Photo-post-curing resin composition

A resin composition and post-curing technology, applied in the field of light post-curable resin compositions, can solve the problems of component deterioration, shortened life, and deterioration of luminous properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

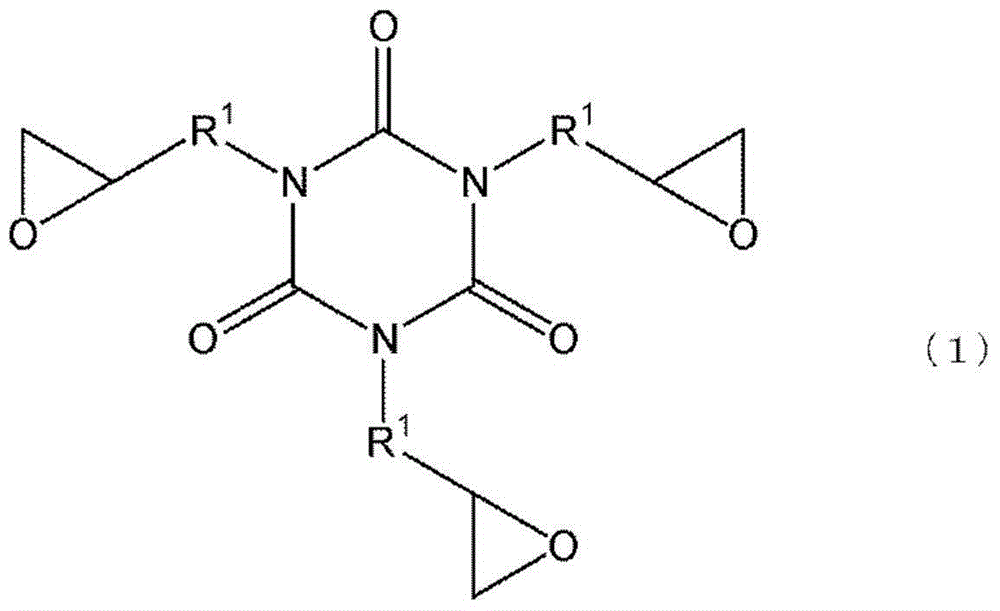

[0084] 50 parts by weight of bisphenol F type epoxy resin (manufactured by DIC Corporation, "EPICLON EXA-830LVP"), 25 parts by weight of hydrogenated bisphenol A type epoxy resin (manufactured by Mitsubishi Chemical Corporation, "jER YL8034") Parts by weight, and 25 parts by weight of hydrogenated bisphenol F-type epoxy resin (manufactured by Mitsubishi Chemical Corporation, "jER YL6753"), aromatic sulfonium salt as a photocationic polymerization initiator (manufactured by Midori Kagaku, "DTS-200") 1.0 parts by weight, 5 parts by weight of triglycidyl isocyanurate (manufactured by Nissan Chemical Co., Ltd., "TEPIC") as a compound having a tertiary amino group and a cationic polymerizable functional group, 2,4-diethylene glycol as a sensitizer 0.01 part by weight of thioxanthone (manufactured by Nippon Kayaku Co., Ltd., "DETX-S"), γ-glycidoxypropyltrimethoxysilane (manufactured by Shin-Etsu Silicone Co., Ltd., "KBM-403") as a silane coupling agent ") and 1 part by weight of a f...

Embodiment 2~6、 comparative example 1~3

[0086] According to the compounding ratio of Table 1, each material described in Table 1 was stirred and mixed similarly to Example 1, and the photopost-curable resin composition was produced.

[0087]

[0088] The following evaluations were performed about each photopost-curable resin composition obtained in the Example and the comparative example. The results are shown in Table 1.

[0089] (1) Viscosity

[0090] About each photopost-curable resin composition obtained by the Example and the comparative example, the viscosity in 25 degreeC and conditions of 100 rpm was measured using the E-type viscometer (made by Toki Sangyo Co., Ltd., "VISCOMETER TV-22").

[0091] (2) Curing delay

[0092] Using an ultraviolet irradiation device (manufactured by Oak Corporation, "JL-4300-3S"), 1500 mJ / cm was irradiated to the test pieces of each photo-post-curable resin composition obtained in Examples and Comparative Examples 2 of ultraviolet light. Curability was confirmed after 10 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com