Temporary grounding clamp of transmission line tower

A temporary grounding and transmission line technology, applied in the direction of cable installation, contact parts, electrical components, etc., can solve the problems of grounding resistance not meeting the requirements, inconvenient to find the main grounding network, etc., to avoid line damage, ensure firmness, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

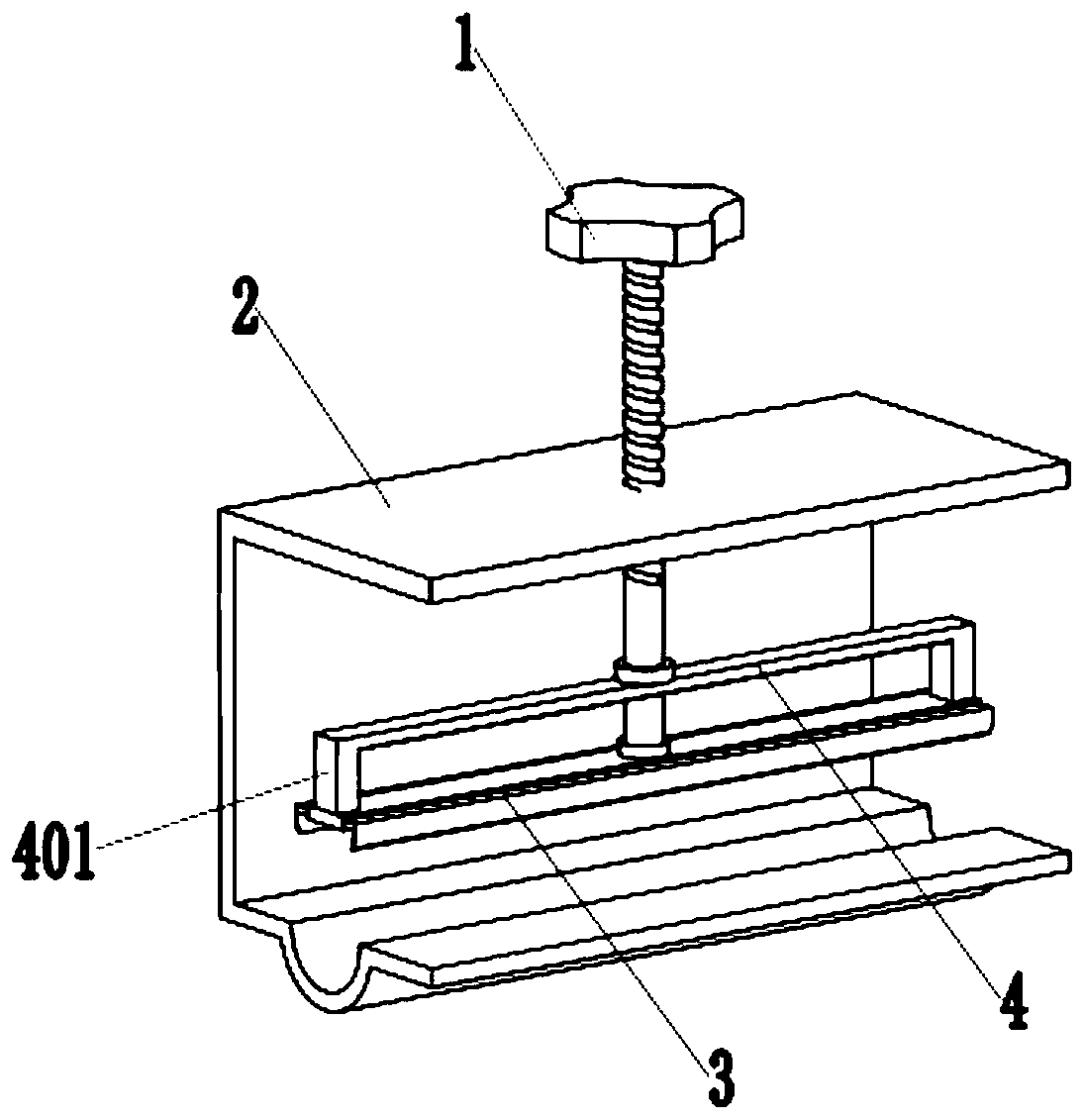

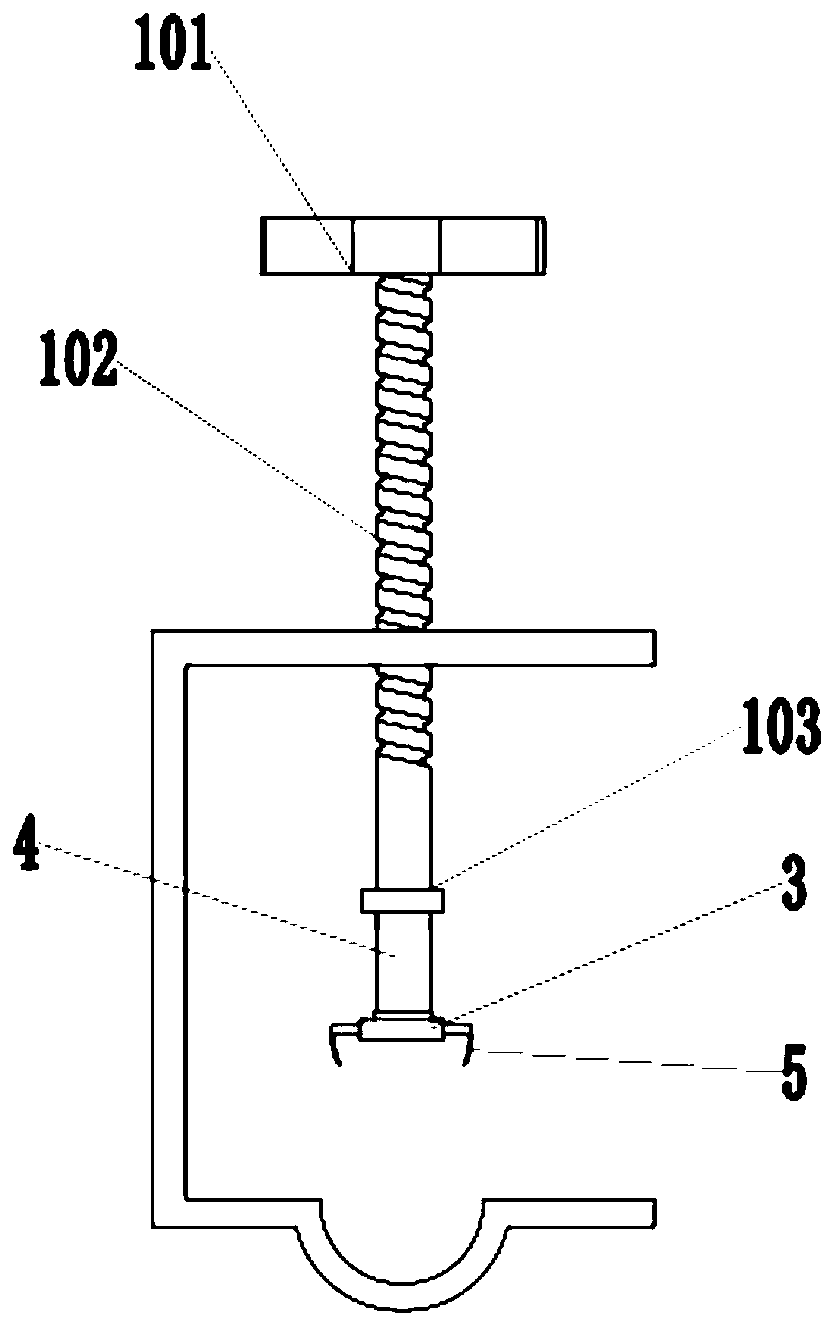

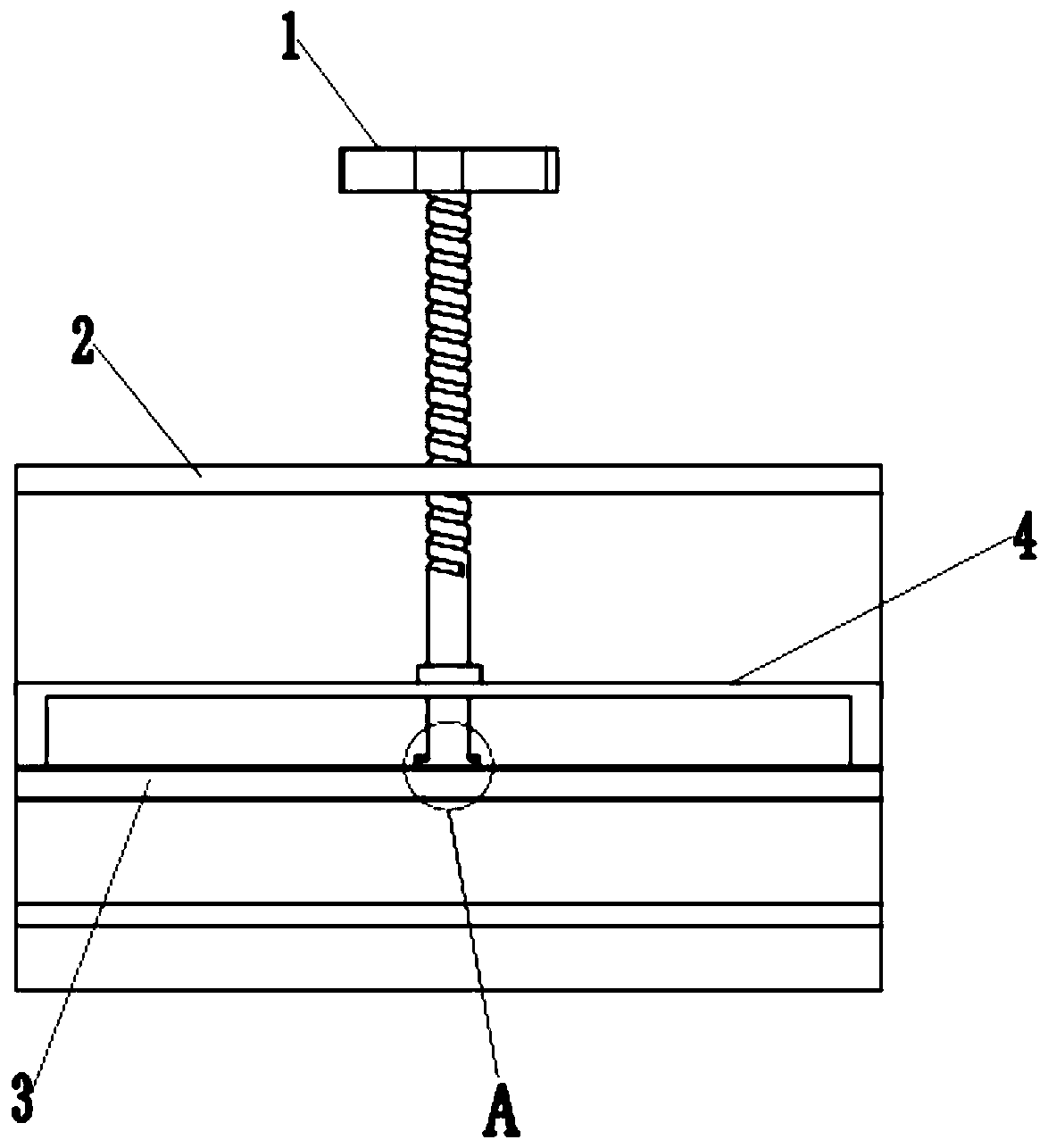

[0034] like Figure 1-3 As shown, a temporary grounding fixture for a power transmission line tower includes an adjusting rod 1, a supporting shell 2, and a pressing rod 3, such as Figure 5 As shown, the support shell 2 includes a support plate 201, a connecting plate 203, and a pressure plate 205. The support