Patents

Literature

62results about How to "Increase the pressing area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

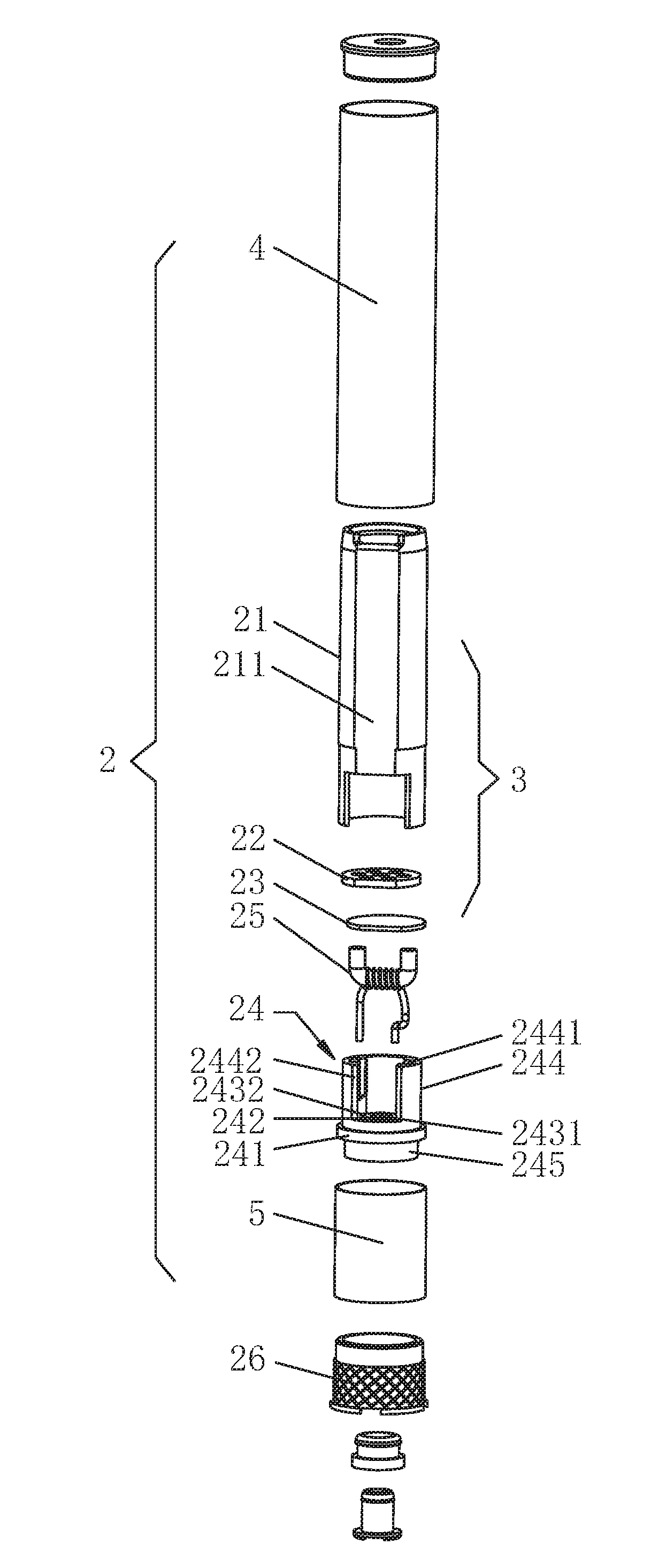

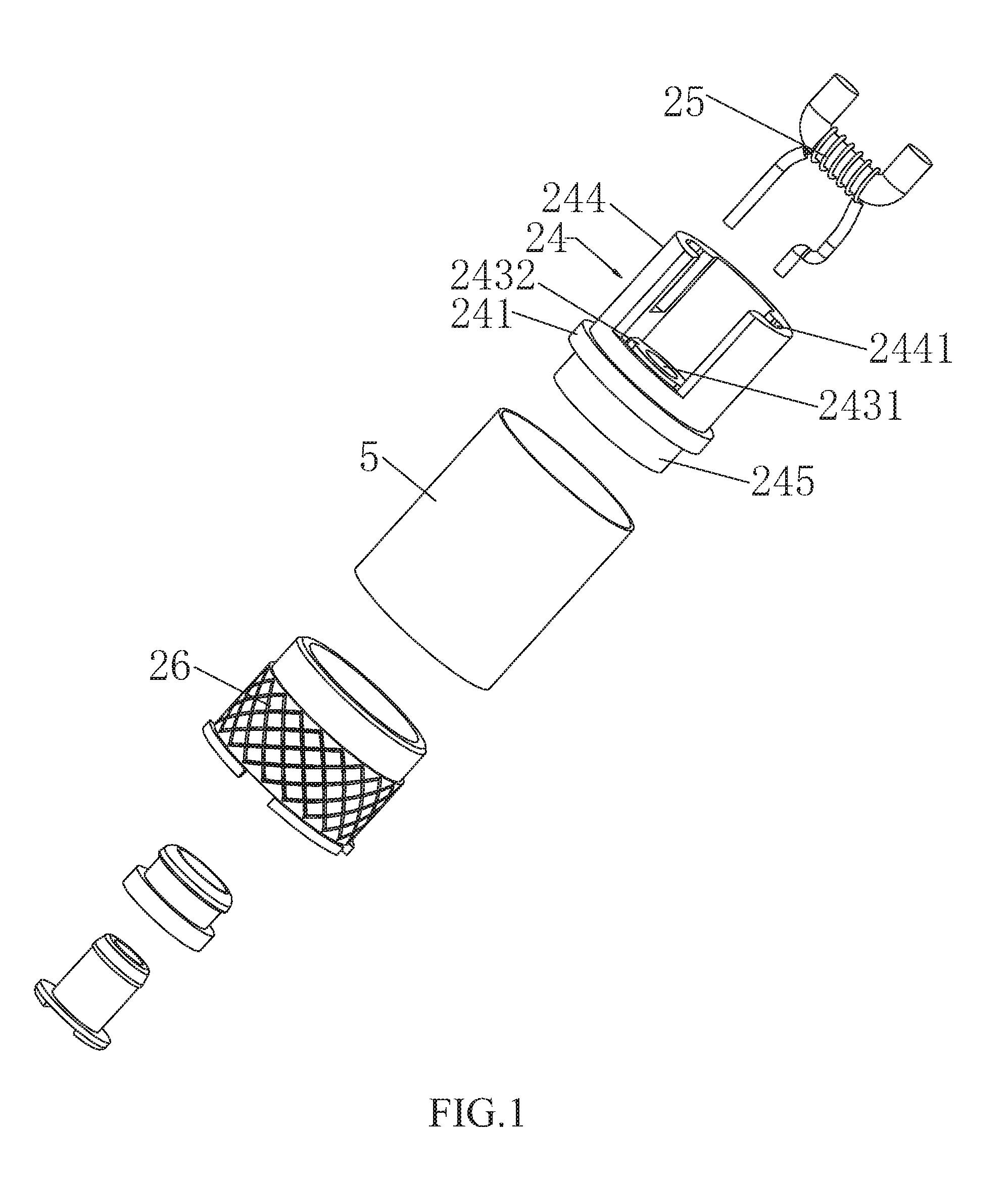

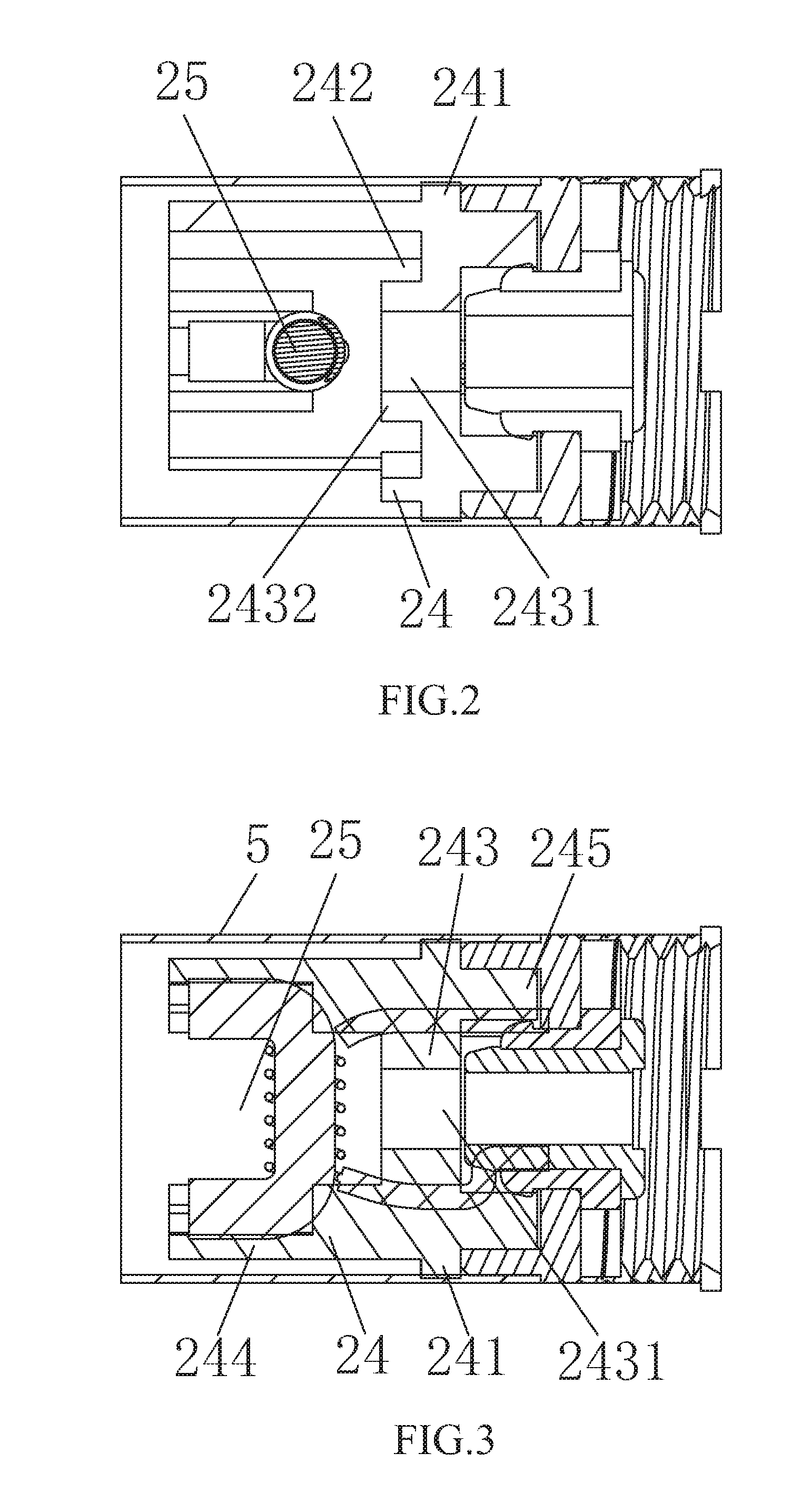

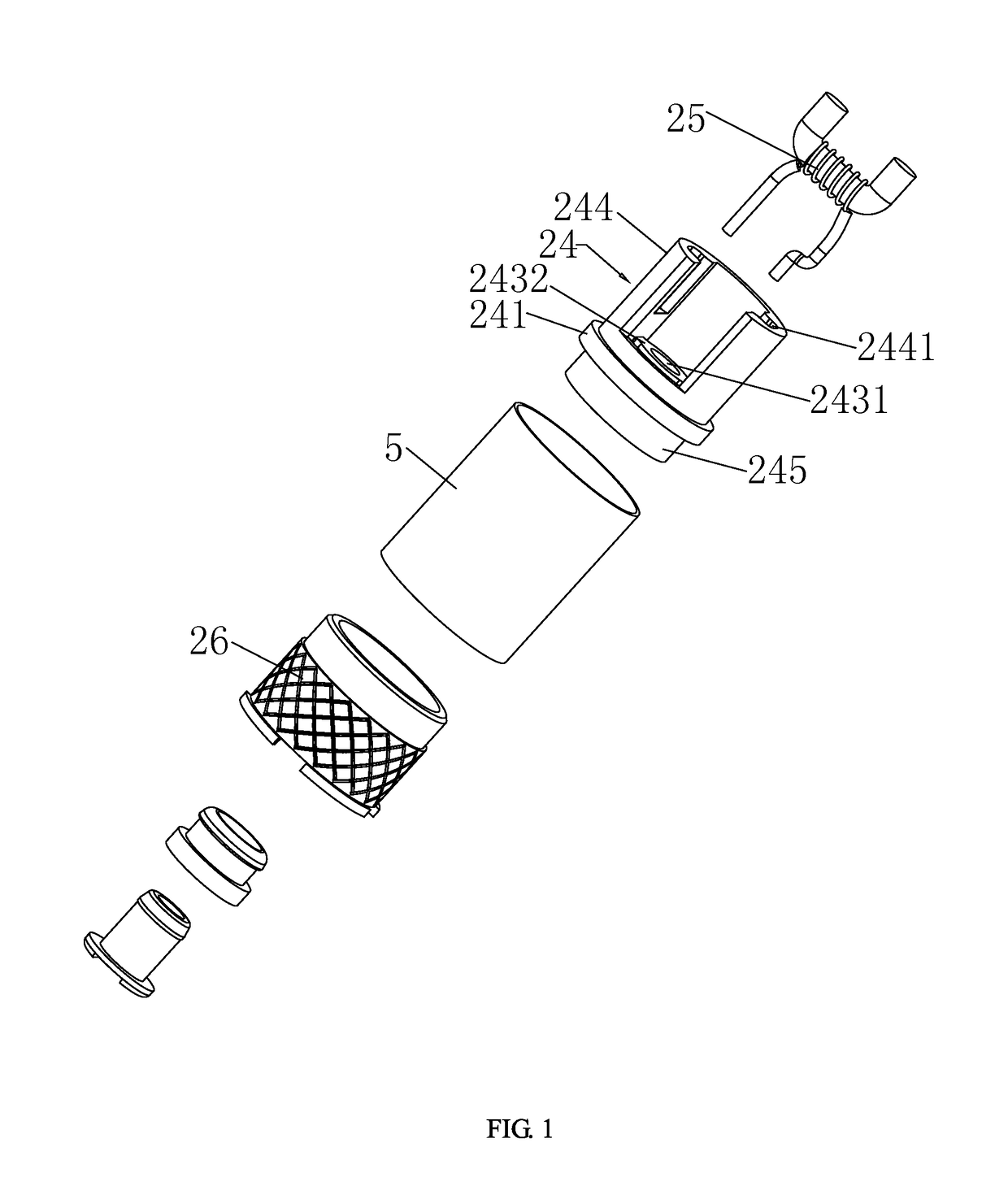

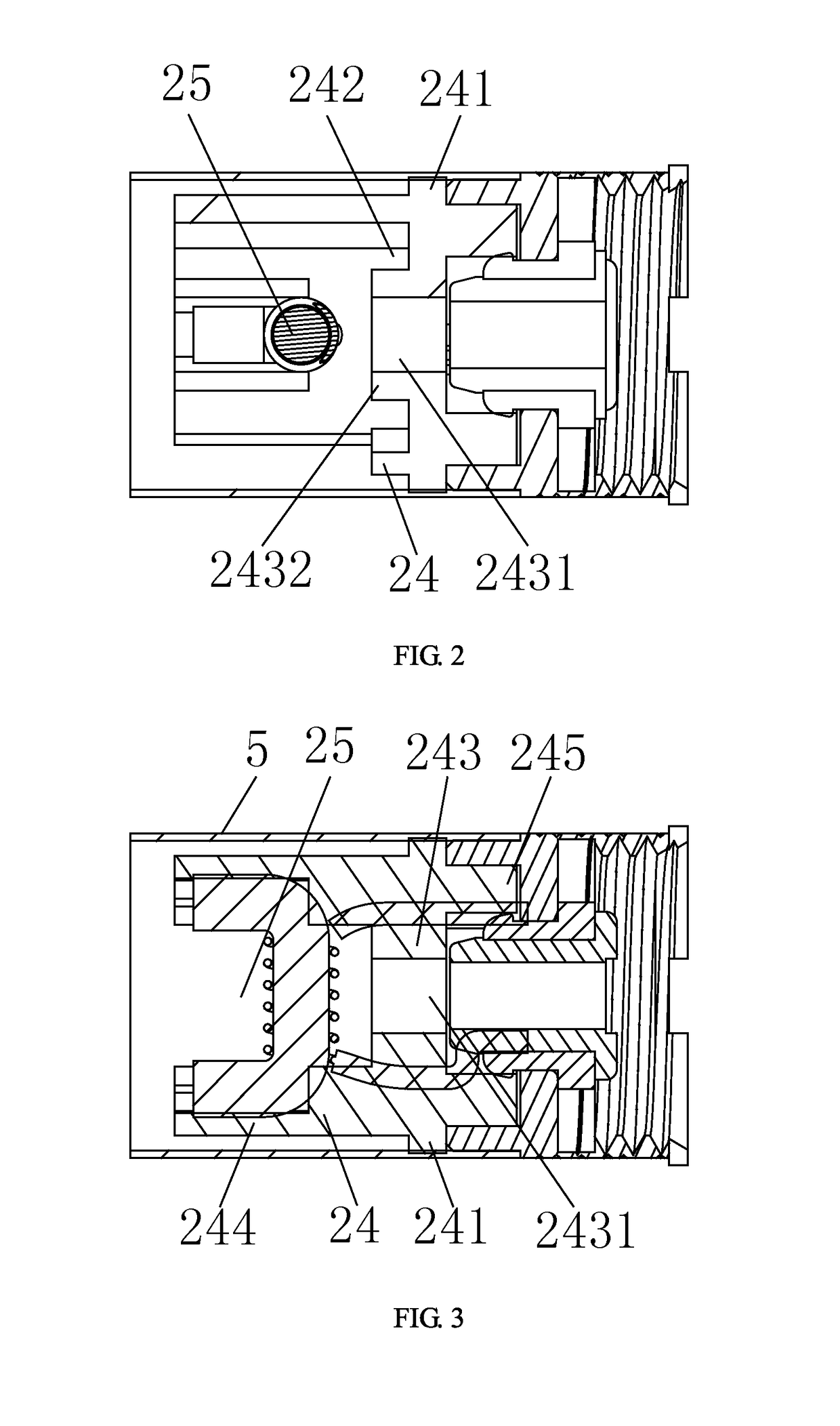

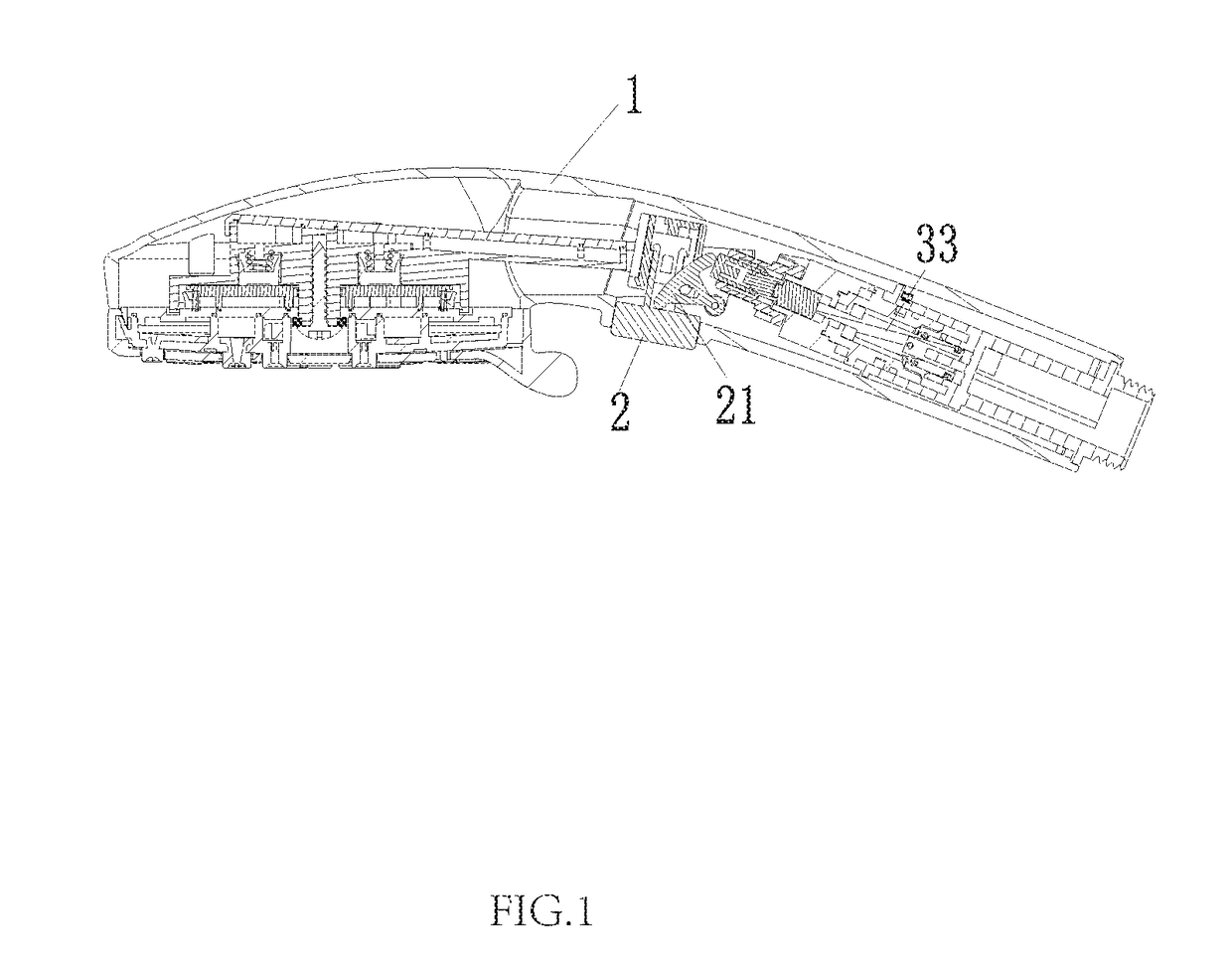

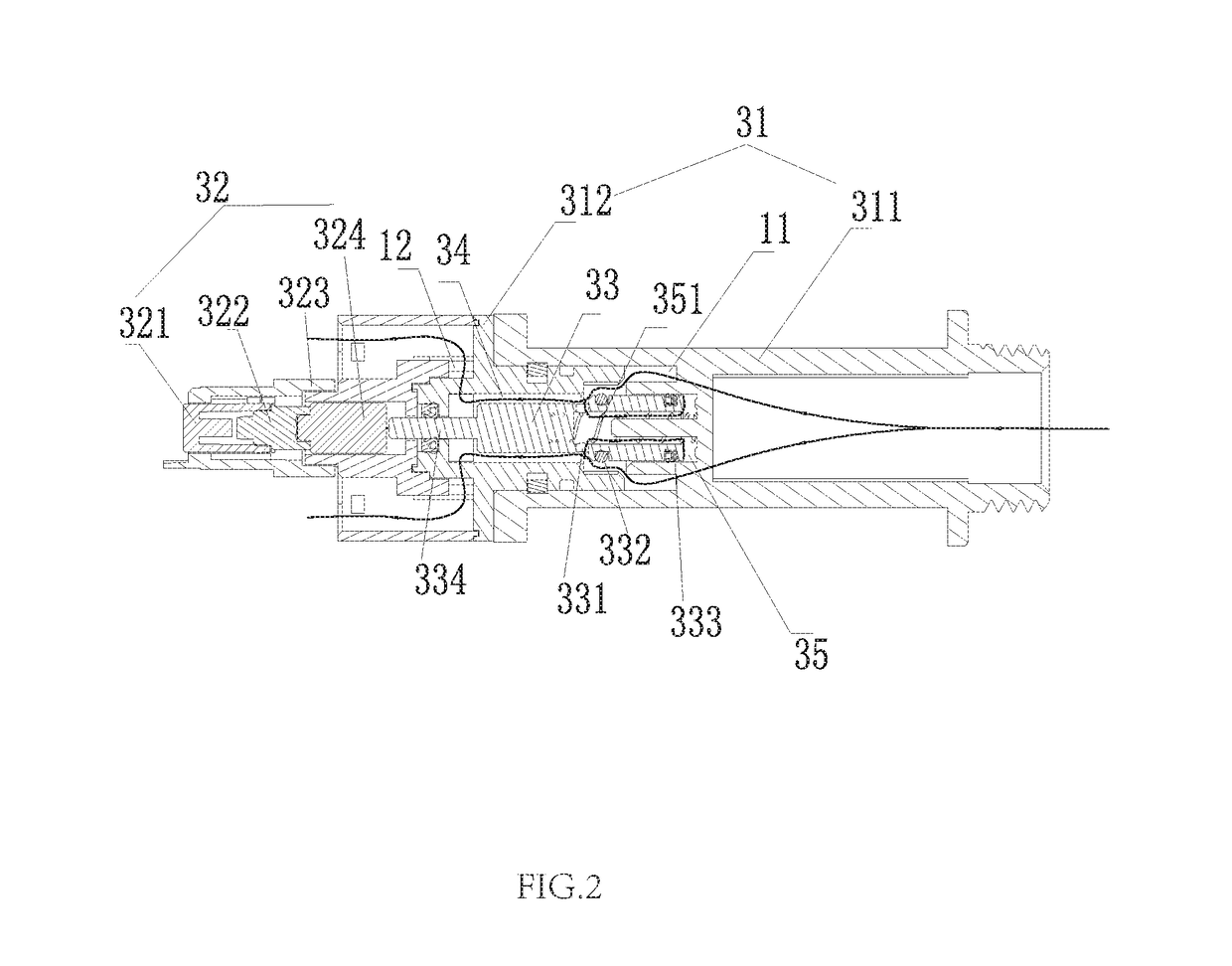

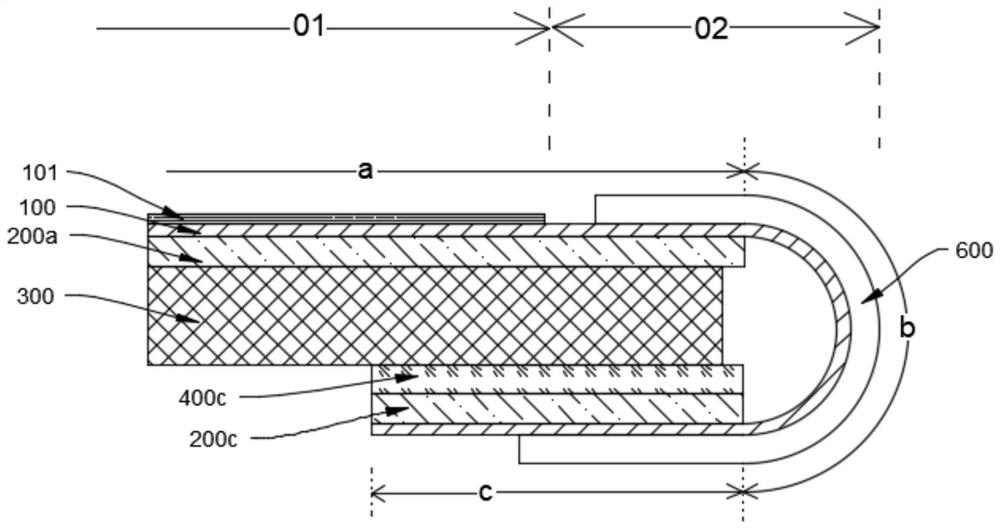

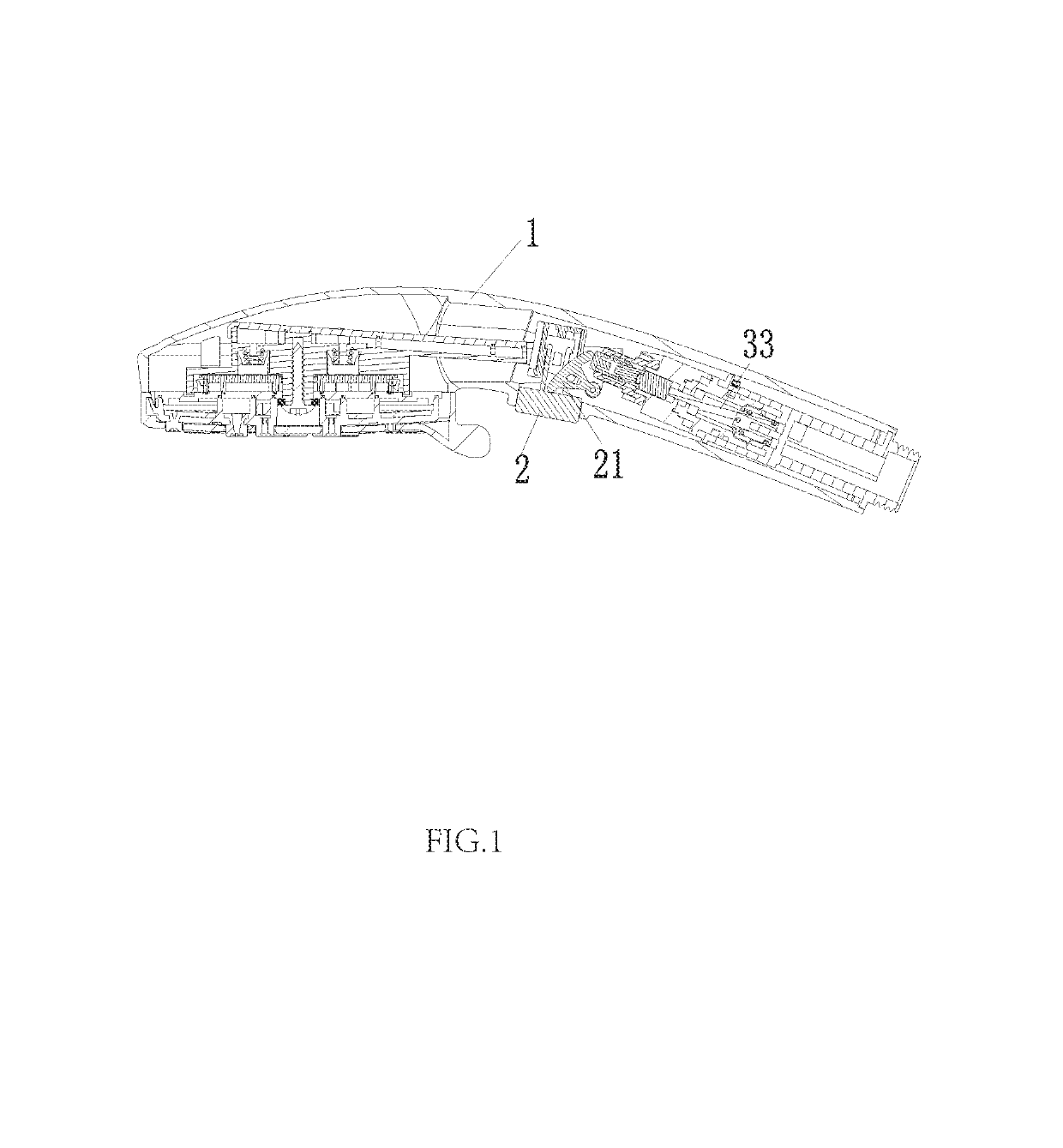

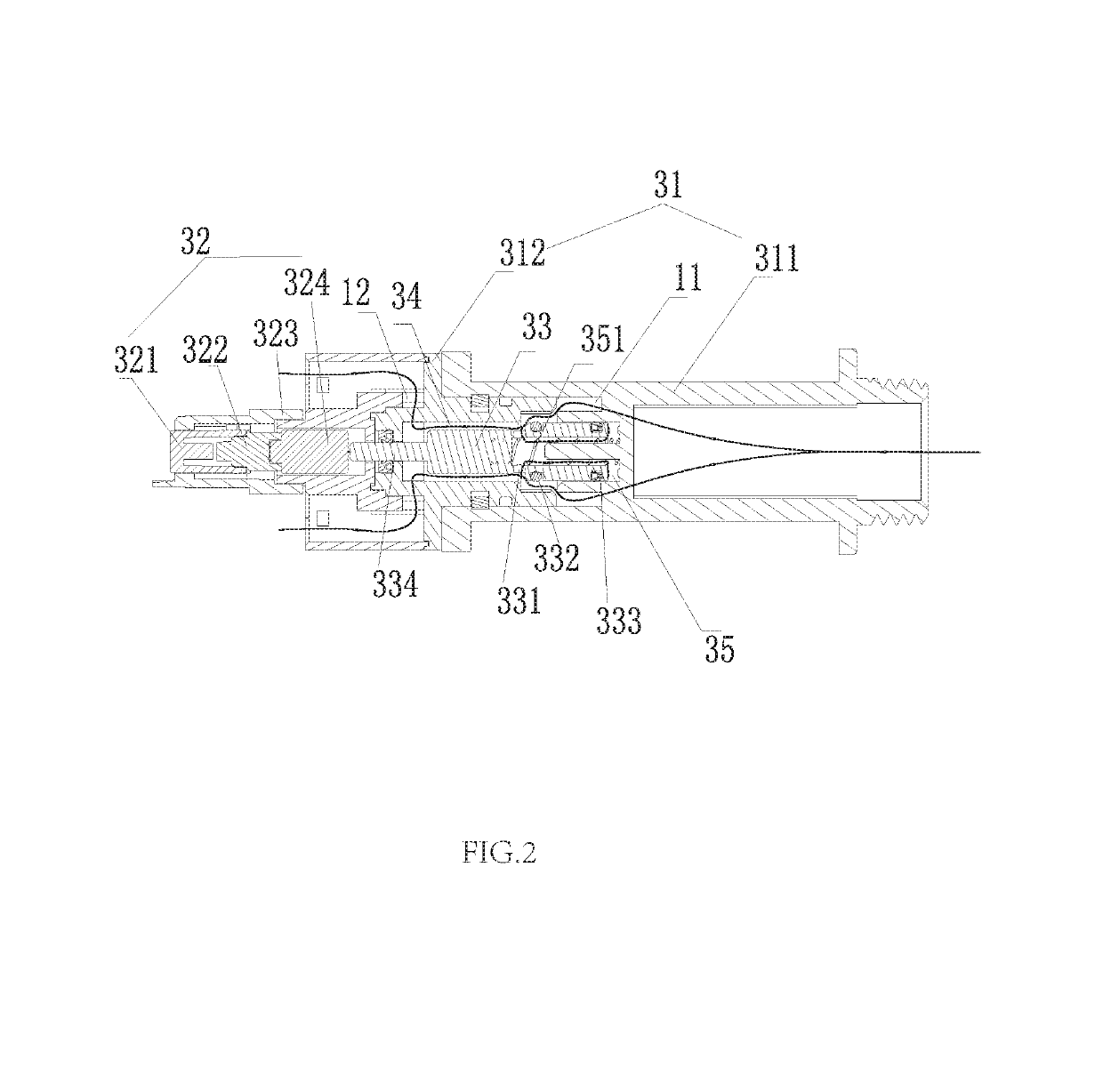

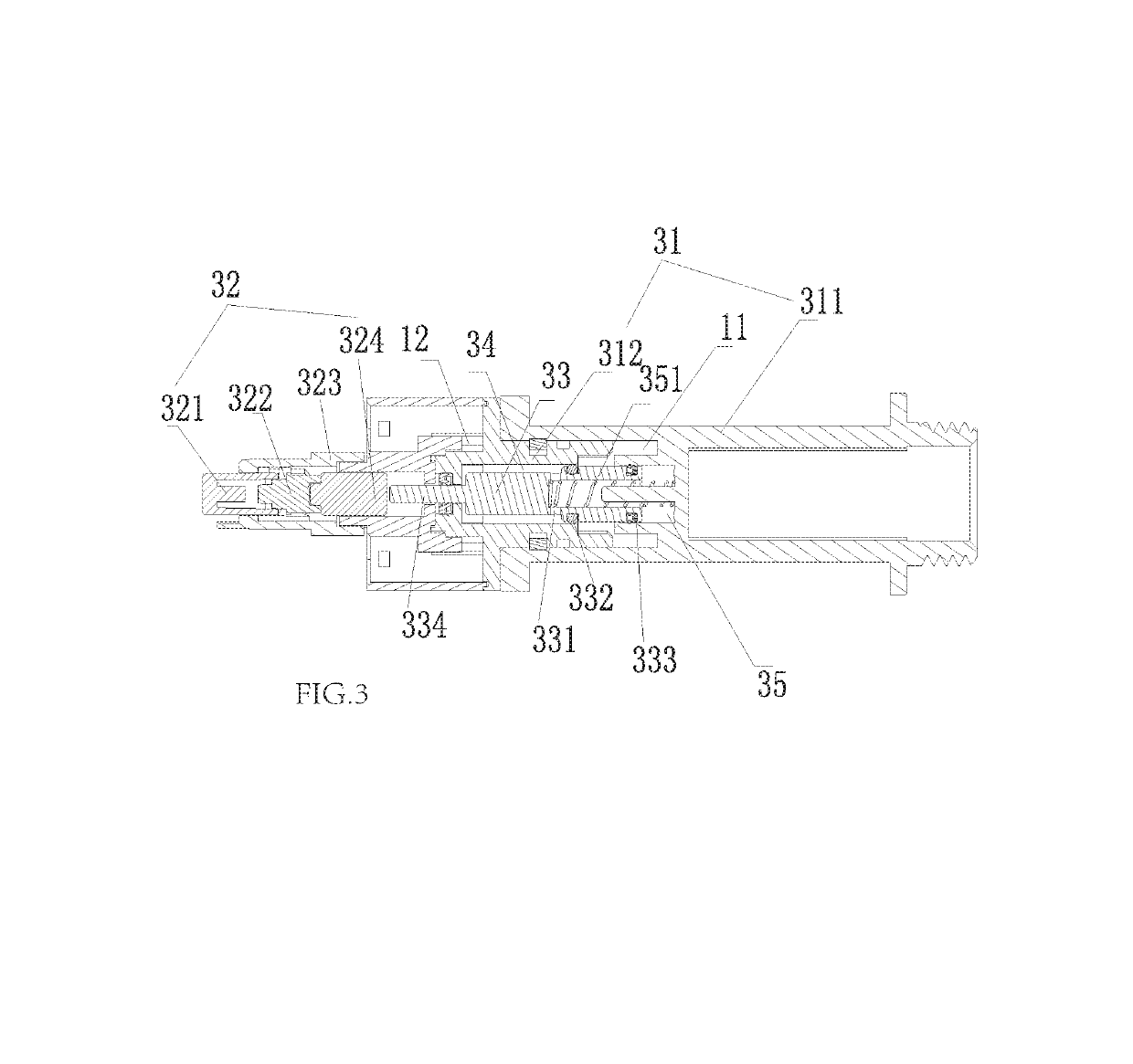

Vaporizer device of cotton-free electronic cigarette

ActiveUS20160286863A1Effective supportPrevent leakageTobacco smoke filtersTobacco devicesElectronic cigaretteEngineering

A vaporizer device of cotton-free e-cigarette, comprising: an outer sleeve, a supporting frame arranged inside the outer sleeve, a vaporizer unit fixed into the supporting frame, a filter piece and a liquid percolation piece sequentially connected to one end of the supporting frame, and a fixation seat connected to other end of the supporting frame. A backflow groove is made inside the supporting frame to prevent leakage caused by the backflow of residual liquid. The filter piece is made of heat-resisting material. The liquid percolation piece is connected at one end with a liquid storage cup by snap joints. Another end of the filter piece keeps a safe distance away from the vaporizer unit to avoid being burned. The liquid storage cup and the outer sleeve are assembled to form a slit therebetween to prevent the backflow of residual liquid.

