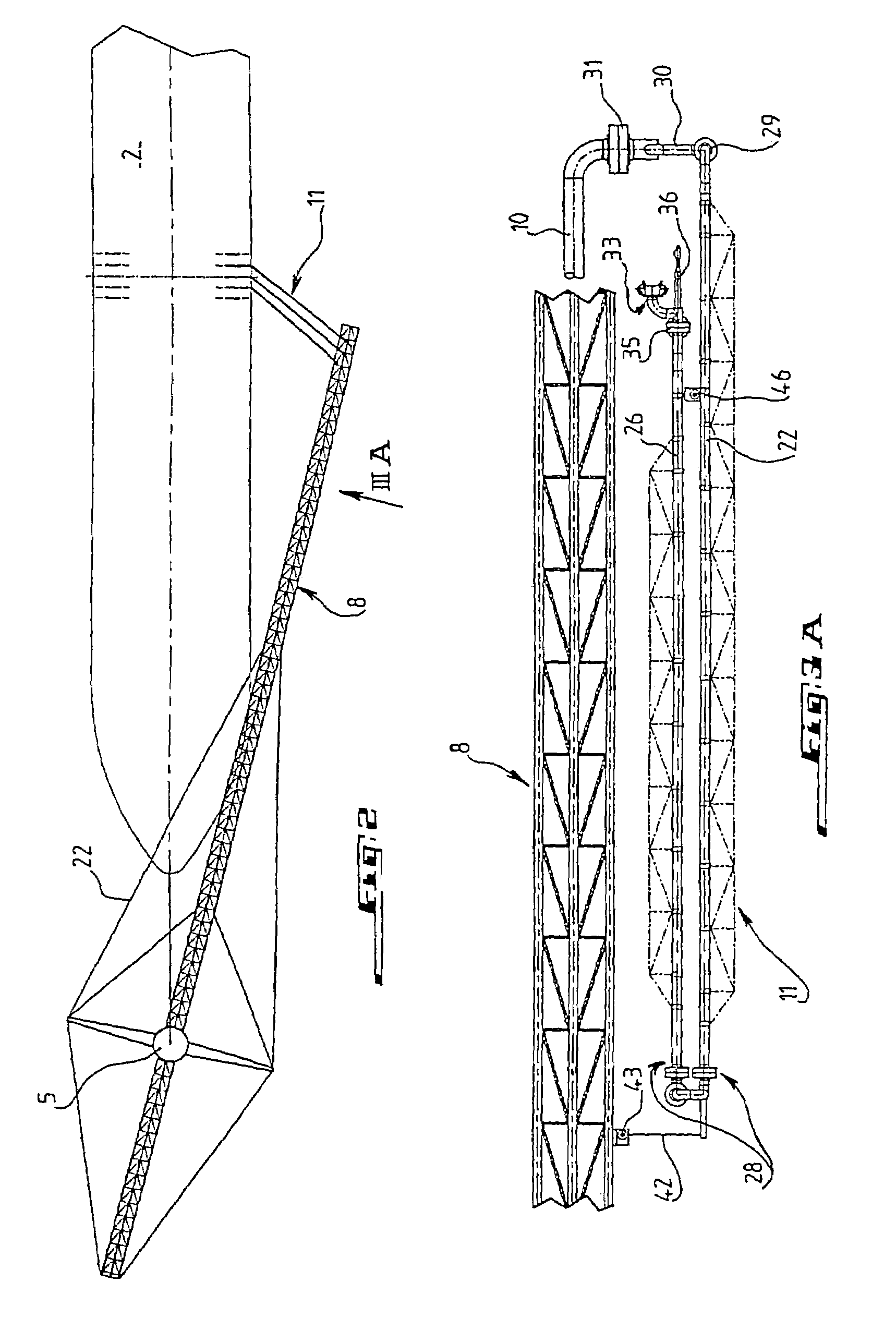

System for transfer of a fluid product, particularly liquefied natural gas, between a transport vehicle, such as a ship, and an installation for receiving or supplying this product

InactiveUS7147021B2Reduces and cancel stressAvoid excessive numberGas handling applicationsGas handling/storage effectsMarine engineeringVertical axis

A device for transferring a product between a ship and a fixed installation. The device is supported at one end by a support structure and the other end is capable of being connected to the ship's manifold. The support structure includes a boom carrying a transfer pipe, rotatable about a vertical axis above the ship, and a deformable transfer device, one end of which is connected to the pipe, and the other end is mobile between a stowed position proximate the boom and a position for connection to the ship's manifold. The invention is useful for transferring liquefied natural gas.

Owner:SOC EURO DINGENIERIE MECANIQUE EURODIM SA

Device and method for pressure control of cargo tank of liquefied natural gas carrier

InactiveUS6901762B2Guaranteed uptimeLow costSolidificationLiquefactionEngineeringPressure controlled ventilation

An apparatus for controlling the pressure in a cargo tank 1 supplies BOG generated from liquefied natural gas stored in the cargo tank 1 to a burning system 6 through a compressor. In this apparatus, a reliquefaction plant 5 is disposed on the downstream side of first and second compressors 3 and 4 and on the upstream side of the cargo tank 1 so that BOG discharged from the second compressor 4 is liquefied by the reliquefaction plant 5 and the liquefied fluid is returned again into the cargo tank 1.

Owner:MITSUBISHI SHIPBUILDING CO LTD +3

Generation and delivery system for high pressure ultra high purity product

The invention relates to a process and apparatus for delivering an ultra high purity fluid comprising at least one component to a point of use at a required pressure without mechanical pumping. In one embodiment, a high purity feed comprising at least one component in gaseous or liquid form is charged into a vessel and at least partially converted to a solid phase source. As the feed is converted to a solid phase source, additional feed may be added until the vessel is at least substantially filled with a solid phase source or slush. Once filled, the solid phase source or slush may be isochorically heated whereby the solid phase source is converted to a product at an elevated pressure.

