Cement laying device for building engineering

A technology of construction engineering and laying device, applied in construction, building structure, processing of building materials, etc., can solve the problems of engineering quality, hollow, unable to lay cement, etc., and achieve the effect of easy pressing and increasing pressing area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

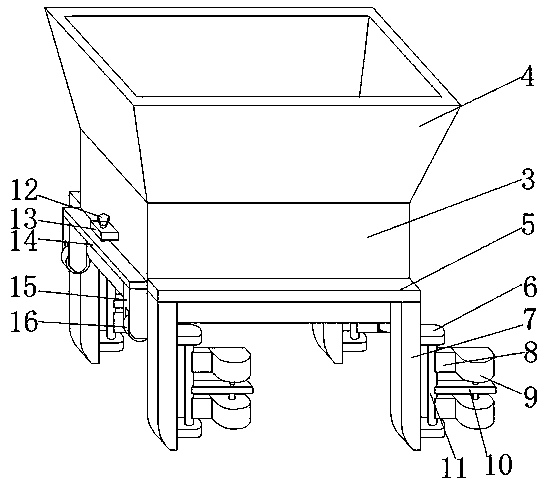

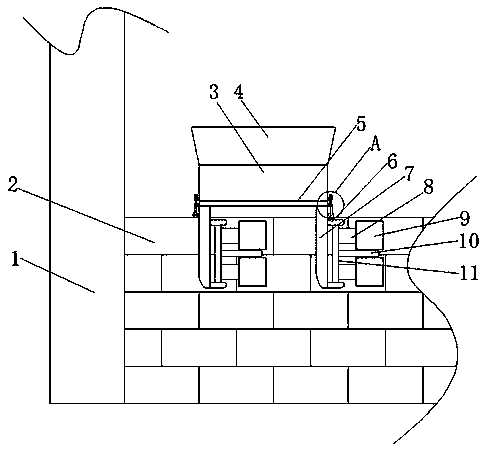

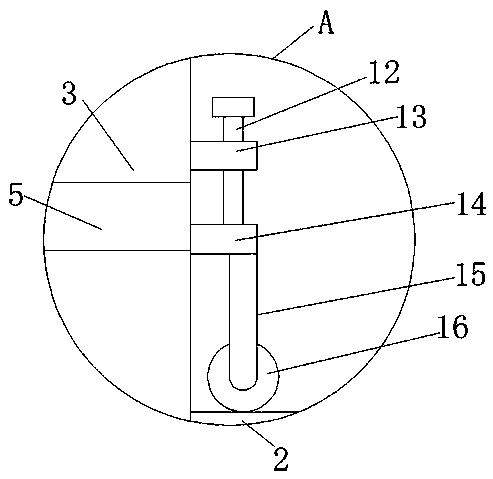

[0030] refer to Figure 1-5 , a cement laying device for construction engineering, comprising a column 1 and a main body 3 at the top of the wall 2, the middle part of the main body 3 is welded with a third fixed plate 24, and the bottom end of the third fixed plate 24 is welded with a pressing plate 25, the first The top of three fixed plate 24 is welded with spring 20, and the top of spring 20 is welded with rotating plate 18, and one end of rotating plate 18 is connected with main body 3 rotations, and the internal rotation of main body 3 is connected with rotating body 17, and the exterior of rotating body 17 is welded with A plurality of pressing blocks 26, the rotating body 17 is on one side of the third fixed plate 24, the first fixed plate 5 is welded on both sides of the main body 3, and the bottom end of the first fixed plate 5 is welded with two first fixed columns 7 , one side of the first fixed column 7 is welded with two fixed blocks 6, and a rotating rod 11 is c...

Embodiment 2

[0040] refer to Image 6 , a cement laying device for construction engineering. Compared with Embodiment 1, in this embodiment, in order to enhance the practicability of the device, facilitate the movement of the device and the adhesion between cement and bricks, one side of the main body 3 is welded with a handle 27 , the bottom end of the handle 27 is welded with a connecting rod 28, the bottom end of the connecting rod 28 is welded with a fourth fixed plate 29, the fourth fixed plate 29 is V-shaped, and the bottom end of the fourth fixed plate 29 is provided with a brush 30, through During the process of pulling the main body 3 by the handle 27, the V-shaped brush 30 can push the dust on the brick surface to both sides, so as to increase the adhesion between the cement and the brick.

[0041] When in use, the device can walk on the wall 2 through the second rollers 23. While walking, the two layers of second rollers 23 contact and clamp the two layers of bricks respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com