Owner:LIN GUANGRONG

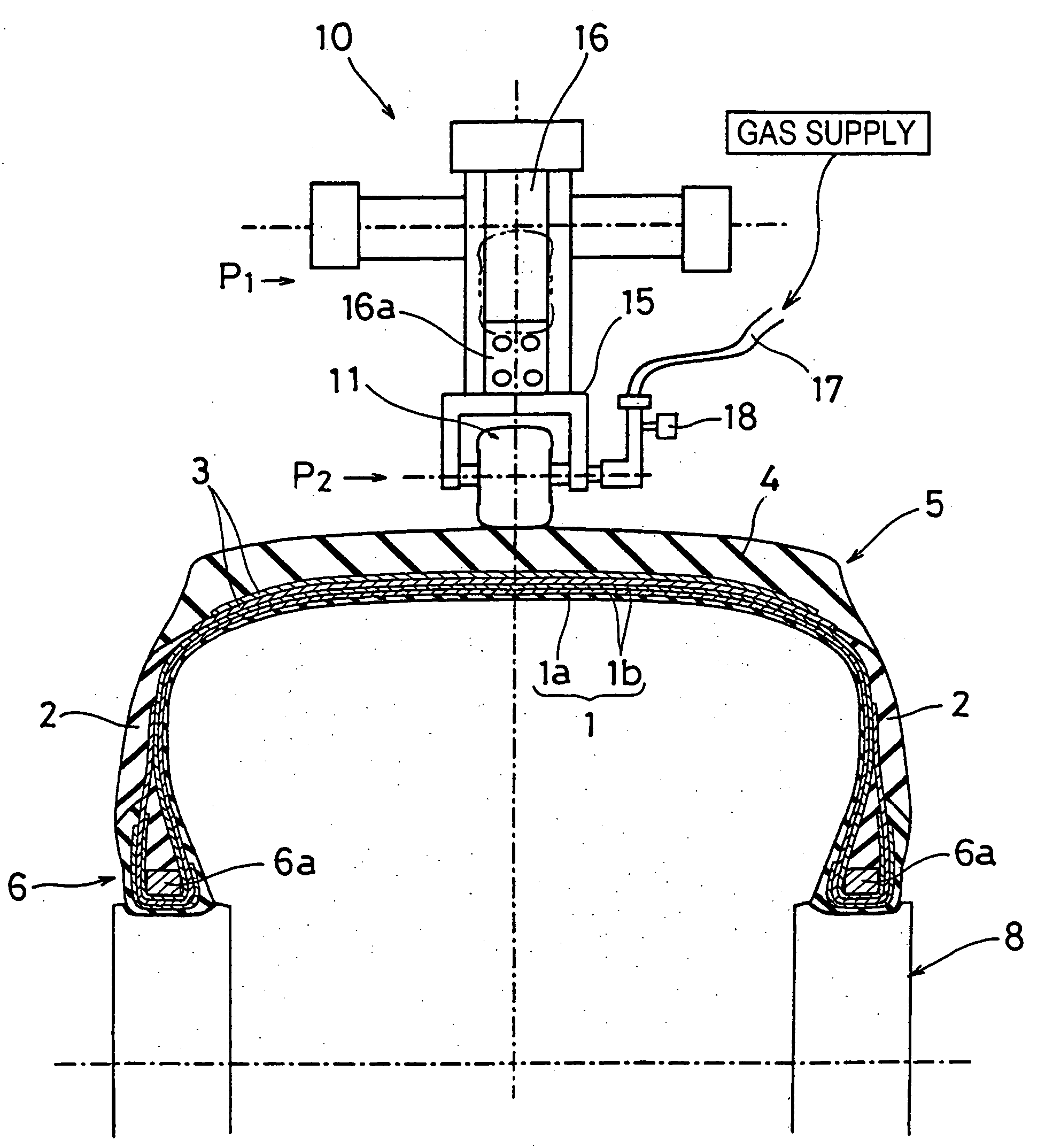

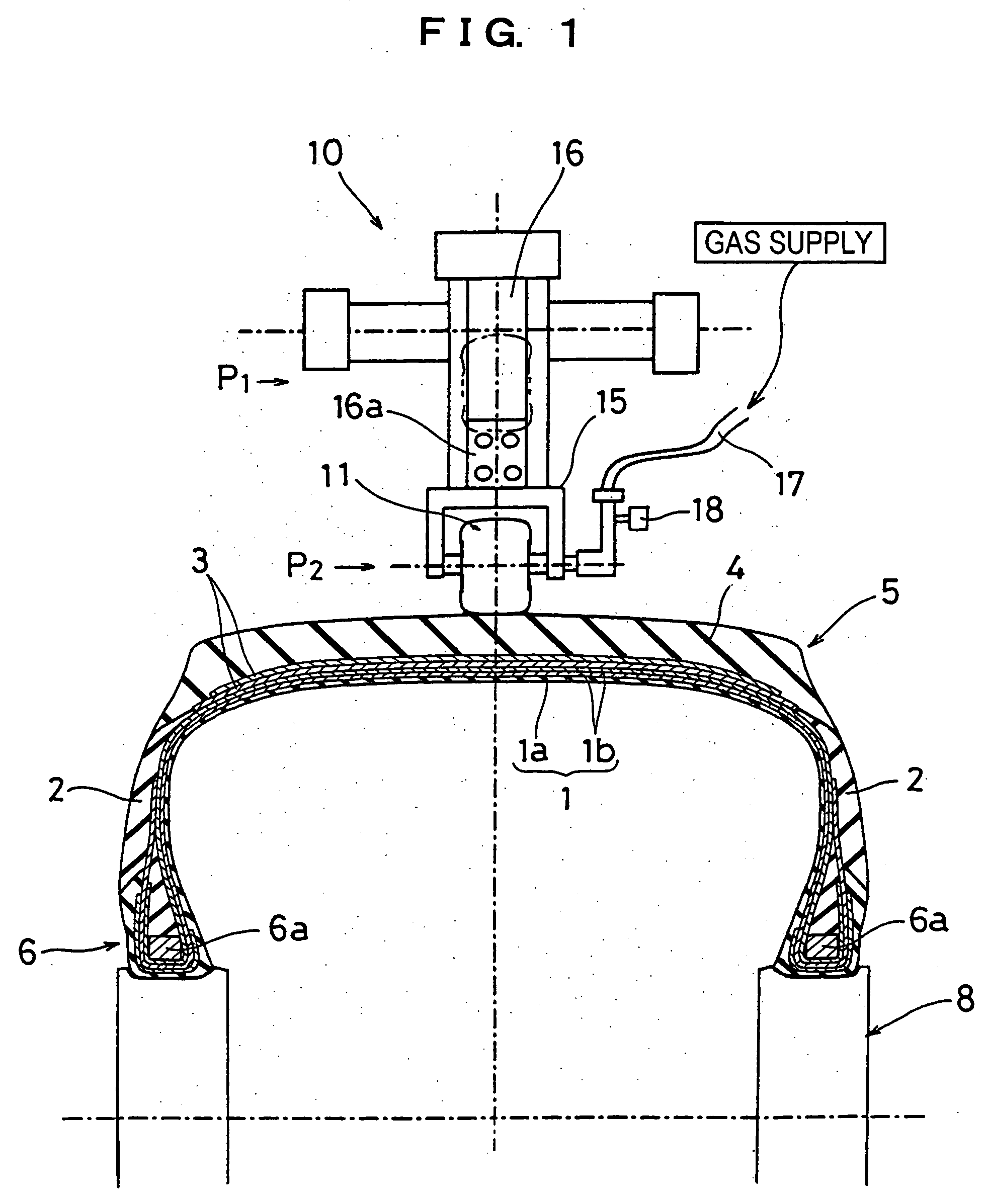

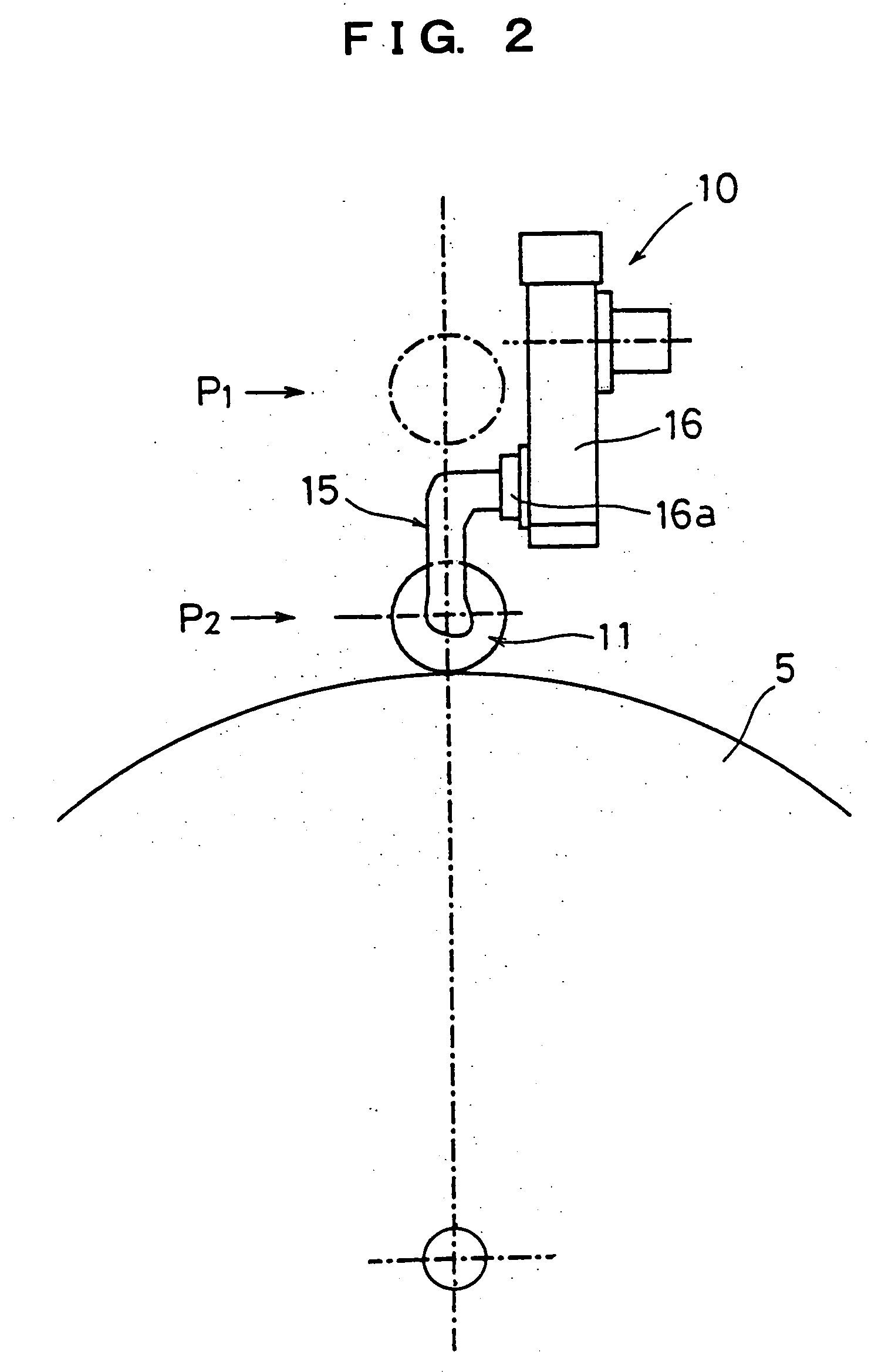

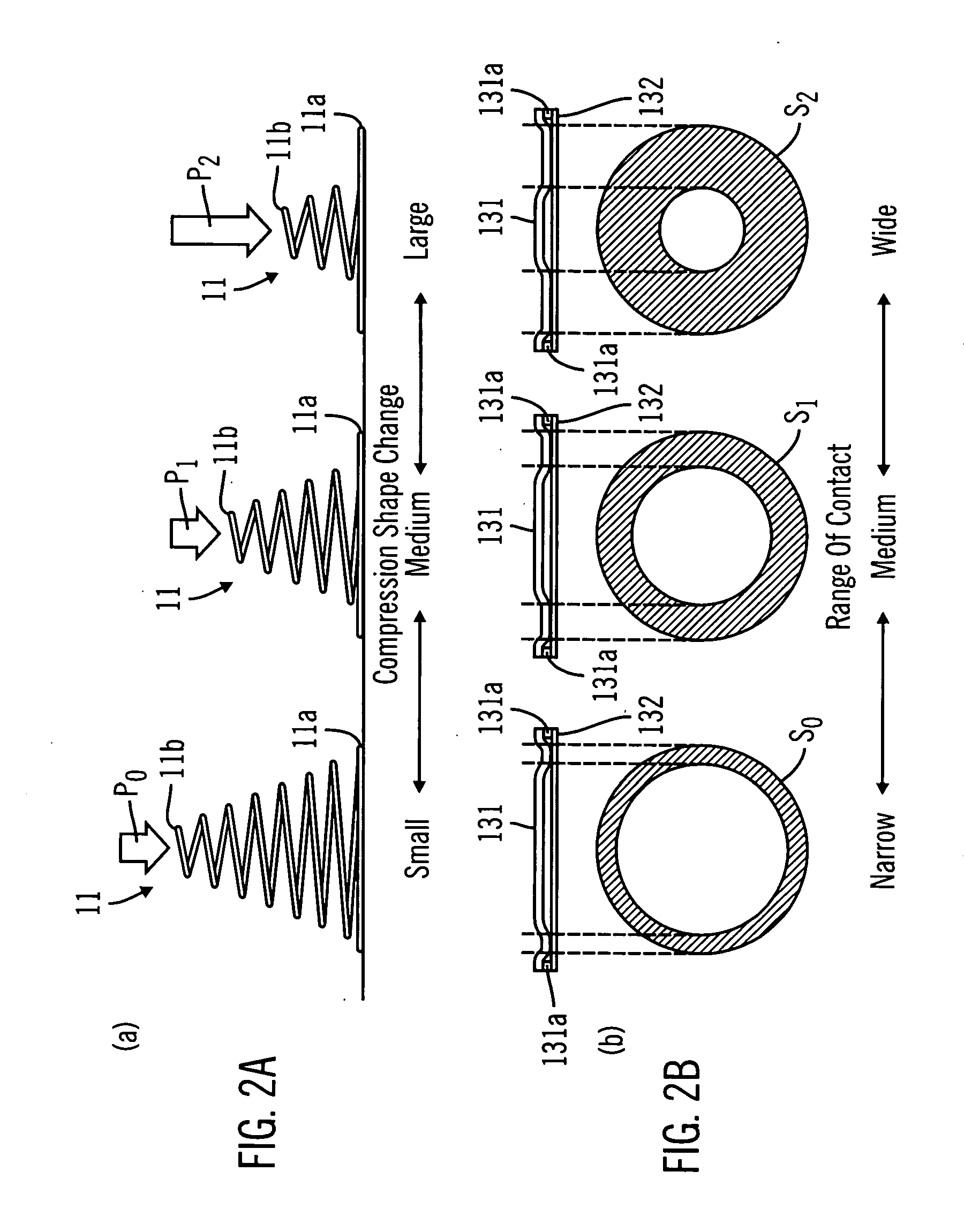

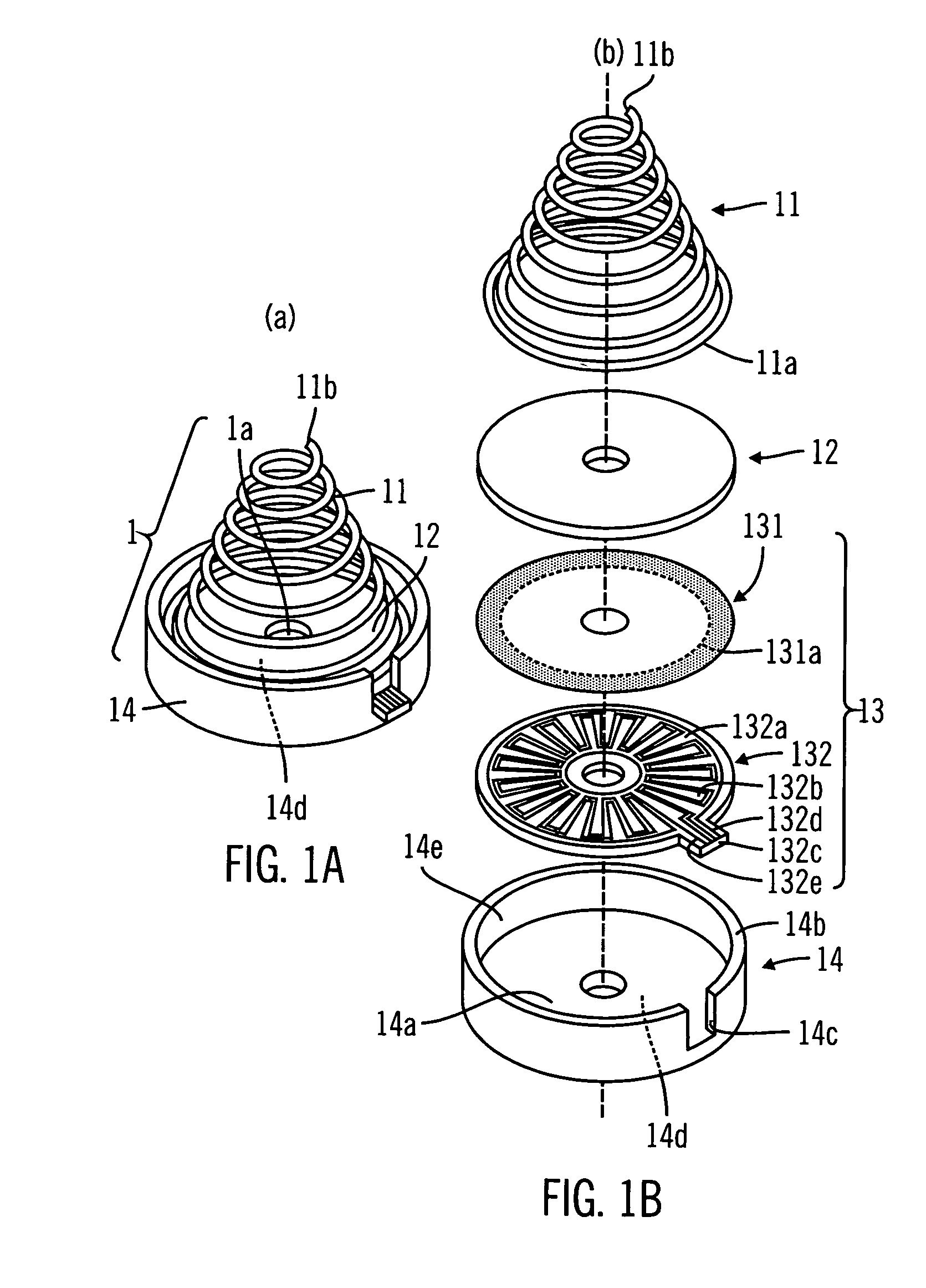

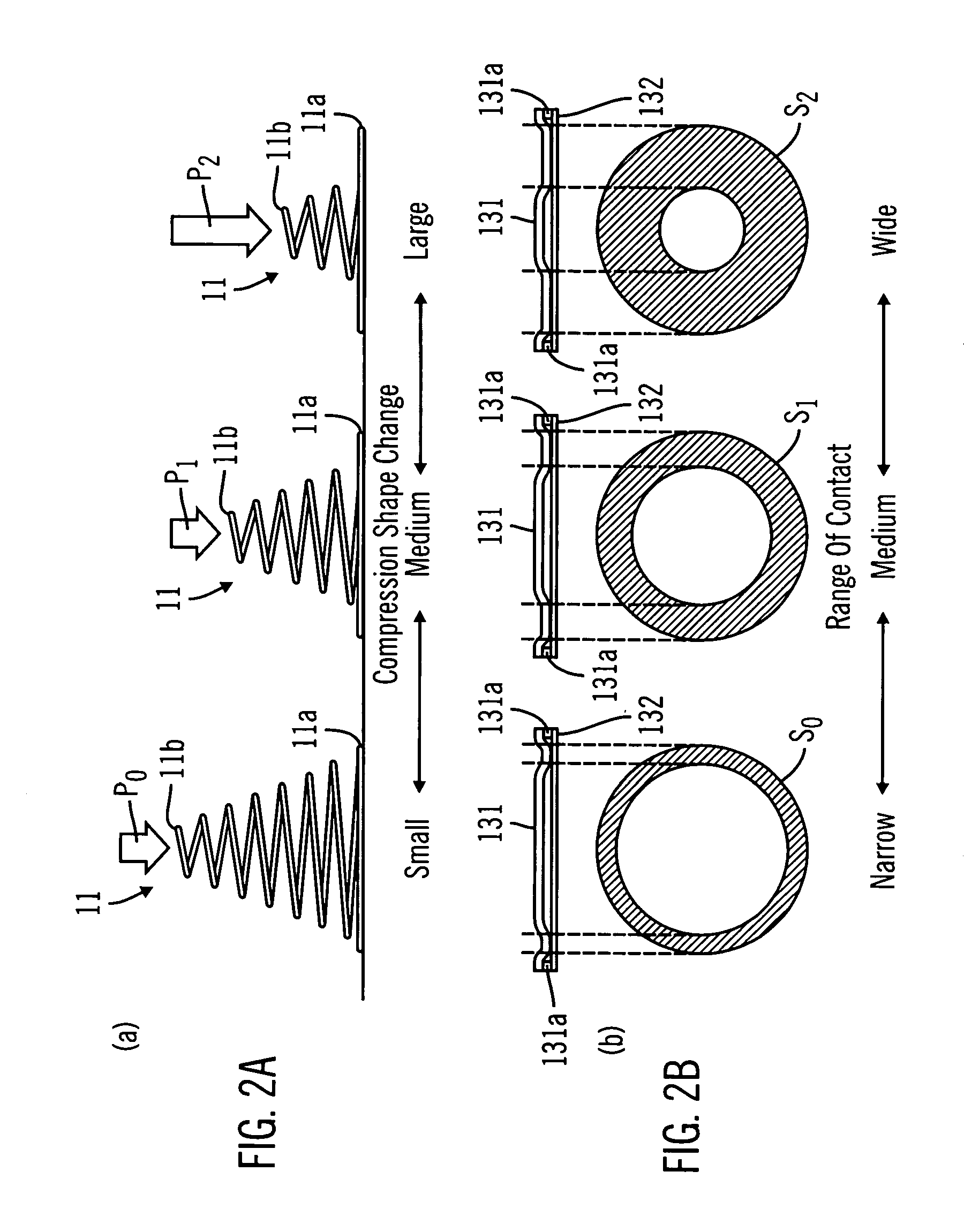

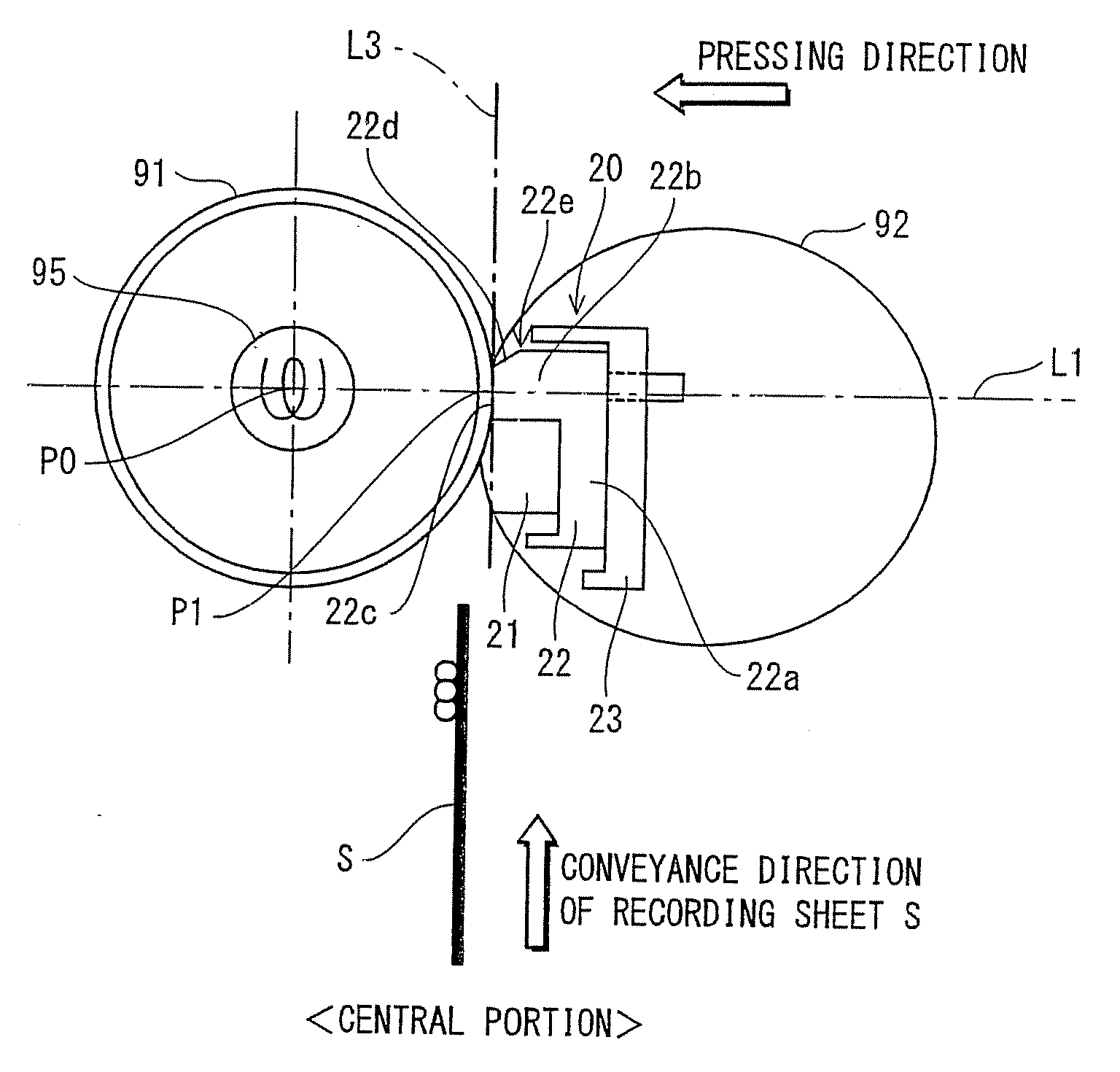

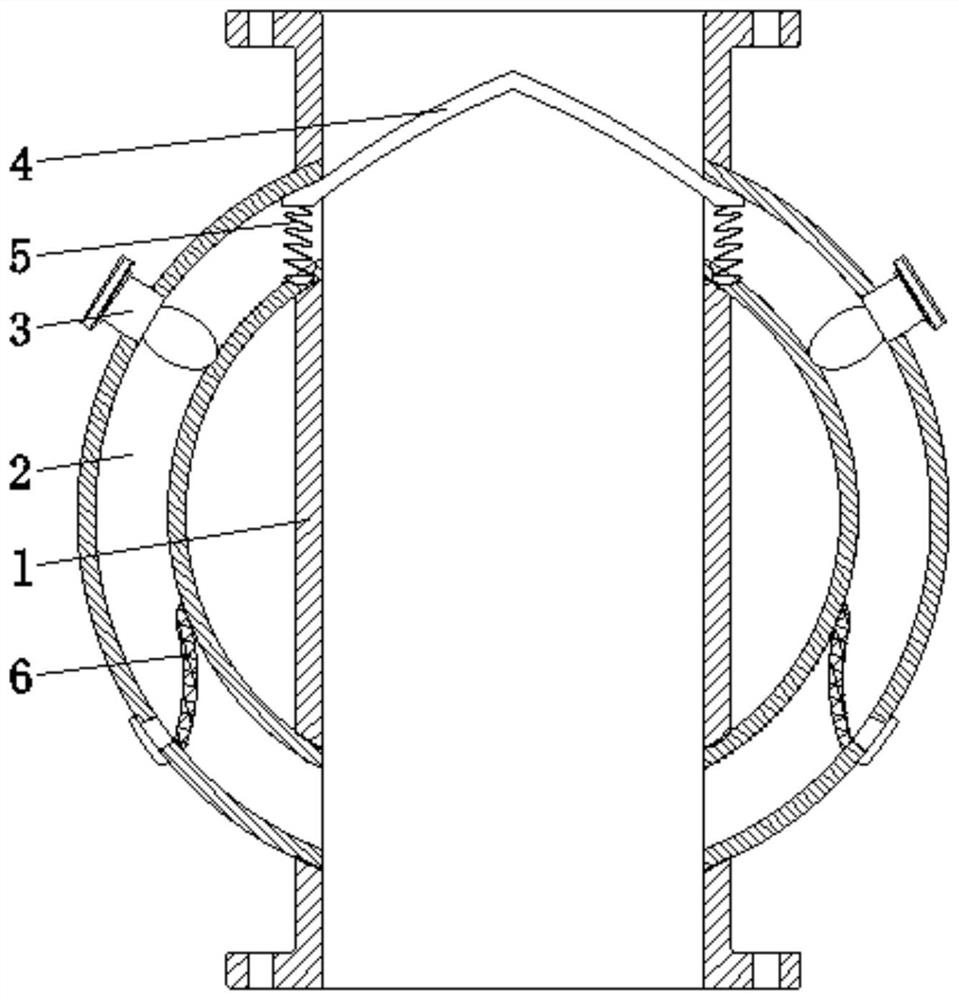

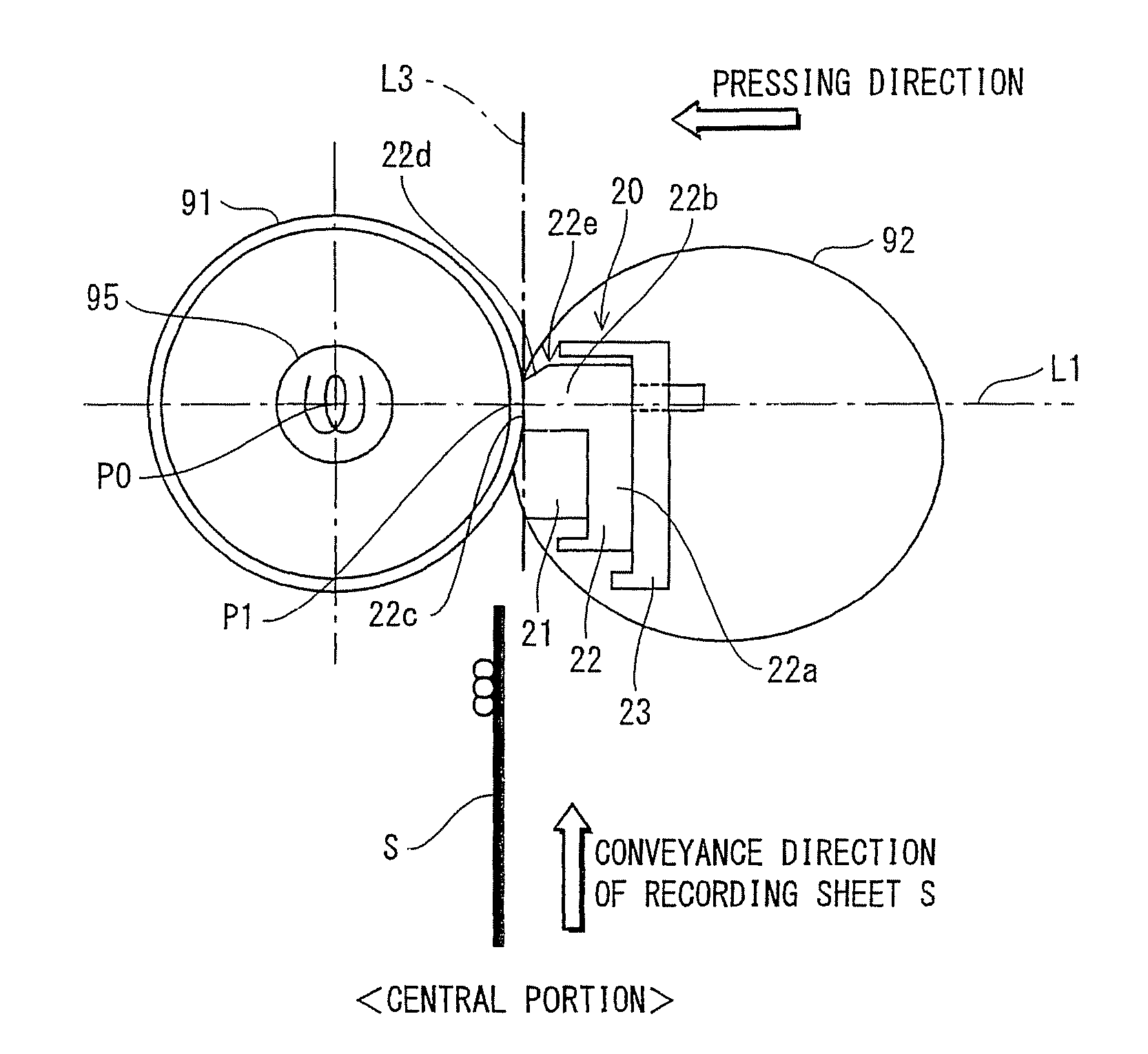

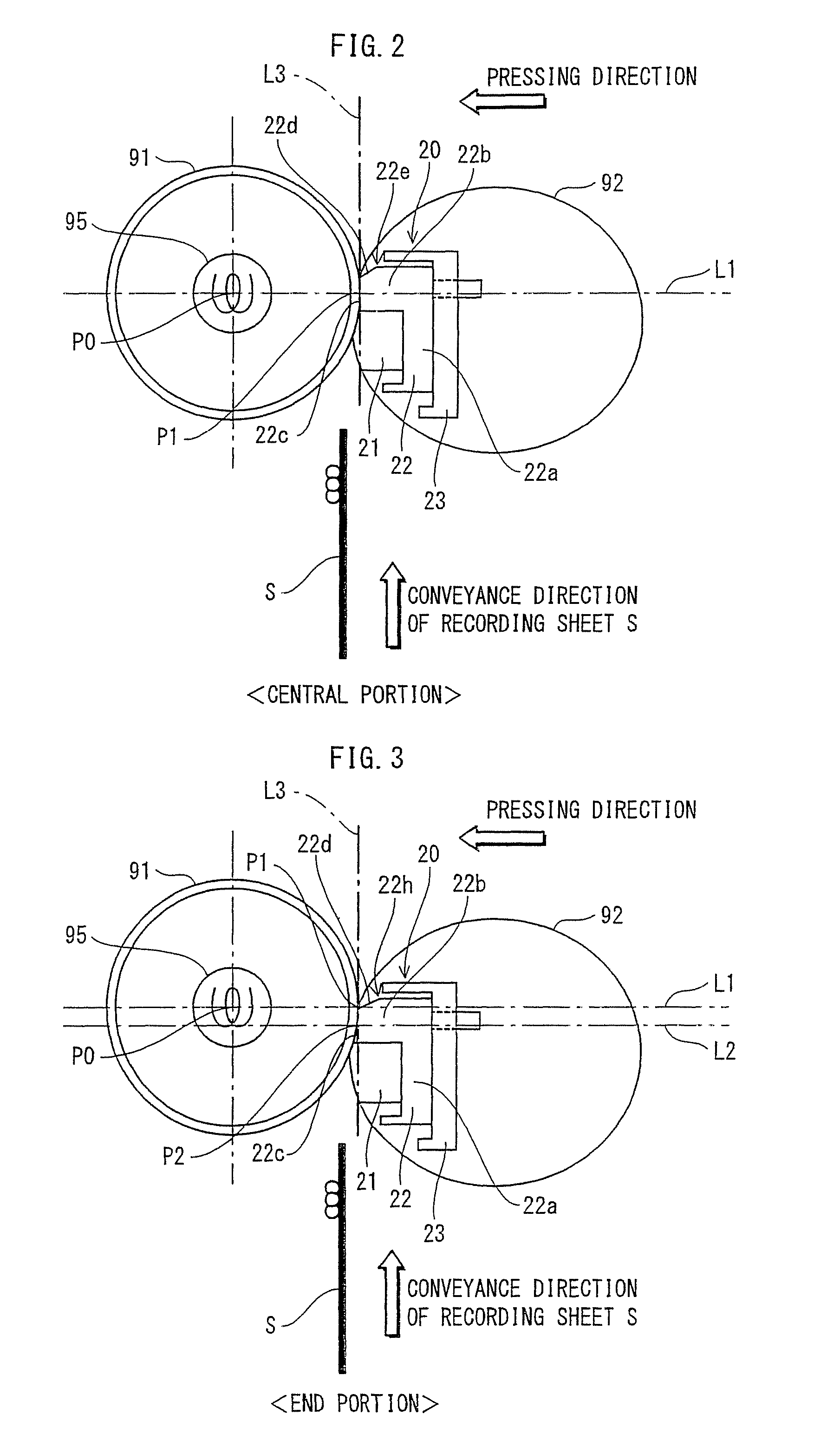

Tire building method and stitcher device

InactiveUS20060048884A1Well-balanced mannerIncrease the pressing areaTyresEngineeringProcess efficiency

A tire building method and a stitcher device therefore, which are aiming for achieving reliable pressing for bonding between a plurality of tire members all over outer face of the tire members, without forming a void between them, even though the outer face of the tire members have ups and downs, so as to curb strain in a carcass cord and to improve process efficiency. The method comprising: laying one or more of the tire members on a rotary support body such as a building drum; and press-contacting a press-contact part of a stitcher device on said one or more of the tire members on the rotary support while the rotary support being rotated, so as to bond together said one or more of the tire members; said press-contact part being a pneumatic-tire roller maintained with a certain level of inner pressure.

Owner:TOYO TIRE & RUBBER CO LTD

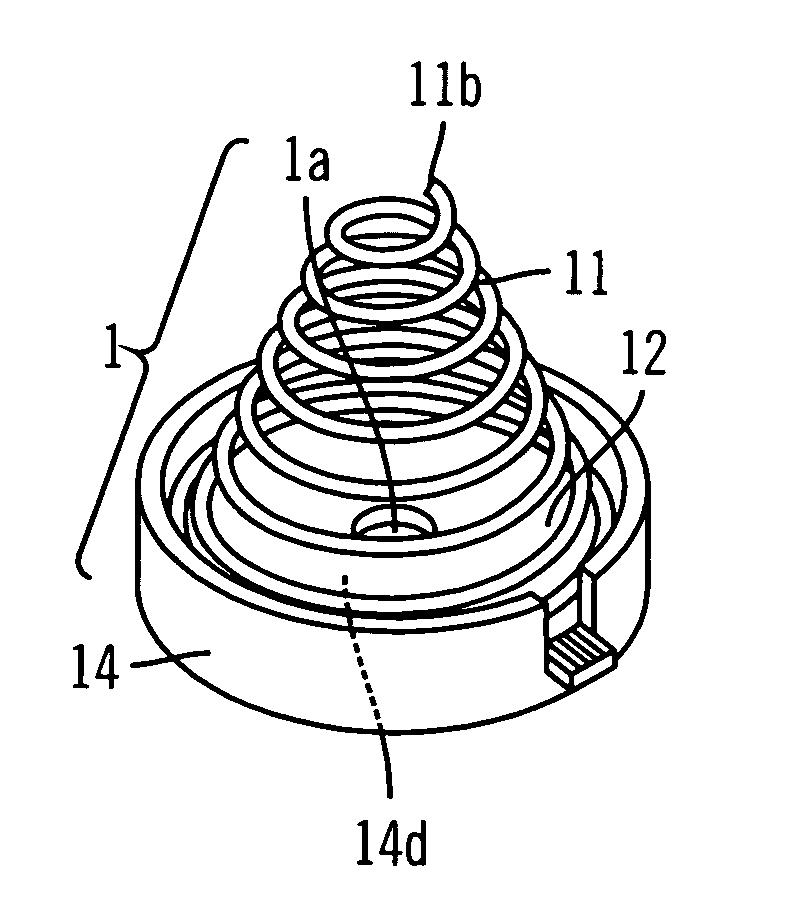

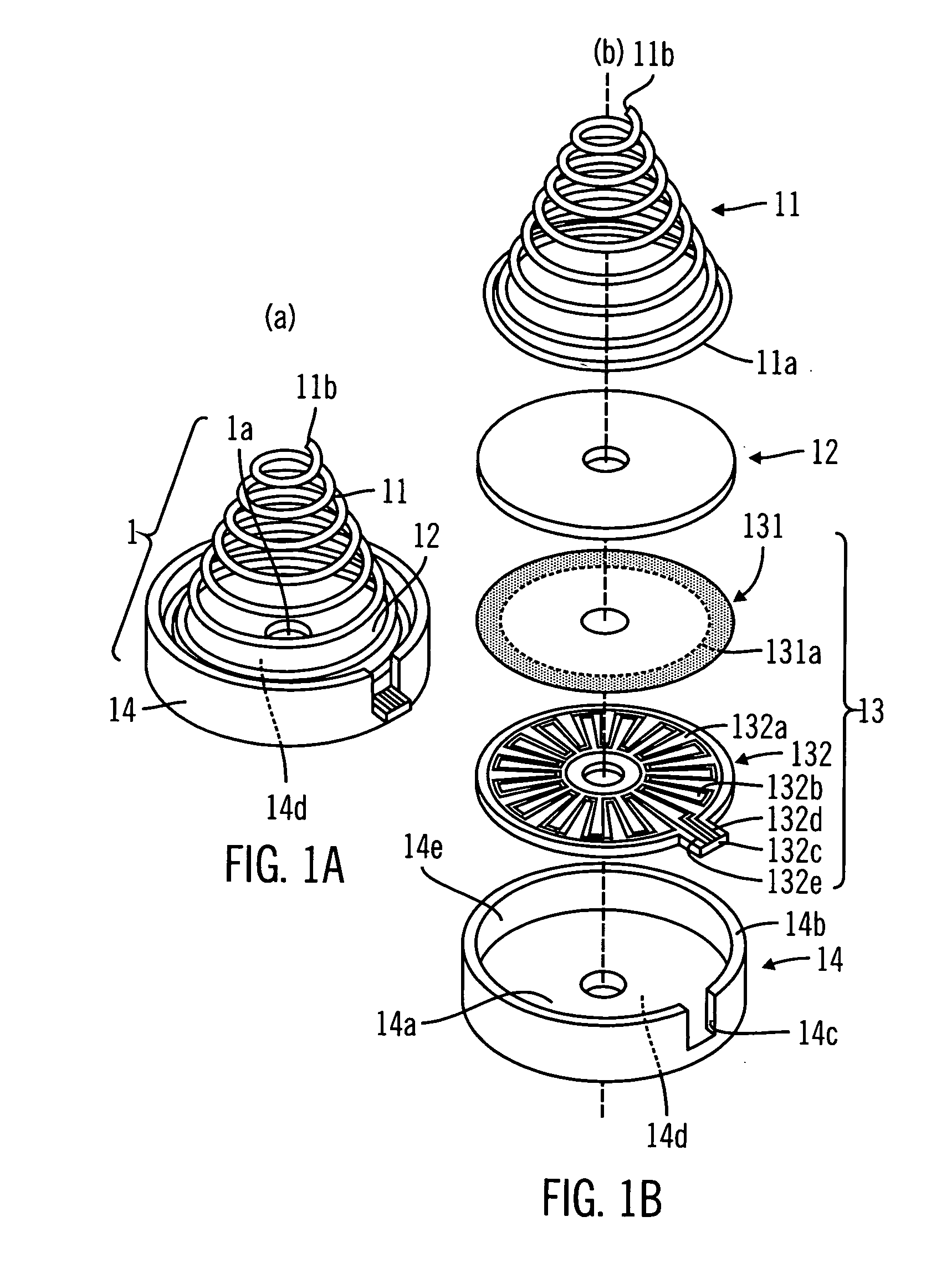

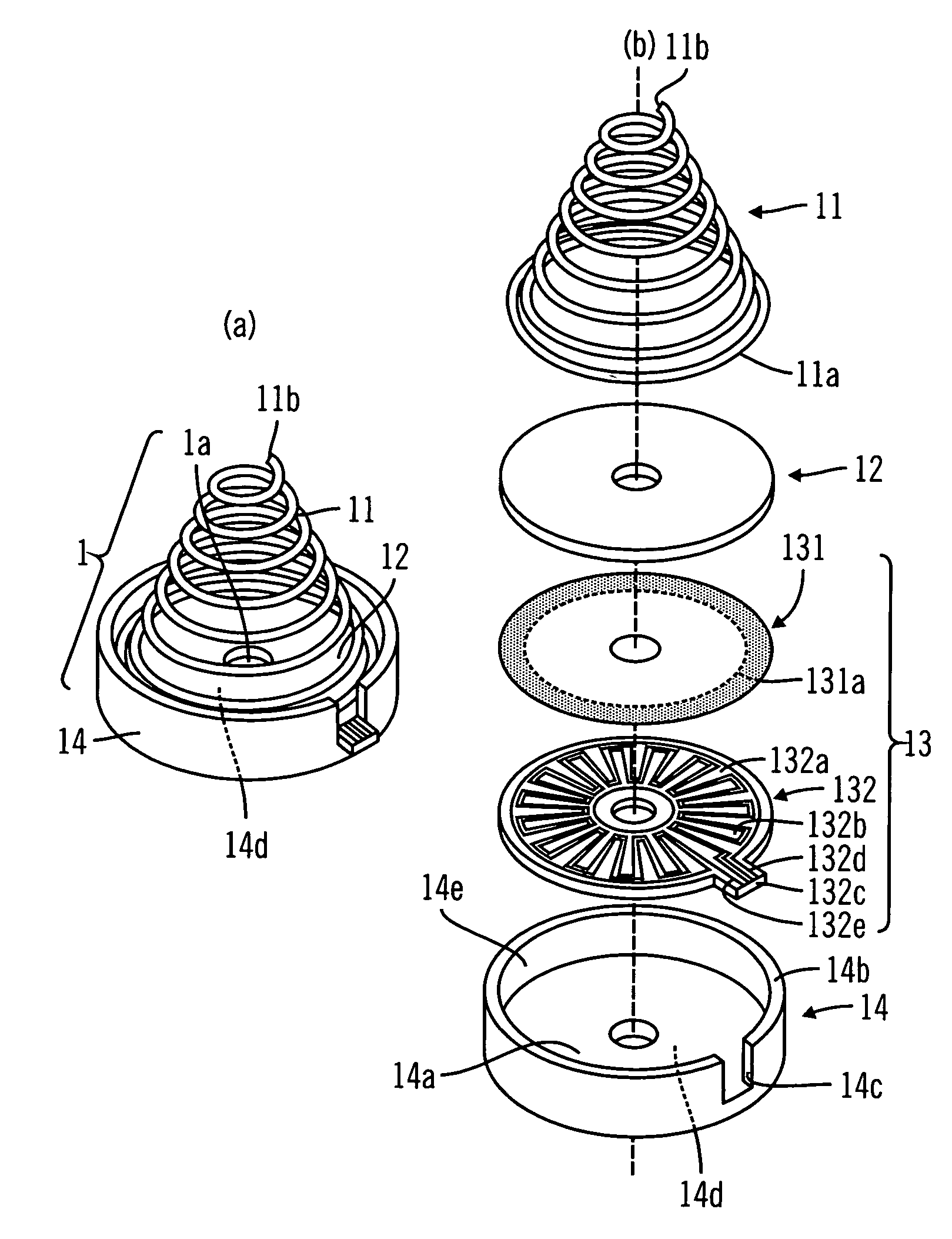

Apparatus and method for detecting displacement of a movable member of an electronic musical instrument

ActiveUS20060096448A1Improve mechanical durabilityIncrease the pressing areaElectrophonic musical instrumentsElectronic instrumentEngineering

An apparatus for detecting the displacement of a movable member of an electronic musical instrument. The apparatus has superior mechanical durability compared to displacement sensors of the past and can withstand long-term use. The apparatus includes a sensor that provides a detectable electrical characteristic having a value and a spring that, when compressed upon displacement of the movable member acts with the sensor, causing the value of the electrical characteristic to change. The value of the electrical characteristic represents the amount of displacement of the movable member and is used by a controller of the electronic musical instrument.

