Functionally Graded Shape Memory Polymer

a memory polymer and functional grade technology, applied in the field of shape memory polymers, can solve the problem that none of these techniques have ever been applied to smps, and achieve the effect of less exposure time and lower tg

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

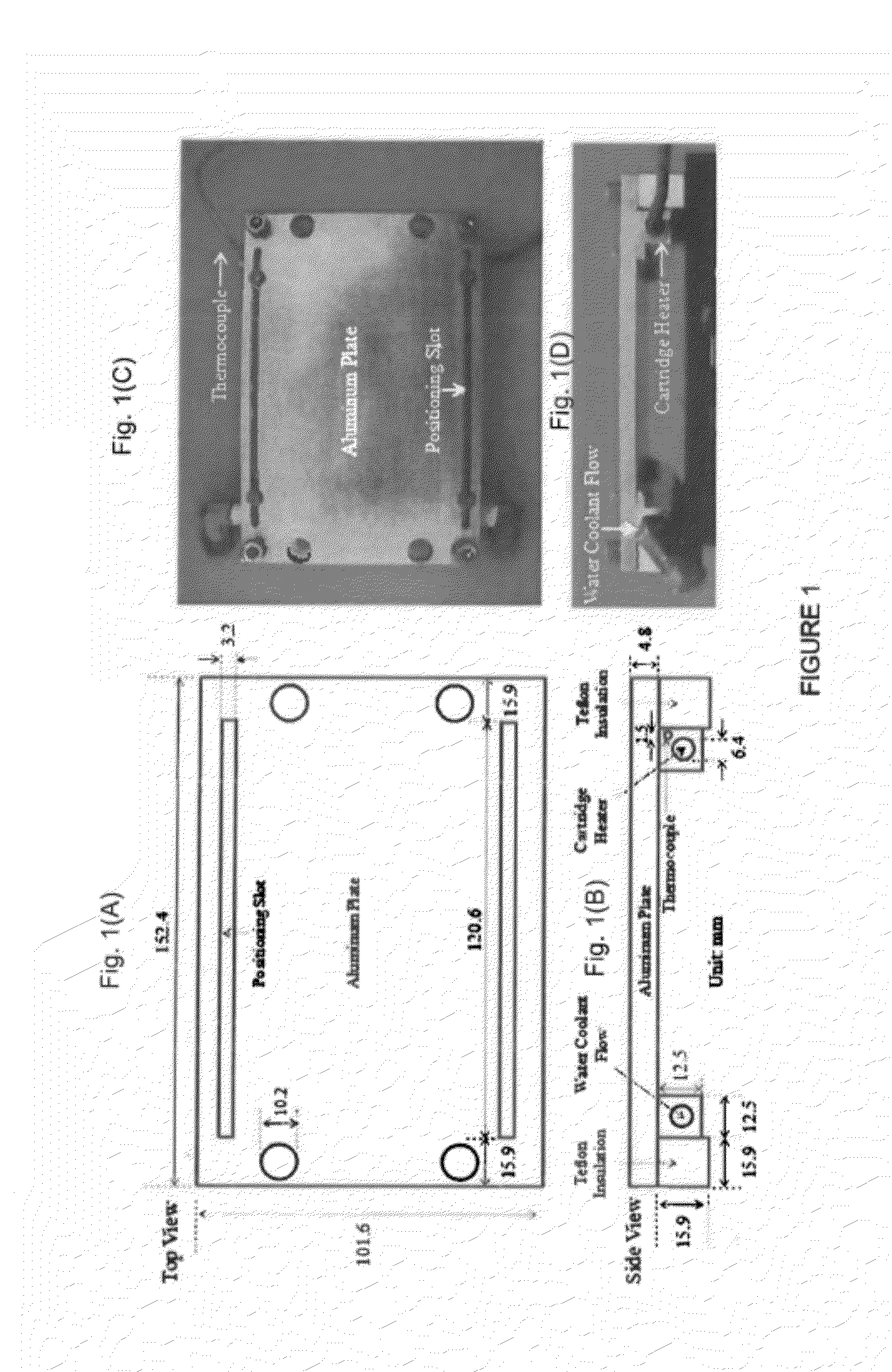

Fabrication of Temperature Gradient Hot Stage

[0042]A custom made temperature gradient hot stage was used to impart Tg gradient to the SMP system, shown in FIG. 1. The stage was designed and fabricated following a technical guide published by NIST. A temperature gradient is produced by heating at one end (via a heating unit) and maintaining a constant low temperature (via a cooling unit) at the other end. The heating unit consists of a cartridge heater (output power=300 W, Mcmaster-Carr) and a temperature controller (ETR-9090 from OGDEN Manufacturing Company) with a type T thermocouple. The cooling unit functions by circulating cold water at a constant flow rate using a submersion pump (model 1C-MD-1, March MFG., Inc.). Thermal insulation between the entire apparatus and the laboratory table is provided by two machined Teflon blocks. Besides varying the temperatures of the heating and cooling units, the temperature gradient can be further controlled via adjusting the distance between...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Shape memory effect | aaaaa | aaaaa |

| Shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com