In-mold foaming forming system and technology for rubber double-density product

A foam molding and double-density technology, which is applied in the in-mold foam molding system of rubber double-density products and its technology field, can solve the problems of large equipment investment, cumbersome process, and high cost, so as to reduce energy consumption, improve production efficiency, The effect of reducing the scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

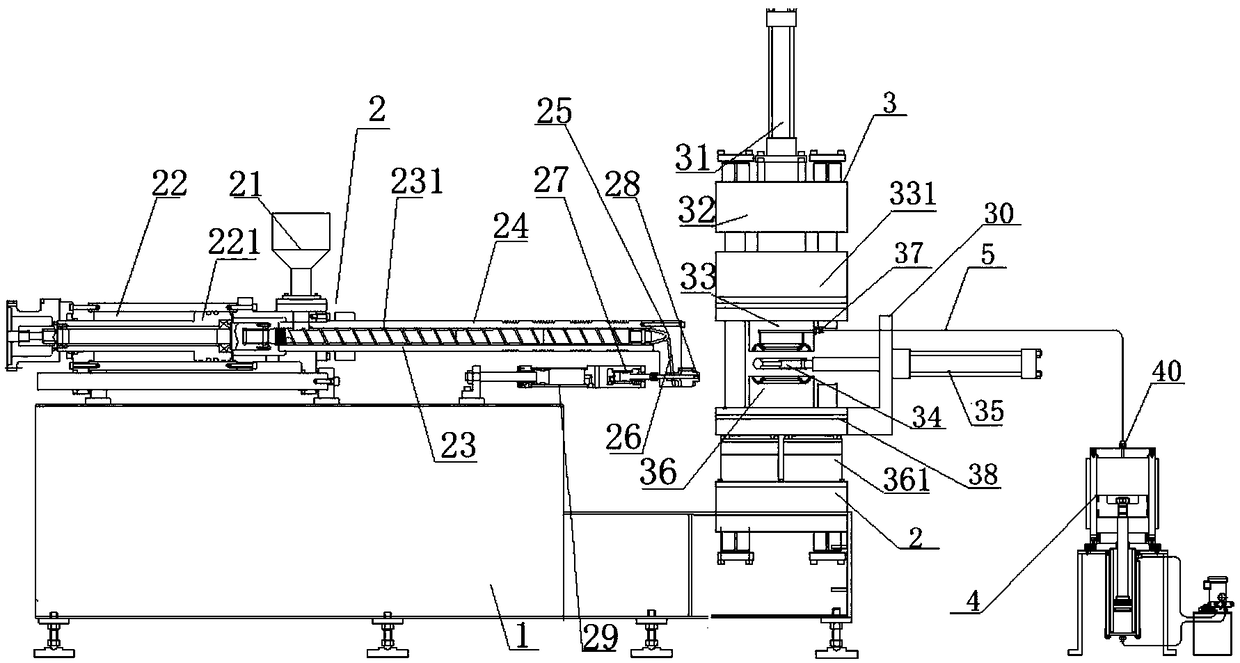

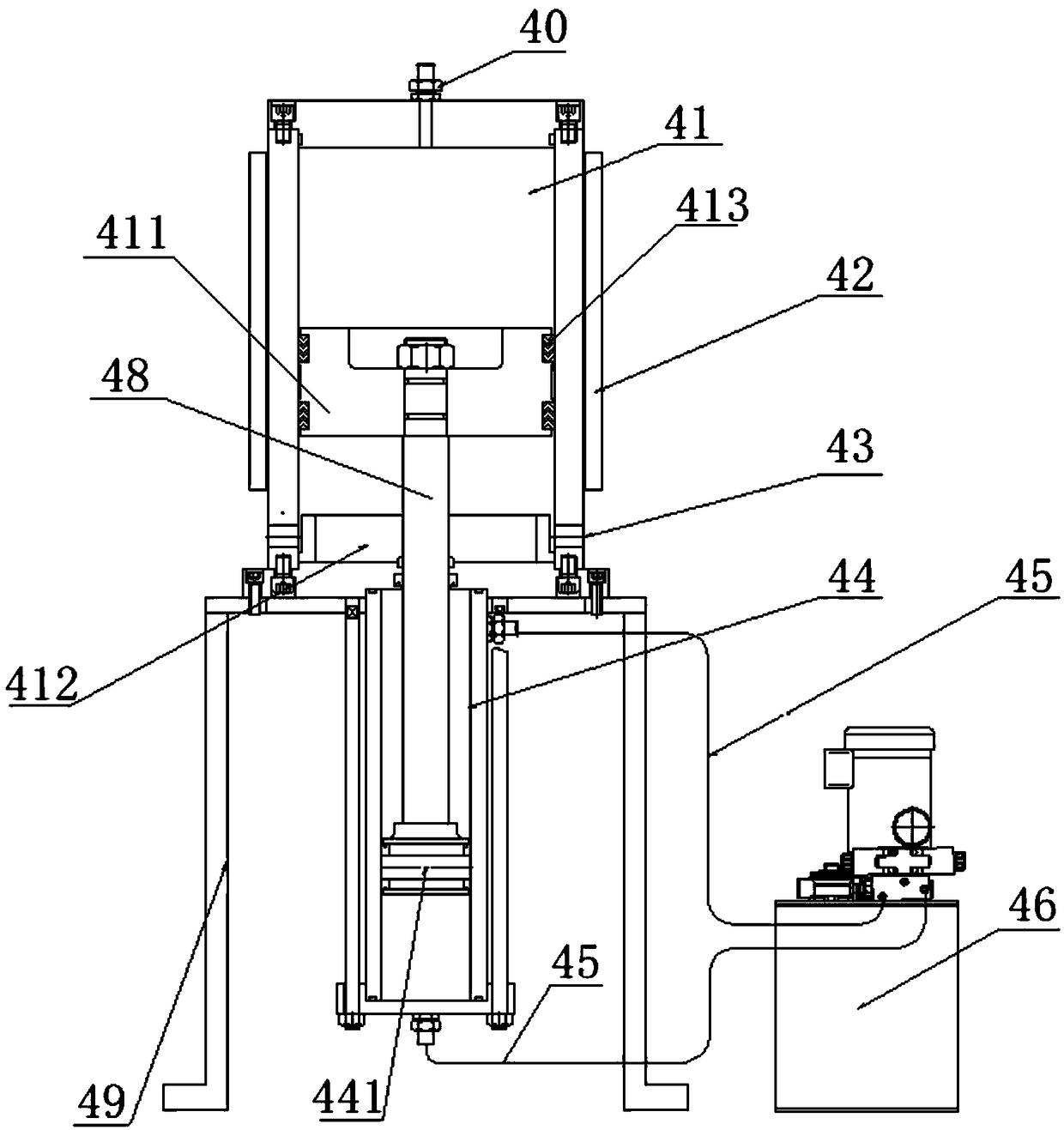

[0046] The in-mold foam molding system of the rubber double-density product of the present embodiment, such as figure 1 As shown, it includes a mold exhaust and hollow inflation mechanism 4, and also includes an injection machine base 1, a foaming and vulcanization molding pedestal 5, and an injection device 2 and a foaming and vulcanization molding device 3 respectively fixed on the two. The device 2 communicates with the mold of the foaming and vulcanization molding device 3; the foaming and vulcanization molding device 3 foams and vulcanizes the outer layer of high-density rubber and the inner layer of foamed rubber added sequentially in the mold. Such as figure 2 As shown, the mold exhaust and hollow inflation mechanism 4 includes a support 49, a cylinder 41, an oil cylinder block 44 and a hydraulic station 46; the support 49 is an annular stand with a through hole in the middle, and the cylinder 41 is fixed on On the ring-shaped table, the cylinder block 44 is fixed on ...

Embodiment 2