Owner:ROLAND CORP

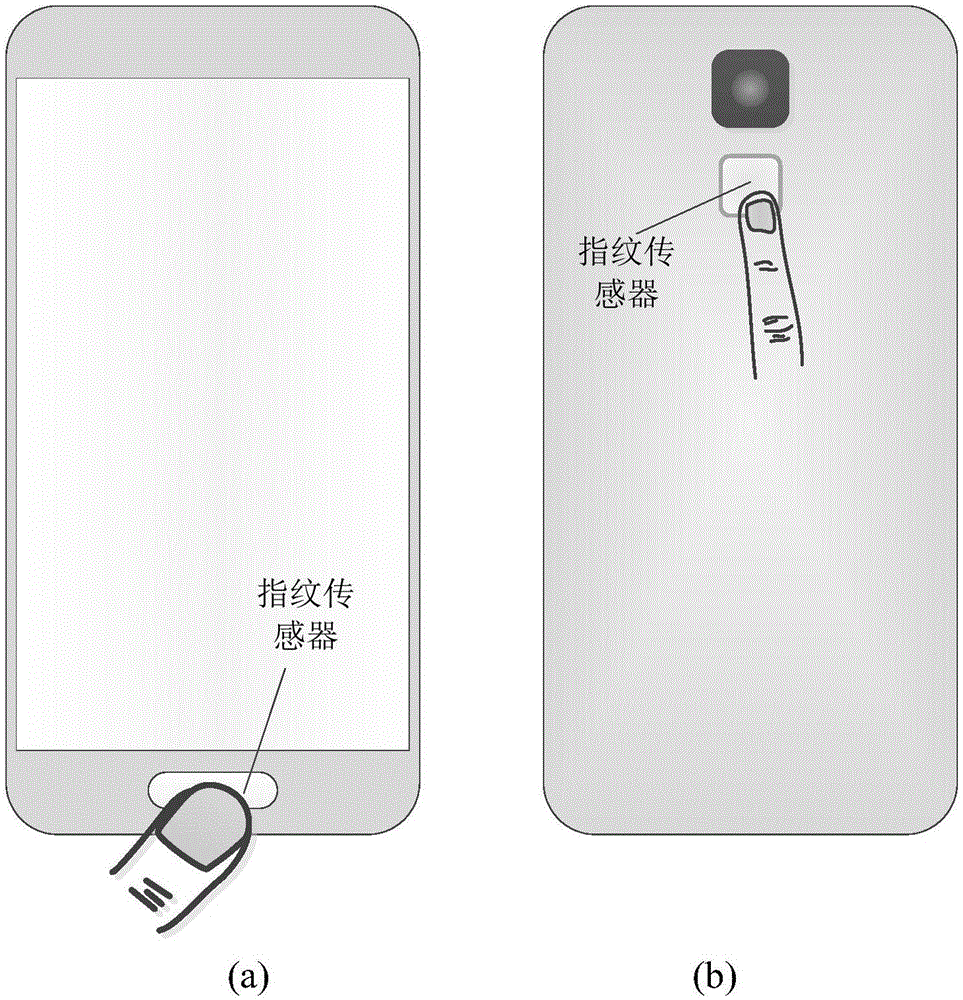

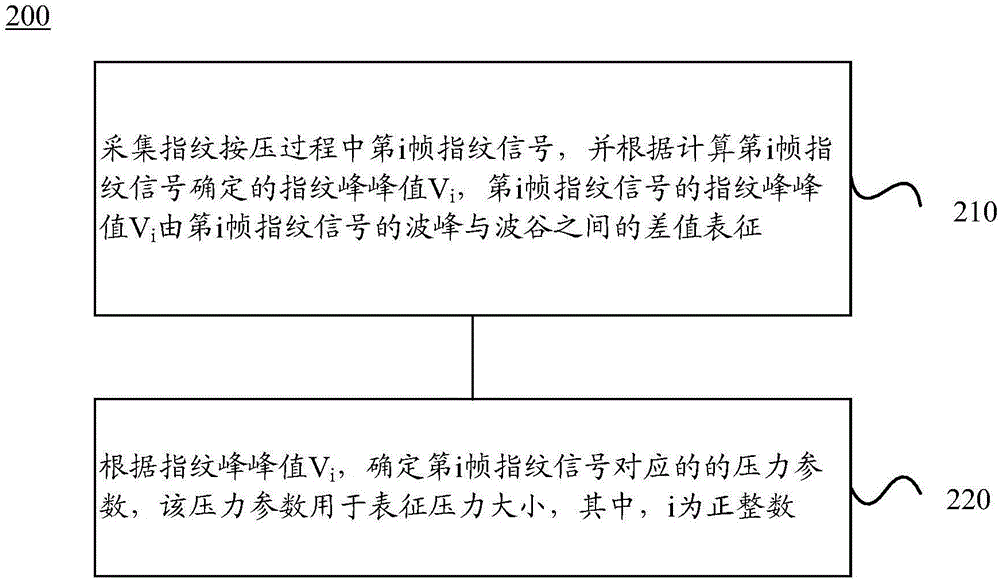

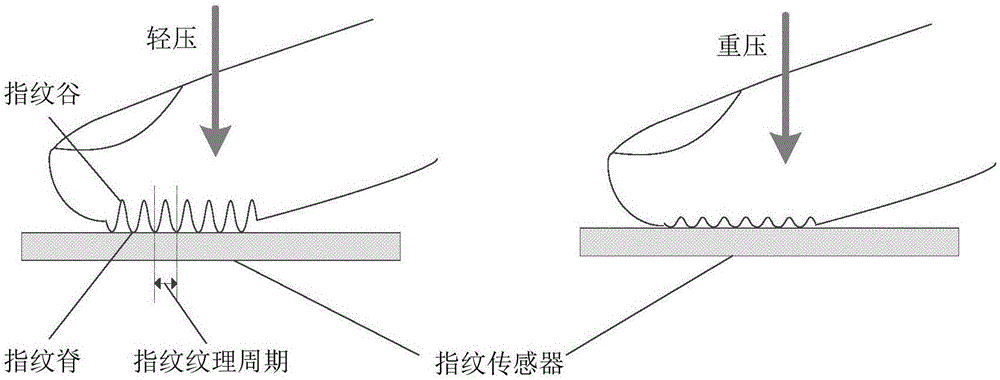

Fingerprint-based pressure detection method and apparatus

The embodiment of the present invention provides a fingerprint-based pressure detection method and apparatus, the method is applied to a fingerprint identification device, comprises: acquiring an i-th frame fingerprint signal during a fingerprinting process and determining a fingerprint peak-to-peak value Vi based on the i-th frame fingerprint signal, wherein fingerprint peak-to-peak value Vi of the i-th frame fingerprint signal is represented by the difference between the crest and the trough of the i-th frame fingerprint signal; and determining the the pressure parameter corresponding to the i-th frame fingerprint signal based on the fingerprint peak-to-peak value Vi, which is used to characterize the pressure magnitude, where i is a positive integer. Therefore, the fingerprint-based pressure detecting method provided by the embodiment of the present invention can improve the stability and accuracy of fingerprint-based pressure detection.

Owner:SHENZHEN GOODIX TECH CO LTD

Apparatus and method for detecting displacement of a movable member of an electronic musical instrument

ActiveUS7459626B2Improve mechanical durabilityIncrease the pressing areaElectrophonic musical instrumentsElectricityElectronic instrument

An apparatus for detecting the displacement of a movable member of an electronic musical instrument. The apparatus has superior mechanical durability compared to displacement sensors of the past and can withstand long-term use. The apparatus includes a sensor that provides a detectable electrical characteristic having a value and a spring that, when compressed upon displacement of the movable member acts with the sensor, causing the value of the electrical characteristic to change. The value of the electrical characteristic represents the amount of displacement of the movable member and is used by a controller of the electronic musical instrument.

