Automobile tire tread rubber

A technology for automobile tires and tread rubber, applied in special tires, tire parts, vehicle parts, etc., can solve problems such as loss of use value and loss, and achieve improved anti-aging performance, good anti-aging performance, and anti-wet skid. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0086] Automobile tire tread rubber, comprising the following components in parts by weight:

[0087] Natural rubber 50 SBR 40

[0088] Polybutadiene Rubber 20 Bromobutyl Rubber 20

[0089] Stearic acid 2 Sulfur 2

[0090] Carbon black 20 Paraffin 2

[0091] Six line oil 8 Zinc oxide 2

[0092] Pine Tar 3 ISAF20

[0093] Accelerator DM2 Accelerator CZ2

[0094] 2,2,4-Trimethyl-1,2-dihydroquinoline polymer 7

[0095] High wear-resistant furnace black 10 Coumarone resin 2

[0096] Gas black 10 .

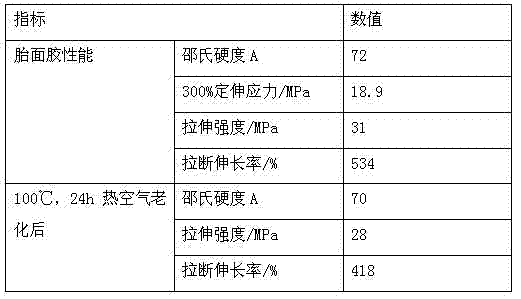

[0097] The tire made by the formula of above-mentioned embodiment 1, its performance parameter is as follows:

[0098]

Embodiment 2

[0114] Automobile tire tread rubber, comprising the following components in parts by weight:

[0115] Natural Rubber 10 Styrene Butadiene Rubber 10

[0116] Polybutadiene Rubber 10 Bromobutyl Rubber 10

[0117] Stearic acid1 Sulfur1

[0118] Carbon black 1 Paraffin wax 1

[0119] Six thread oil 1 Zinc oxide 1

[0120] Pine tar 1 ISAF1

[0121] Accelerator DM1 Accelerator CZ1

[0122] 2,2,4-Trimethyl-1,2-dihydroquinoline polymer 1

[0123] High wear-resistant furnace black 1 Coumarone resin 1

[0124] Gas black 1 .

Embodiment 3

[0126] Automobile tire tread rubber, comprising the following components in parts by weight:

[0127] Natural rubber 80 SBR 60

[0128] Polybutadiene Rubber 40 Bromobutyl Rubber 30

[0129] Stearic acid 4 Sulfur 2

[0130] Carbon black 30 Paraffin 3

[0131] Six thread oil 15 Zinc oxide 8

[0132] Pine Tar 4 ISAF30

[0133] Accelerator DM4 Accelerator CZ4

[0134] 2,2,4-Trimethyl-1,2-dihydroquinone polymer 10

[0135] High wear-resistant furnace black 20 Coumarone resin 4

[0136] Gas Carbon Black 20 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| 300% modulus stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com