Owner:AIR PROD & CHEM INC

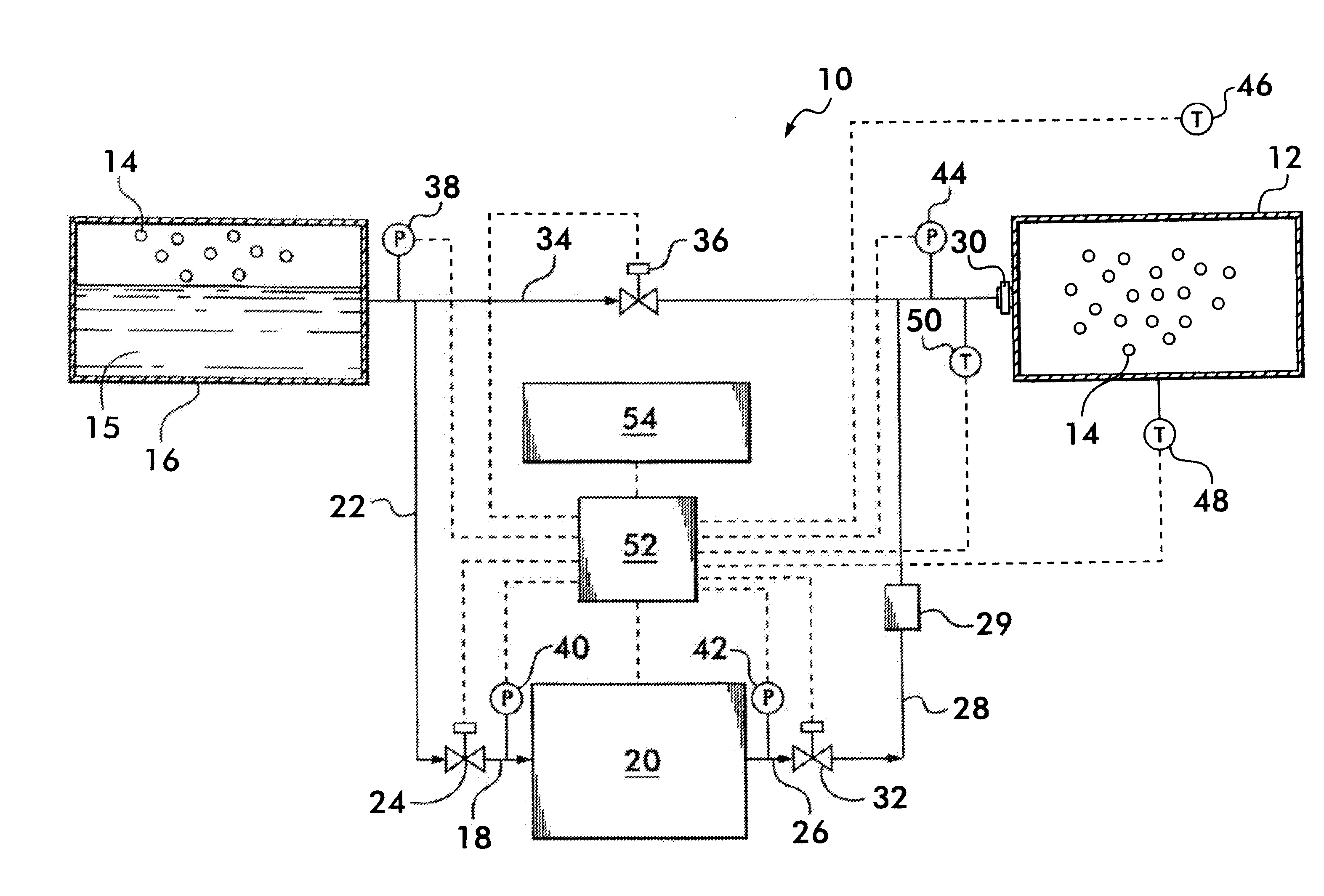

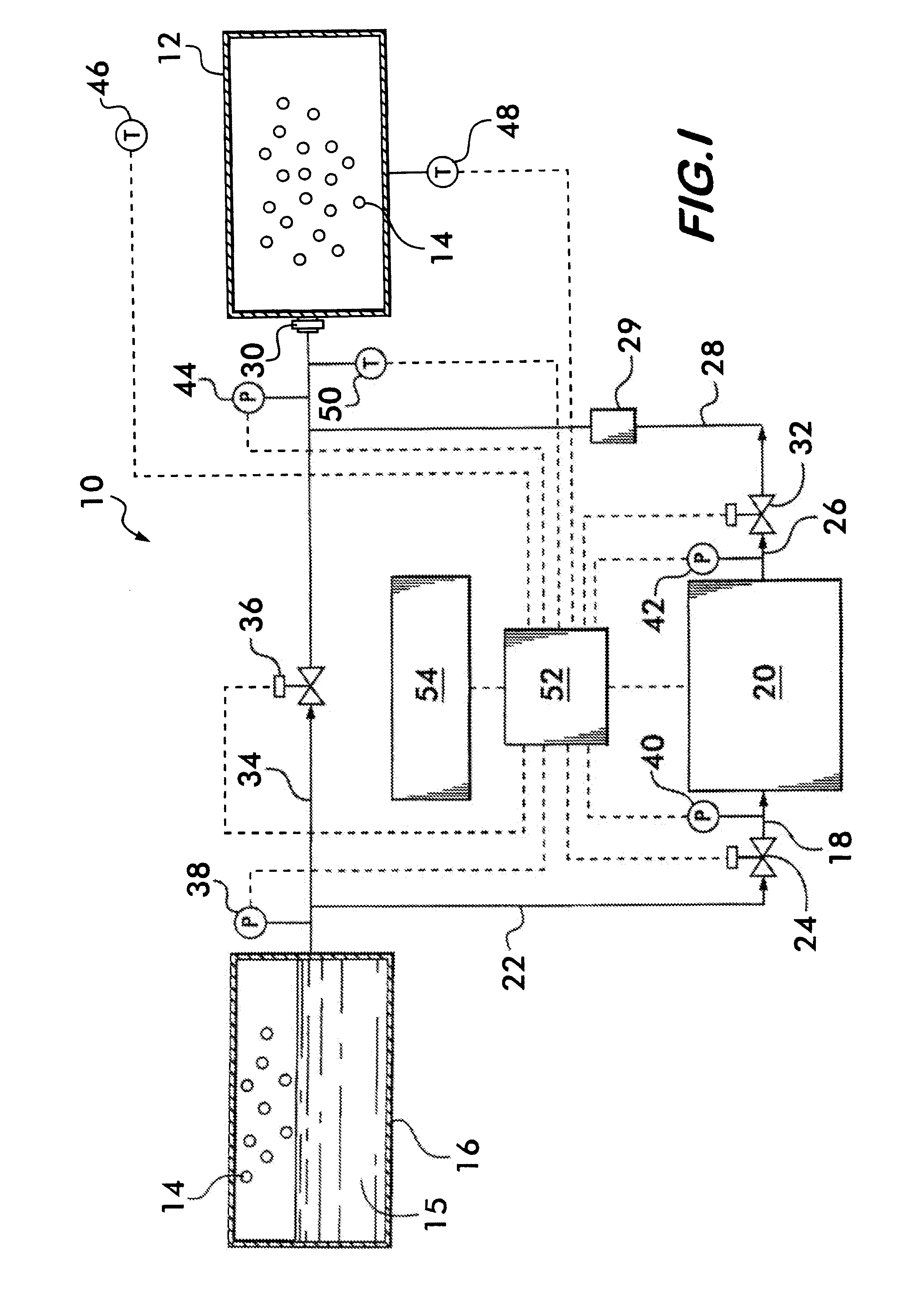

Pumpless fluid dispenser

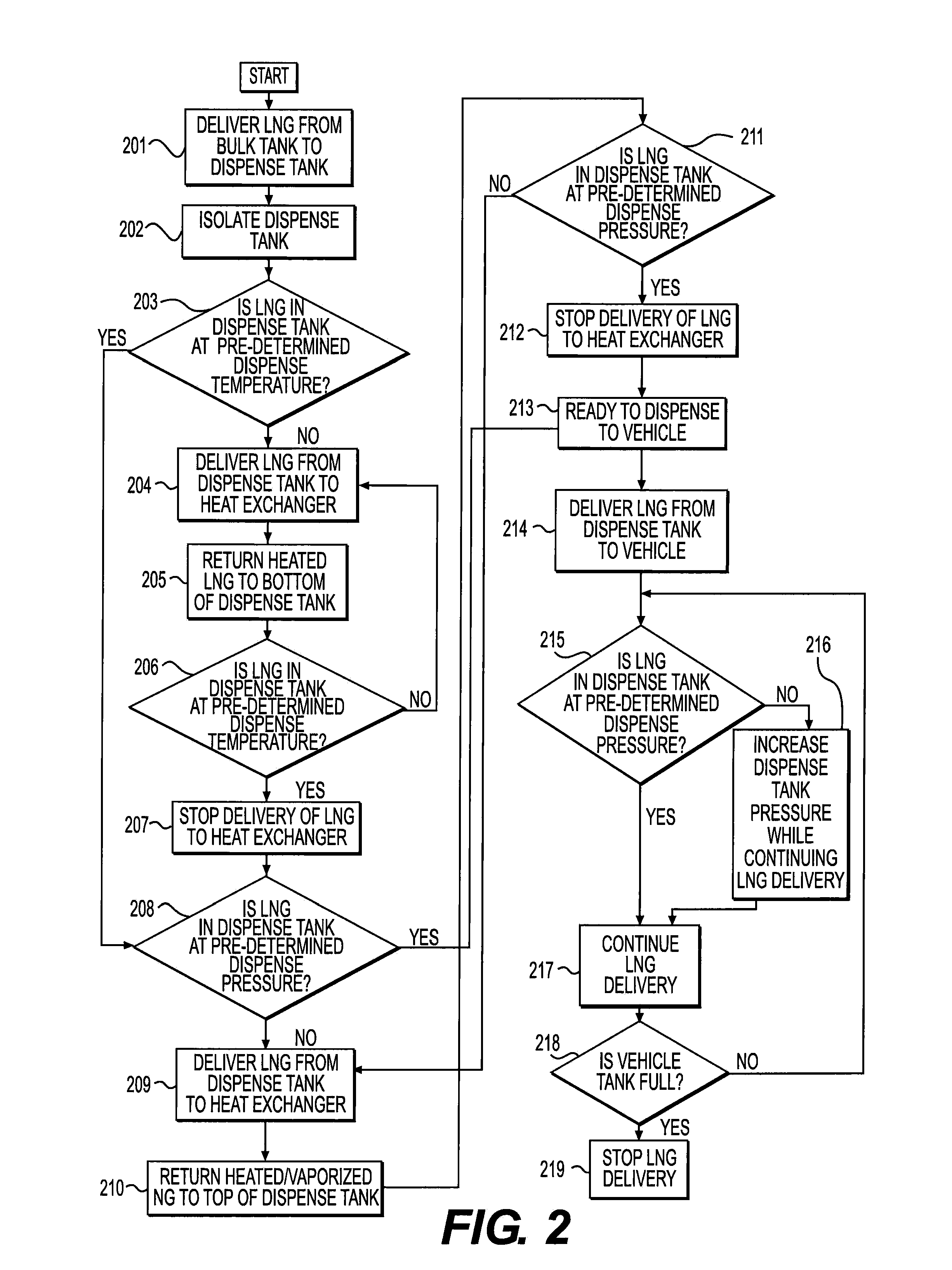

A fluid dispensing system may include a first tank configured to contain a first fluid and a second tank configured to contain a second fluid. The system may also include a conditioning system fluidly connected to the second tank. The conditioning system may include at least one conduit fluidly coupled to a lower region of the second tank. The conditioning system may also include a heat exchanger. In addition, the conditioning system may include at least one conduit fluidly coupled to an upper region of the second tank.

