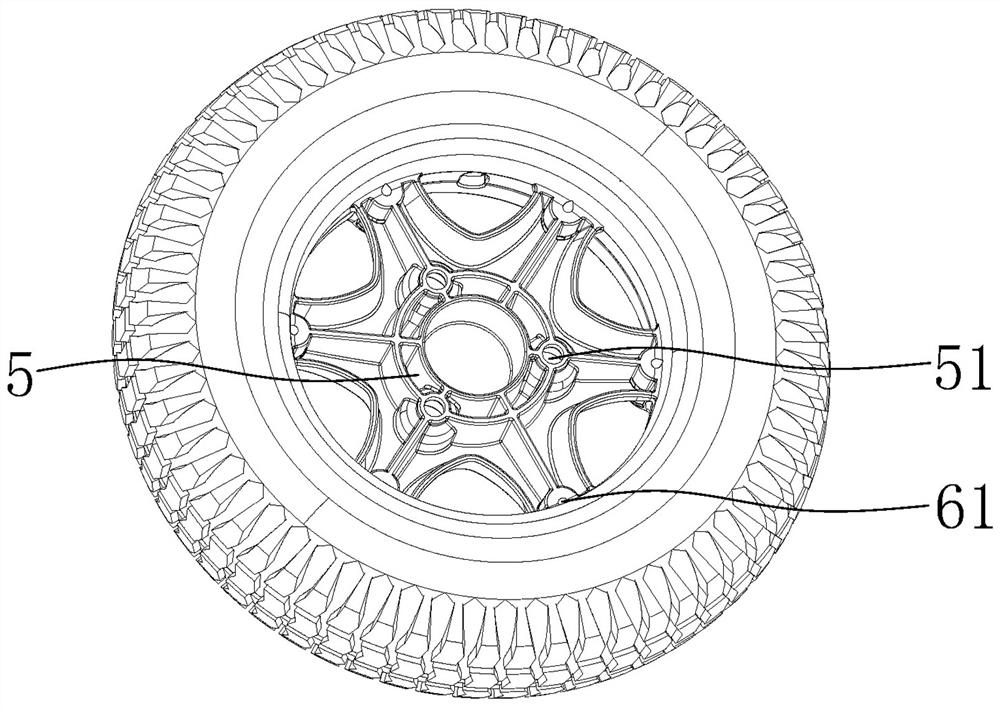

Auxiliary device for assembling solid tire and hub

An assembly-assisted, solid tire technology, applied in wheel assembly equipment, wheels, wheel manufacturing, etc., can solve the problems of thread fit of hub assembly holes, difficult to achieve the assembly of the main hub unit and the secondary hub unit, etc., to ensure the tightness effect, easy to assemble, easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

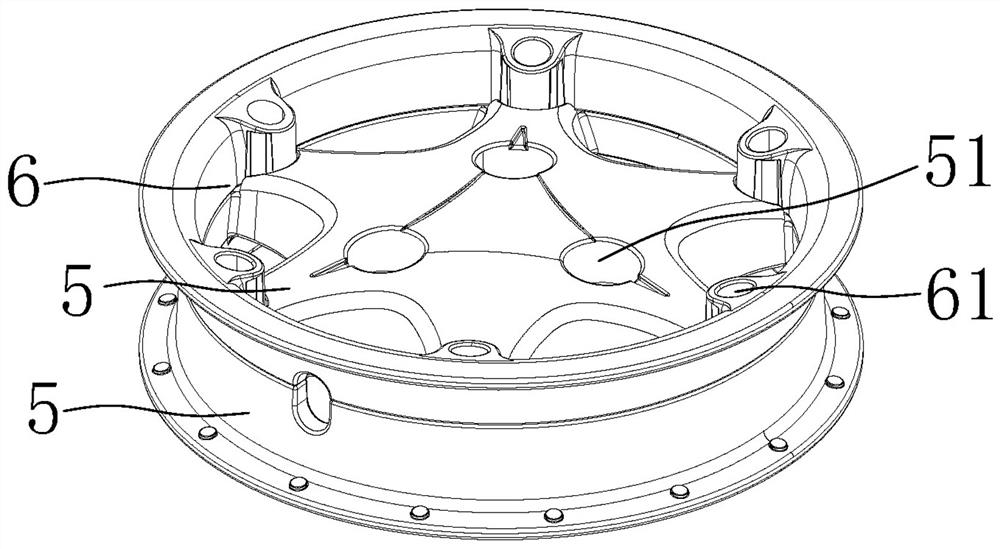

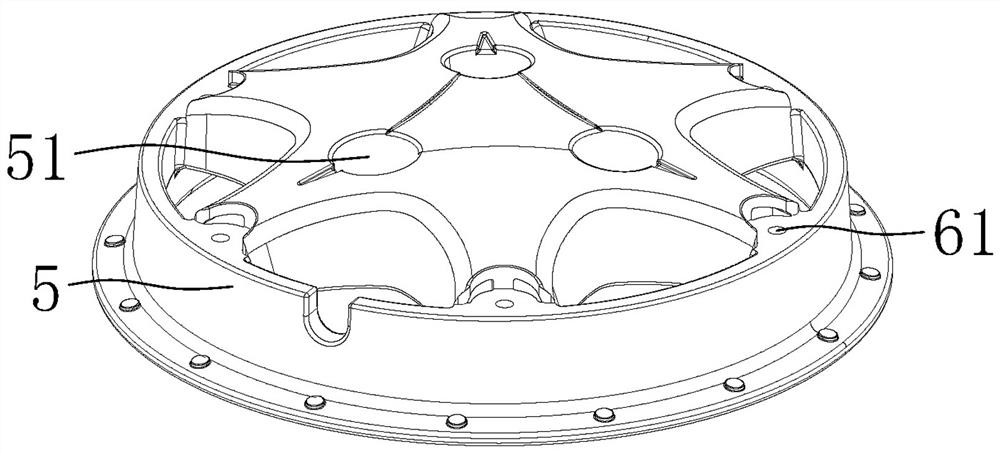

[0025] Such as Figure 4 to Figure 6 As shown, a solid tire and wheel hub assembly auxiliary device includes a base plate 2, a pressure plate 1 is arranged above the base plate 2, four connecting columns 12 are arranged between the pressure plate 1 and the first driving mechanism 3, and the upper ends of the connecting columns 12 and the pressure plate 1 is fixed, and the lower end of the connecting column 12 is fixed with the first driving mechanism 3 located below the base plate 2. Wherein, the first driving mechanism 3 is a linear cylinder arranged in the vertical direction, and the connecting column 12 is slidingly fitted with the base plate 2 .

[0026] The upper side of the base plate 2 is provided with a positioning plate 4, and the base plate 2 is provided with a second driving mechanism 23 for driving the positioning plate 4 to move horizontally below and outside the pressing plate 1. Rail 21, sliding on slide rail 21 is equipped with slide block 22, and positioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com