Spray-coating machine for external surface of tire

A technology of outer surface and spraying machine, which is applied in the field of spraying machine and tire outer surface spraying machine, which can solve the problems of complex tire outer surface and achieve the effect of improving tire appearance, spraying quality and working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

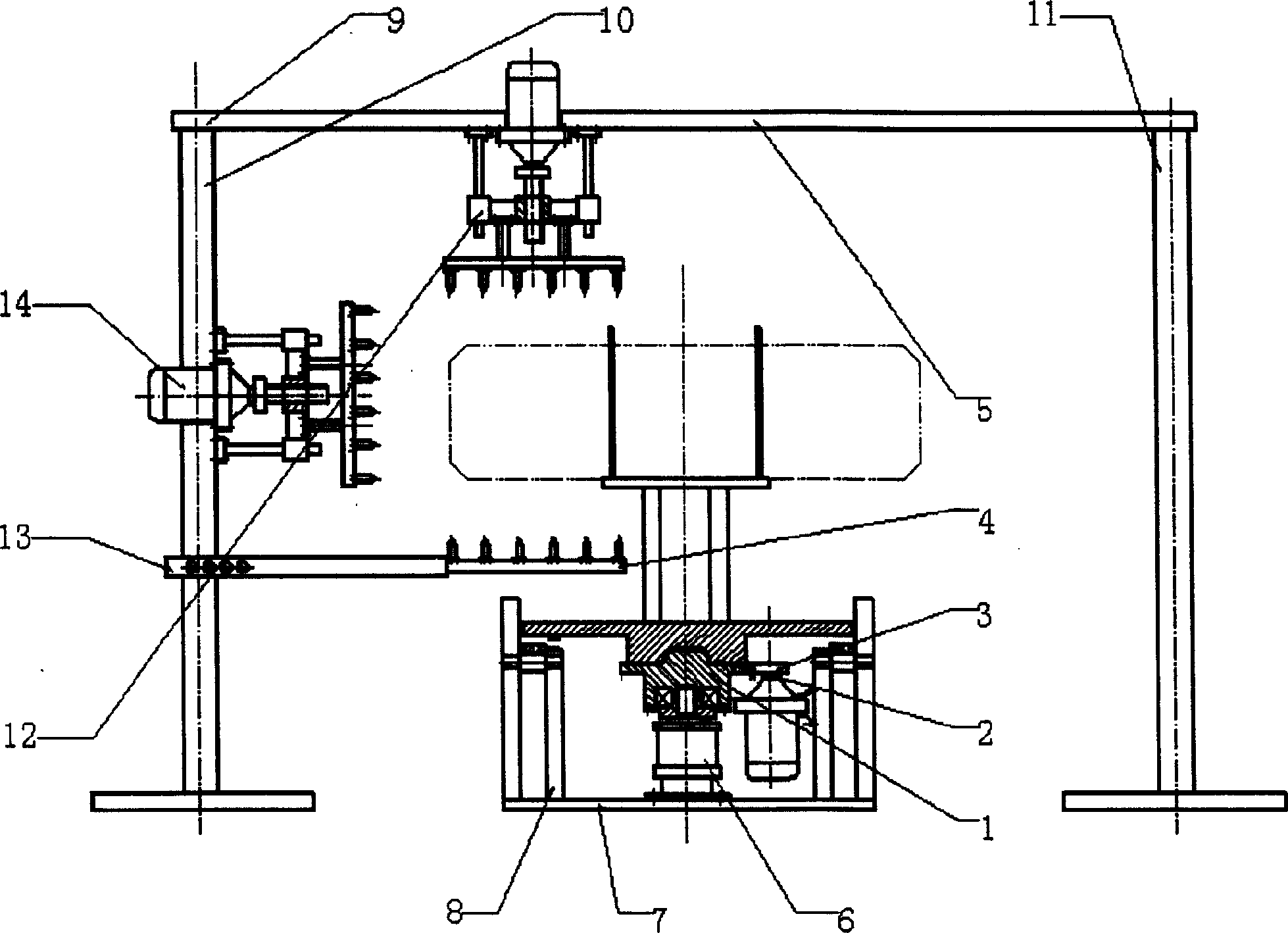

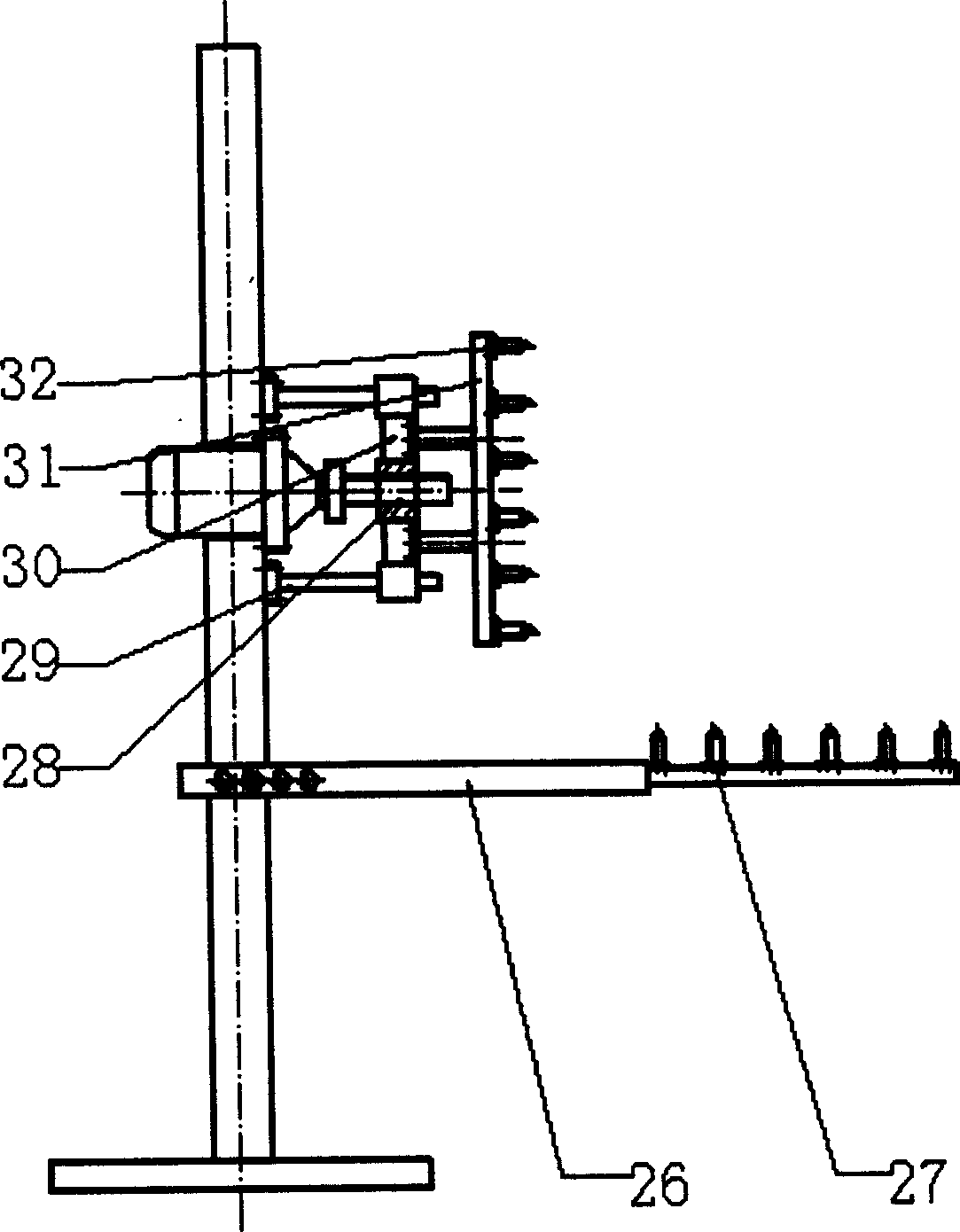

[0024] Such as figure 1 , figure 2 and image 3 As shown, the present invention comprises: tire jacking device 1, tire conveying device 2, tire turning device 3, tire nozzle group 4 and support 5, and its connection mode is: the jacking cylinder 6 of tire jacking device 1 is arranged on support 5 When the tire conveying device 2 is jacked up on the bottom plate 7, the tire jacking device 1 and the tire conveying device 2 are positioned through the structure of the beveled boss and the concave platform, and the tire rotating device 3 is fixed on the side bracket 8, and the side bracket 8 is arranged on On the bottom plate 7 of the bracket 5 , the tire turning device 3 is connected with the tire conveying device 2 through gear transmission, and the tire nozzle group 4 is arranged on the bracket 5 .