Owner:CRYOGENIC IND LLC

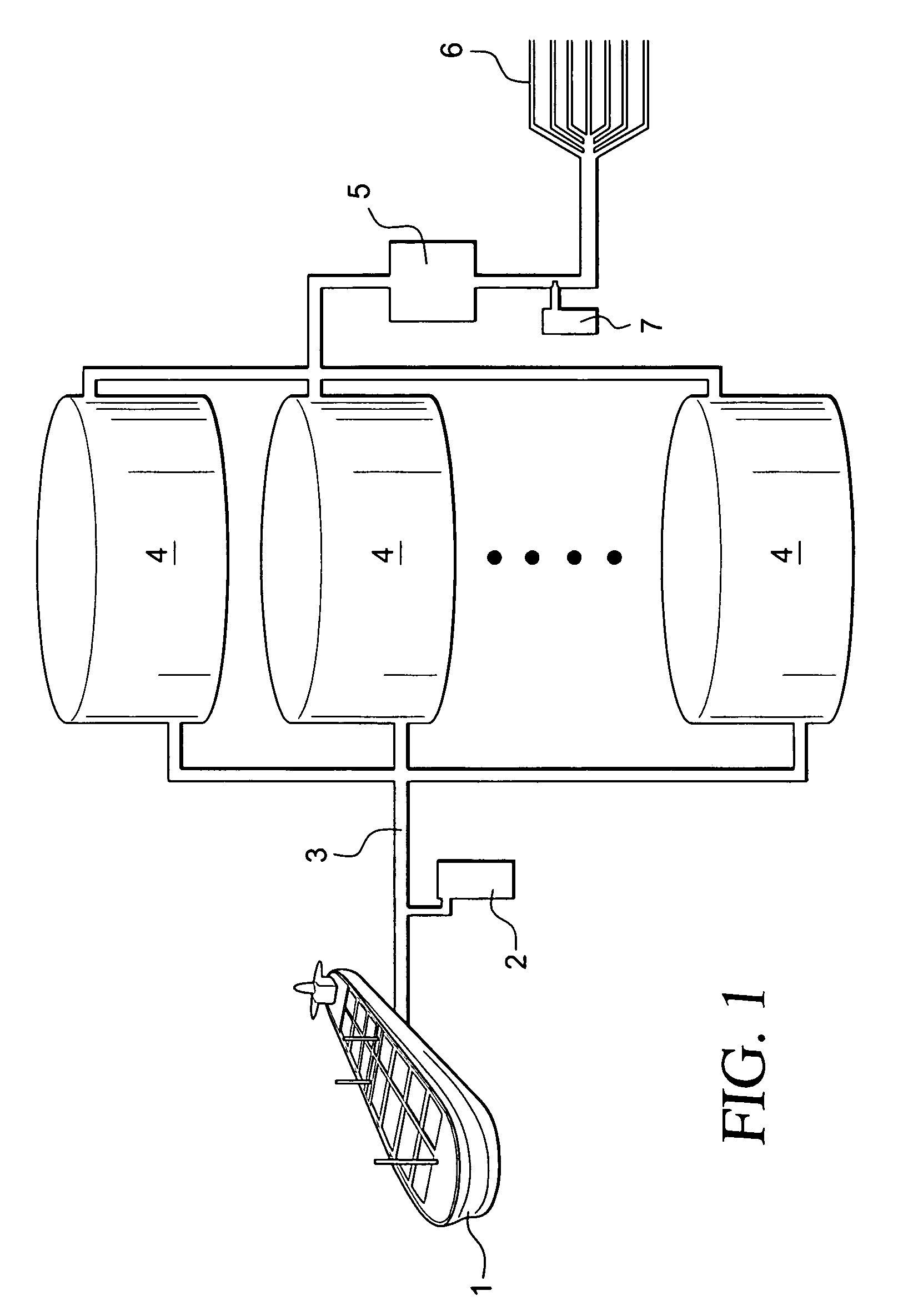

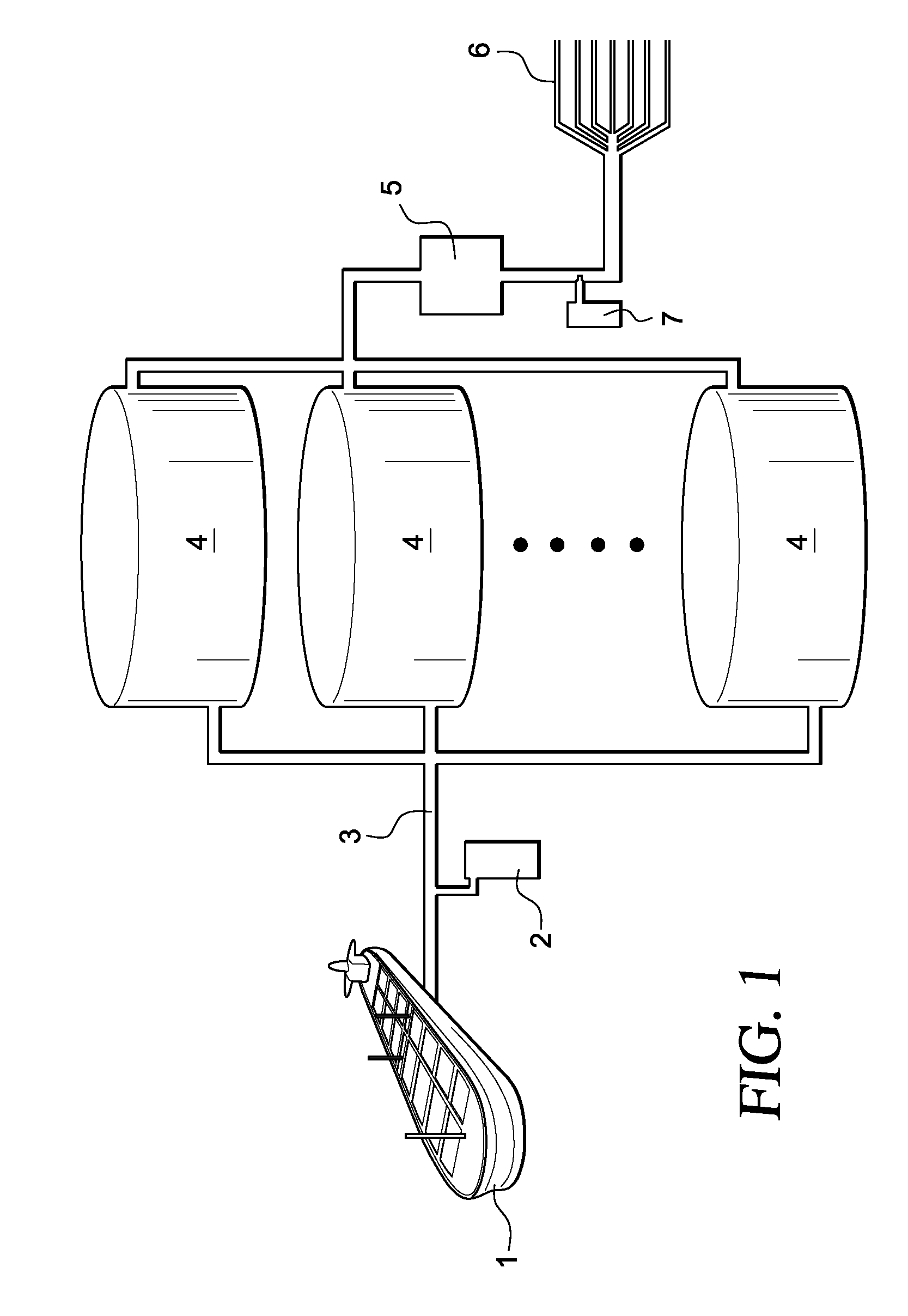

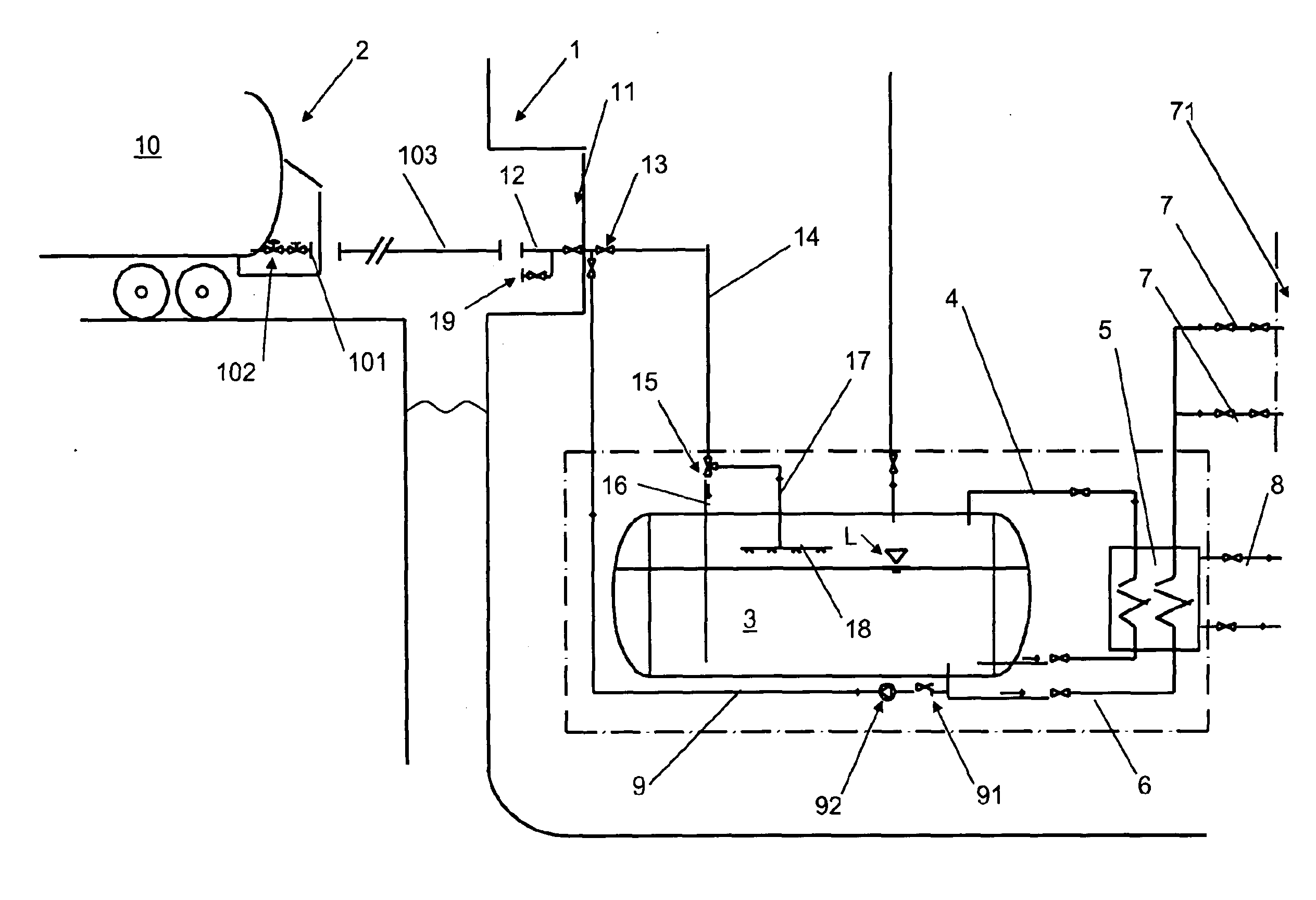

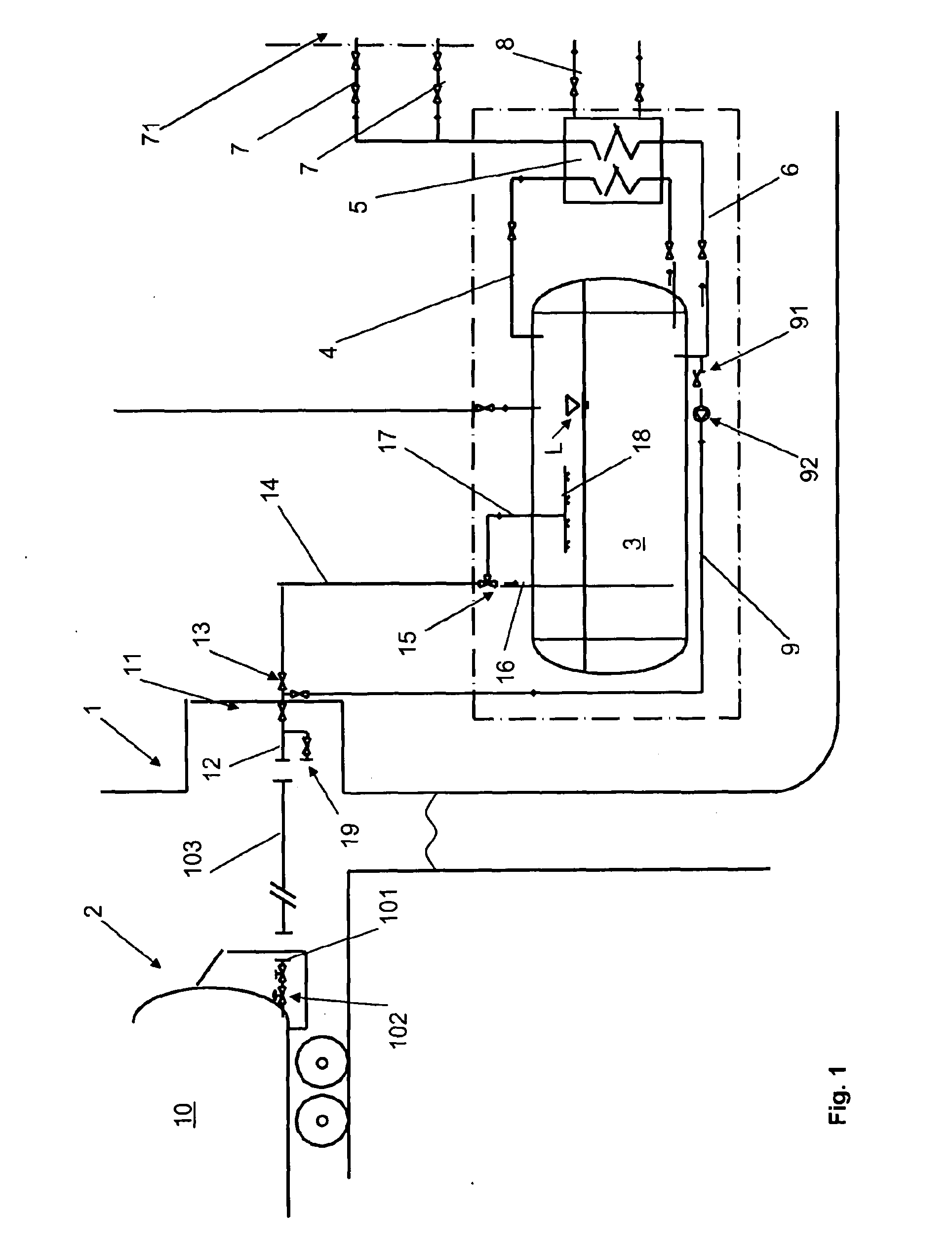

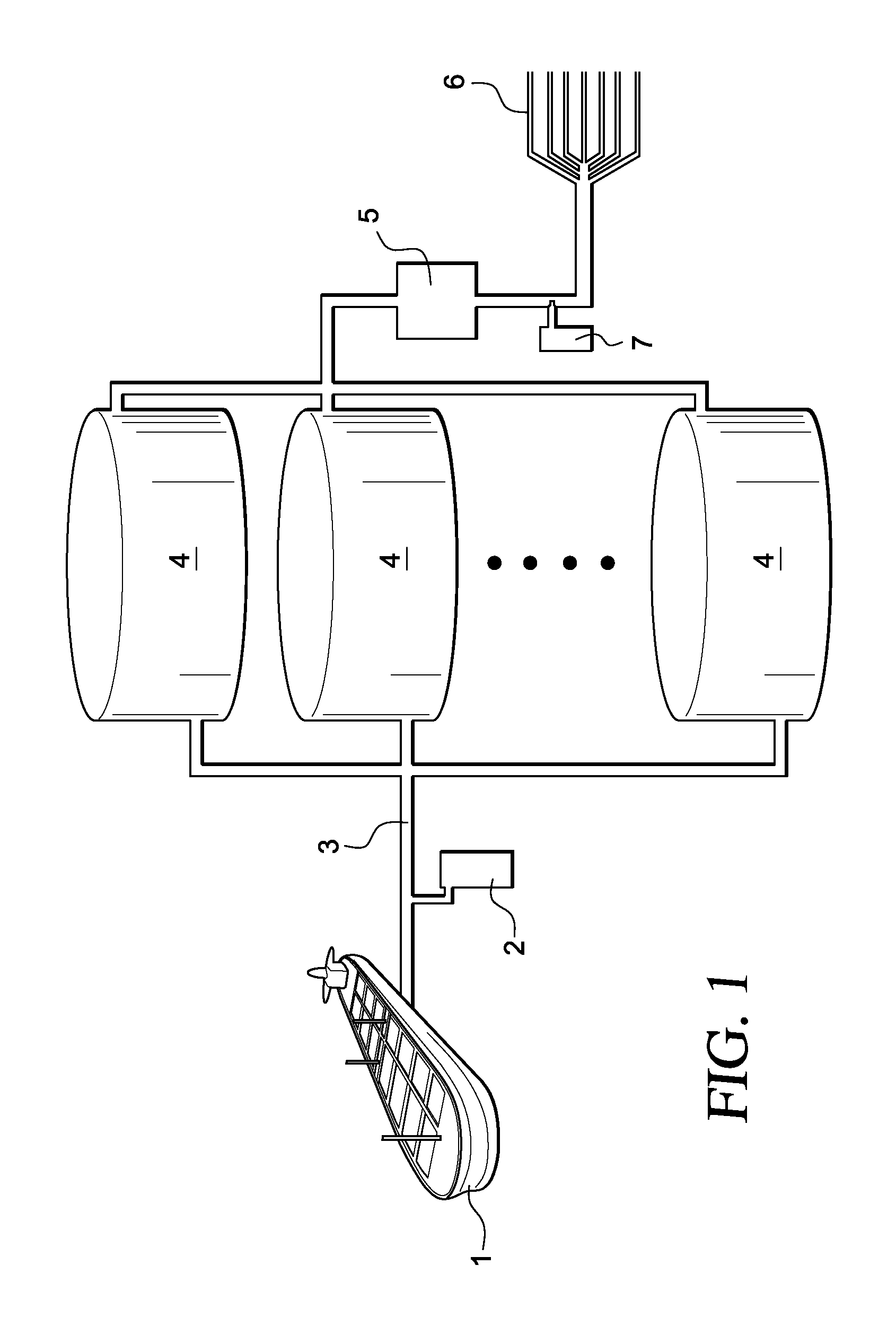

Method for operating a LNG fuelled marine vessel

InactiveUS20110179810A1Efficient transferRestricting fuel flowAuxillariesGas handling applicationsLine tubingMarine engineering

The invention relates to a method and system for operating a LNG fuelled marine vessel. The marine vessel (1) comprises a LNG storage tank (3) and a LNG fuelled power plant (71). LNG is stored in the LNG storage tank, and in connection with a bunkering operation the marine vessel is supplied with LNG by connecting a source of LNG to a bunkering line (14) of the marine vessel and subsequently supplying the marine vessel with LNG through the bunkering line. In order to achieve a faster bunkering operation the bunkering line (14) is cooled down prior to the bunkering operation.

Owner:WARTSILA FINLAND OY

Liquid Gas Vaporization and Measurement System and Method

ActiveUS20120017669A1Efficiently and accurately sampling and measuringEfficiently flash vaporizeComponent separationGas handling applicationsMass storageLiquid state

