Variable spiracula lifting device

A valve lift and valve technology, which is applied to valve devices, engine components, machines/engines, etc., can solve problems such as cost and packaging energy balance, and achieve the effects of simple structure, reduced fuel consumption, and convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

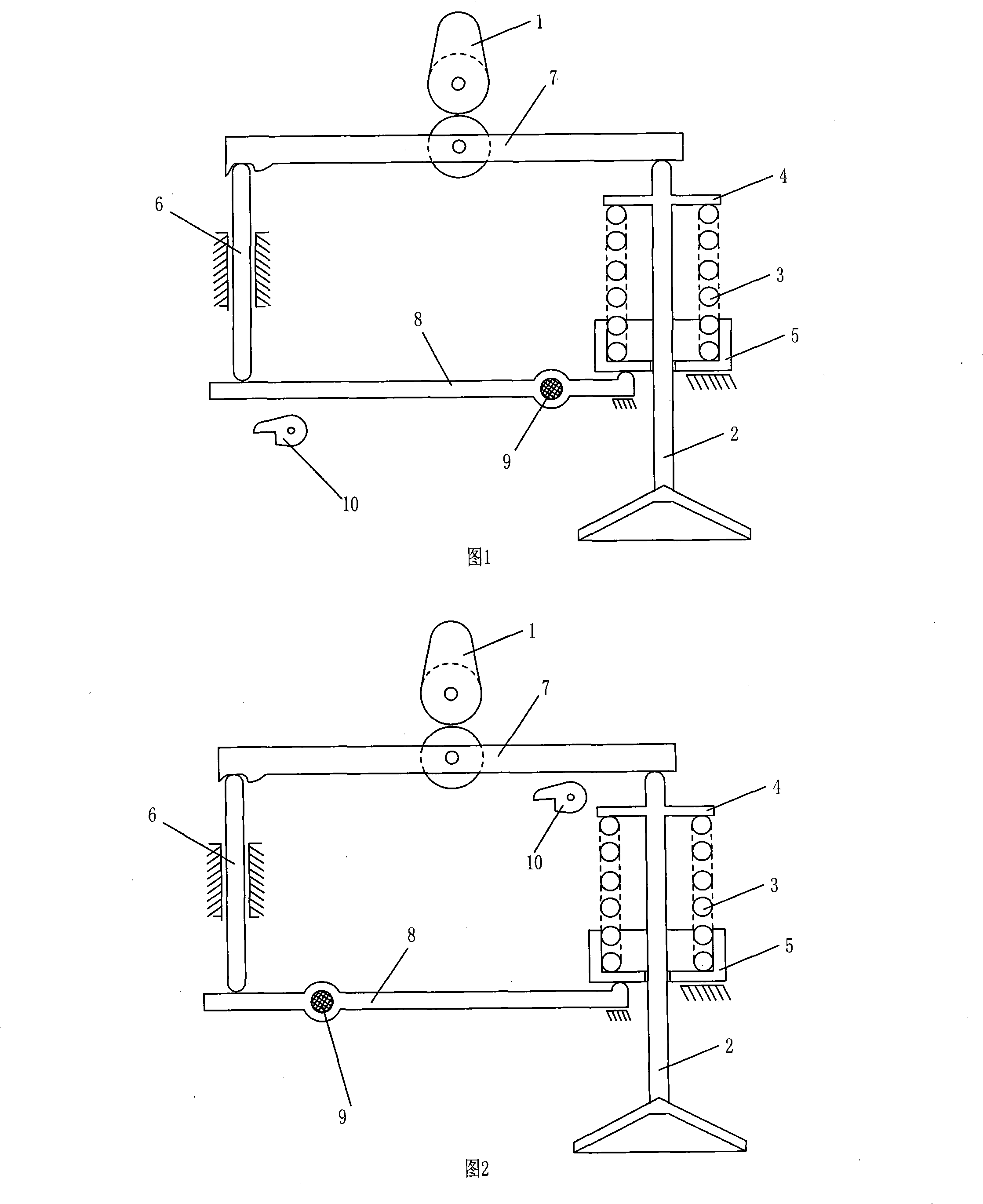

[0016] Embodiment 1: As shown in Fig. 1 , it is a schematic structural diagram of Embodiment 1 of the present invention. The variable valve lift device in this embodiment includes a valve 2, a valve spring 3 and a cam 1. The valve 2 is installed in the air passage of the cylinder head and is used to control the opening and closing of the air passage. The cam 1 is located above the valve 2 and is used to drive the valve 2 to move up and down. Valve 2 overcoats a valve spring 3, and the upper end of the valve 2 is fixedly connected with a spring upper seat 4, which can compress the valve spring 3. At the lower end of the valve spring 3, a seat under the spring is provided with a very cup 5, and the seat under the spring is very cup 5 and is positioned on the cylinder head.

[0017] Compared with the existing variable valve lift device, the improvement of this embodiment is mainly that a lever mechanism is added. Under the normal rotation of the cam 1, the mechanism can transfer...

