Composite material pulling and extruding molding method by heating baking-path to solidify

A composite material and pultrusion molding technology, which is applied in the field of composite material molding, can solve the problems of difficult pultrusion production, dead mold, and large frictional resistance in the curing area of the pultrusion mold.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

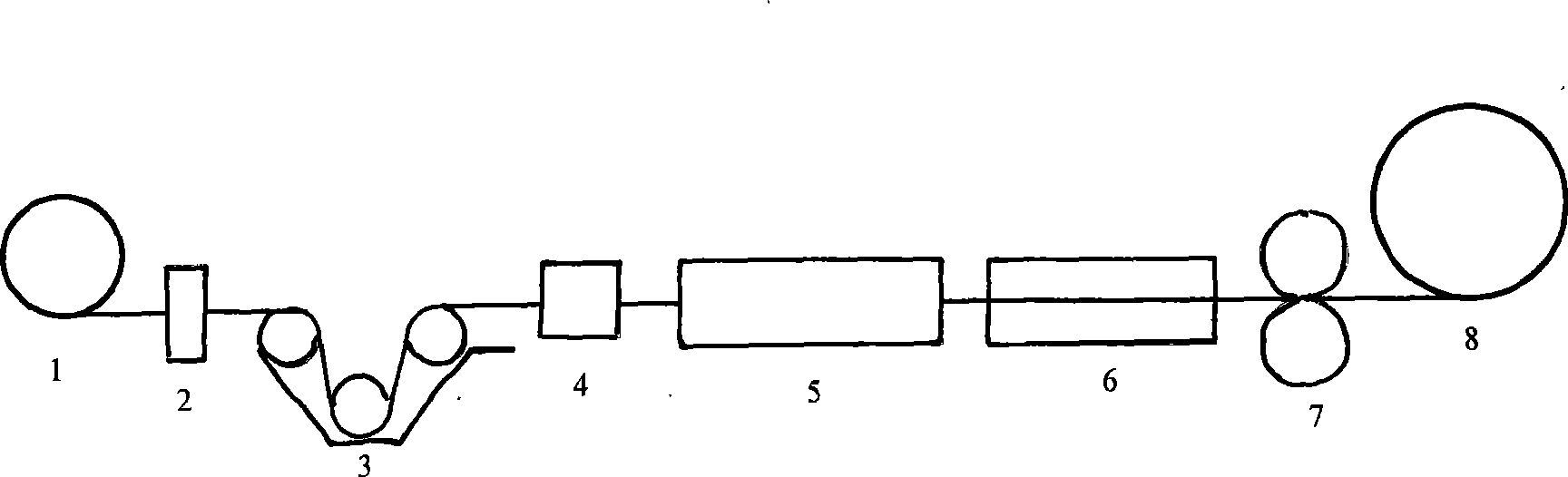

Method used

Image

Examples

Embodiment Construction

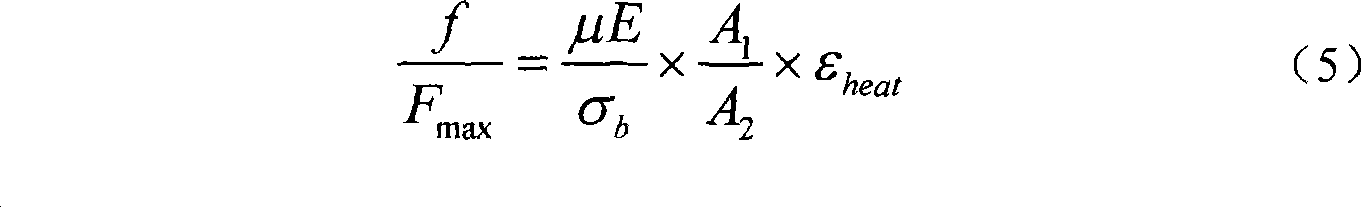

[0020] Using FW-77 high temperature curing system epoxy resin and T300 carbon fiber to pultrude a composite material round rod with a diameter of 0.3mm.

[0021] 1. Determination of the temperature of the dipping tank

[0022] According to the viscosity-temperature test, it is determined that the dipping tank can maintain the viscosity of the resin at 0.5 Pa.s to 2 Pa.s for 3 hours within the range of 35 °C ± 2 °C, and the temperature of the dipping tank is set at 35 °C.

