Elastomeric diaphragm filter plate

A technology of elastic diaphragm and diaphragm filter plate, which is applied in the field of filter press, can solve the problems of poor sealing performance, poor filtering effect, insufficient feeding pressure, etc., and achieve fast filtering speed, large pressing area and high pressing pressure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

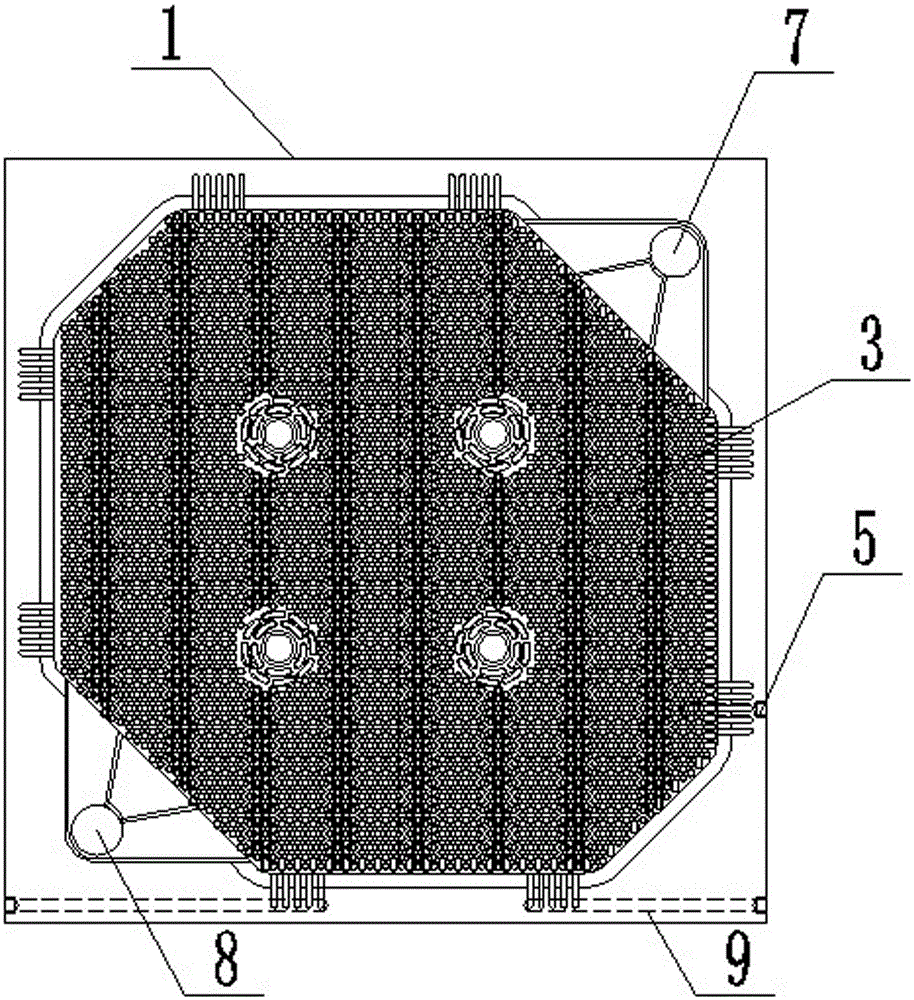

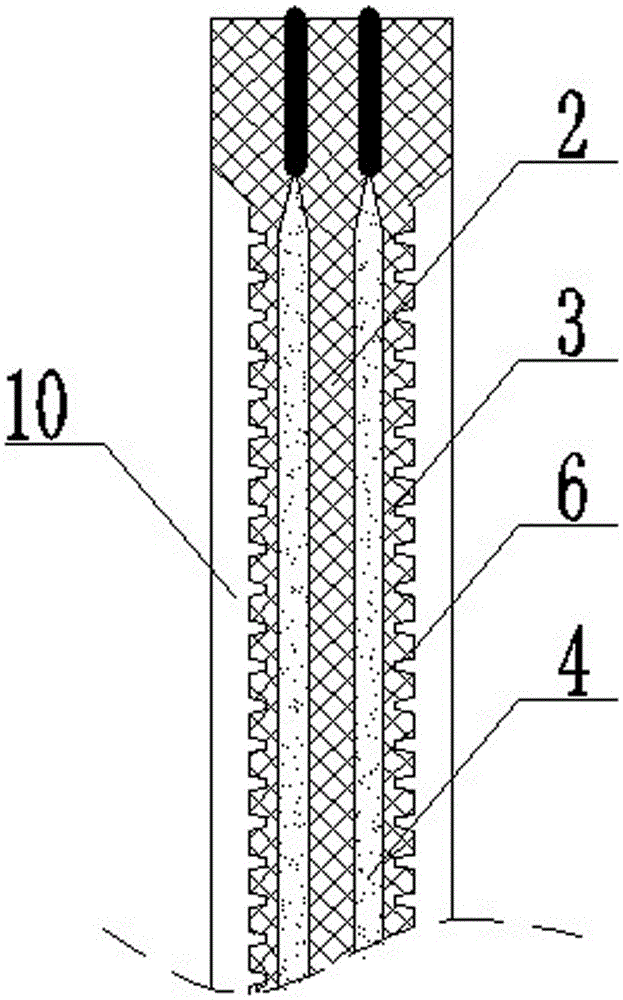

[0017] Below in conjunction with accompanying drawing, the specific embodiment of the present invention is described in further detail:

[0018] As shown in the figure, an elastomer diaphragm filter plate includes a filter frame 1, the central layer of the filter frame 1 is provided with a rigid core plate 2, the front and rear walls of the core plate 2 are covered with an elastic diaphragm 3, and the elastic diaphragm It is reinforced polypropylene film or PPE polymer elastic film. The four edges of the elastic diaphragm 3 are melted and welded between the filter frame 1 and the core plate 2, and the airtight air chamber 4 is formed between the elastic diaphragm 3 and the front and rear walls of the core plate 2, and the outer wall of the elastic diaphragm 3 is provided with a dense Conical convex 6 sets. A water inlet 5 is provided on the side of the filter frame 1, and the water inlet 5 extends into the core plate 2 and extends from the core plate 2 to both sides to commun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com