Owner:ROLAND CORP

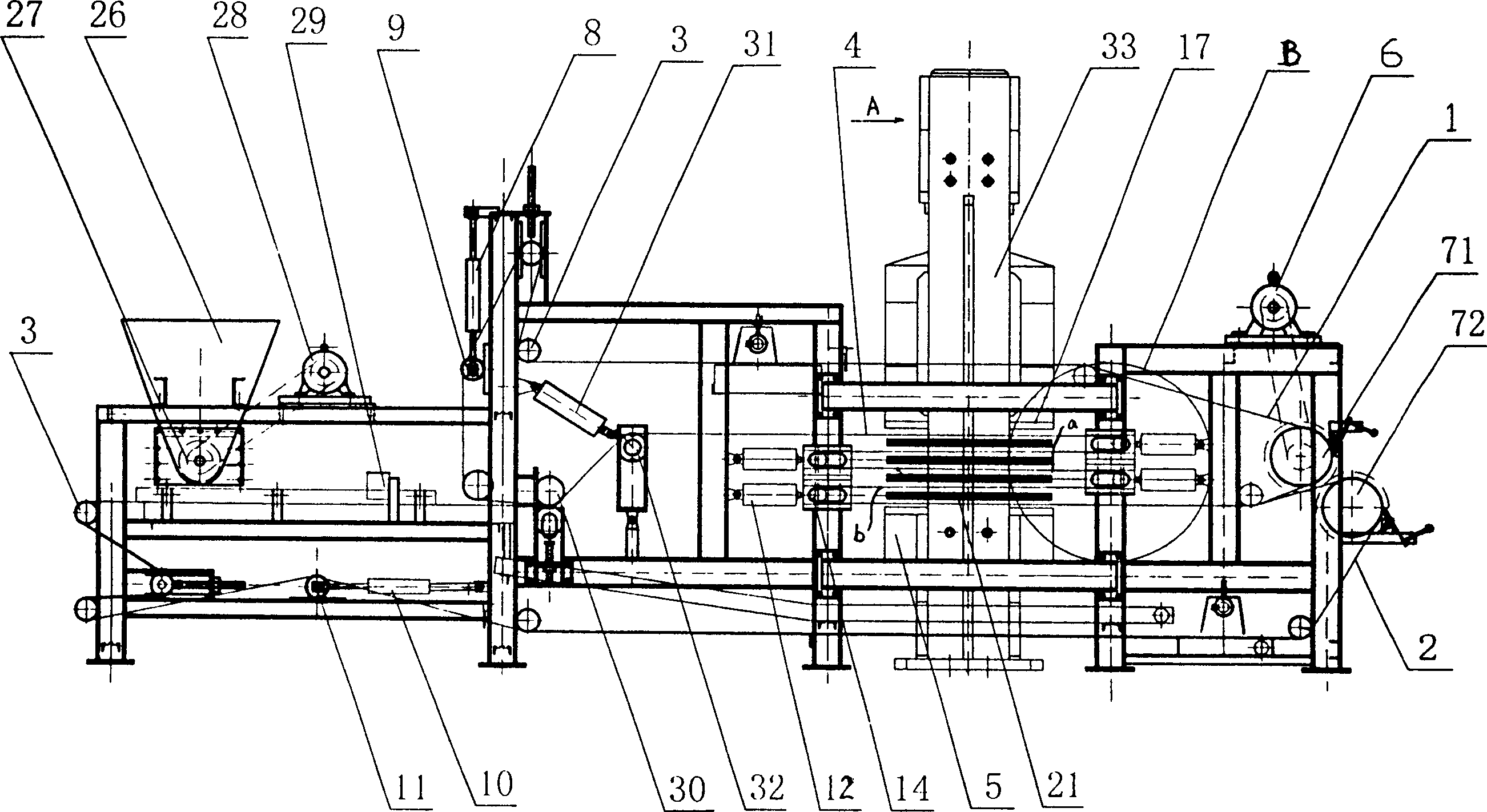

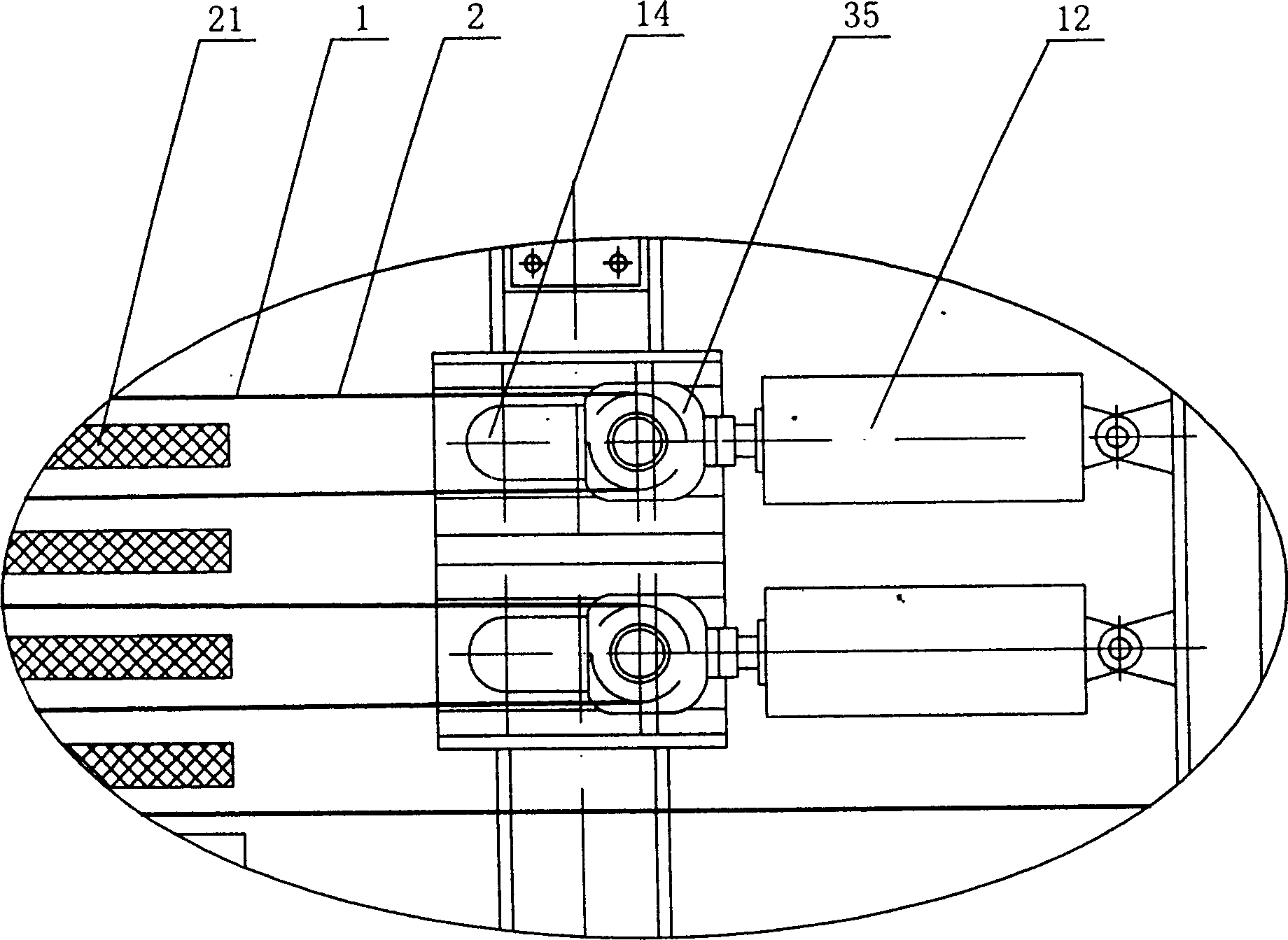

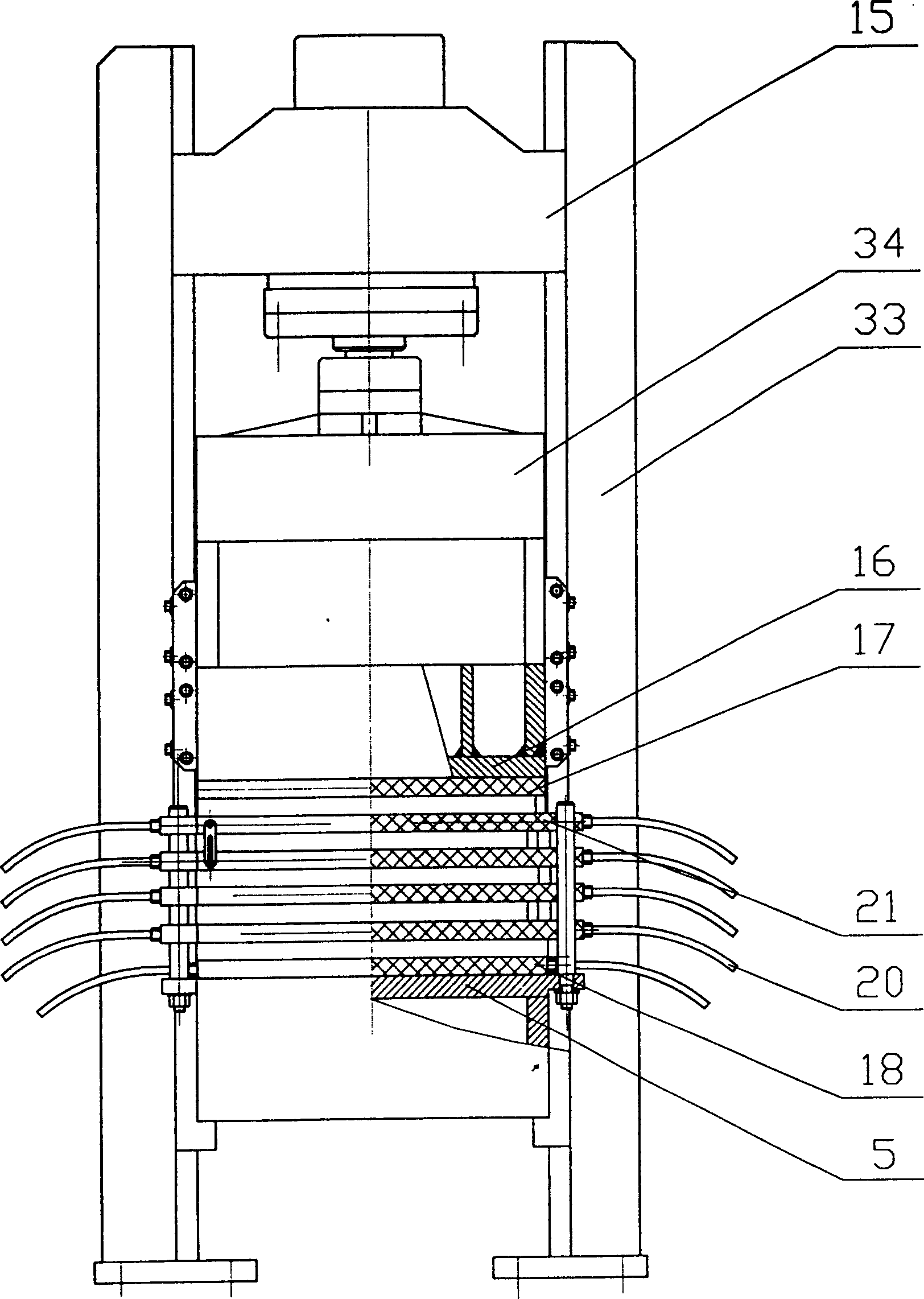

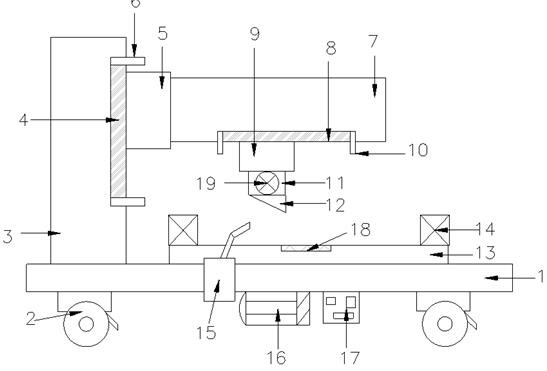

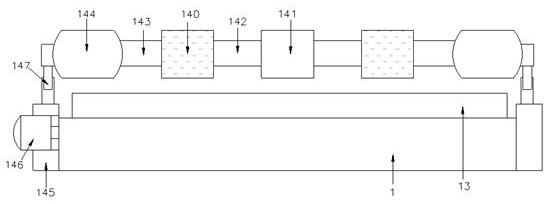

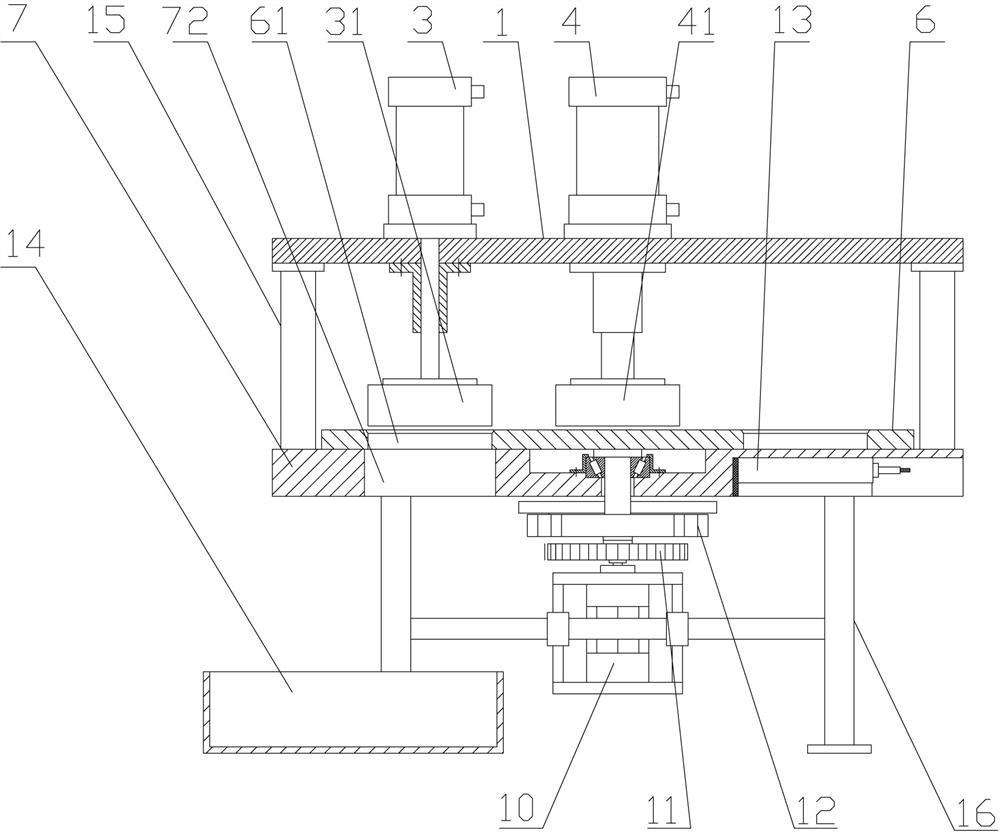

High-efficient strong filter press

InactiveCN1817405AShorten the lengthHigh water removal rateFiltration separationReciprocating motionEngineering

An efficient strong press filter for removing water from material is composed of the endless material conveying netted band and its power unit, guide rollers, the deviation correcting unit and S-shaped press region, where there are press bearing table, upper and lower press plates, and releasing and stretching unit for netted band.

Owner:胡杭虎

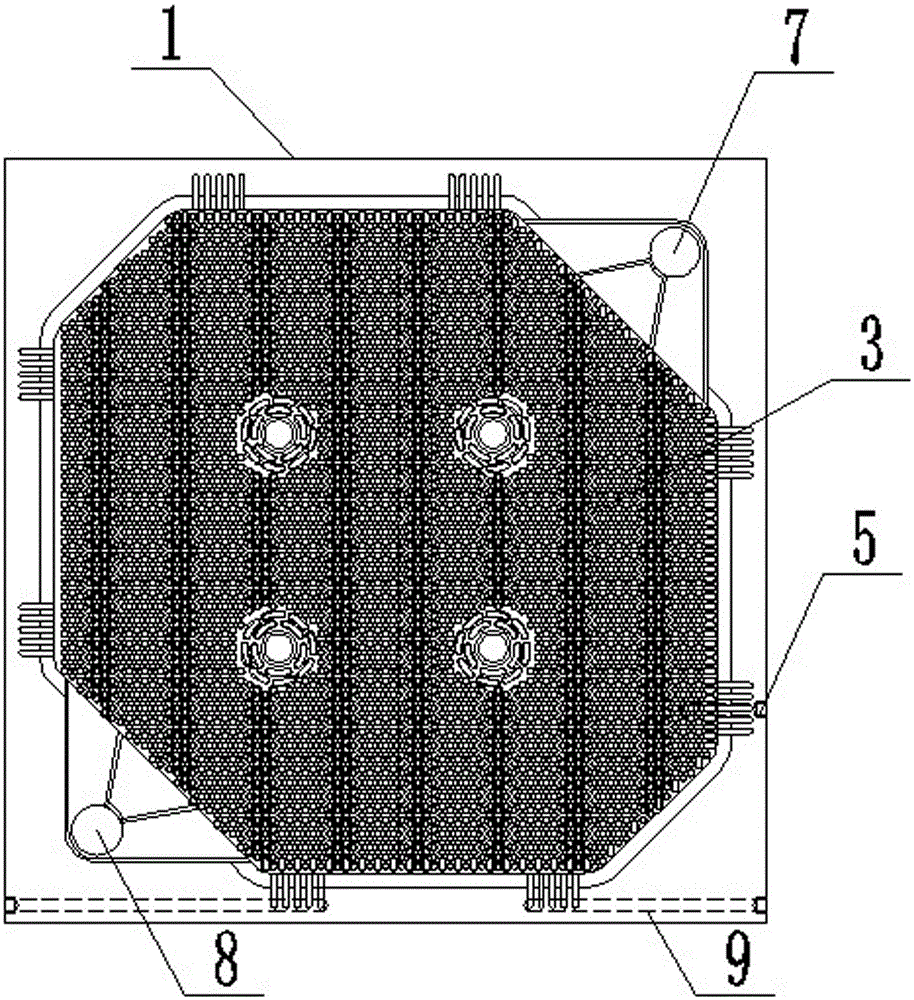

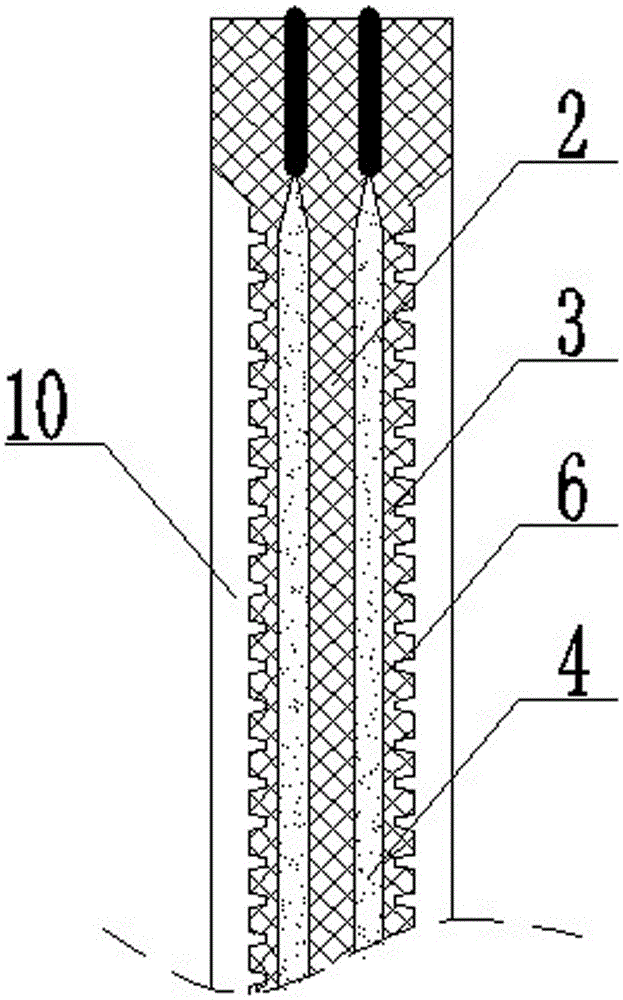

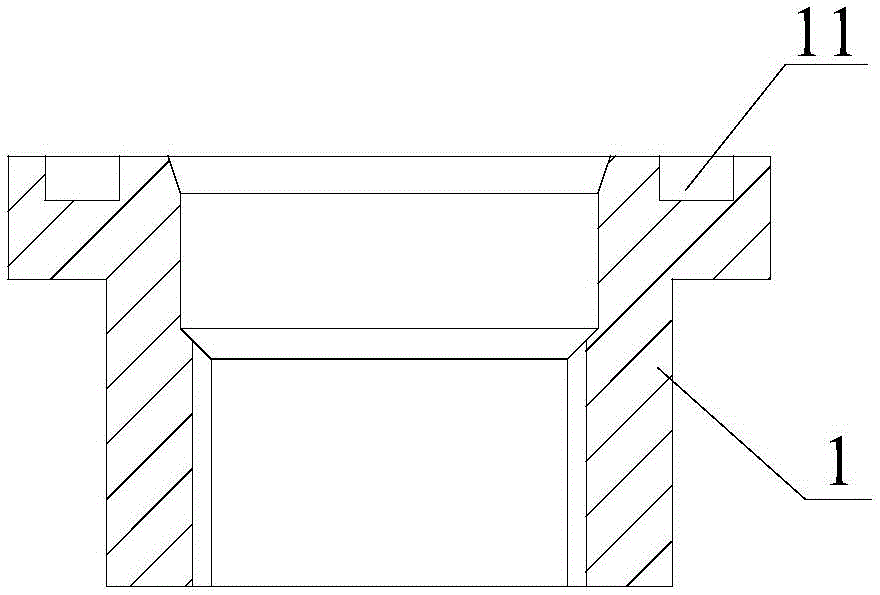

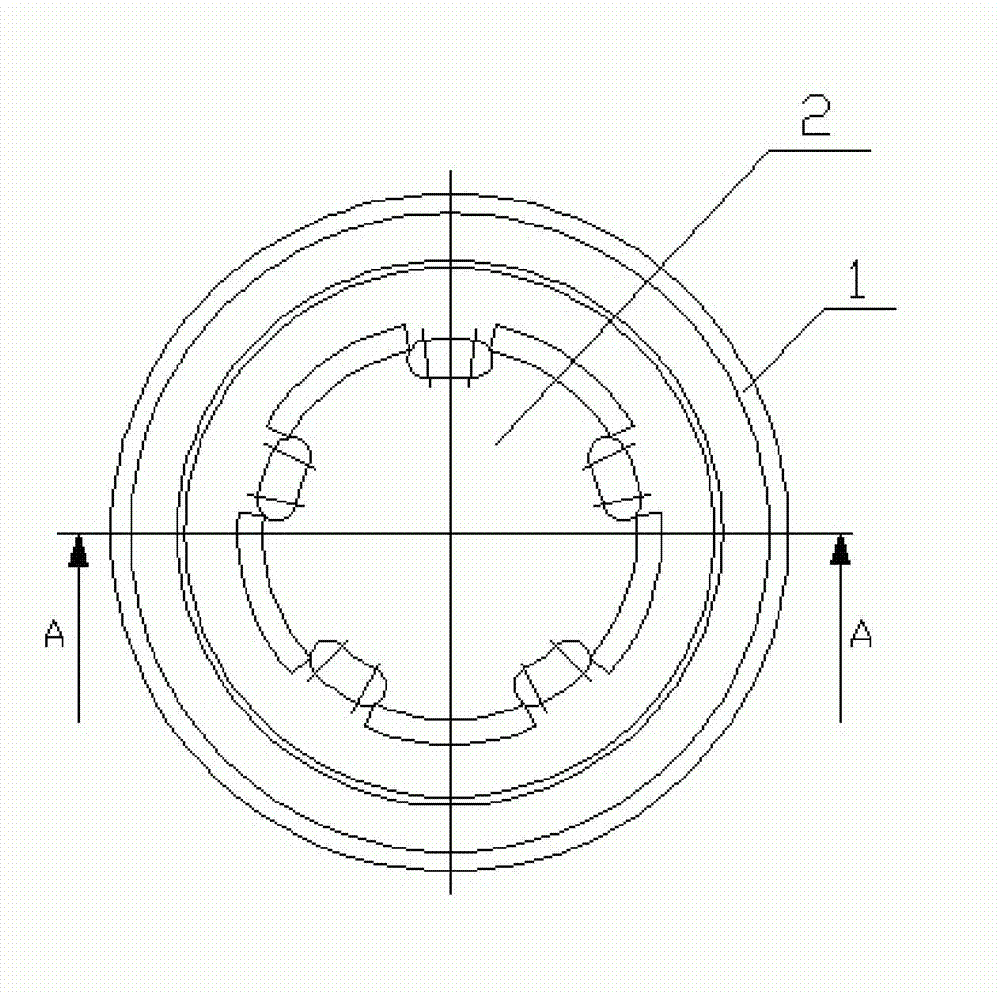

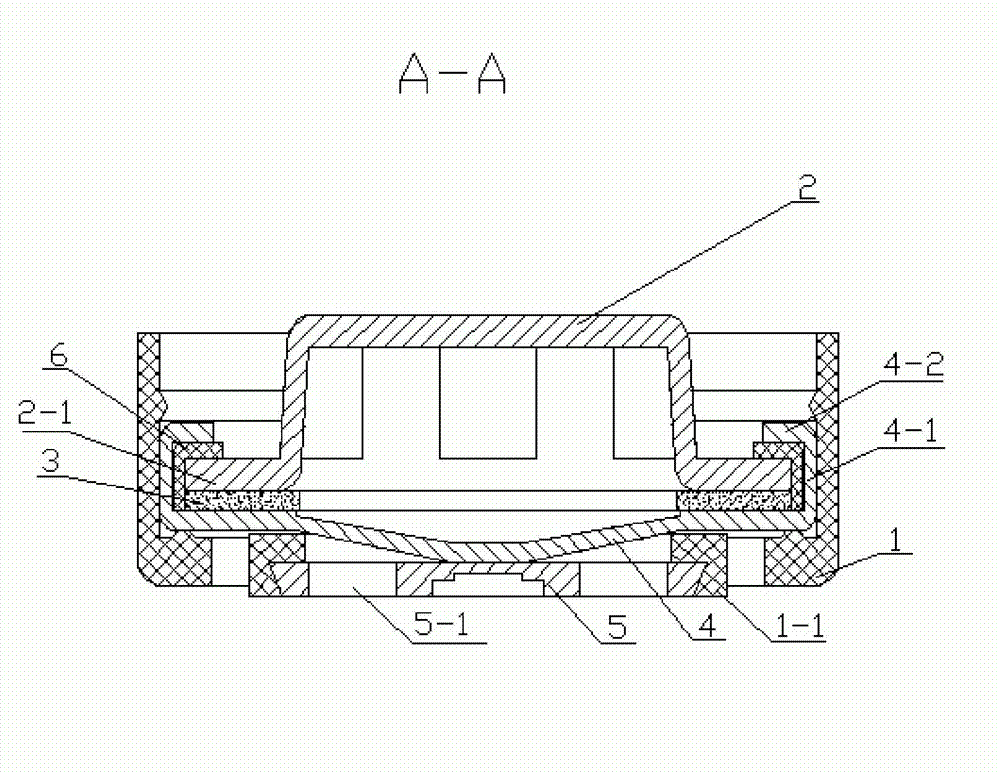

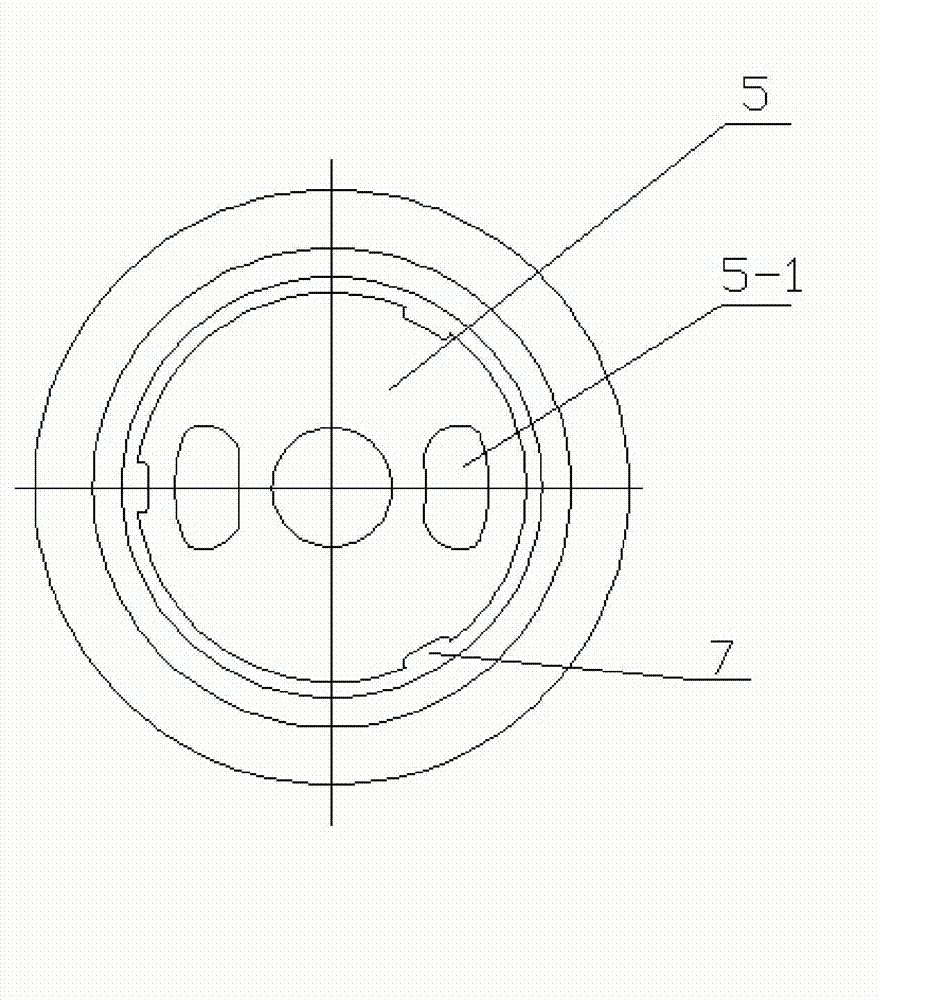

Elastomeric diaphragm filter plate

The invention relates to an elastomeric diaphragm filter plate, which comprises a filter frame. The center layer of the filter frame is provided with a rigid core plate, the front and rear wall of the core plate are both covered with an elastic diaphragm, the elastic diaphragm and four sides of the filter frame are in sealing connection, sealed gas chambers are formed between the elastic diaphragm and the front and rear wall of the core plate, the side of the filter frame is provided with a water inlet of the water inlet hole, which extends into the core plate and extends from the inside of the core plate to both sides and is communicated with the two gas chambers, the apex angle of the filter frame is provided with a feeding hole, the feeding hole is communicated with a cavity outside the elastic diaphragm, the bottom angle of the filter frame is provided with a water outlet hole, the water outlet hole is communicated with the cavity outside the elastic diaphragm, two horizontal liquid outlet pipes are disposed inside the bottom frame of the filter frame, and the liquid outlet pipes are communicated with the cavity outside the elastic diaphragm. The structure has the characteristics of good compaction sealing performance, high filter plate strength, large pressing pressure, more uniform dewatering, and large pressing area, etc.