[0049] The in-mold foam molding system for rubber double-density products of this embodiment has the same basic structure as that of Embodiment 1, and the improvements are as follows: figure 1 As shown, the injection device 2 includes a feeding hopper 21, an injection cylinder 22, a plasticizing injection screw barrel 23, a plasticizing heater 24, an injection nozzle control cylinder 27, an injection head 28 and an injection seat moving cylinder 29; The starting ends of the plasticizing injection screw barrel 23 are connected, and the starting end of the plasticizing injection screw barrel 23 is inserted into the cylinder barrel of the injection cylinder 22, and is pressed against the injection piston 221 in the injection cylinder 22; the plasticizing injection screw barrel 23 has a built-in plasticizer Injection screw 231, at the end of plasticizing injection screw 231, a pre-stored plasticizing material cavity 25 is reserved; the pre-stored plasticizing material cavity 25 con...

Embodiment 3

[0063] The basic structure of the in-mold foam molding system for rubber double-density products of this embodiment is the same as that of Embodiment 2, and the improvements are as follows:

[0064] The foaming and vulcanization molding device 3 also includes a mold clamping upper seat 331 and a mold clamping lower seat 361, and the upper mold half 33 and the lower half mold 36 are respectively supported by the mold clamping upper seat 331 and the mold clamping lower seat 361 to improve injection, foaming and vulcanization. , the stability of the whole system. The outer arm of the cylinder 41 is surrounded by a fixed cylinder heater 42, and the bottom side of the cylinder 41 is provided with a cylinder air discharge hole 43; It can be in the heating stage, and the exhaust gas can be heated slightly to meet the requirements. During the inflation process, the inner cavity of the product is in a sealed state. After the cylinder is filled with gas, it is in a pressure-holding stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com