Online measuring device and measuring and controlling method for tread thickness of tire tread winding

A technology of tread thickness and tire tread, applied in measurement devices, optical devices, instruments, etc., can solve problems such as the influence of measurement accuracy, limited winding accuracy, large measurement errors, etc., and achieve the effect of improving quality and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

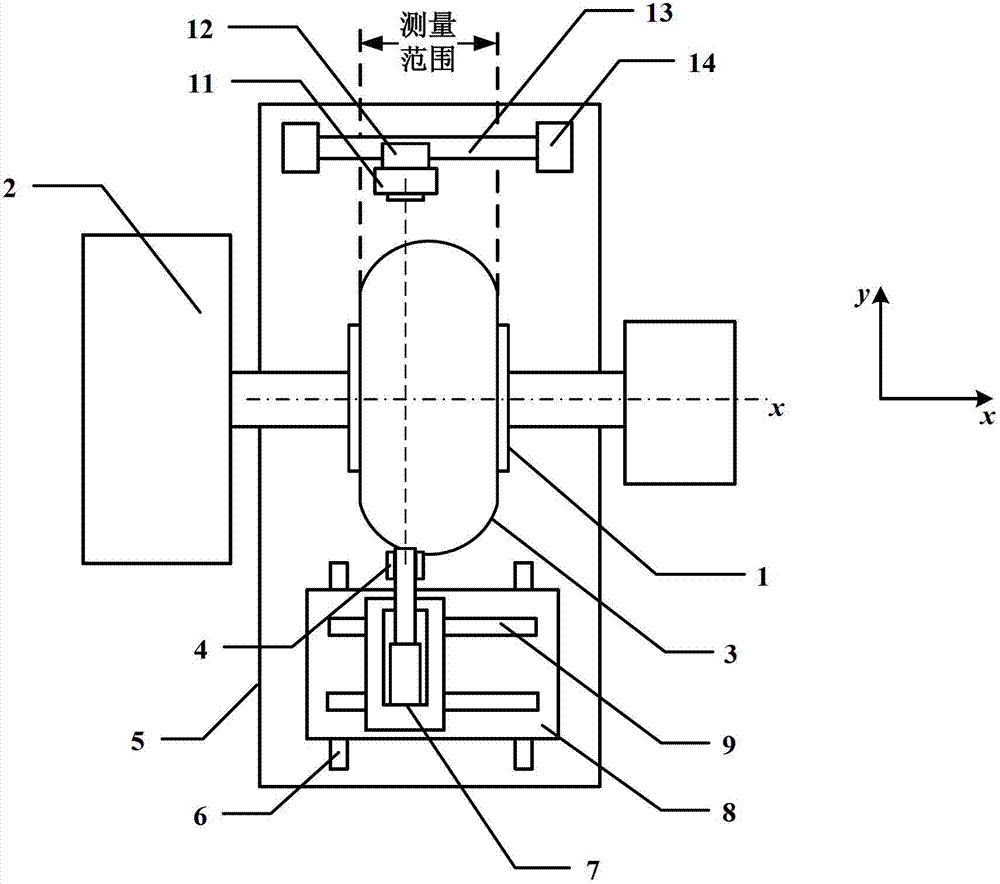

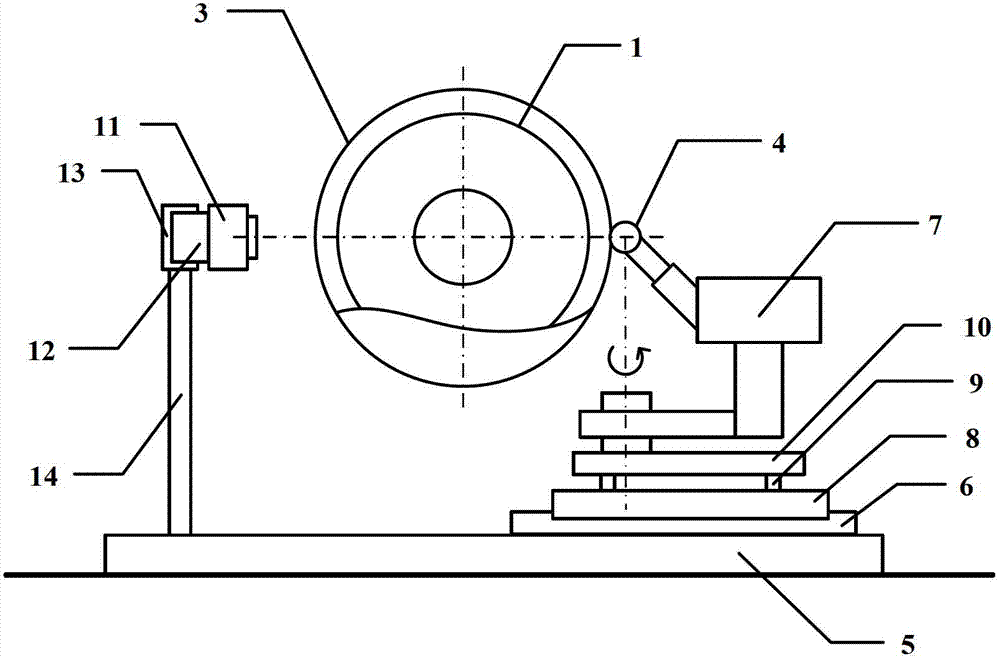

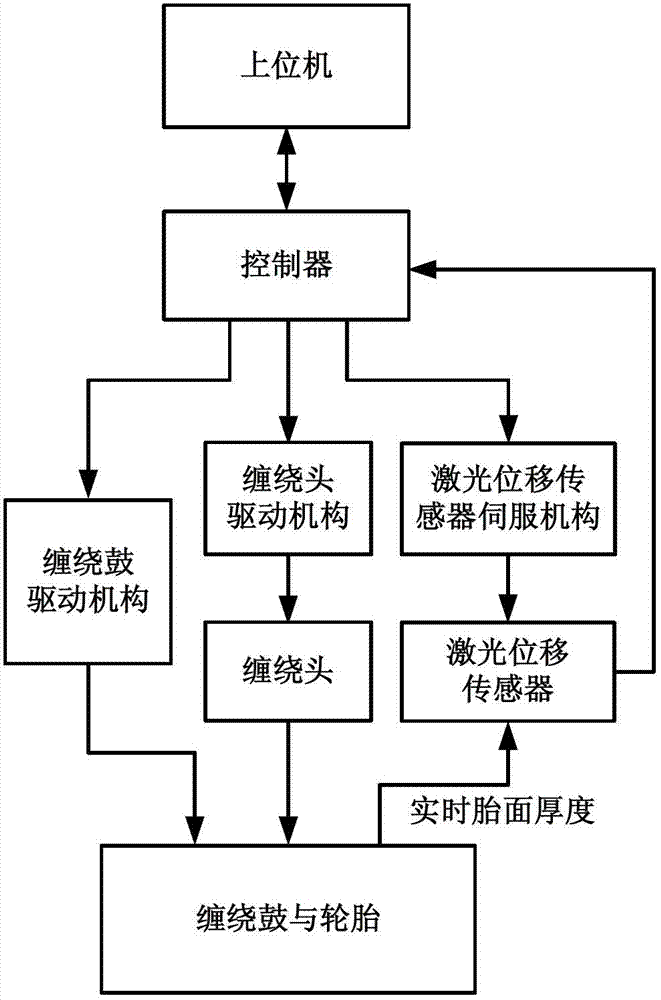

[0024] The online tread thickness measurement device and closed-loop measurement and control method for tire tread winding proposed by the present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

[0025] like figure 1 and figure 2 As shown, the tire tread winding device includes a host computer (PC, not shown in the figure), a winding drum driving mechanism 2, a winding head 4 and its driving mechanism. The winding head 4 can move horizontally and vertically under the drive of the driving mechanism. The winding head driving mechanism is composed of a winding head support 7, a transverse guide rail base 8, a transverse guide rail 9, a lateral moving platform 10, a longitudinal guide rail 6 and corresponding servo drives and transmission components. Winding head 4 is installed on the winding head support 7, and winding head 4 can drive rubber strip feeding and winding by rotation, and can rotate around the fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com