Owner:JIANGSU XINGXIN SEPARATION EQUIP MFR

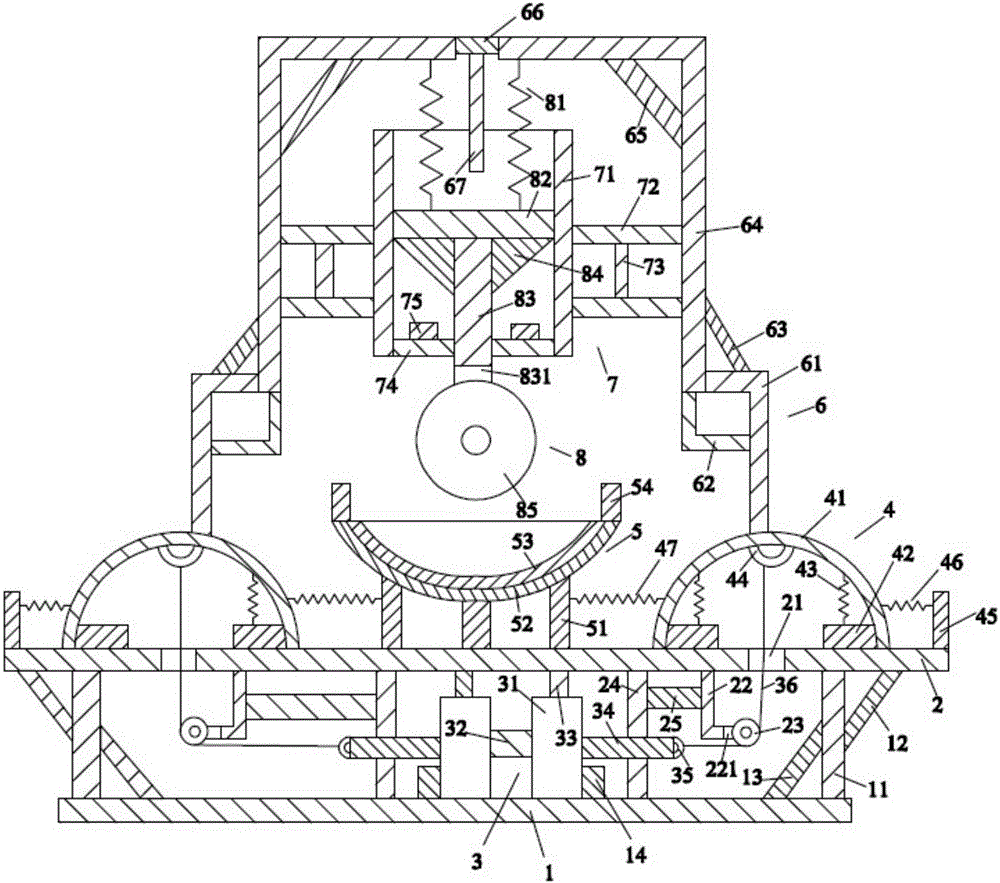

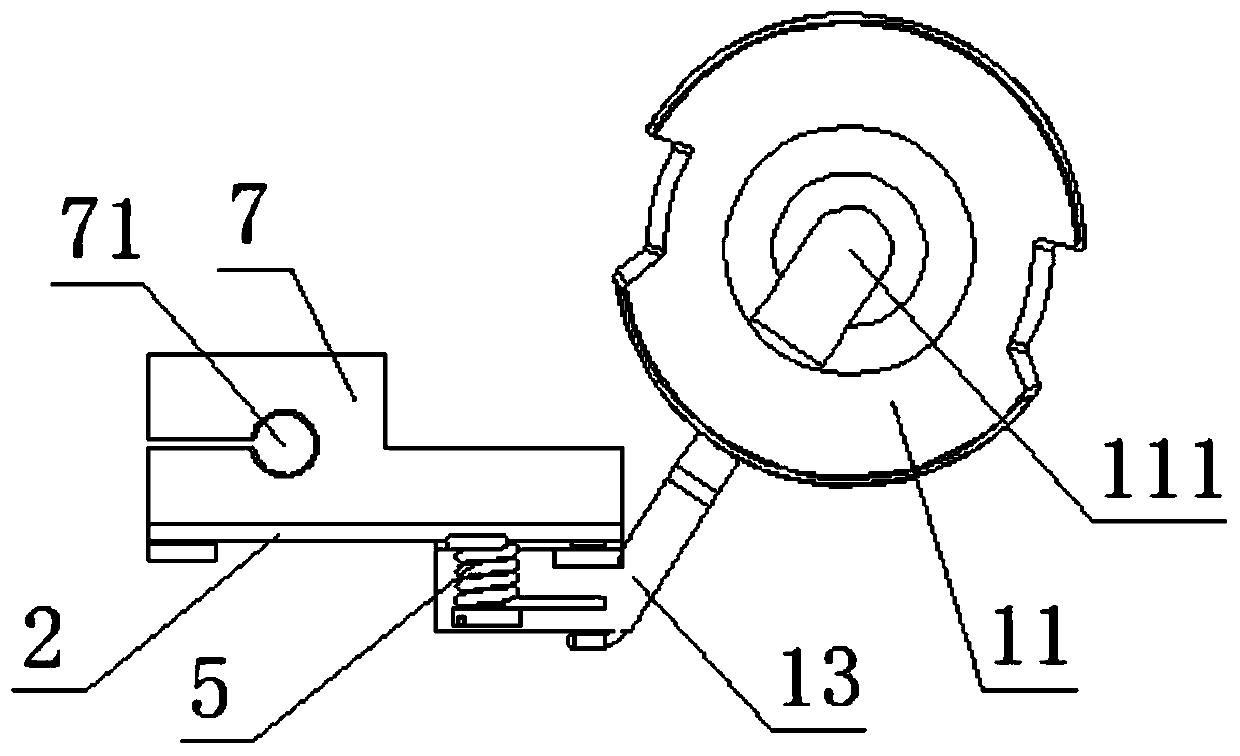

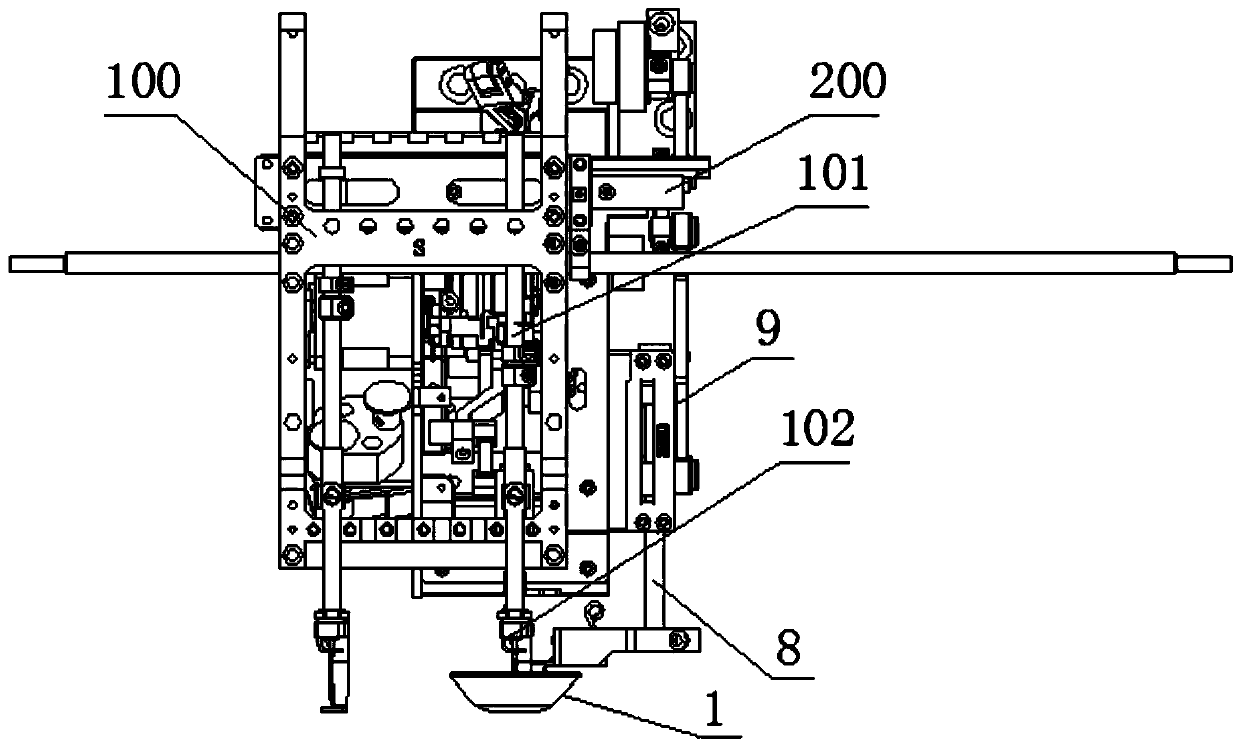

Nursing massage device

A nursing massage device comprises a base plate (1), a supporting plate (2), a cylinder device (3), an elastic device (4), a supporting device (5), a support device (6), a positioning device (7) and a massage structure (8). The base plate (1) is provided with a first supporting rod (11), a first inclined rod (12), a second inclined rod (13) and a first fixed block (14). The supporting plate (2) is provided with a first through hole (21), a first support (22), a first roller (23), a first cross rod (25) and a second supporting rod (24). The cylinder device (3) comprises a cylinder (31), a second fixed block (33), a second cross rod (32), a push rod (34), a first fixing ring (35) and a draw wire (36). The elastic device (4) comprises an elastic rod (41), a sliding block (42), a first spring (43), a second fixing ring (44) and a third fixed block (45). Users are massaged more comfortably through the nursing massage device, and patients can recover as soon as possible.

Owner:迟玉辉

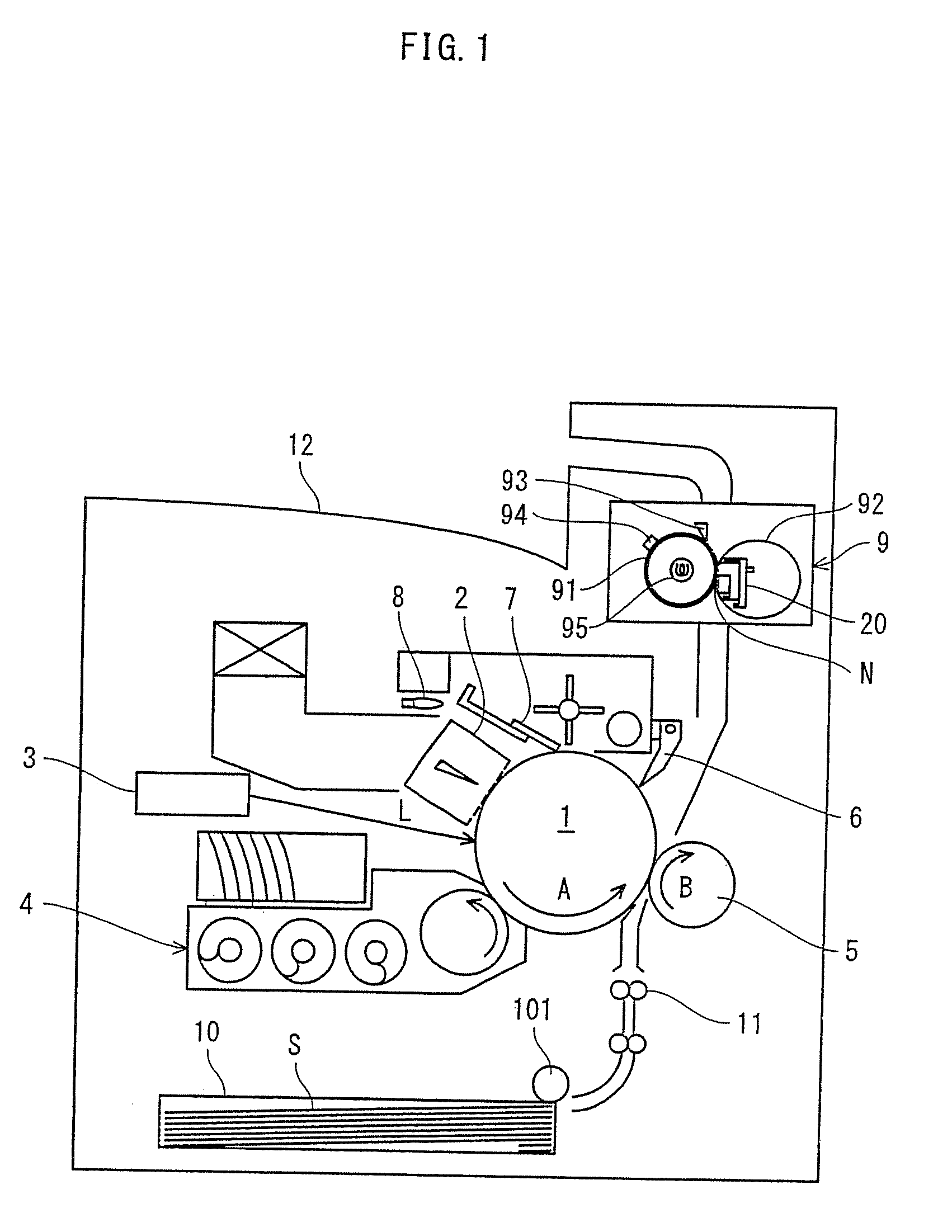

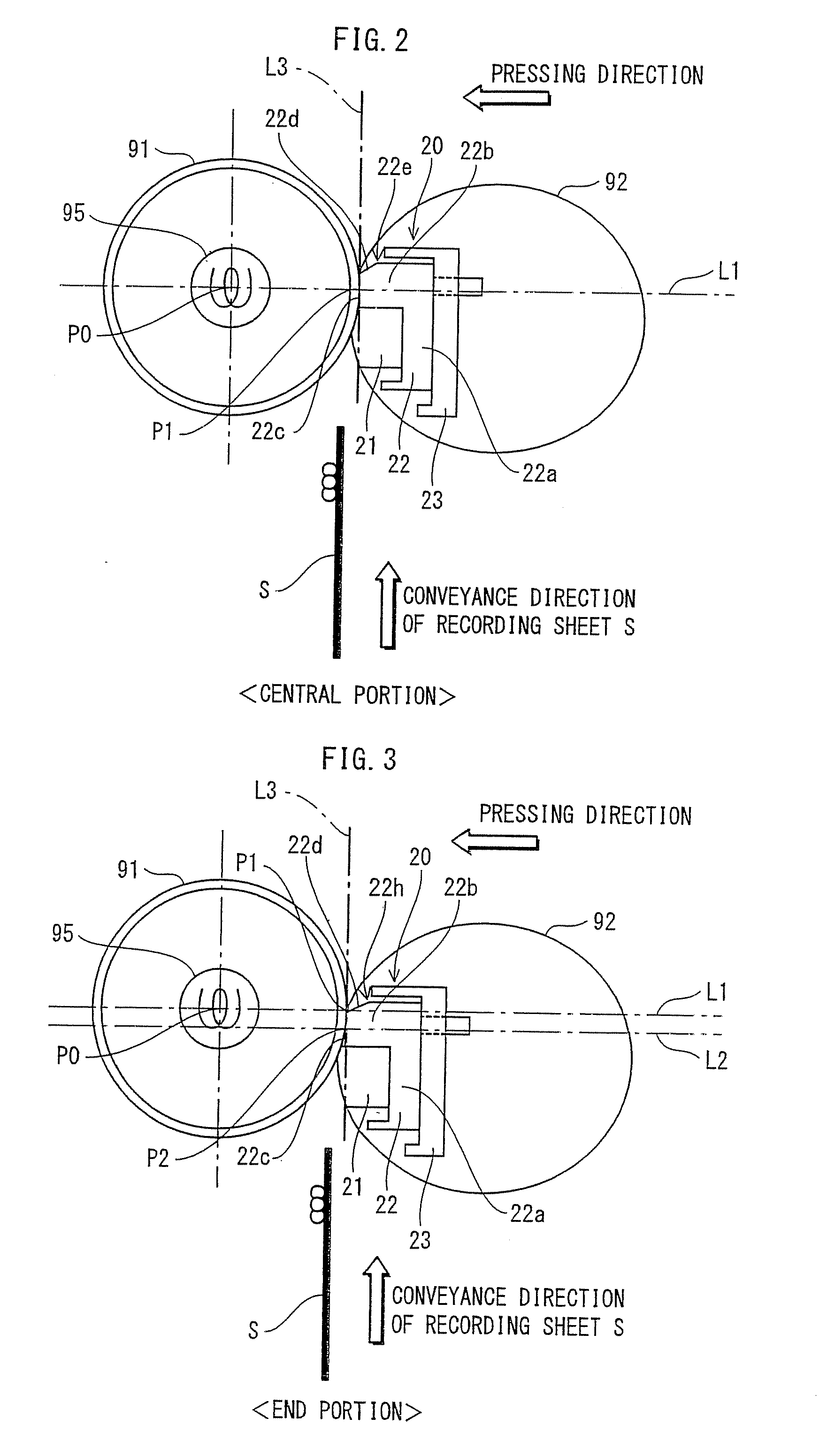

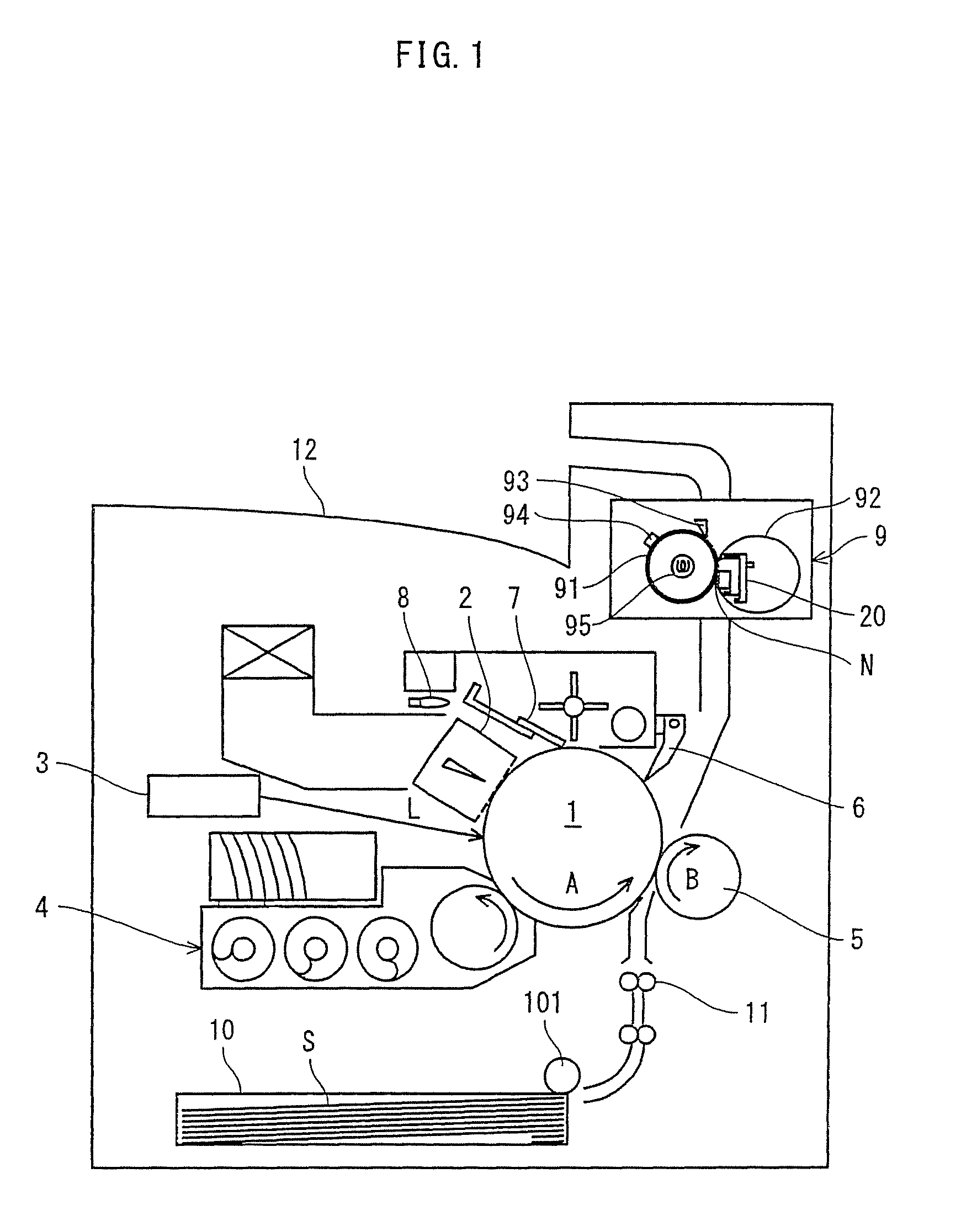

Fixing device and image formation apparatus

ActiveUS20090317154A1Avoid creasesProductively and economically efficientElectrographic process apparatusImage formationEngineering

Owner:KONICA MINOLTA BUSINESS TECH INC

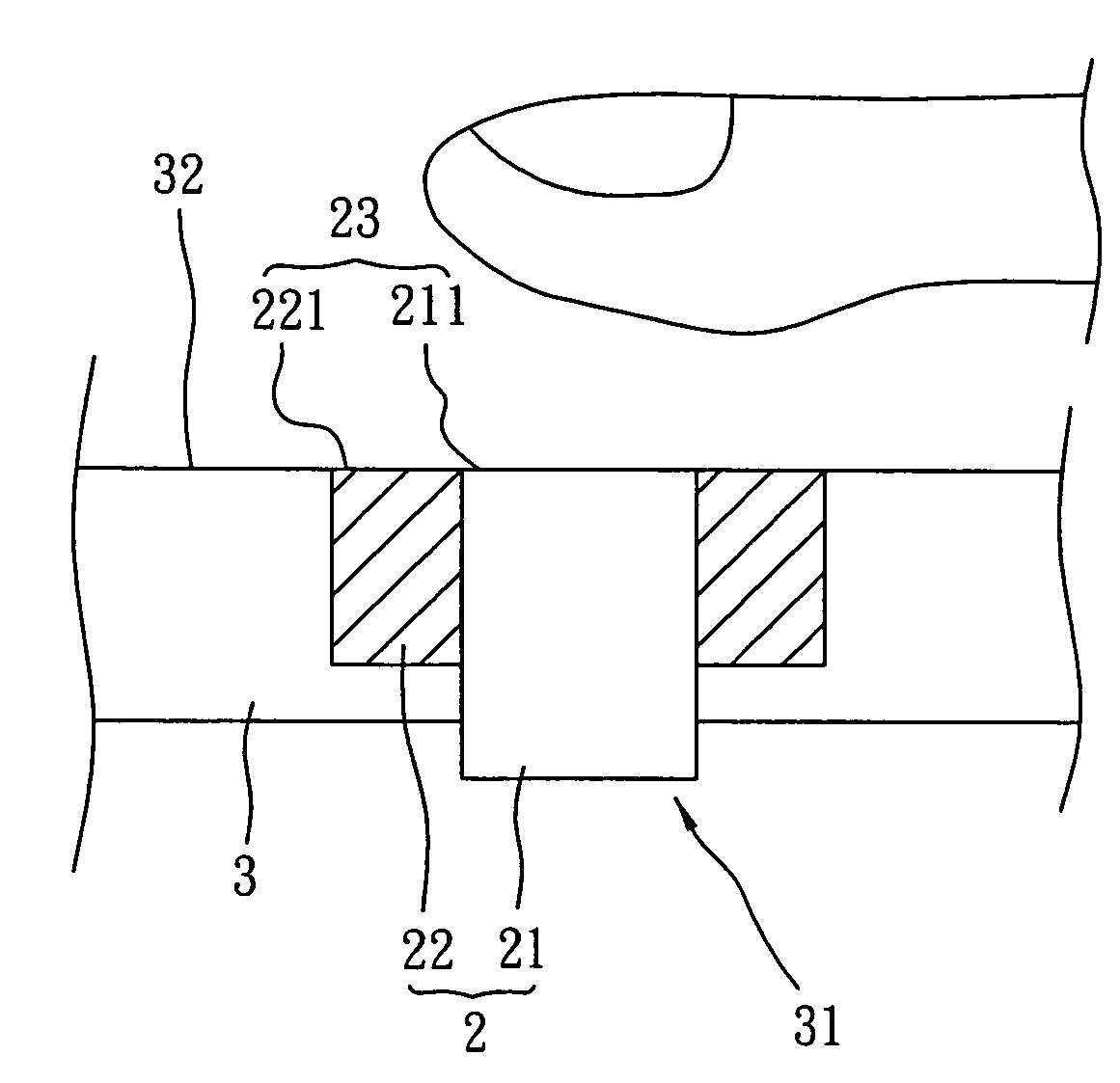

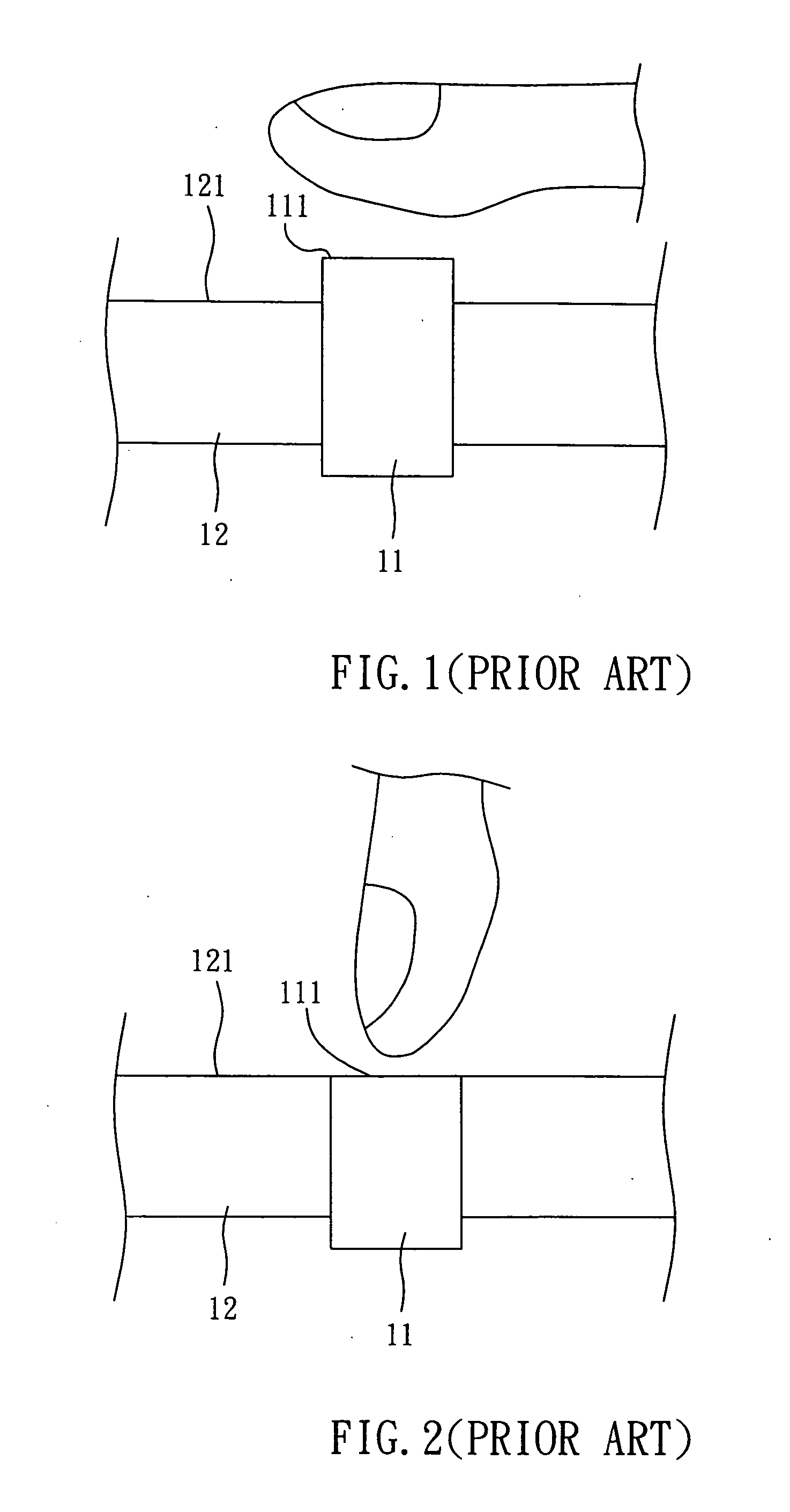

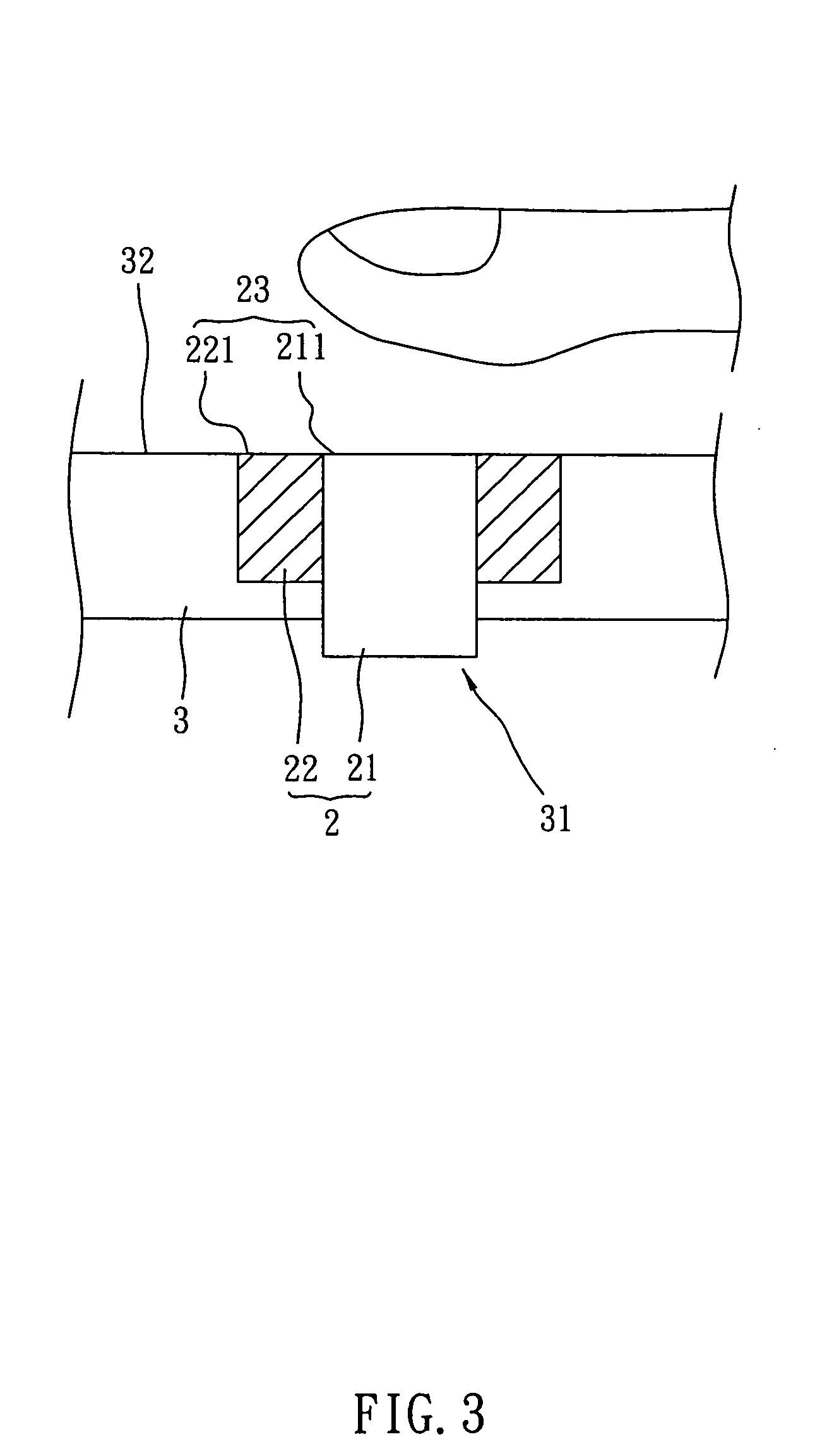

Key module

InactiveUS7586735B2Intentional depression of the keys more convenientIncrease the pressing areaEmergency actuatorsContact surface shape/structureEngineeringMechanical engineering