[0023] 2. Determination of mold temperature

[0024] After testing, the mold temperature was selected to be 140°C, which would not cause a large pultrusion resistance in the mold but also allow the resin to quickly gel in a short period of time and increase the pultrusion rate.

[0025] 3. Determination of pultrusion rate

[0026] At a mold temperature of 140°C, a pultrusion rate of 0.75m / min is selected to control the resin to reach a gel state after exiting the mold.

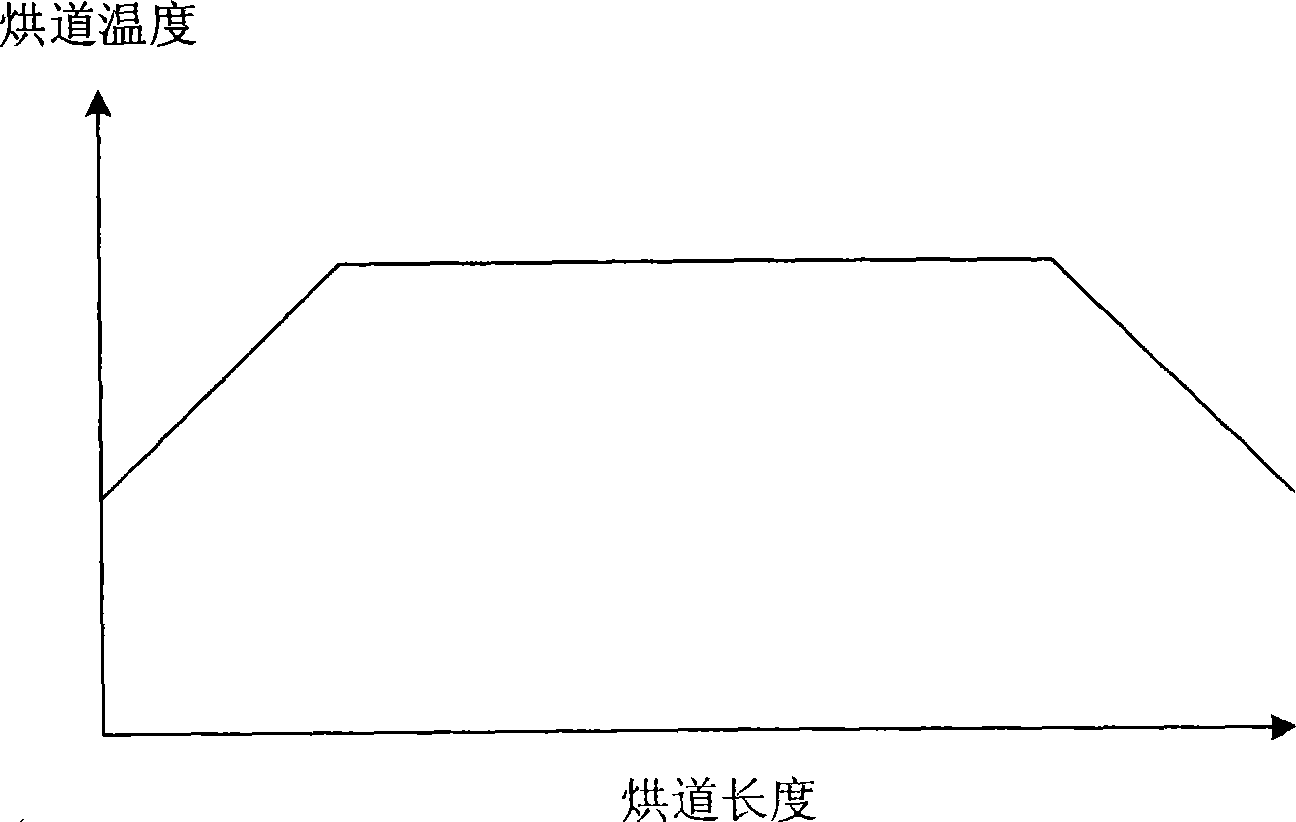

[0027] 4. Determination of drying ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com