Embodiment 2

[0021] Embodiment two: as shown in accompanying drawing 2. The scheme disclosed in this embodiment is similar to the scheme disclosed in Embodiment 1. In this scheme, the control cam wheel 10 is changed from controlling the lower lever 8 to controlling the upper lever 7. At the same time, the cam 1 and the upper lever 7 contact the force point and the upper lever. 7 and valve 2 distances are less than lower lever shaft 9 and lower lever 8 and spring seat tappet 5 contact point distances. The positions and connections of other components are consistent with those in Embodiment 1.

[0022] Contrary to Embodiment 1, when the valve 2 is required to move to the maximum extent with the rotation of the cam 1, firstly the control cam wheel 10 needs to be rotated until there is a distance between its upper edge and the upper lever 7, when the cam 1 rotates and pushes the upper lever 7 to act , the upper lever 7 is directly tilted to the right, thereby pressing down the valve 2, and th...

Embodiment 3

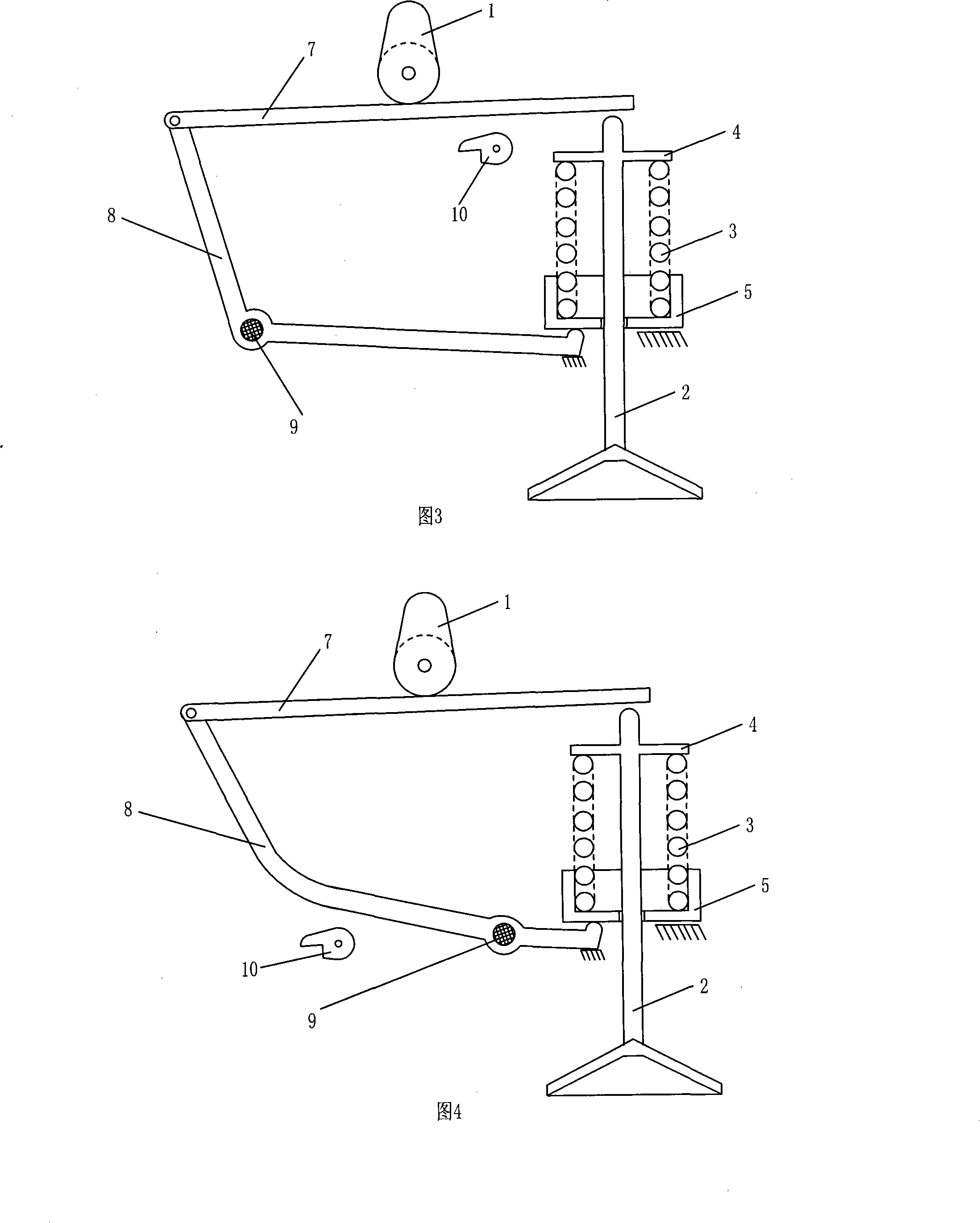

[0023] Embodiment three: as shown in accompanying drawing 3. This embodiment is consistent with the second embodiment in terms of structure and principle, and is a simplification of the second embodiment. The connecting transmission rod 6 in the second embodiment is canceled, and the upper lever 7 and the lower lever 8 are directly connected together through hinges. The transmission of power is realized through the hinge between the upper lever 7 and the lower lever 8 . The control and working process of this embodiment are consistent with the second embodiment, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com