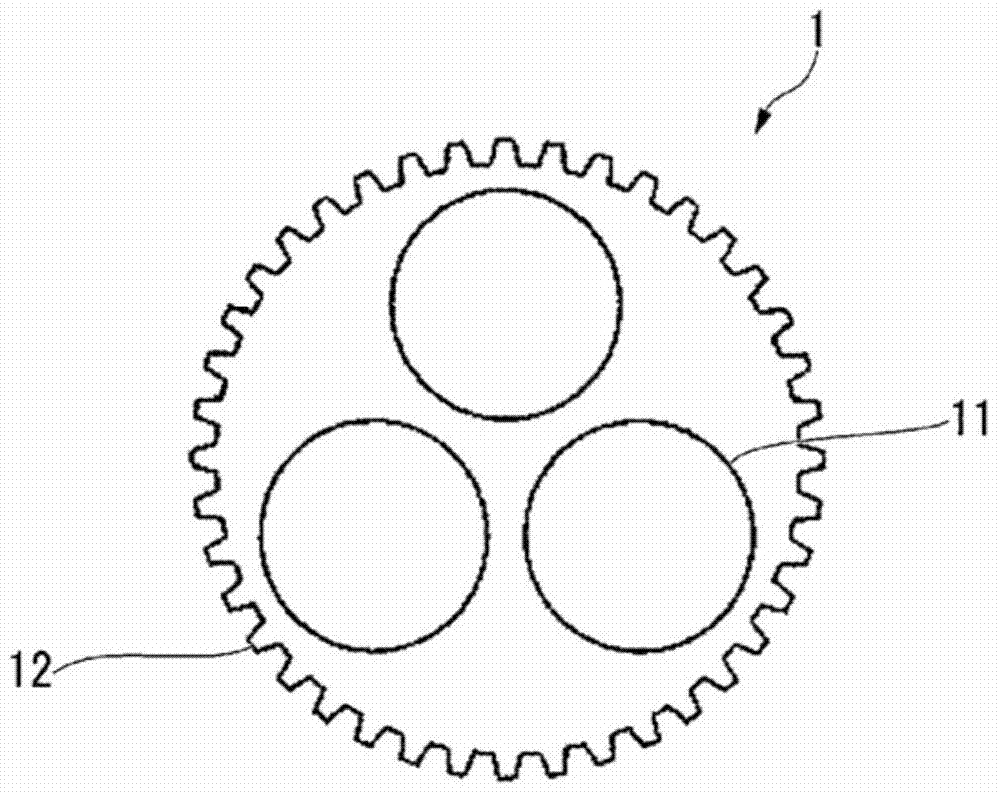

Material for holding item to be polished, and laminate plate using same

A technology for objects to be ground and holders, applied in the direction of grinding workpiece supports, fabrics, electrical components, etc., can solve different problems, achieve the effect of inhibiting scratches, contributing to economic efficiency, and improving plate thickness accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Preparation of resin composition varnish for the first and second fiber substrates

[0065] To a mixture consisting of 50 parts by mass of cresol novolak type epoxy resin 1, 20 parts by mass of bisphenol A type epoxy resin 1, 30 parts by mass of phenol novolak resin 1, and 0.1 parts by mass of 2P4MZ, add As the solvent, methyl ethyl ketone was prepared into a varnish of the resin composition A in which the mass% of the solid content was 55.

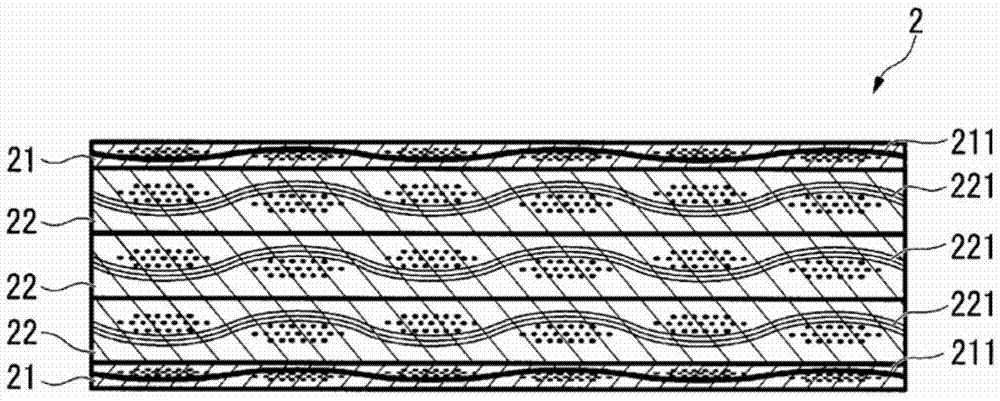

[0066] Preparation of the first prepreg

[0067] The glass fiber fabric 1 was impregnated with the varnish of the resin composition A and dried to prepare a prepreg 1A40 (GC1 / resin composition A / resin composition with a resin composition content of 40% by mass and a glass fiber fabric content of 60% by mass 40% by mass).