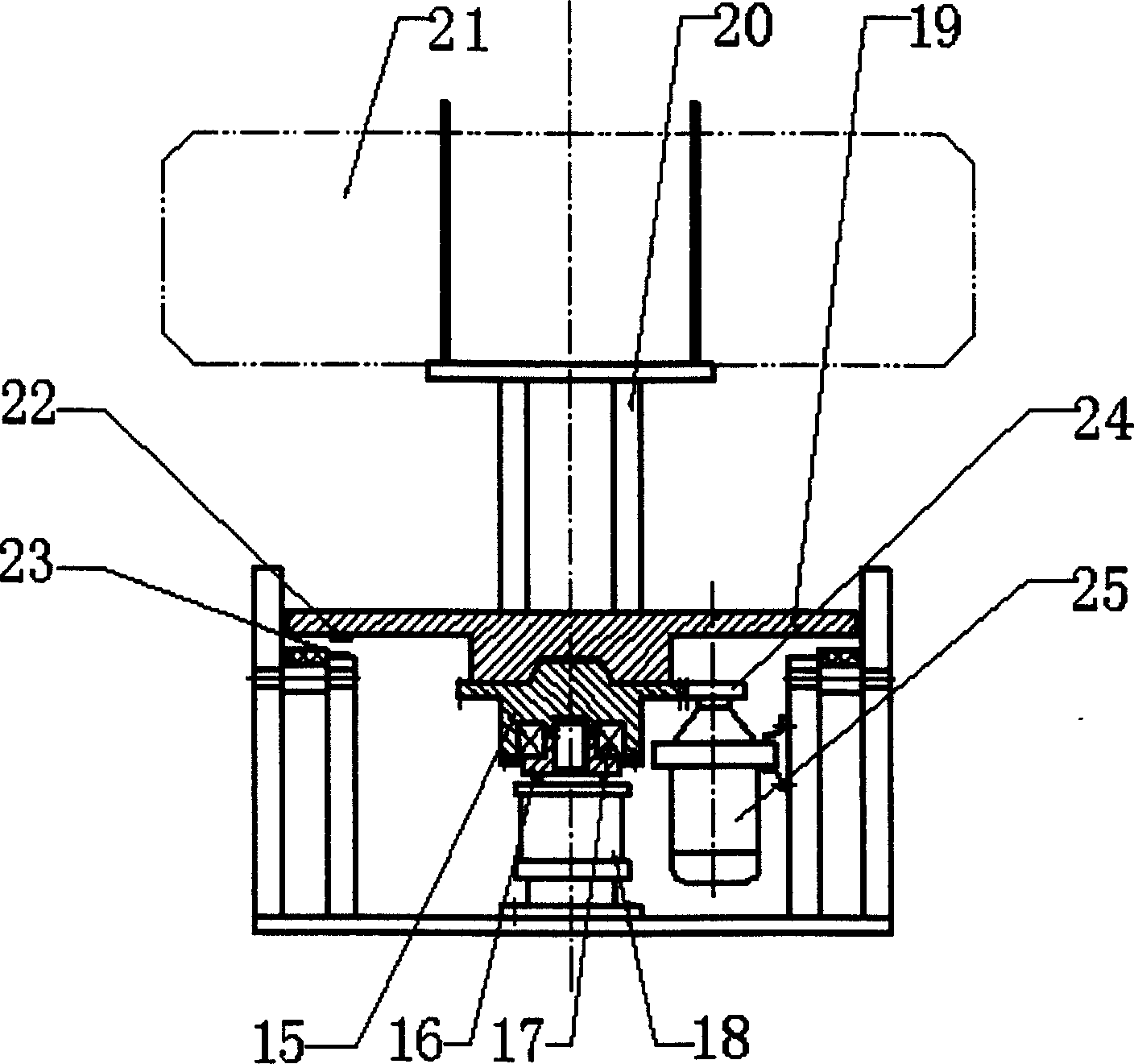

[0025] Tire jacking device 1 comprises: tire rotary drive disc 15, axle sleeve 16, rolling bearing 17 and jacking cylinder 18, and the cylinder block of jacking cylinder 18 is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com