Owner:INVENTEC CORP

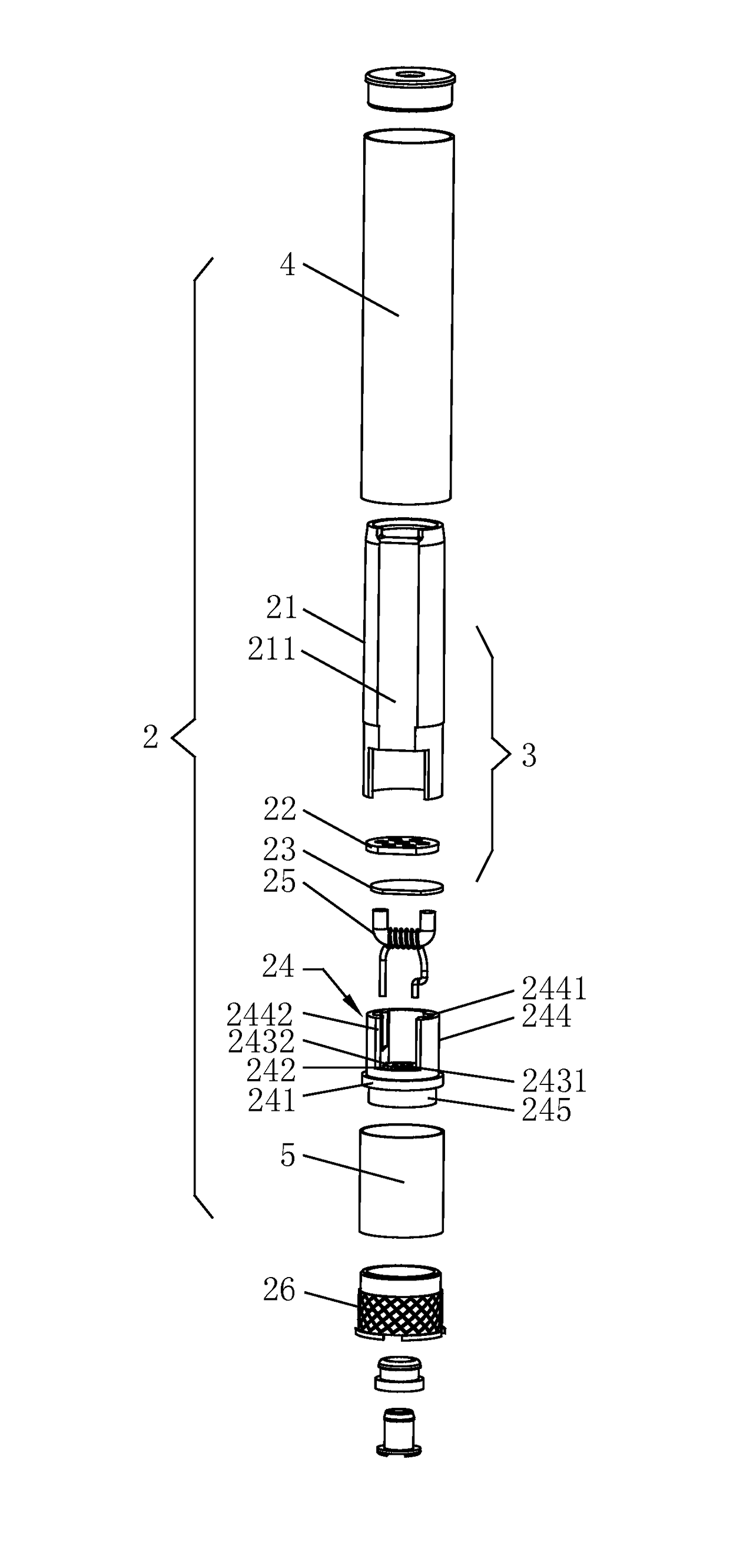

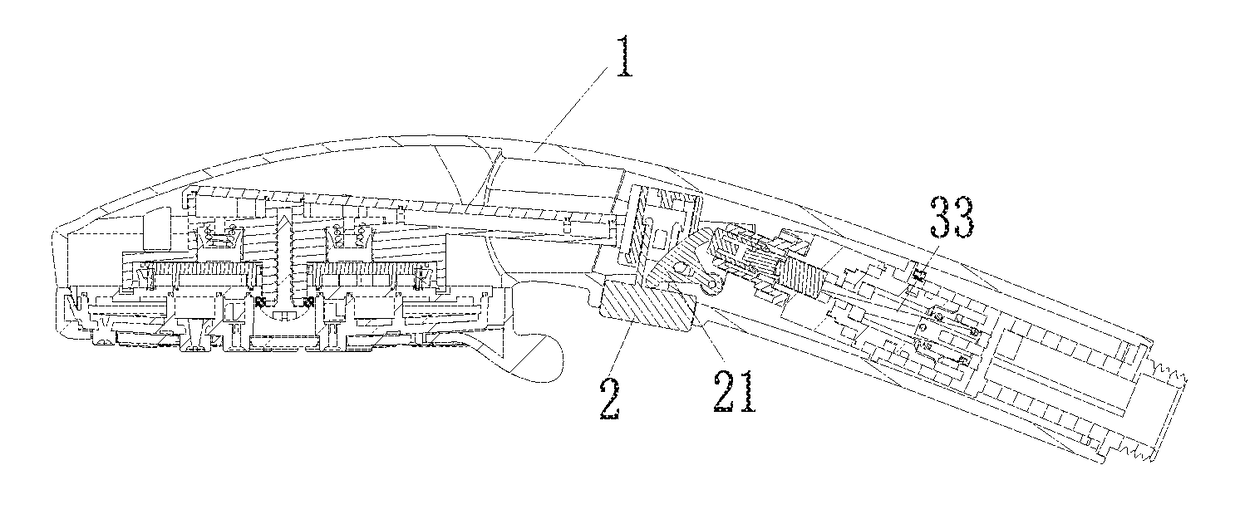

Vaporizer device of cotton-free electronic cigarette

ActiveUS9913496B2Effective supportPrevent leakageTobacco smoke filtersTobacco devicesElectronic cigaretteEngineering

A vaporizer device of cotton-free e-cigarette, comprising: an outer sleeve, a supporting frame arranged inside the outer sleeve, a vaporizer unit fixed into the supporting frame, a filter piece and a liquid percolation piece sequentially connected to one end of the supporting frame, and a fixation seat connected to other end of the supporting frame. A backflow groove is made inside the supporting frame to prevent leakage caused by the backflow of residual liquid. The filter piece is made of heat-resisting material. The liquid percolation piece is connected at one end with a liquid storage cup by snap joints. Another end of the filter piece keeps a safe distance away from the vaporizer unit to avoid being burned. The liquid storage cup and the outer sleeve are assembled to form a slit therebetween to prevent the backflow of residual liquid.

Owner:LIN GUANGRONG

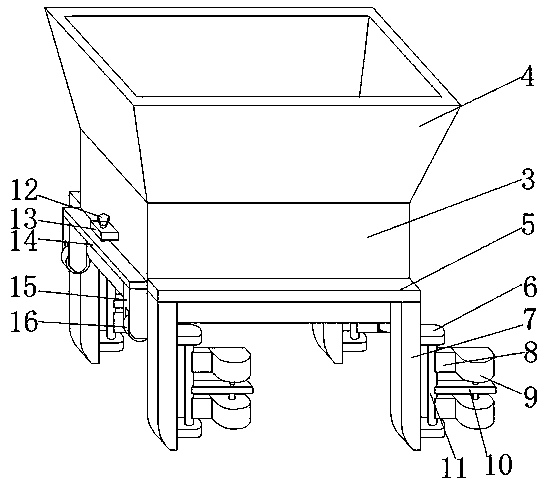

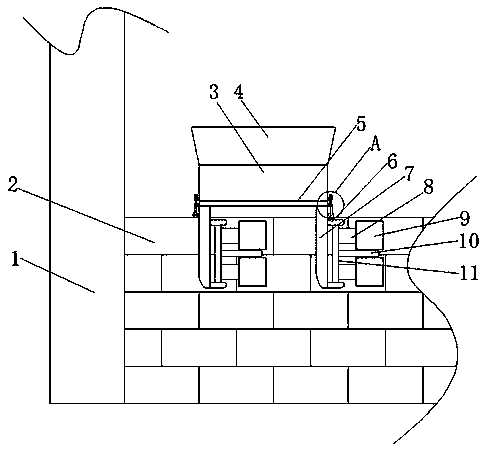

Cement laying device for building engineering

InactiveCN111021754AWeight increaseChange diameterBuilding material handlingBrickArchitectural engineering

The invention belongs to the technical field of engineering buildings, and particularly relates to a cement laying device for building engineering. Aiming at the problem that a general bricklaying robot cannot well lay cement during use, so that hollow possibly exists inside the cement after the cement is laid, and engineering quality problems are caused, the following scheme is presented now. According to the scheme, the cement laying device comprises a stand column and a main body located at the top end of a wall body, wherein a third fixing plate is welded to the middle of the main body, apressing plate is welded to the bottom end of the third fixing plate, a spring is welded to the top end of the third fixing plate, and a rotating plate is welded to the top end of the spring. According to the cement laying device, the device encounters a gap between bricks in the travelling process to form jounce and up-down shaking, the rotating plate is formed to rotate up and down through the spring, the inclined rotating plate enables the cement to quickly slide on the wall body, the cement can drive a rotating body to rotate through pressing blocks in the sliding process, and the pressingblocks press the cement falling on the wall body in the rotating process, so that air in the cement is discharged.

Owner:深圳市河图建设项目管理有限公司

Key module

InactiveUS20070268659A1Increase the pressing areaEasy to useEmergency actuatorsMechanically variable capacitor detailsEngineeringMechanical engineering

Owner:INVENTEC CORP

Improved oil cooler welding joints

InactiveCN105371690AIncrease the pressing areaIncreased compression tightnessHeat exhanger sealing arrangementHeat exchanger casingsEngineeringHigh pressure

The invention relates to improved oil cooler welding joints arranged on the two sides of a core of an oil cooler to connect the core of the oil cooler with a water chamber. Each improved oil cooler welding joint is characterized in that sealing trenches are formed in the connection contact face of the welding joint and the water chamber, and sealing rings are arranged in the sealing trenches. Compared with the prior art, the improved oil cooler welding joints are applied in press fitting of the oil cooler and the water chamber, the pressing area can be increased, pressing airtightness is improved accordingly, product leakage cannot occur even when the working condition is severe, and the welding joints can bear higher pressure. In addition, threads for assembling welding joints are likely to be damaged and scrapped when the existing joints are assembled multiple times, and it is difficult to achieve the long-term normal working condition use purpose even though the existing joints are assembled; and due to the fact that the sealing rings are additionally arranged on each improved oil cooler welding joint, and after-sale services caused by leakage due to assembly are avoided.

Owner:SHANGHAI DELANG AUTO PARTS MFG

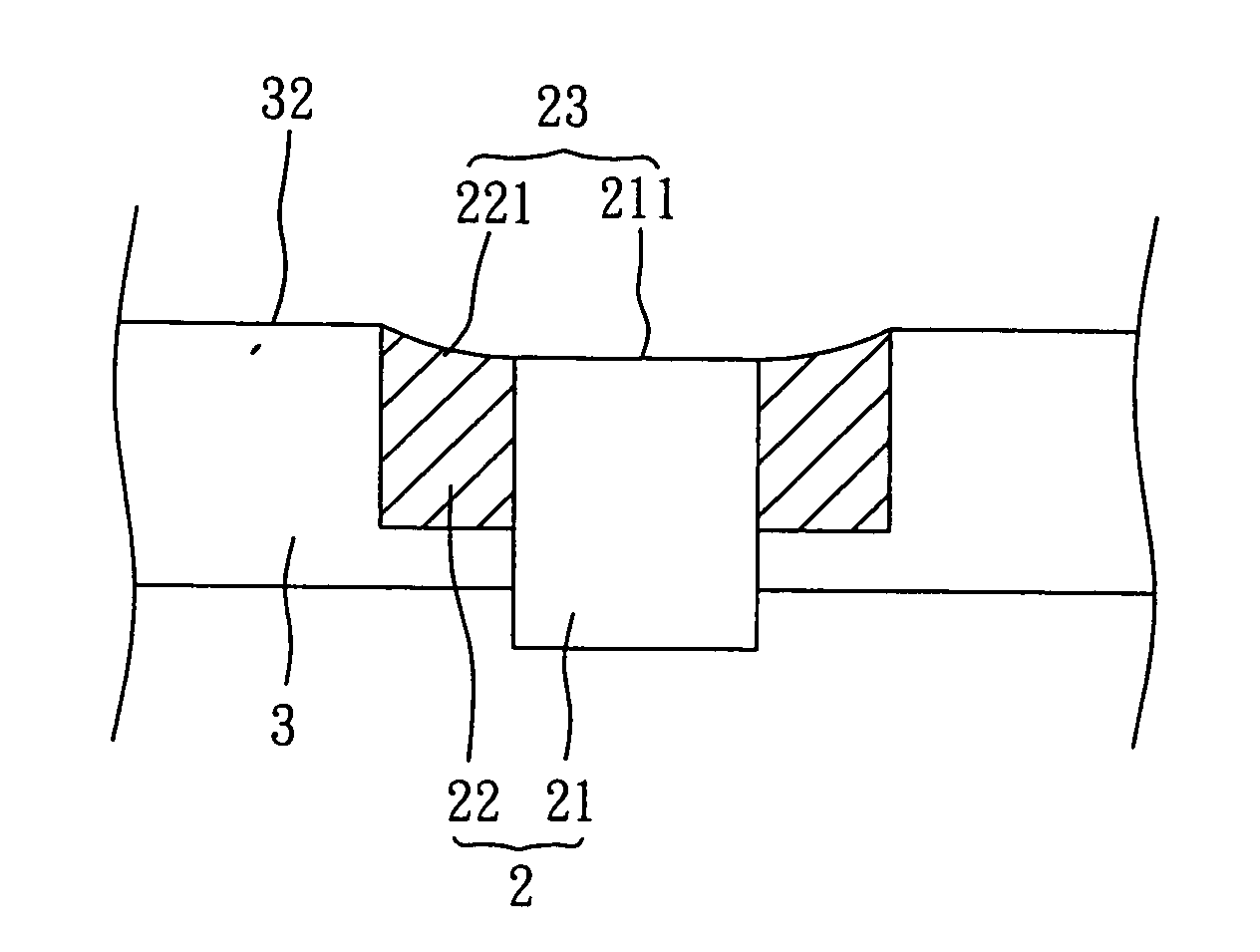

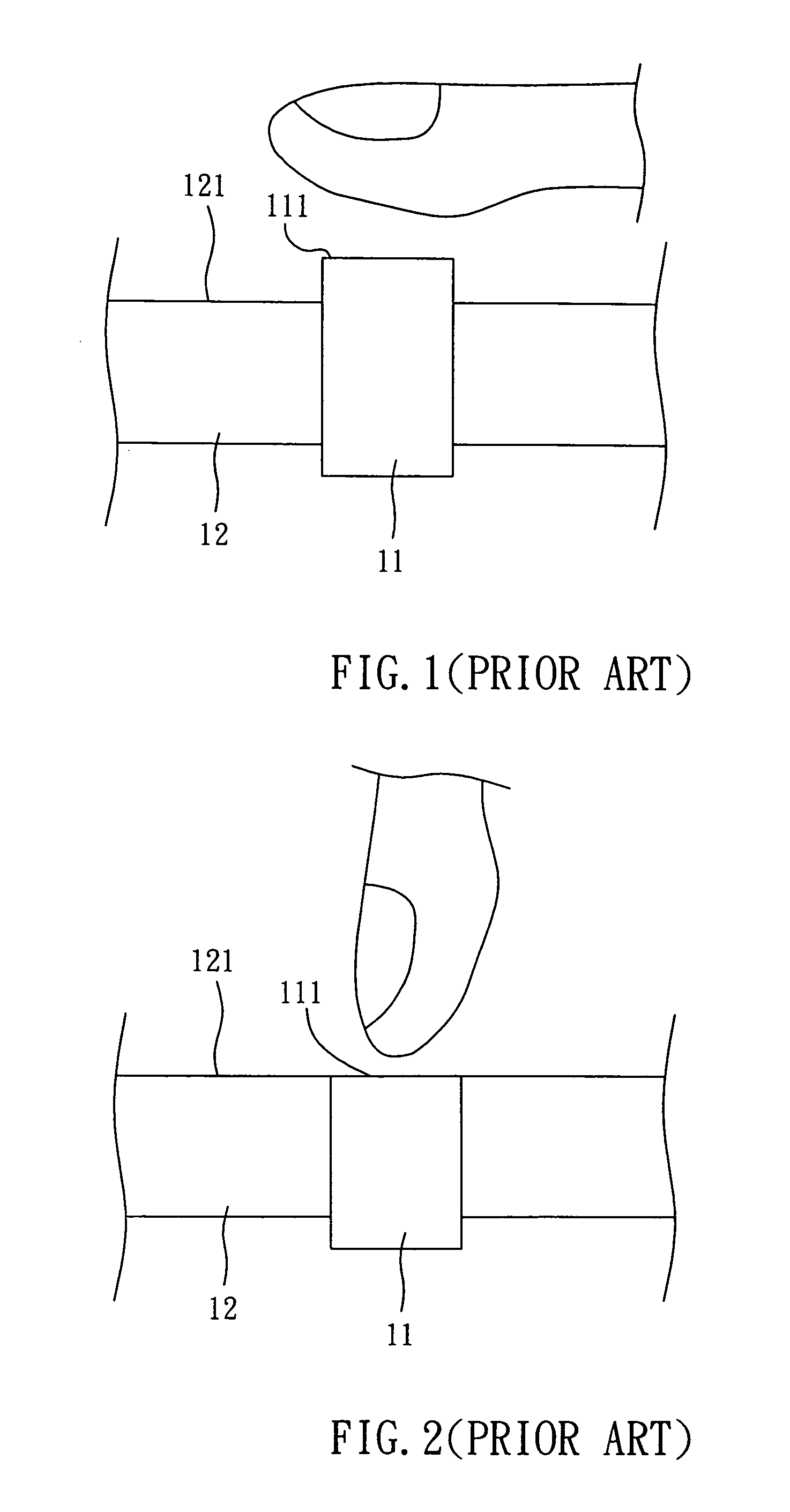

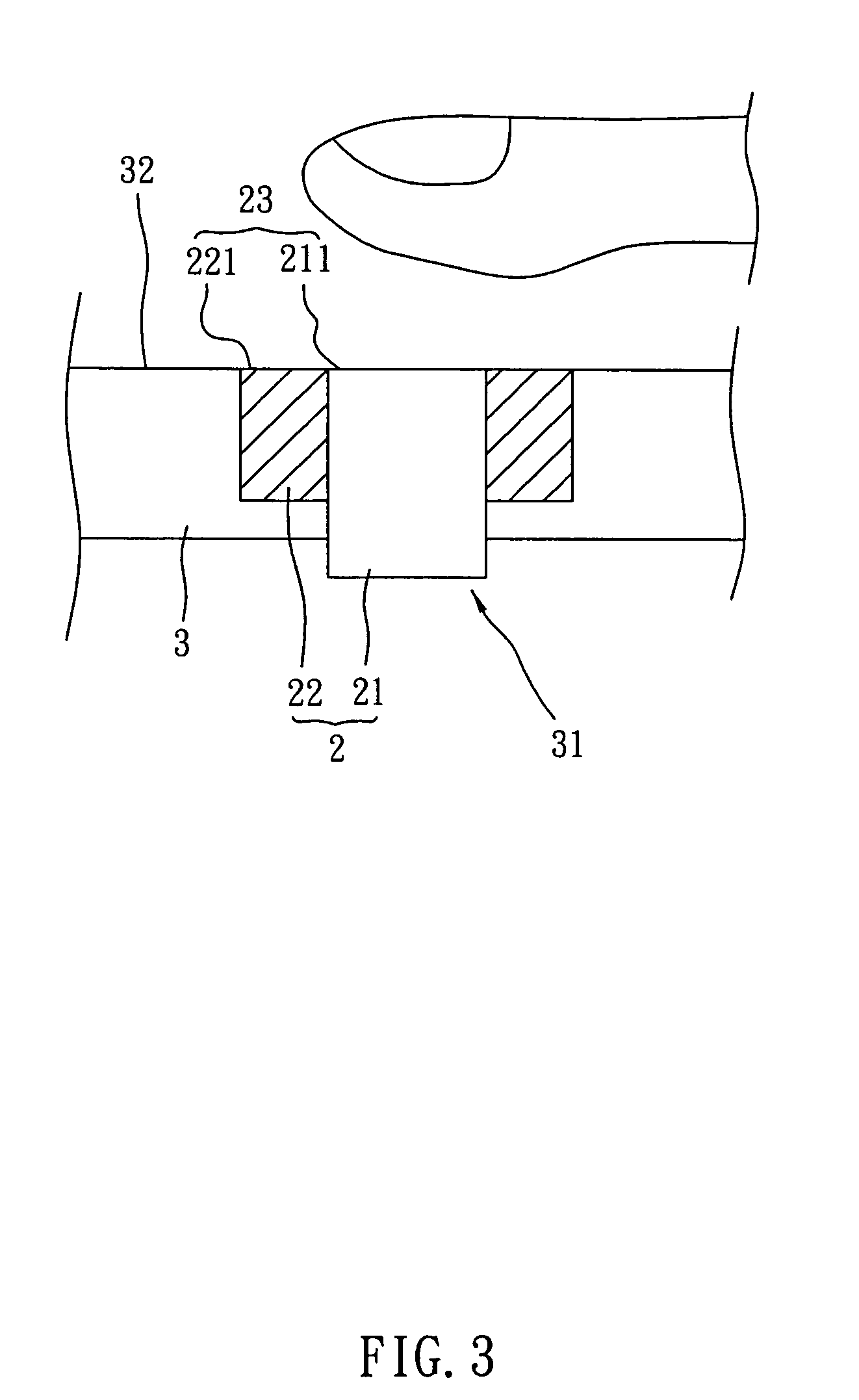

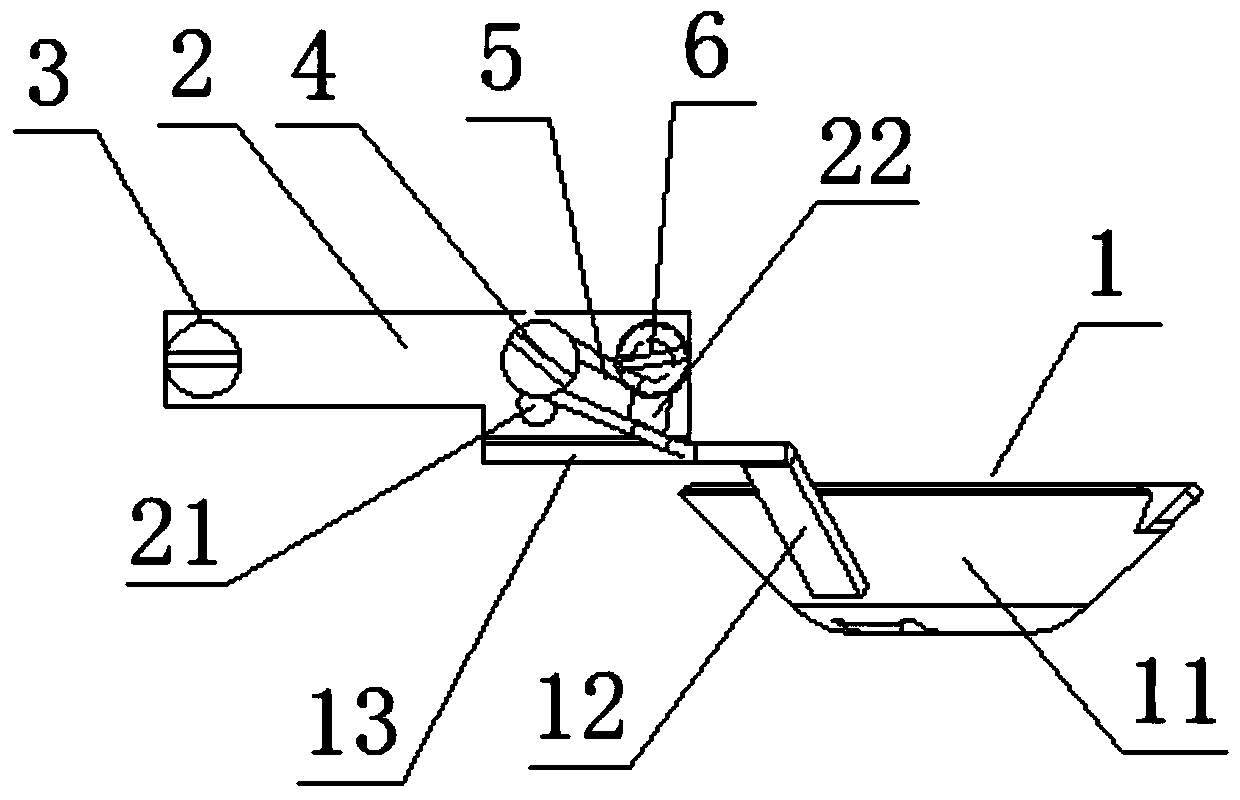

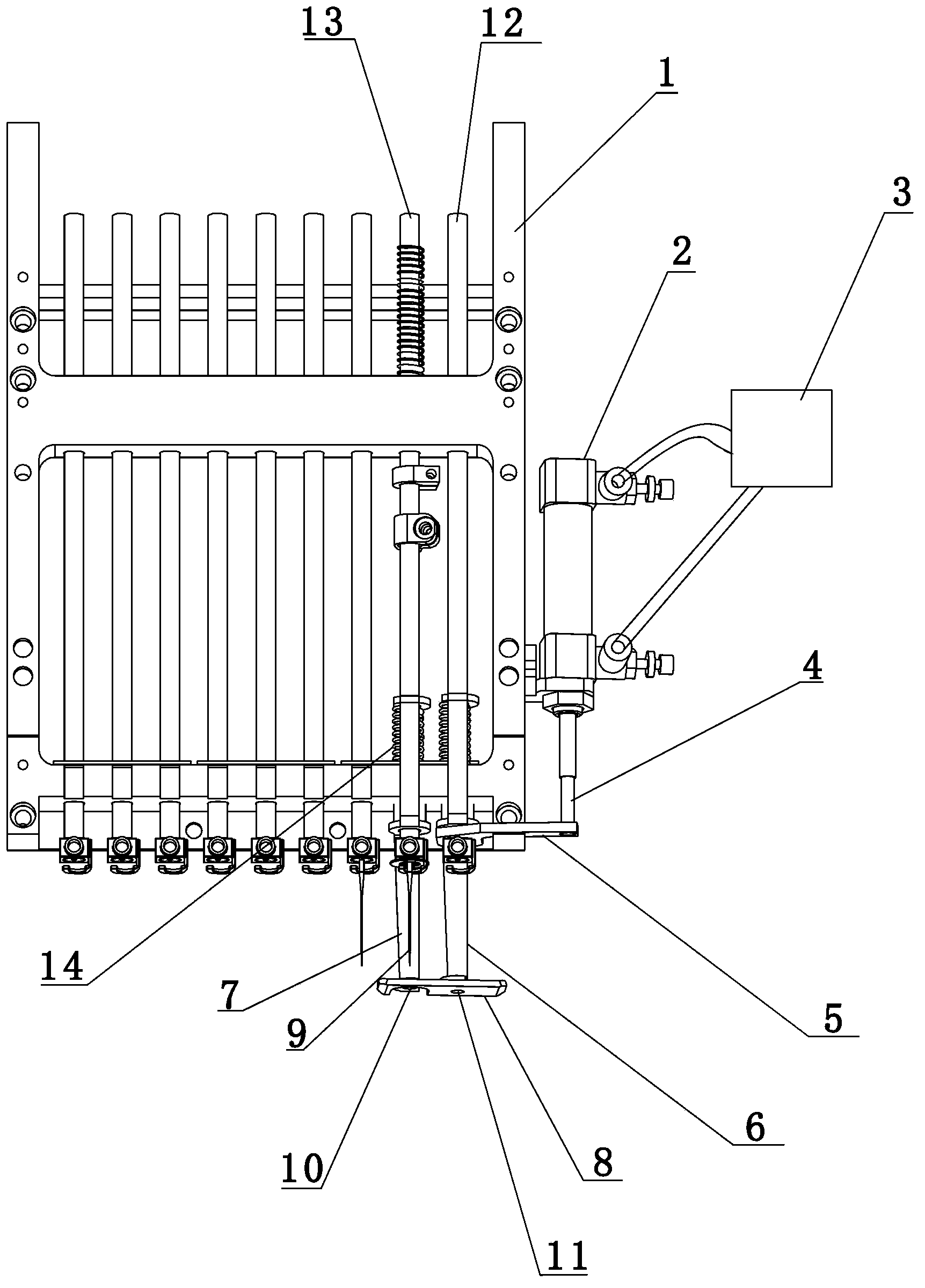

Water stop switch device and shower head

ActiveUS20180001331A1Increase the pressing areaIncrease air pressureOperating means/releasing devices for valvesPressure relieving devices on sealing facesEngineeringPressure difference

A water stop switch device includes: a main body, a transmission element and a sealing element; the main body is disposed with a water passage, the sealing element is disposed in the water passage; one end of the sealing element is coupled to the transmission element in transmission way, the sealing element moves in the water passage to open the water passage; the other end of the sealing element and the main body surround to form a chamber; the side wall of the sealing element is disposed with a through hole connecting the water passage and the chamber; when the water passage is open, the chamber is full of water to reduce the pressure difference at two ends of the sealing element.

