Walnut oil squeezing device and method

A technology of walnut oil and transmission device, which is applied in the direction of presses, stamping machines, fat oil/fat production, etc., can solve the problems of incomplete oil extraction, achieve the effects of improving oil extraction efficiency, shortening oil extraction path, and expanding the pressing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

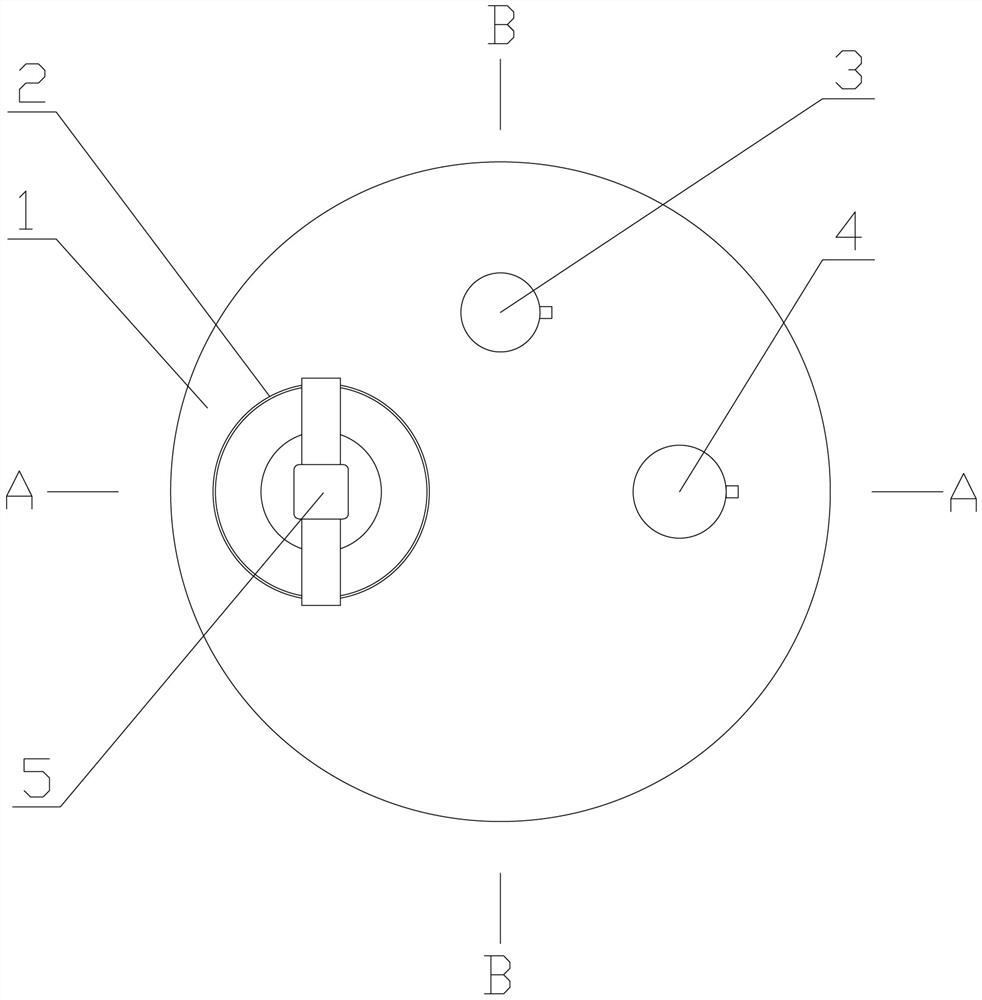

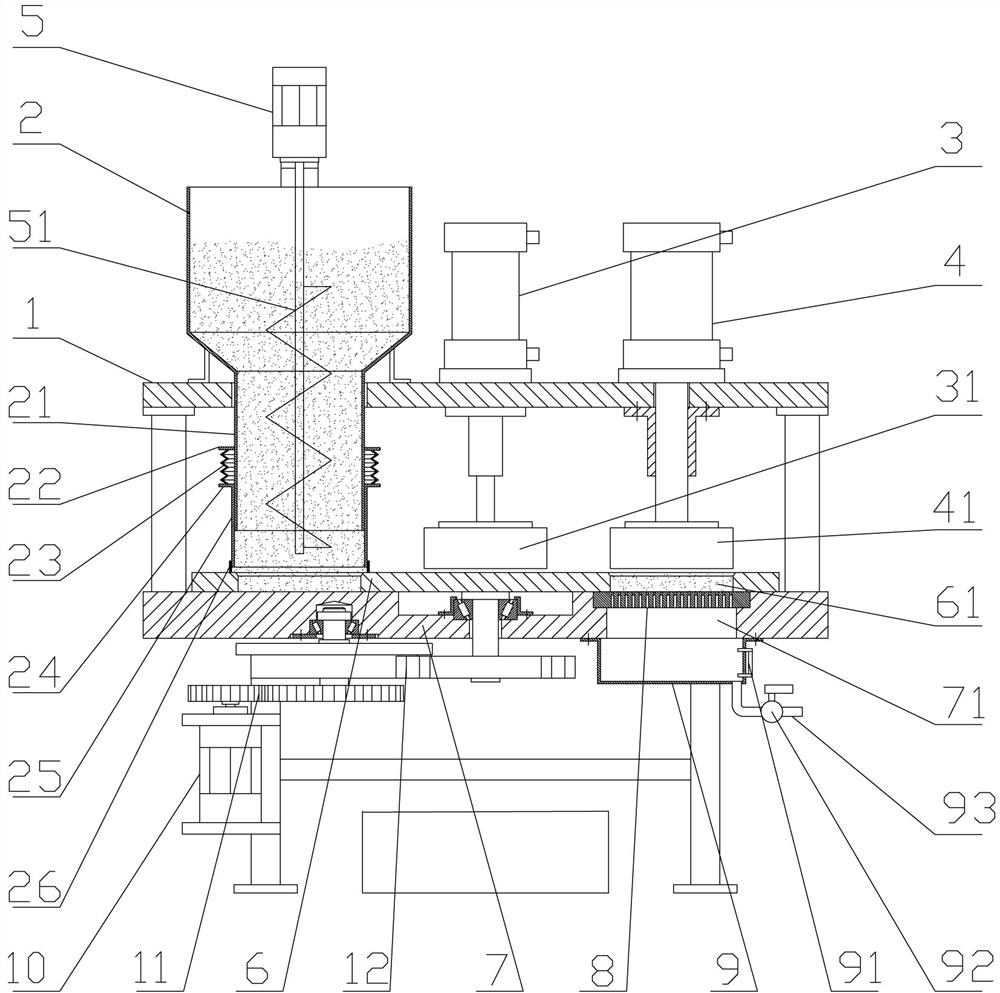

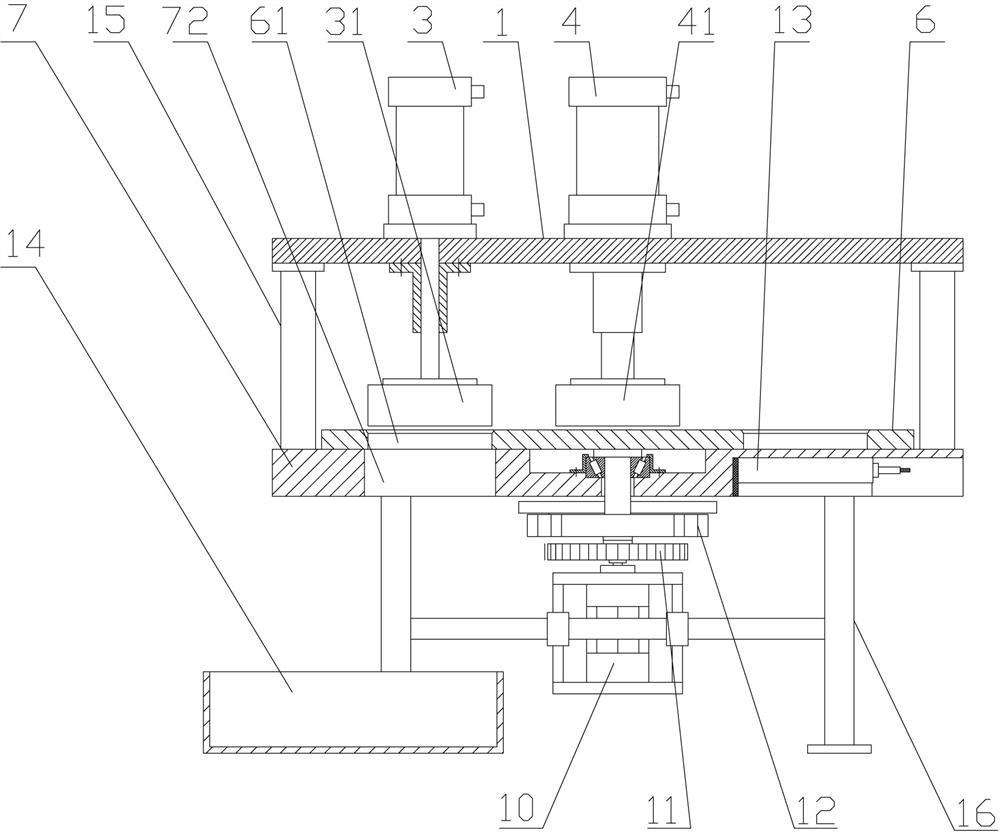

[0024] Such as Figures 1 to 4 As shown, the walnut oil pressing device includes a support 16, the support 16 is fixedly connected with a base plate 7, the base plate 7 is fixedly connected with the top plate 1 through a support rod 15, and the upper shaft of the base plate 7 is connected with a turntable 6, and the turntable 6 is connected to the fixed plate through a transmission device. The drive motor 10 that is installed on the bracket 16 is connected by transmission, and the material storage hopper 2, the oil extraction cylinder 4 and the discharge cylinder 3 are installed on the top plate 1, and the oil extraction pressure head 41 is installed at the lower end of the piston rod of the oil extraction cylinder 4. The lower end of the piston rod of the material oil cylinder 3 is equipped with a discharge pressure head 31, and the lower end of the storage hopper 2 is against the surface of the turntable 6; the turntable 6 is provided with a plurality of storage holes 61, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com