[0068] Preparation of the second prepreg

[0069] The glass fiber fabric 2 was impregnated with the varnish of the resin composition A and dried to prepare a prepreg 2A41 (GC2 / resin composition A / resin composition with a...

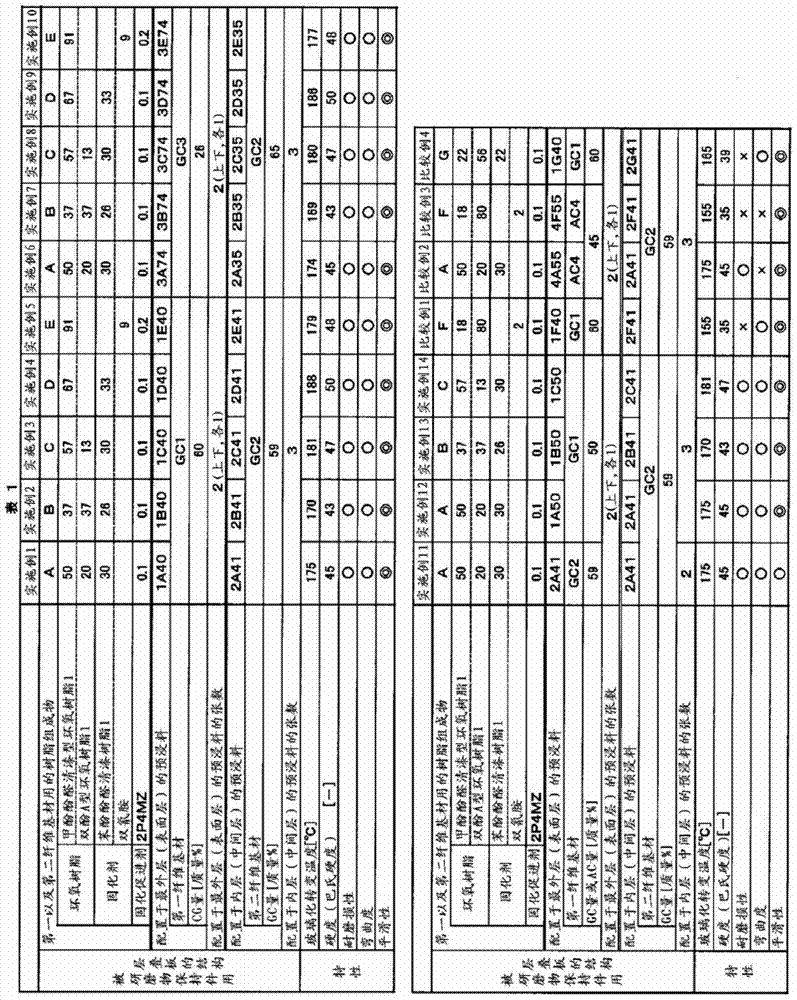

Embodiment 2~14、 comparative example 1、4

[0075] They were blended with the composition shown in Table 1, and the varnishes of the resin compositions A to G were adjusted as the varnishes of the resin compositions for the first and second fiber base materials. After that, GC1 to GC3 as the first fiber base material were impregnated with the varnish of the resin composition in the combination shown in Table 1 so that the GC amount shown in Table 1 was impregnated, and then dried as the outermost layer. 1B40 (GC1 / resin composition B / resin composition content means 40% by mass, the following only differs in resin composition types), 1C40, 1D40, 1E40, 1F40, 1G40, 1A50 (GC1 / Resin composition A / resin composition amount means 50% by mass, and only the type of resin composition is different below), 1B50, 1C50, 2A41 (GC2 / resin composition A / resin composition amount means 41% by mass), 3A74 (GC3 / resin composition A / resin composition amount means 74% by mass, and only the type of resin composition is different below), 3B74, 3C74...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com