plate 201 and the pressure plate 205 are arranged in parallel, and the connection plate 203 connection, the upper end of the crimping plate 205 is provided with a fixing groove 204 with openings at both ends, the fixing groove 204 is a semi-circular arc structure, the length of the fixing groove 204 and the wire pressing plate 205 are the same as 150mm, and the adjusting rod 1 is provided with an external thread 102 on the side wall, one end of the adjustment rod 1 is rotationally connected with the middle part of the pressure rod 3, the support plate 201 is provided with a threaded hole 202, the adjustment rod 1 is matched with the threaded hole 202, and the pressure r...

Embodiment 2

[0041] In order to make it more convenient to fix the wire during use, a guide rod 7 is added to replace the manual fixing of the pressure rod 3, and the position of the pressure rod can be limited when the adjustment rod is rotated to ensure that the pressure rod can only move up and down to prevent the pressure rod from rotating. Increase the convenience of use.

[0042] like Figure 8 As shown, both sides of the threaded hole 202 are provided with guide holes 206, the guide holes 206 are arranged near the end of the support plate 201, and both sides of the upper end of the reinforcing rod 4 are provided with guide rods 7, the The guide rod 7 cooperates with the guide hole 206 .

[0043] like Figure 9 As shown, the guide rod 7 is covered with a second spring 8 , the upper end of the second spring 8 is connected to the lower end surface of the support plate 201 , and the lower end of the second spring 8 is connected to the upper end surface of the reinforcing rod 4 .

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com