Owner:XIAMEN SOLEX HIGH TECH IND CO LTD

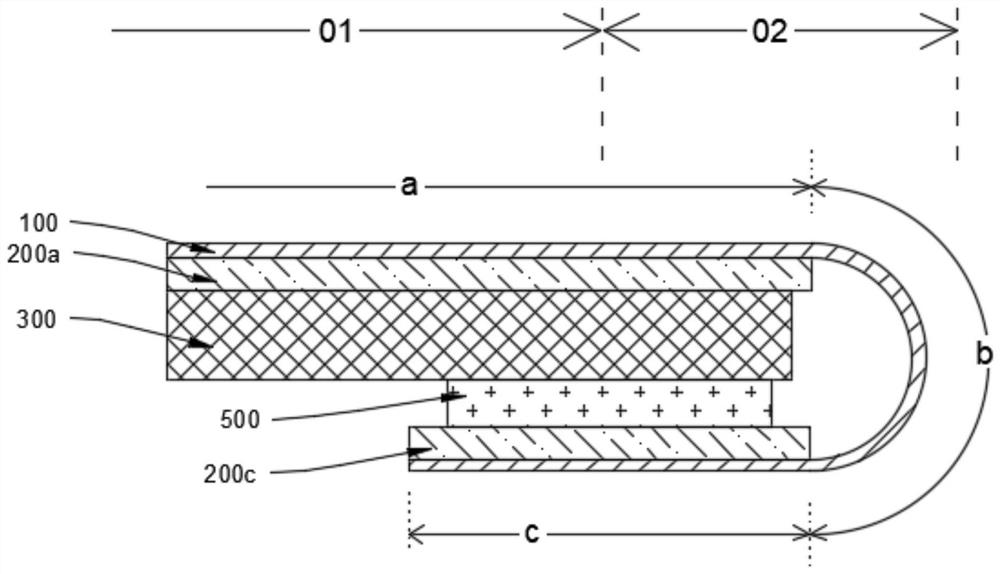

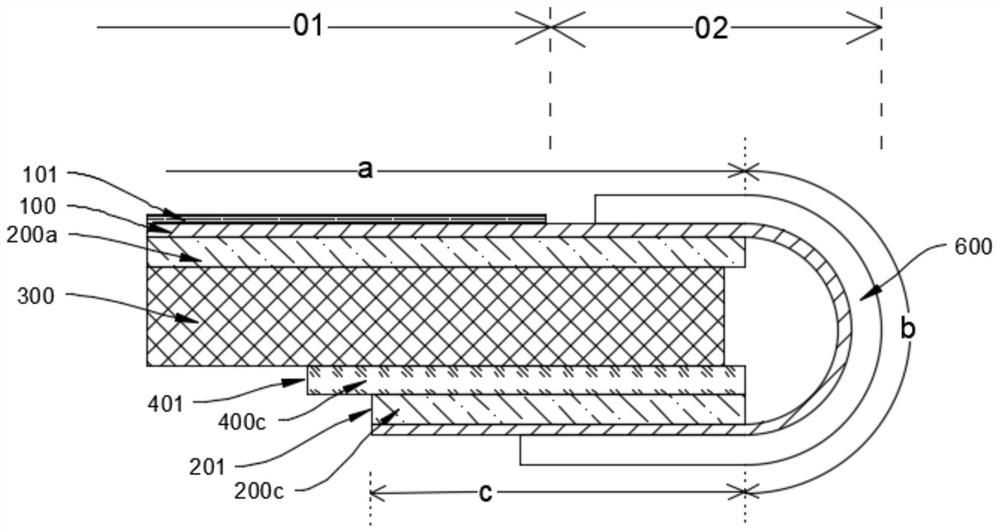

Display module, manufacturing method thereof and display device

ActiveCN113436530AIncrease the pressing areaImprove appearance yieldIdentification meansDigital data processing detailsDisplay deviceEngineering

The invention provides a display module, a manufacturing method thereof and a display device. The display module comprises a substrate, a display function layer, a supporting layer, a buffer layer and a first bonding layer. The substrate comprises a display section, a bending section and an extension section; the supporting layer is arranged on one side, far away from the display function layer, of the substrate, and comprises a first supporting layer arranged close to the extension section and a second supporting layer arranged on the display section; the buffer layer is arranged on one side, deviating from the substrate, of the second supporting layer; the first bonding layer is arranged between the first supporting layer and the buffer layer; and the distance from one end, far away from the non-display area, of the first bonding layer to the non-display area is larger than or equal to the distance from one end, far away from the non-display area, of the buffer layer to the non-display area. The technical problem that the appearance of a display module product is affected due to the fact that a buffer layer is excessively thinned in order to achieve a narrow frame effect in an existing terminal bending process, so that a bonding layer on the display module is impressed obviously is solved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

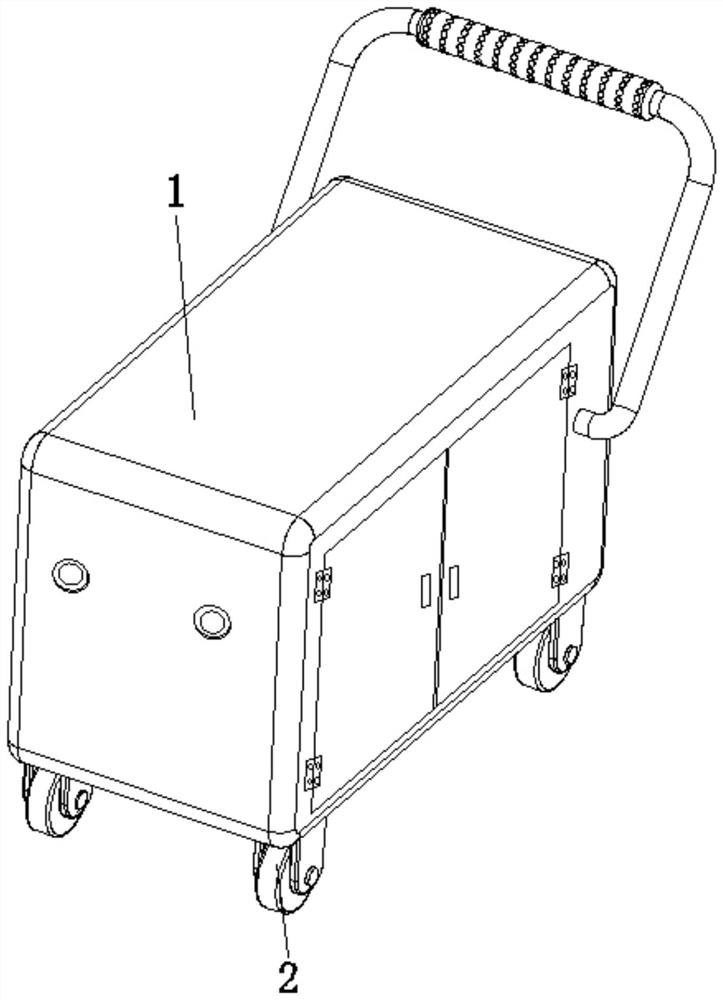

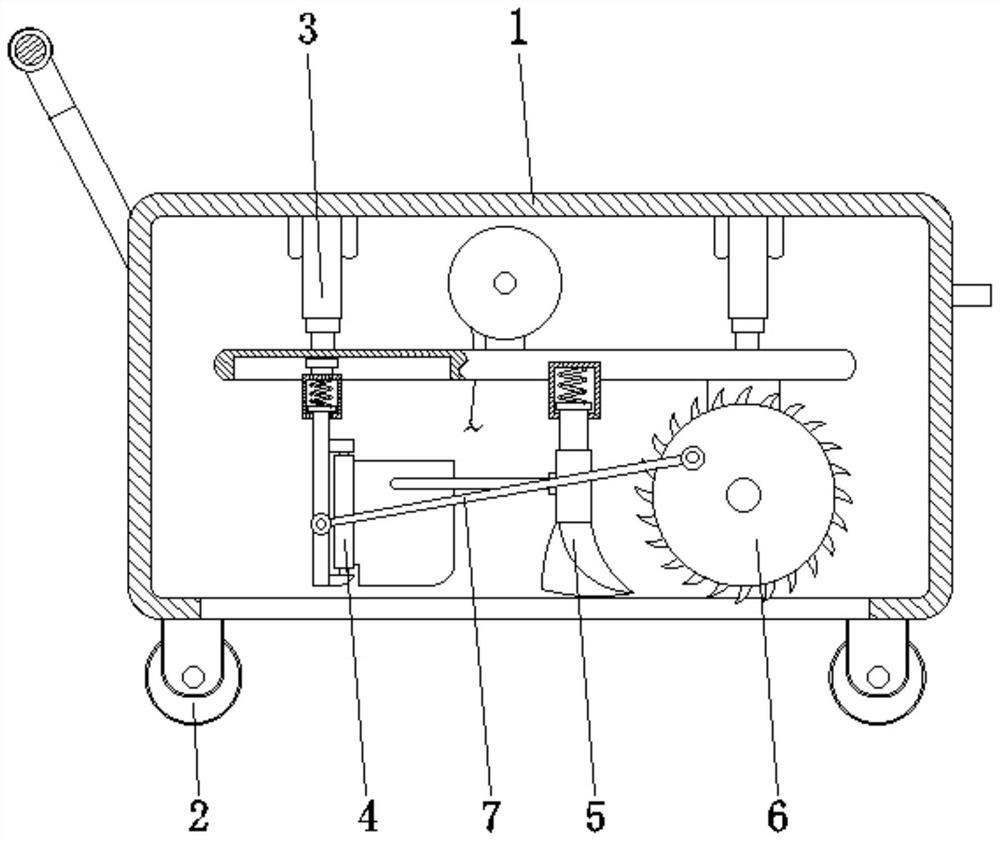

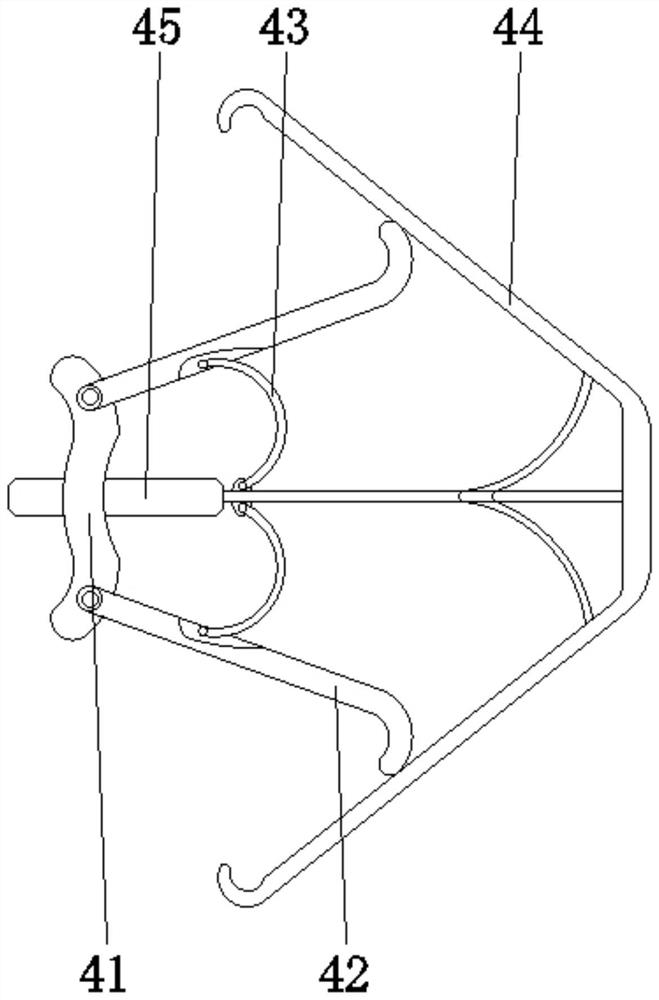

Cutting device special for cloth-cutting machine

InactiveCN112359587AEasy to moveIncrease pressureSevering textilesMetal working apparatusEconomic benefitsElectric machinery

The invention relates to a cutting device special for a cloth-cutting machine. The cutting device special for the cloth-cutting machine comprises a base, wherein fixable pulleys are arranged at the bottom of the base; a stand column is arranged on the base; a sliding rail is arranged on the stand column; a ram matched with the sliding rail is arranged on the sliding rail; first limiting assembliesare arranged at the two ends of the sliding rail; a transverse shaft is arranged on the ram; a sliding groove is formed in the bottom of the transverse shaft; a sliding block is arranged in the sliding groove; second limiting assemblies are arranged at the two ends of the sliding groove; a supporting rod is arranged on the sliding block; a cutter is arranged on the supporting rod; a workbench isarranged on the base; pressing devices are arranged at the two ends of the workbench, and are connected with a dust collection assembly; and the dust collection assembly is connected with a motor. Thecutting device special for the cloth-cutting machine provided by the invention is high in pressing performance, convenient to cut, high in automation degree, good in positioning effect, capable of effectively improving the working efficiency and accuracy, stable and firm in overall structure, capable of prolonging the service life, capable of rapidly recycling sweeps, capable of guaranteeing environmental sanitation, wide in application range, capable of reducing cost and capable of improving comprehensive economic benefits.

Owner:夏炜

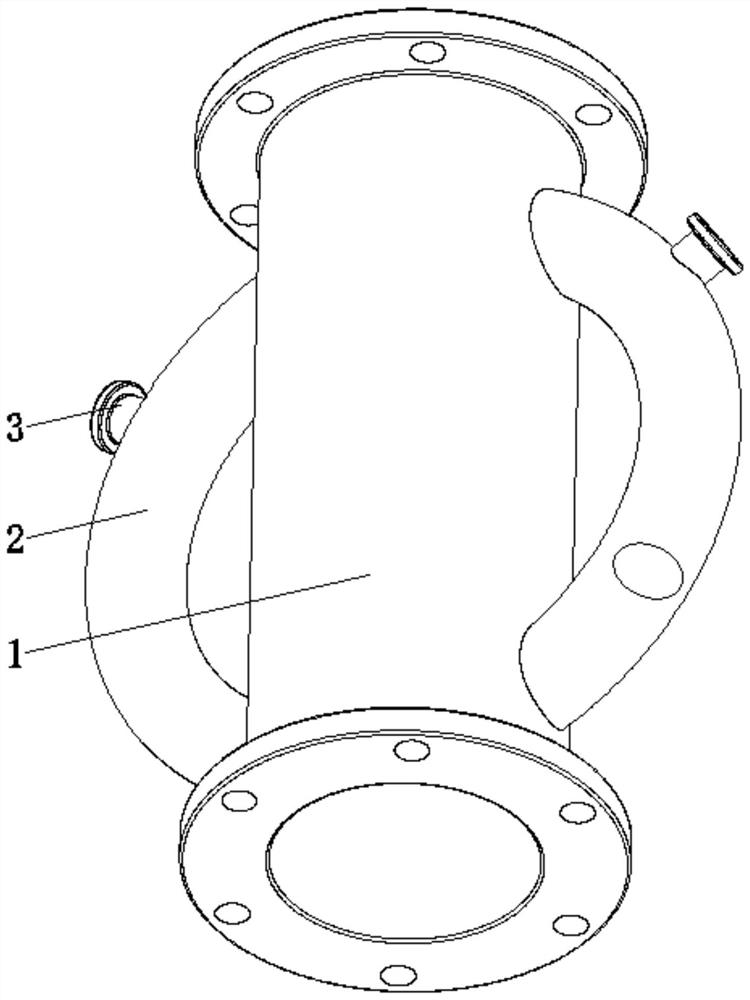

Municipal drainage equipment

ActiveCN112962757AAvoid blockageReduce the frequency of manual cleaningFatty/oily/floating substances removal devicesSewerage structuresEnvironmental engineeringVALVE PORT

The invention discloses municipal drainage equipment, and relates to the technical field of drainage equipment. The equipment comprises a flange pipe, arc-shaped residual discharging pipes and valves, the arc-shaped residual discharging pipes are fixed to the two corresponding sides of the surface of the flange pipe, the arc-shaped residual discharging pipes communicate with each other, and the valves are arranged on the surfaces of the arc-shaped residual discharging pipes and are close to the flange pipe; an impurity removing device is arranged in the flange pipe and close to the end, the position, located on the edge, of the top of the surface of the impurity removing device is connected with the inner wall of the end of each arc-shaped residual discharging pipe in a matched mode, the bottom of the surface of the impurity removing device is connected with the inner wall of the end of each arc-shaped residual discharging pipe through a return spring, and the end, away from the impurity removing device, of the inner wall of each arc-shaped residual discharging pipe is fixedly connected with an arc-shaped filter screen. According to the municipal drainage equipment, the purposes of impurity removal and blockage prevention are achieved, impurities can be filtered out in time and automatically cleared, impurity accumulation is reduced, the blockage is avoided, the drainage efficiency is high, and the use performance is improved.

Owner:新疆杰建建设工程有限公司

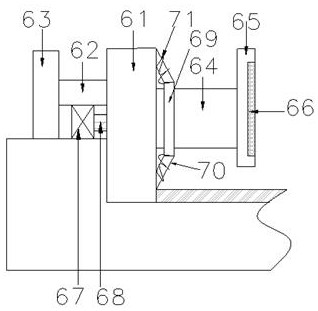

Device with functions of assisting presser foot and protecting presser foot and embroidery machine

PendingCN110485078AAvoid shockAvoid direct impactAuxillary devicesFeedersWorking environmentEngineering

The invention discloses a device with functions of assisting a presser foot and protecting the presser foot and an embroidery machine. The device comprises a protection piece, a fixed base and an elastic buffering piece, the protection piece is provided with a via hole for a needle bar and the presser foot to pass through, the protection piece is movably connected with the fixed base, the elasticbuffering piece is arranged between the protection piece and the fixed base, and when the protection piece is under impact, the elastic buffering piece absorbs and buffers impact force. The device isprovided with the protection piece and the elastic buffering piece, when misoperation occurs, the protection piece can be rebounded through the elastic buffering piece when impacted by a hard object,the situation that the presser foot and the needle bar are directly under impact is avoided, thus the presser foot and the needle bar are protected against damage, and the situation that since the pressure foot and the needle bar are not protected, the maintenance rate is too high is avoided. The protection piece has the function of assisting in cloth pressing, in some working environments where fabric is fluffy, larger cloth pressing areas are needed, and then the protection piece achieves the effect of assisting in cloth pressing.

Owner:ZHEJIANG XINSHENG SEWING EQUIP

Fixing device and image formation apparatus

ActiveUS8265538B2Preventing creases of the recording sheetProductively and economically efficientElectrographic process apparatusImage formationEngineering

Owner:KONICA MINOLTA BUSINESS TECH INC

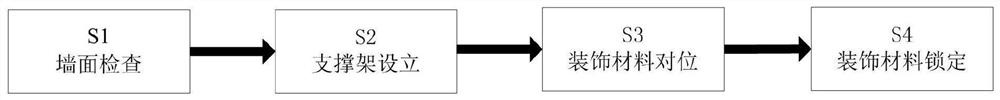

Integrated wall body wall surface decoration material installation method

The invention relates to an integrated wall body wall surface decoration material installation method. The integrated wall body wall surface decoration material installation method adopts a wall surface decoration material installation positioning device, and the wall surface decoration material installation positioning device comprises an installation frame, a lower pressing plate, a lower pressing body, a pressing plate, a positioning mechanism and a rotating shaft. The method for installing an integrated wall body wall surface decoration material by adopting the wall surface decoration material installation positioning device comprises the following steps of S1, wall surface inspection; S2, supporting frame arrangement; S3, decoration material alignment; and S4, decoration material locking. According to the method, the problems that when the decoration material is installed manually in the prior art, the decoration material is prone to being damaged due to manual hammering of the decoration material, the decoration material can be inclined due to uneven stress, and consequently the installation effect of the decoration material is poor, and the position of the decoration material can be changed due to the pressure of an air nail gun when the decoration material is nailed can be solved.

Owner:安庆米锐智能科技有限公司

Lithium cell safety valve

InactiveCN101931069BImprove reliabilitySolving Leakage Quality IssuesCell component detailsEngineeringCell leakage

Owner:CHANGZHOU JIANHU JINCHENG VEHICLE EQUIP CO LTD

Water stop switch device and shower head

ActiveUS10391504B2Small switching forceFeel goodOperating means/releasing devices for valvesPressure relieving devices on sealing facesEngineeringPressure difference

A water stop switch device includes: a main body, a transmission element and a sealing element; the main body is disposed with a water passage, the sealing element is disposed in the water passage; one end of the sealing element is coupled to the transmission element in transmission way, the sealing element moves in the water passage to open the water passage; the other end of the sealing element and the main body surround to form a chamber; the side wall of the sealing element is disposed with a through hole connecting the water passage and the chamber; when the water passage is open, the chamber is full of water to reduce the pressure difference at two ends of the sealing element.

Owner:XIAMEN SOLEX HIGH TECH IND CO LTD

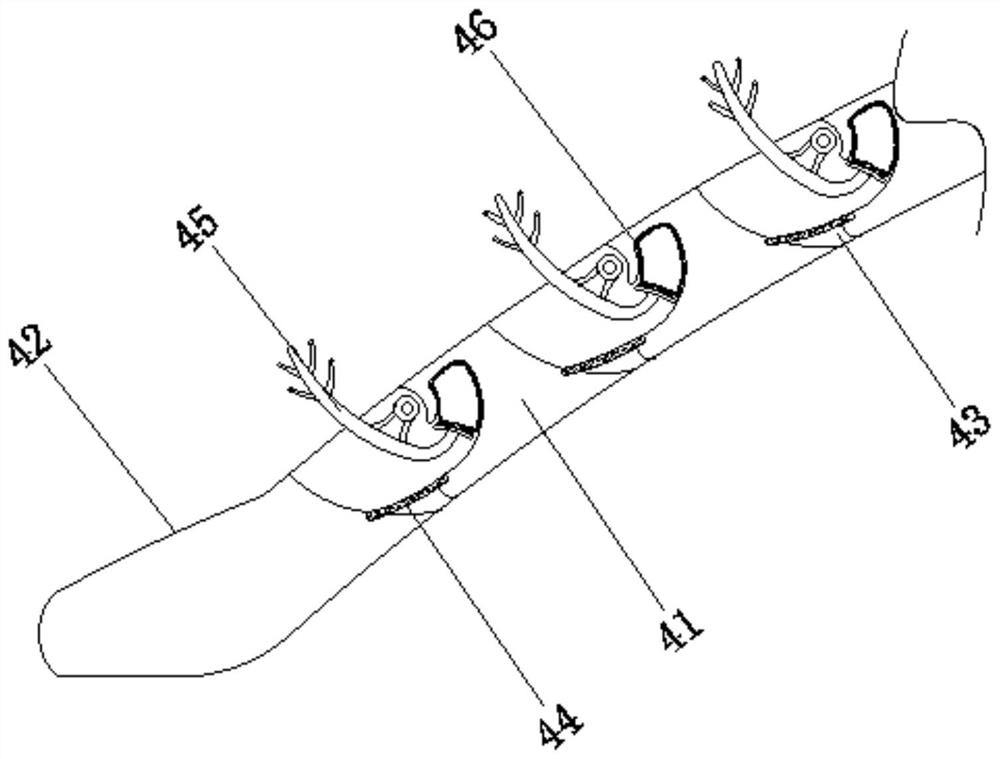

Auxiliary pressing foot of embroidery machine

The invention discloses an auxiliary pressing foot of an embroidery machine. The auxiliary pressing foot is arranged on a needle bar frame, a plurality of needle bars are fixedly arranged on the needle bar frame, an air cylinder is fixedly arranged at one side of the needle bar frame, the auxiliary pressing foot is arranged the bottom of each of a first needle bar and a second needle bar close to the side of the needle bar frame, the auxiliary pressing foot is composed of a first pressing foot pipe, a second pressing foot pipe and a pressing block, the bottom of the first pressing foot pipe and the bottom of the second pressing foot pipe are fixedly connected with the pressing block respectively, the first pressing foot pipe is positioned right below the first needle bar, the top end of the first pressing foot pipe is connected with a piston rod of the air cylinder by a connecting rod, the second pressing foot pipe is located right below the second needle bar, an embroidery needle is arranged at the bottom of the second needle bar and is arranged in the second pressing foot pipe correspondingly. Compared with the prior art, the auxiliary pressing foot can press the cloth all the time during sewing, has large cloth-pressing area and effectively ensures the cloth to be in a flat state in a sewing range.

Owner:JIANGXI HEFENG ELECTRONICS MACHINES

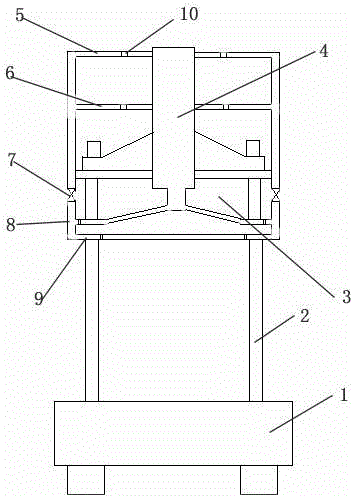

Two-way hydraulic machine

InactiveCN104924645AImprove stabilityHigh starting heightPress ramHydraulic cylinderPulp and paper industry

The invention discloses a two-way hydraulic machine, which comprise a machine seat, upright posts, a rack and a hydraulic cylinder, wherein the hydraulic cylinder is fixed to the rack; the rack is mutually fixed with the machine seat by four upright posts; the left and the right of the upper part of the hydraulic cylinder are symmetrically and respectively connected with upper oil pipes; the left and the right of the lower part of the hydraulic cylinder are symmetrically and respectively connected with lower oil pipes; the hydraulic cylinder are connected with the upper oil pipes and the lower oil pipes at two sides by solenoid directional valves; oil inlet pipes and oil return pipes are bilaterally and respectively arranged at the positions below the solenoid directional valves; and the oil inlet pipes and the oil return pipes are connected with the hydraulic cylinder. According to the invention, the upper oil pipes and the lower oil pipes are arranged at two sides of the hydraulic cylinder, so that the rising height of the whole hydraulic cylinder is high, the pressure is moderate, the pressing area is larger, the usage range is wider, and the stability of the whole hydraulic machine is better; in addition, a filter screen is arranged at each oil pipe, so that impurities in oil can be filtered off, and the service life of the hydraulic machine is longer.

Owner:NANJING BLESSED HYDRAULIC MACHINERY

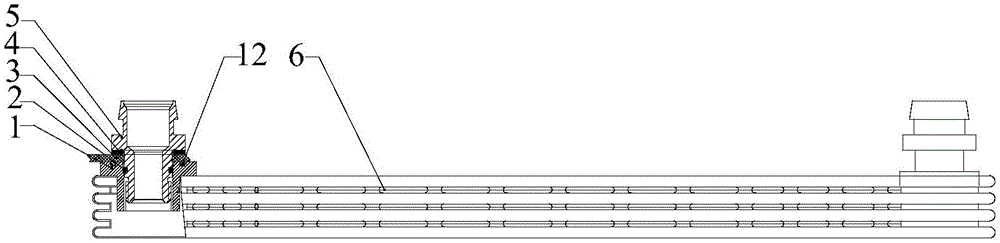

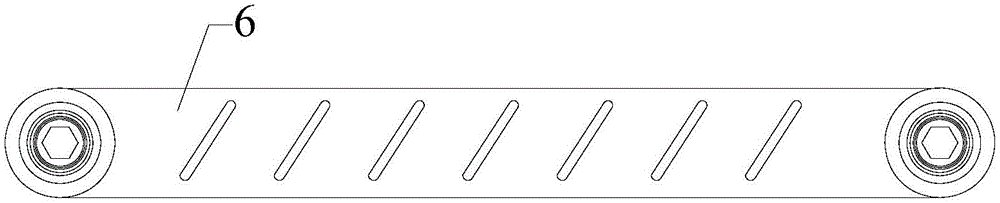

Cable laying device

ActiveCN112952655AImprove laying efficiencyReduce the amount of manual laborApparatus for laying cablesStructural engineeringMachine

A cable laying device disclosed by the present invention comprises a machine body and rollers, the machine body is internally provided with a lifting mechanism, a burying device, a digging plough, a power slotting disc and a connecting rod, and the lifting mechanism is fixed at the center position of the top of the inner wall of the machine body. The top end of the burying device is slidably connected to the bottom of the lifting mechanism and is close to one side of the inner wall of the machine body, the digging plough is arranged at the bottom of the lifting mechanism and is located in the center, the power slotting disc is fixed to the side, away from the burying device, of the bottom of the lifting mechanism, and the two ends of the connecting rod are hinged to the positions between the two corresponding sides of the surface of the burying device and the surface of the power slotting disc correspondingly. The present invention relates to the power construction technical field. According to the cable laying device, the effect of rapid laying is achieved, grooving, laying and burying functions can be integrated, the manual labor amount is reduced, the time and labor are saved, burying is sufficient and reliable, tilting is avoided, the service life is prolonged, and the working efficiency and the use performance are improved.