Owner:MUSTANG SAMPLING

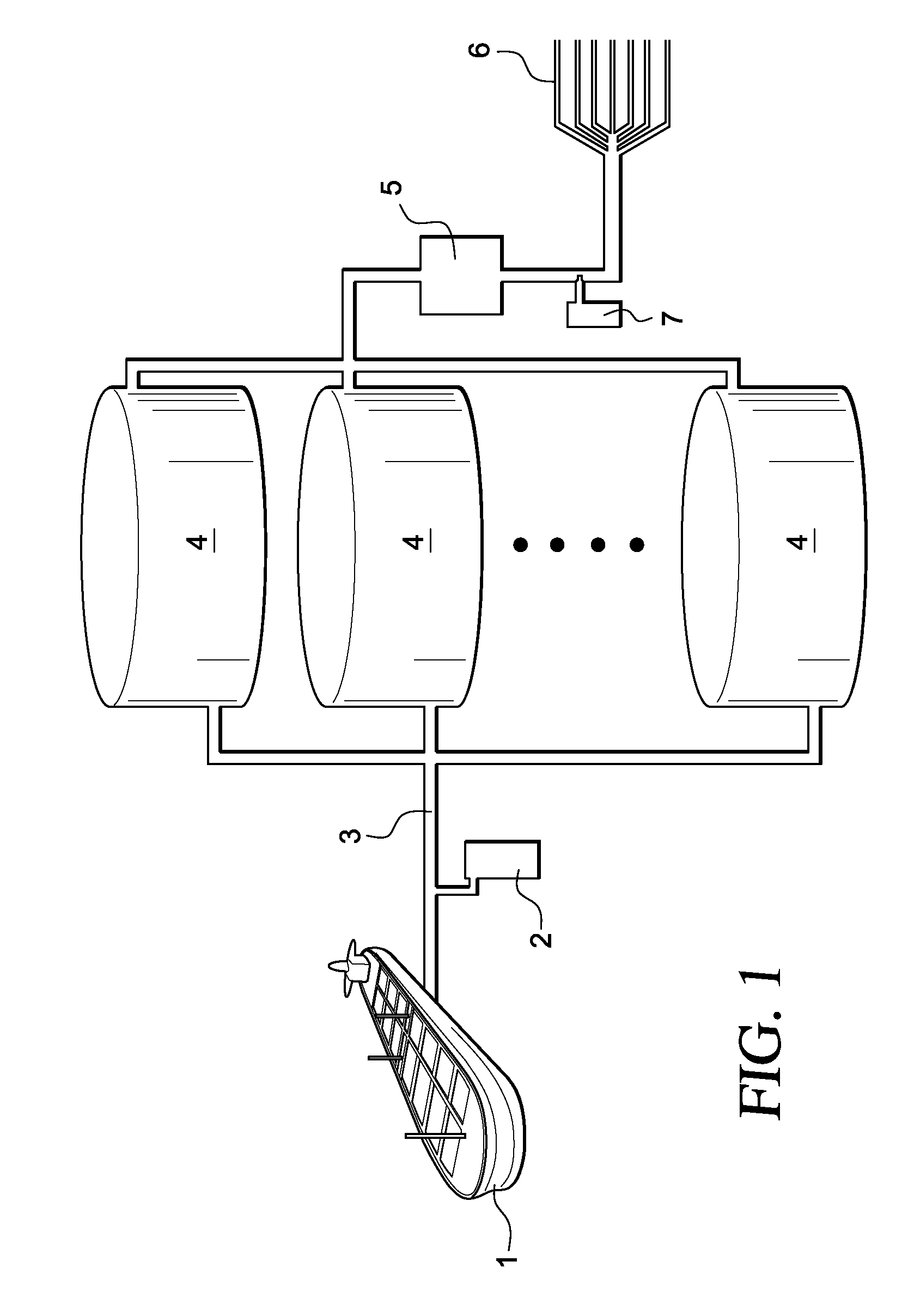

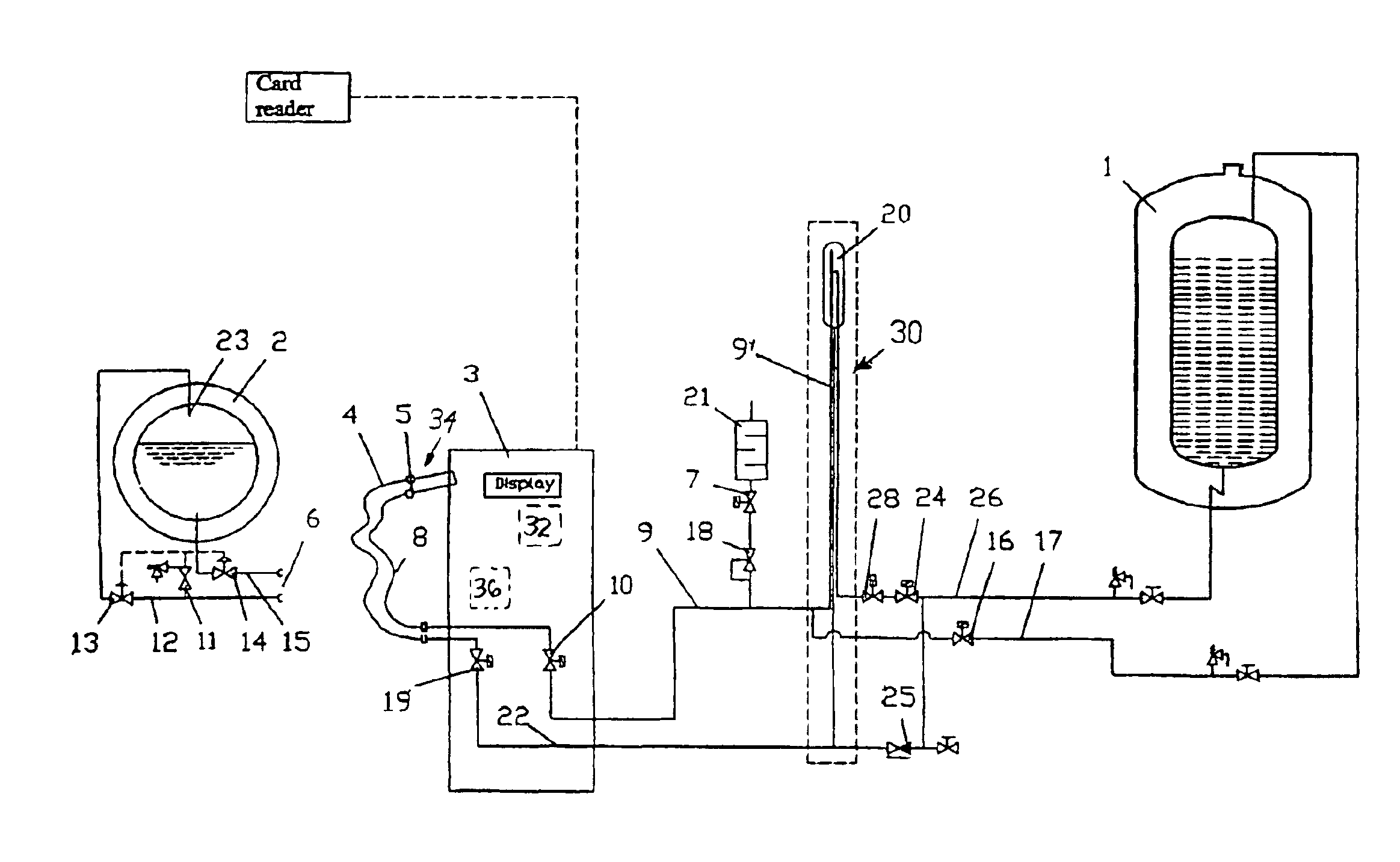

Filling station for the filling of fluids

InactiveUS7021341B2Easy accessEasy to fillGas handling applicationsGas handling/storage effectsProcess engineeringTruck

A method for distribution and sales of cryogenic fluids, in particular CO2, includes a system of filling stations for cryogenic fluids provided in connection with ordinary service stations for the filling of fuels to motor driven vehicles. The filling stations for cryogenic fluids include at least a stationary storage tank (1) and dispenser (3) with flexible hoses (4, 8) and a quick connector (5) for easy connection to a mobile tank (2) on a truck or the like. The filling station further includes a pressure / flow control column (27) with a phase separator (20) provided between the stationary storage tank (1) and the dispenser.

Owner:THERMO KING CORP

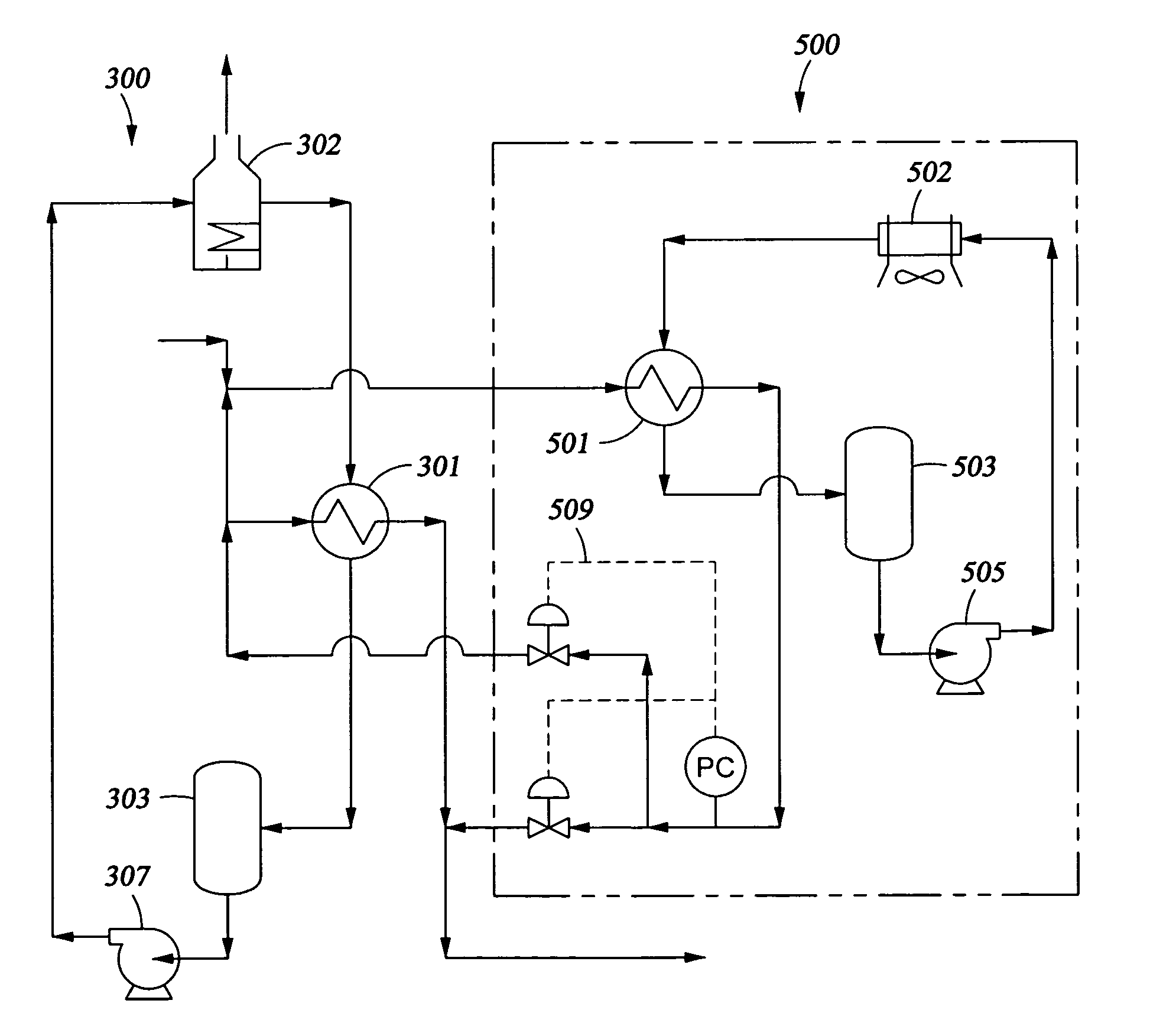

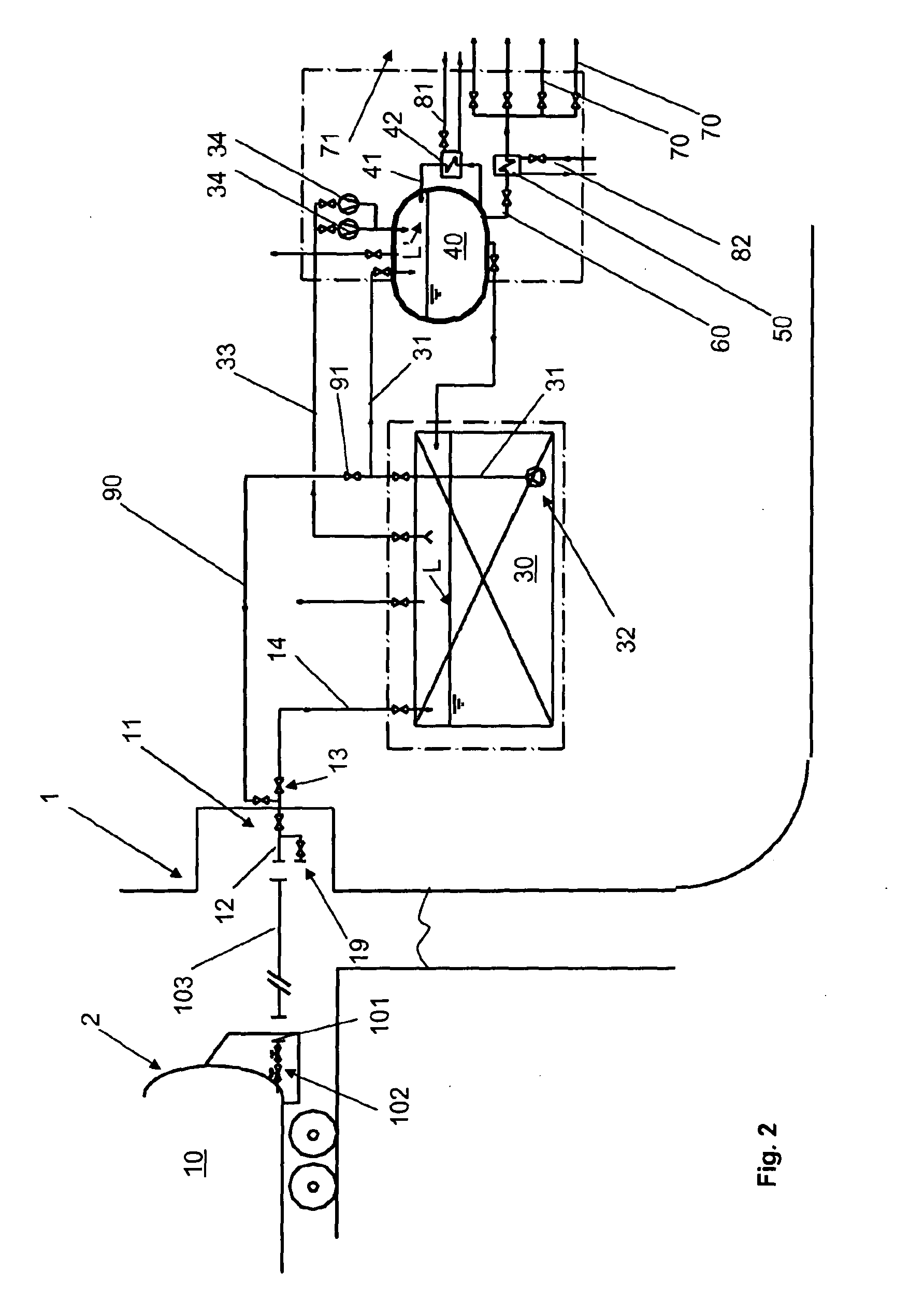

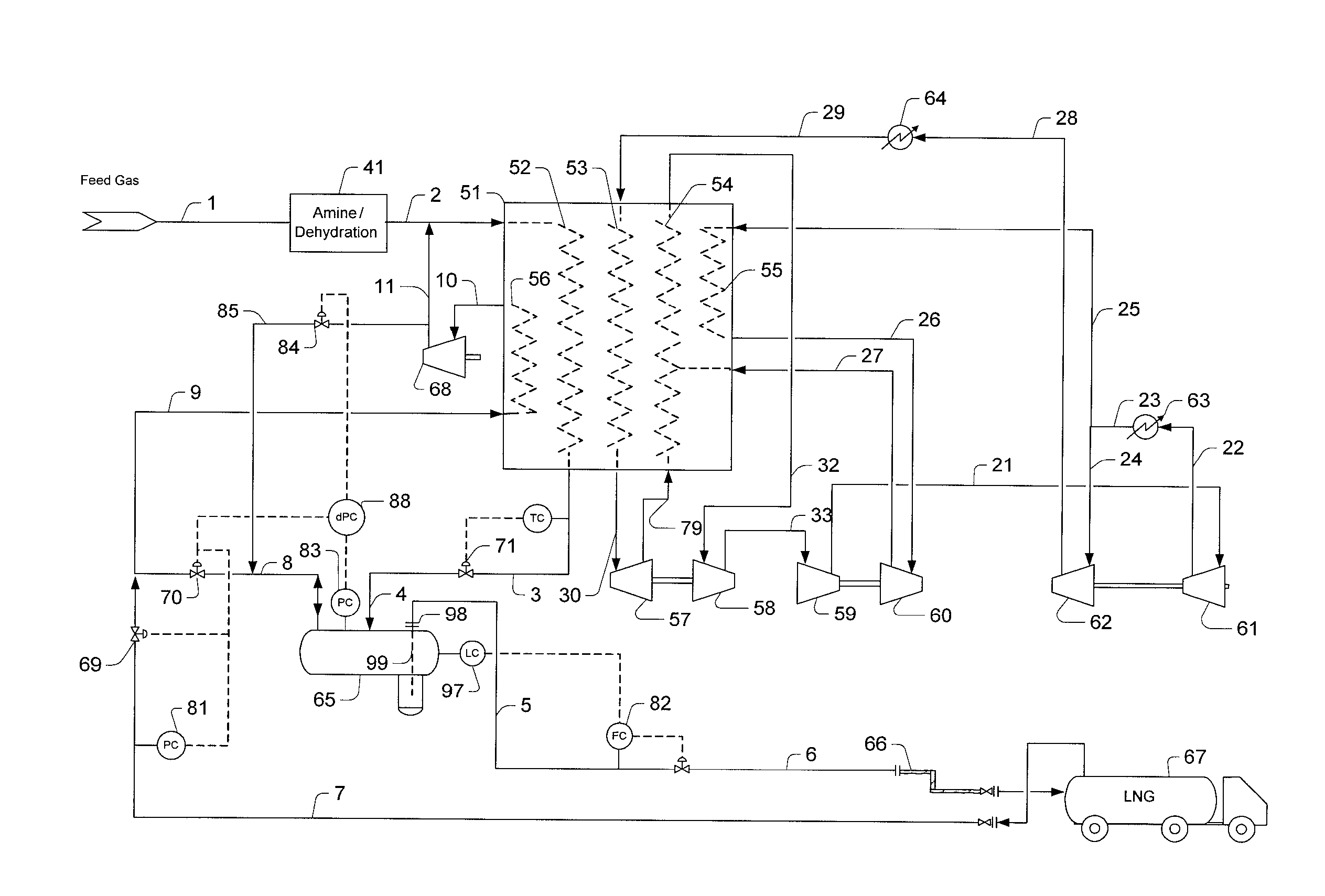

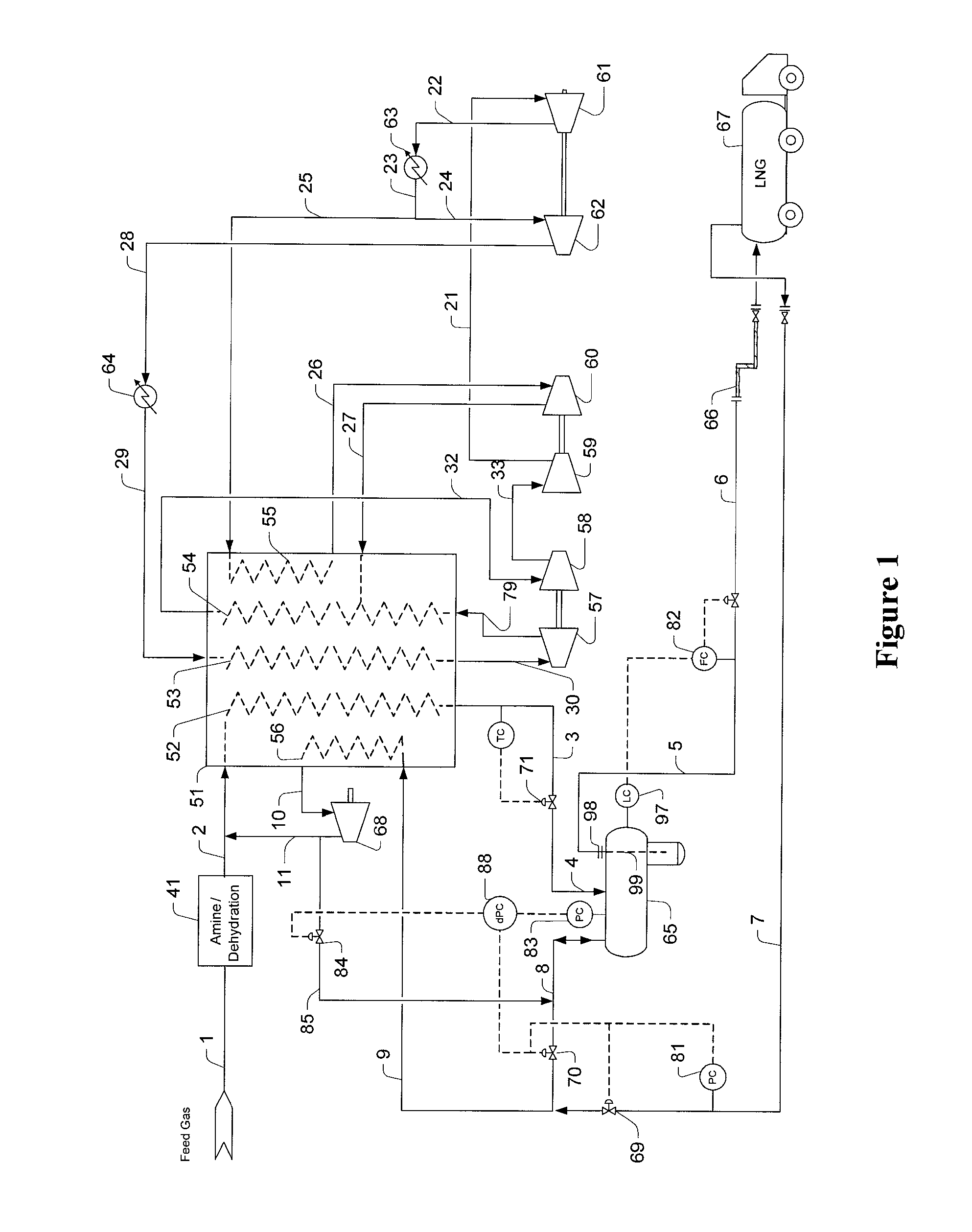

Configurations and methods for small scale LNG production

ActiveUS20130192297A1Eliminates potential hazardSolidificationLiquefactionDifferential pressureControl system

A small scale natural gas liquefaction plant is integrated with an LNG loading facility in which natural gas is liquefied using a multi-stage gas expansion cycle. LNG is then loaded onto an LNG truck or other LNG transport vehicle at the loading facility using a differential pressure control system that uses compressed boil off gas as a motive force to move the LNG from the LNG storage tank to the LNG truck so as to avoid the use of an LNG pump and associated equipment as well as to avoid venting of boil off vapors into the environment.

Owner:FLUOR TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com