Owner:LANGFANG POWER SUPPLY COMPANY STATE GRID JIBEI ELECTRIC POWER COMPANY +1

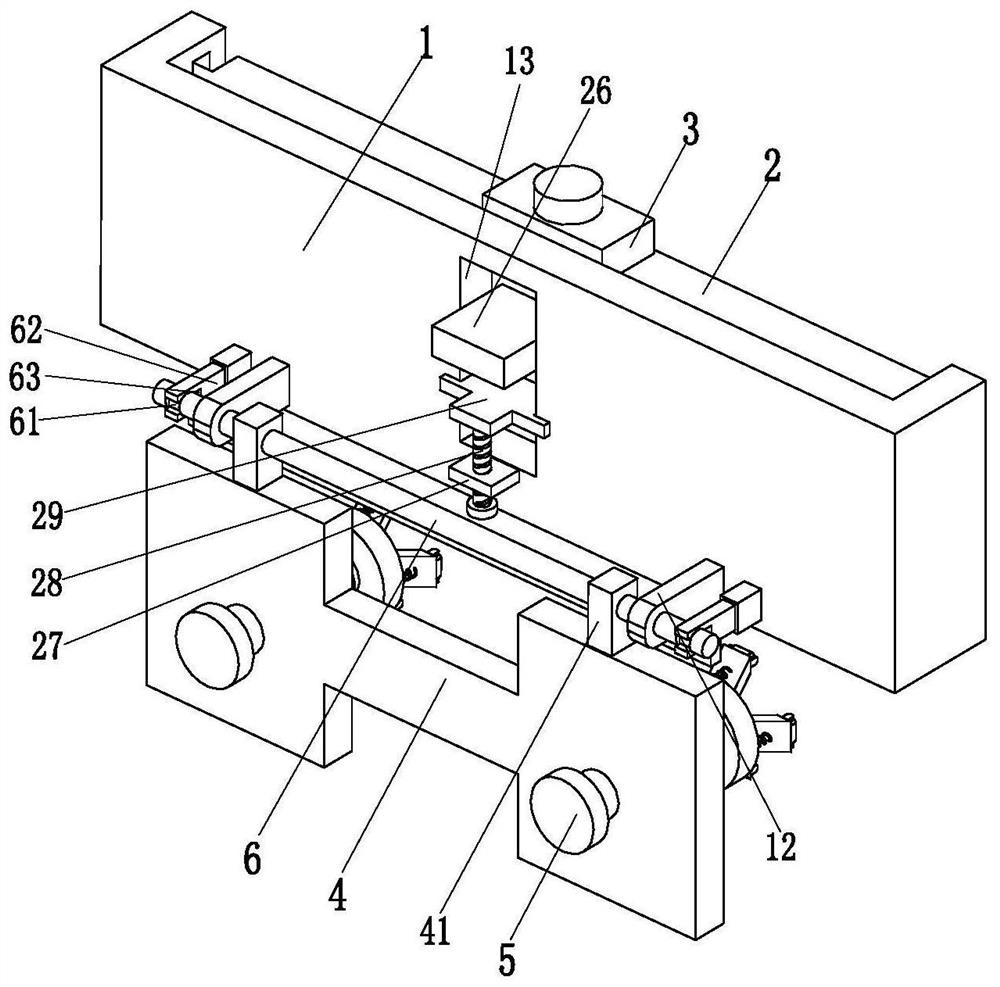

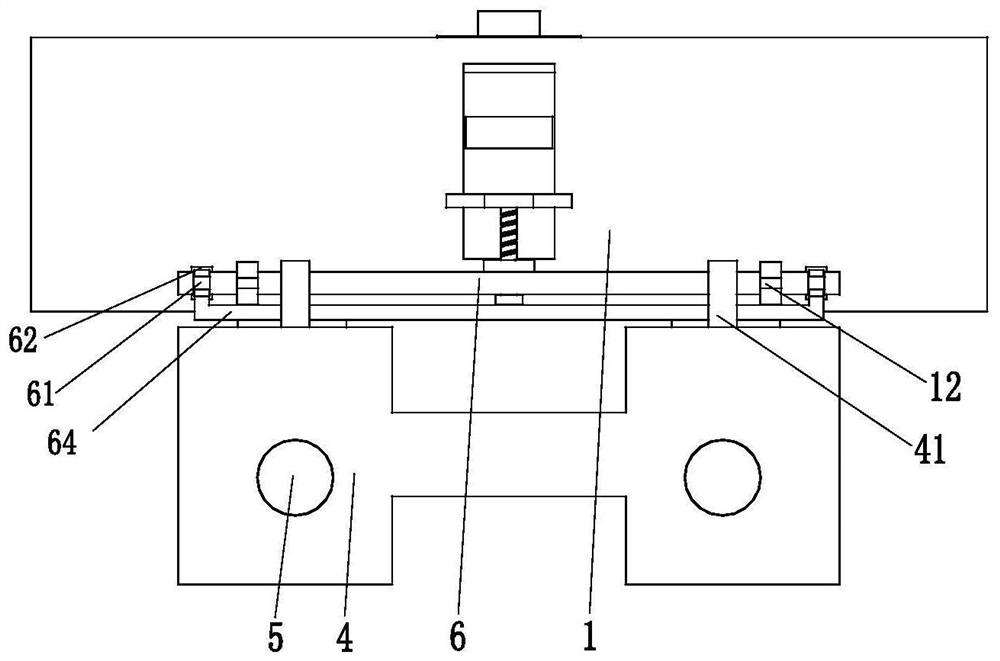

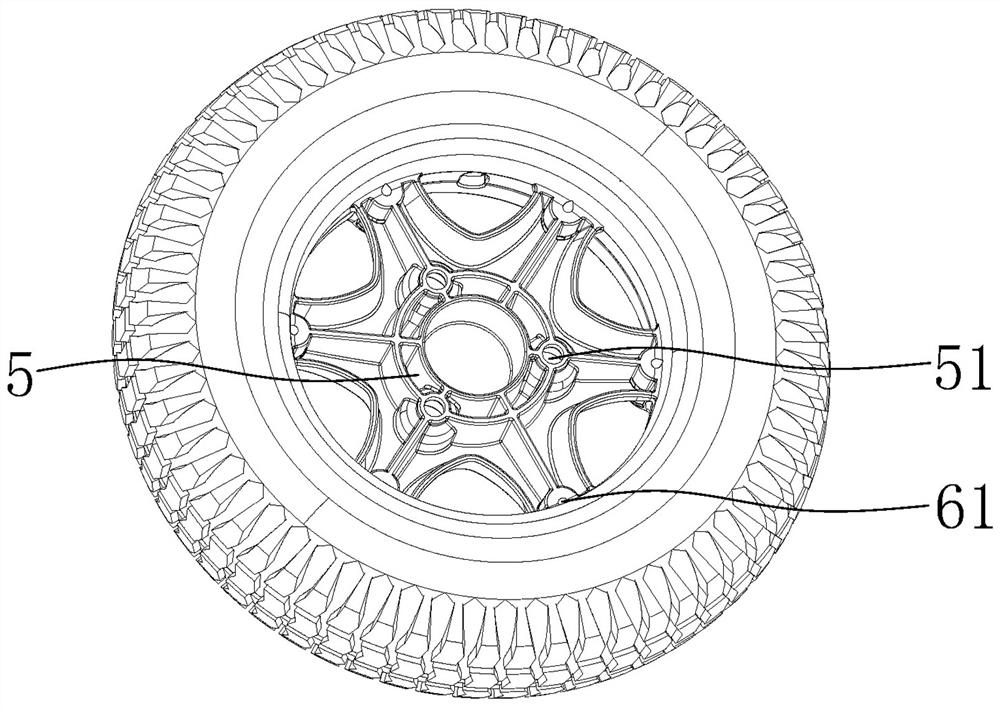

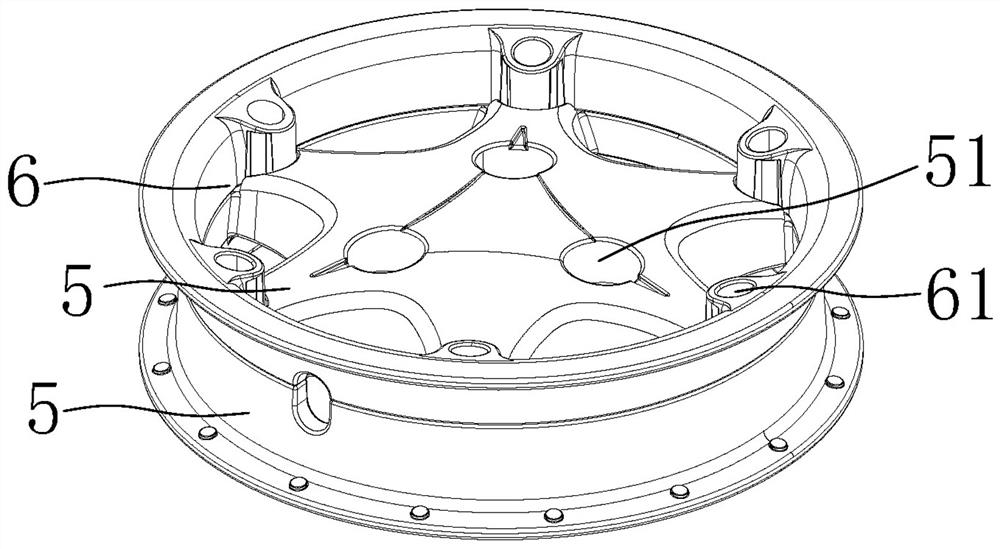

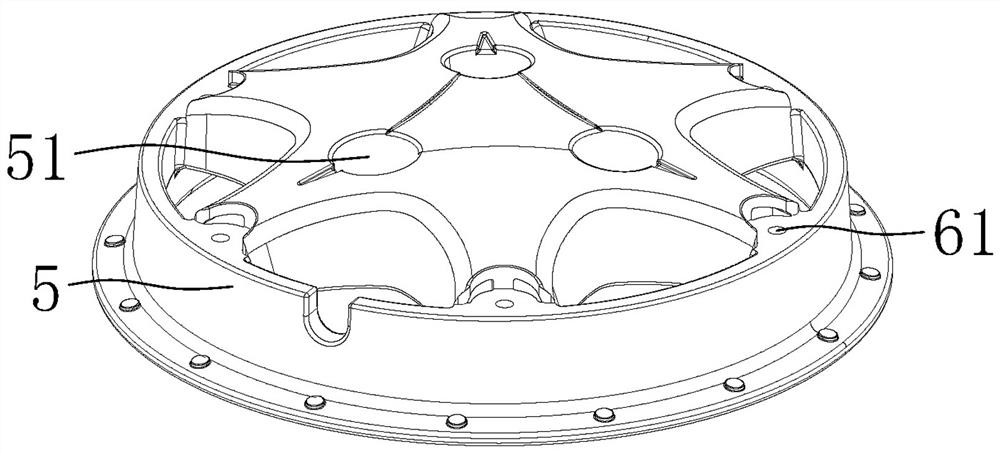

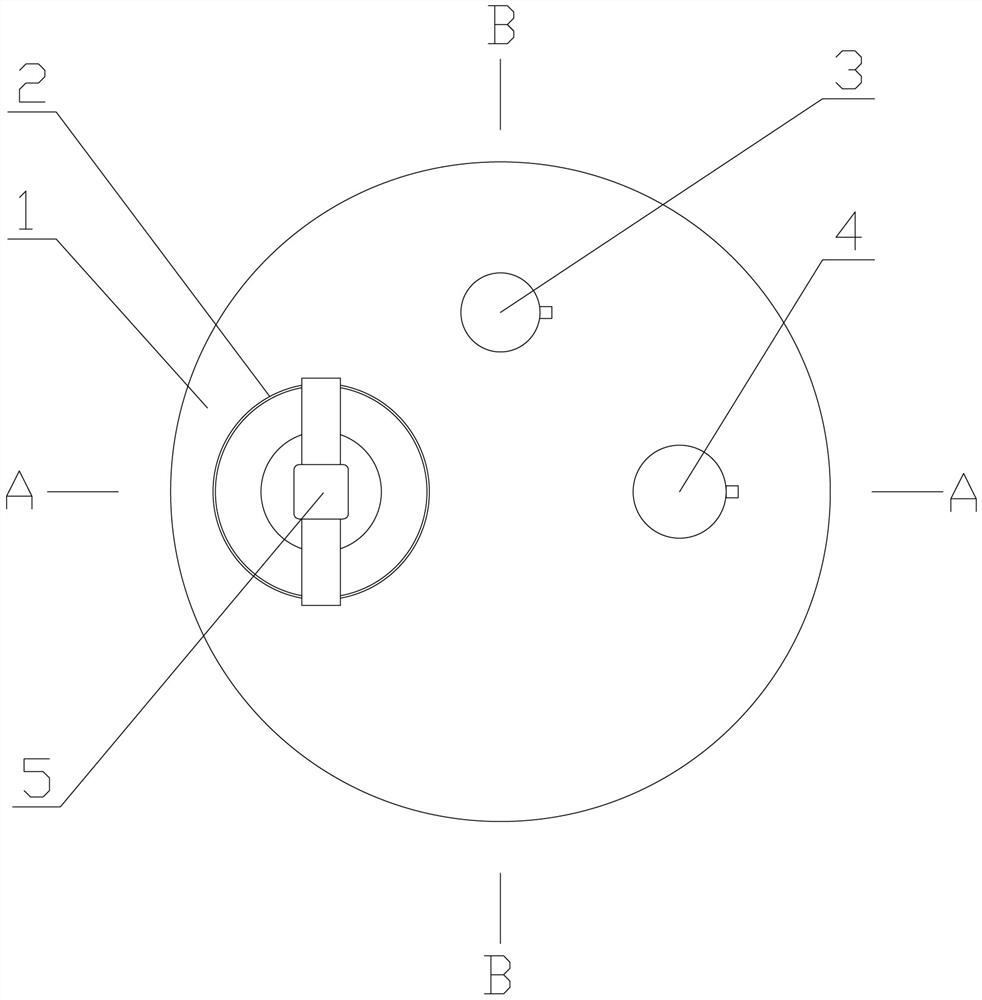

Auxiliary device for assembling solid tire and hub

PendingCN111907258AEasy to assembleEasy to placeWheel assembling toolsWheel manufactureClassical mechanicsEngineering

The invention relates to an auxiliary device for assembling a solid tire and a hub. The auxiliary device for assembling the solid tire and the hub comprises a base plate, a pressing plate is arrangedabove the base plate, the pressing plate is connected with a first driving mechanism used for lifting the pressing plate, a positioning plate is arranged above the base plate, and the positioning plate is horizontally connected to the base plate in a sliding mode. A second driving mechanism used for driving the positioning plate to horizontally move below the pressing plate and on the outer side of the pressing plate is arranged on the base plate, a positioning seat used for positioning the hub is arranged on the positioning plate, and a plurality of receding holes allowing the first bolts topenetrate through are formed in the pressing plate. The auxiliary device has the advantage that the solid tire and the hub can be assembled conveniently.

Owner:HENGDIAN GRP INNUOVO ELECTRIC

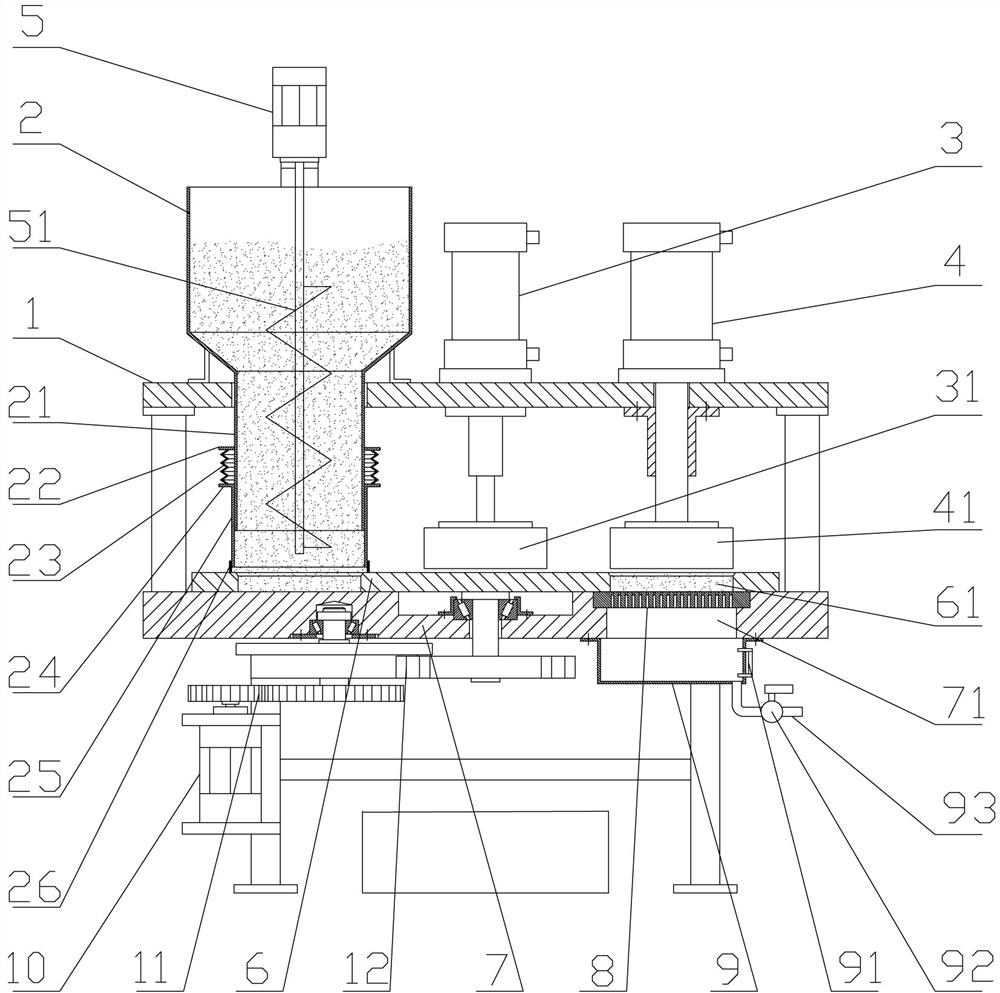

Walnut oil squeezing device and method

PendingCN112373093AReduce press thicknessShorten the oil extraction pathFatty-oils/fats productionPress ramElectric machineryEngineering

The invention discloses a walnut oil squeezing device and method. The walnut oil squeezing device comprises a support, a bottom plate is fixedly connected to the support, the bottom plate is fixedly connected with a top plate through a supporting rod, a rotating disc is connected to the bottom plate through a shaft, the rotating disc is in transmission connection with a driving motor fixedly installed on the support through a transmission device, a material storage hopper, an oil squeezing oil cylinder and a discharging oil cylinder are installed on the top plate, an oil squeezing pressing head is installed at the lower end of a piston rod of the oil pressing oil cylinder, a discharging pressing head is installed at the lower end of a piston rod of the discharging oil cylinder, and the lower end of the material storage hopper abuts against the surface of the rotating disc; and a plurality of material storage holes are formed in the rotating disc, an oil squeezing hole and a discharginghole are formed in the bottom plate, an oil outlet plate is fixedly arranged in the oil squeezing hole, the surface of the oil outlet plate is flush with the bottom plate, the oil squeezing pressinghead corresponds to the oil squeezing hole, and the discharging pressing head corresponds to the discharging hole. The walnut oil squeezing device is used for solving the problem of incomplete oil squeezing of an existing oil squeezing machine.

Owner:HEFEI UNIV OF TECH

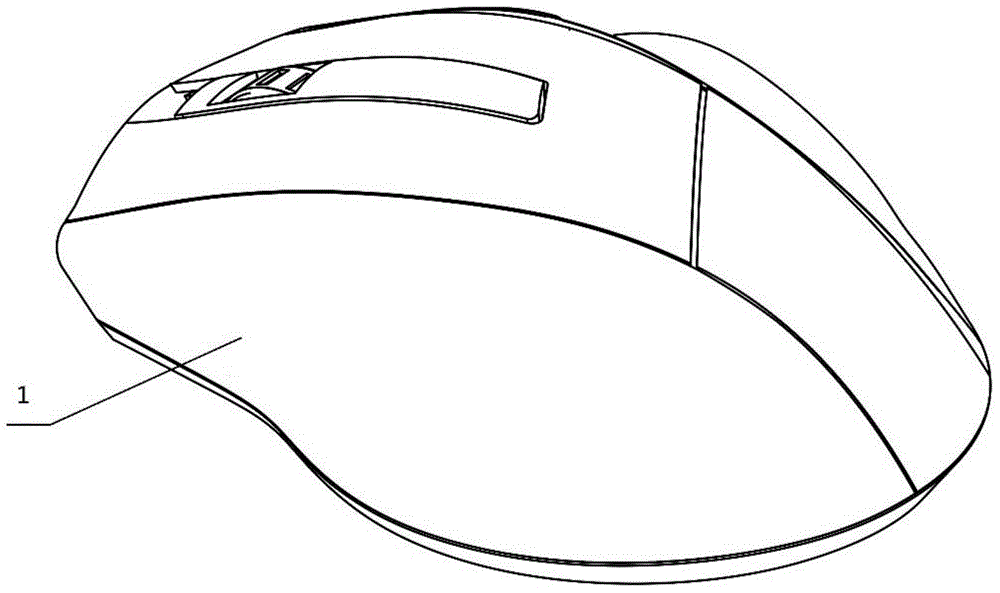

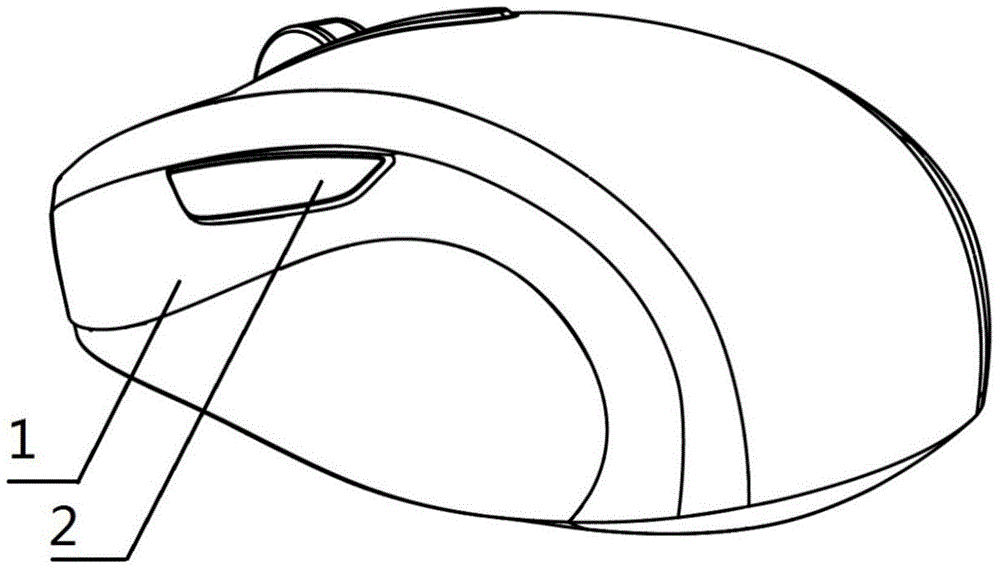

Mouse with large side keys

InactiveCN104461082AImprove convenienceAvoid misuseInput/output processes for data processingLong thumbsShort thumb

Owner:LEVOGE TECH

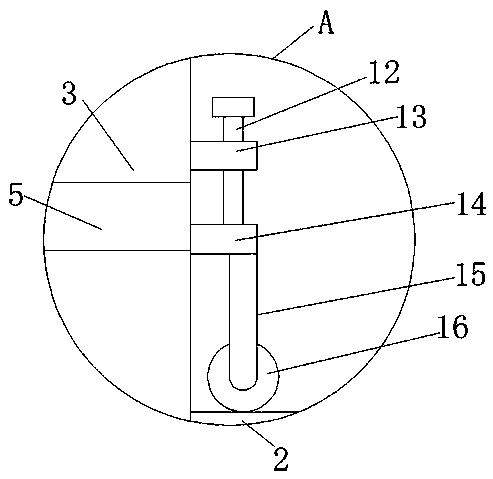

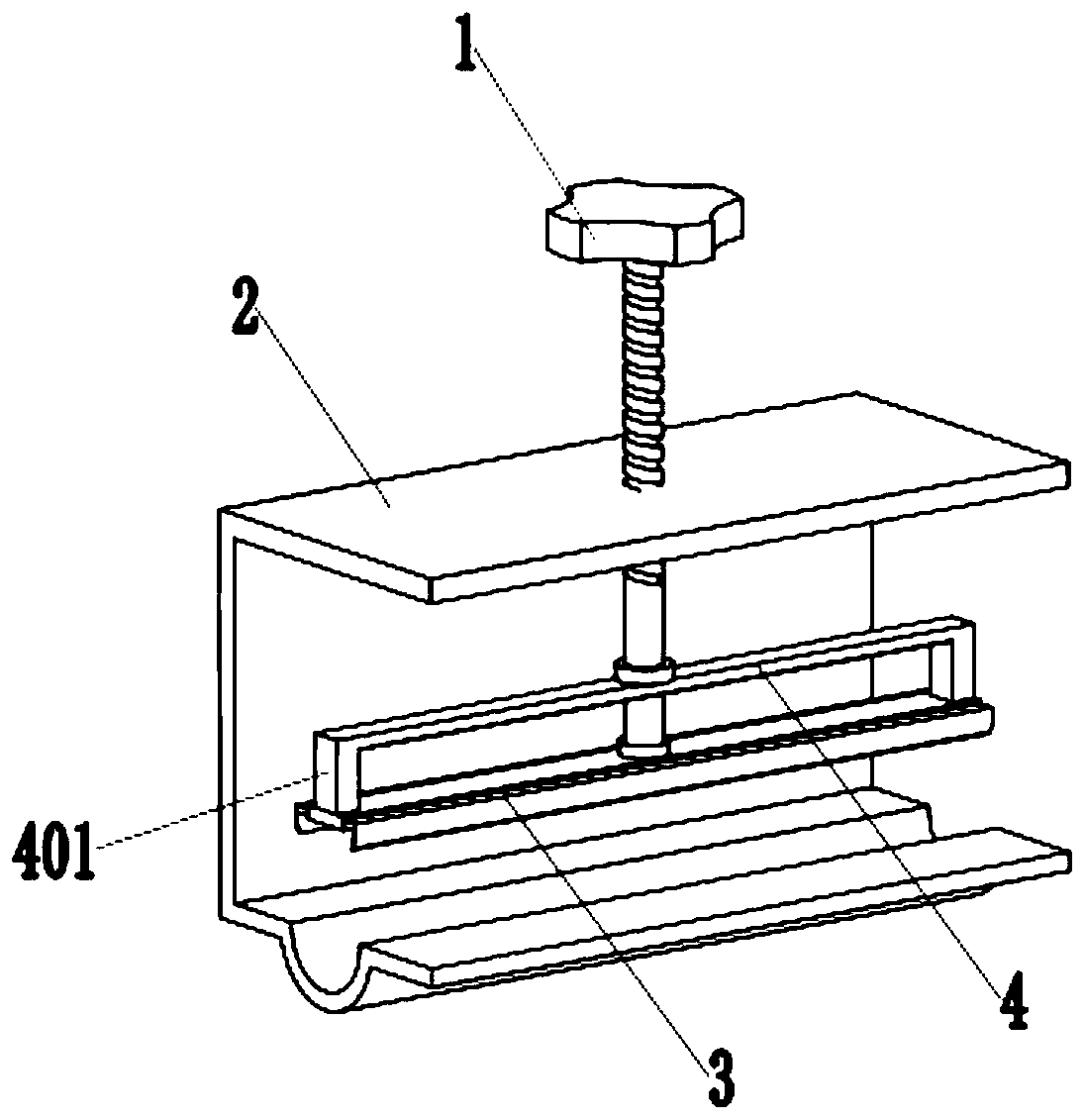

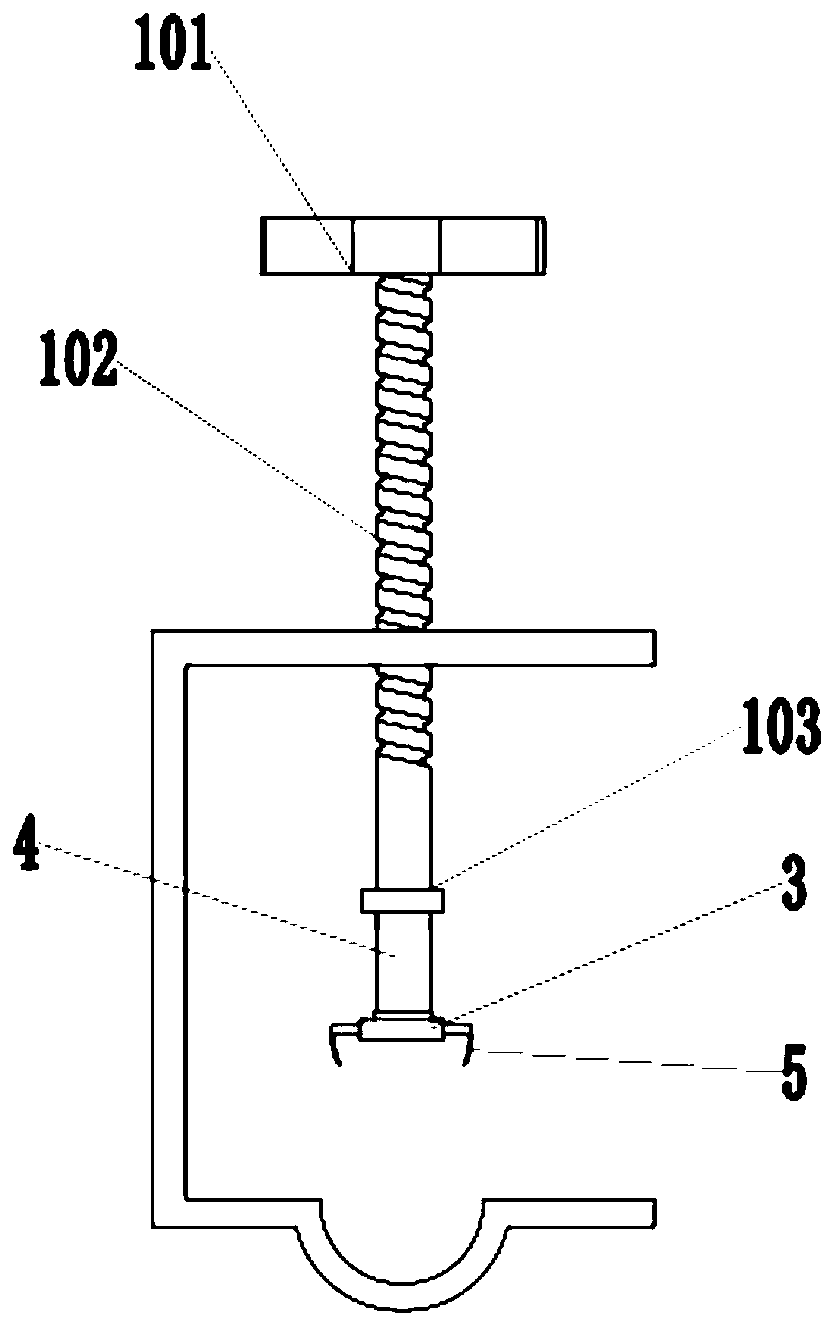

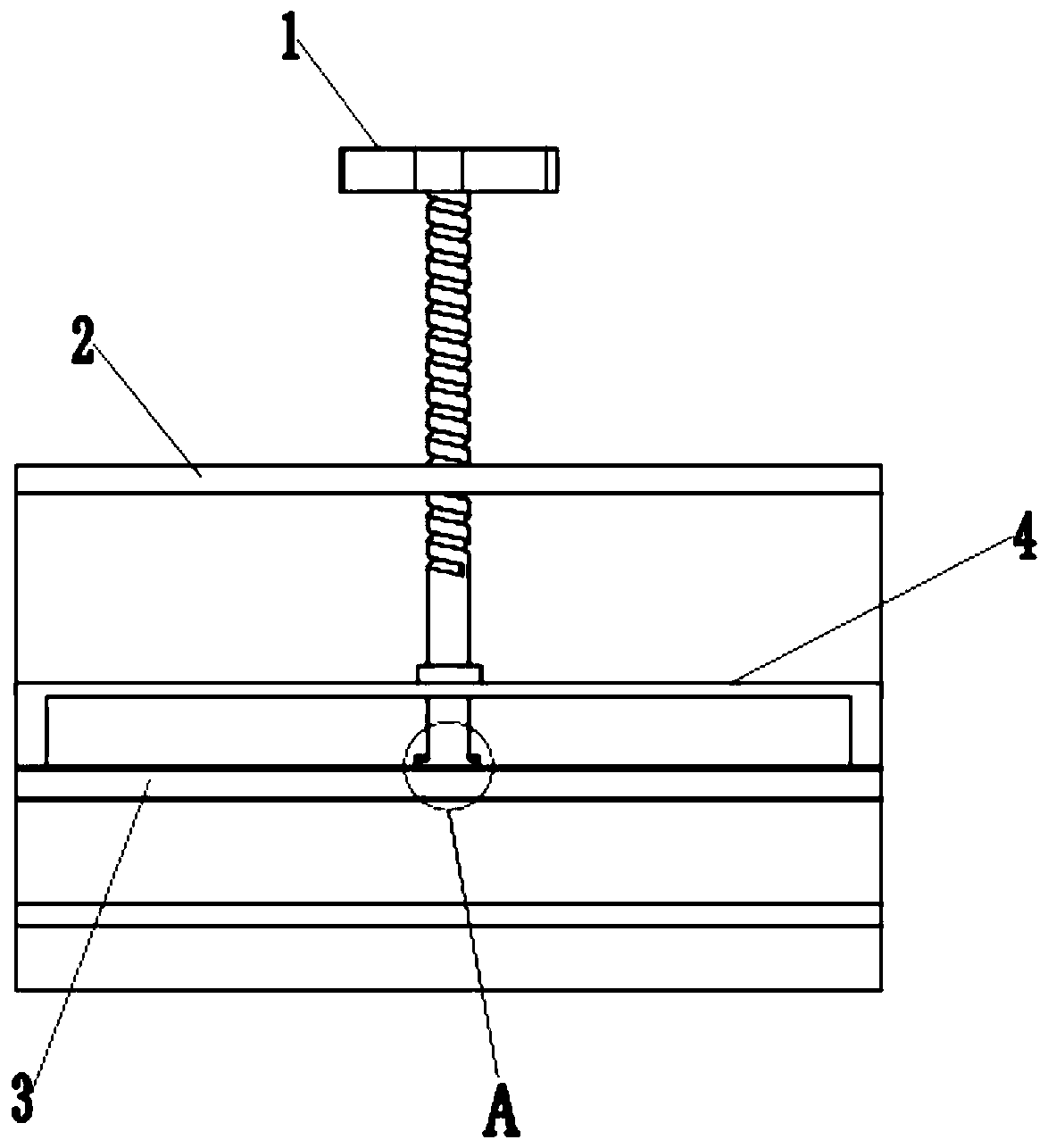

Temporary grounding clamp of transmission line tower

ActiveCN109861013APrevent slidingIncrease the pressing areaOverhead installationCoupling contact membersGrounding gridArchitectural engineering

The present invention discloses a temporary grounding clamp of a transmission line tower. The temporary grounding clamp comprises a regulation rod, a support housing and a pressing rod. The support housing comprises a support plate, a connection plate and a line pressing plate, the support plate is connected with the line pressing plate through the connection plate, the upper end of the line pressing plate is provided with a line fixing groove with two opening ends, the side wall of the regulation rod is provided with external threads, one end of the regulation rod is rotationally connected with the middle portion of the pressing rod, the support plate is provided with a threaded hole, the regulation rod is matched with the threaded hole, the pressing rod is arranged between the support plate and the line pressing plate, and the two sides of the pressing rod are both provided with line collection elastic plates. The temporary grounding clamp can meet the temporary grounding depth of the transmission line and the tight connection of the temporary grounding line and wires and cables of a main grounding grid, can meet the requirement of a grounding resistor, performs bolted connectionwith grounding holes at the tower body when the tower is assembled, and can be taken as a mark line to conveniently find the grounding grid in the formal grounding construction so as to save the latework and improve the work efficiency.

Owner:国网山东省电力公司建设公司 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com