Tire vulcanization capsule structure

A tire vulcanization and bladder technology, applied to tires, other household appliances, household appliances, etc., can solve problems such as poor moisture, and achieve the effect of improving exhaust performance, increasing exhaust channels, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

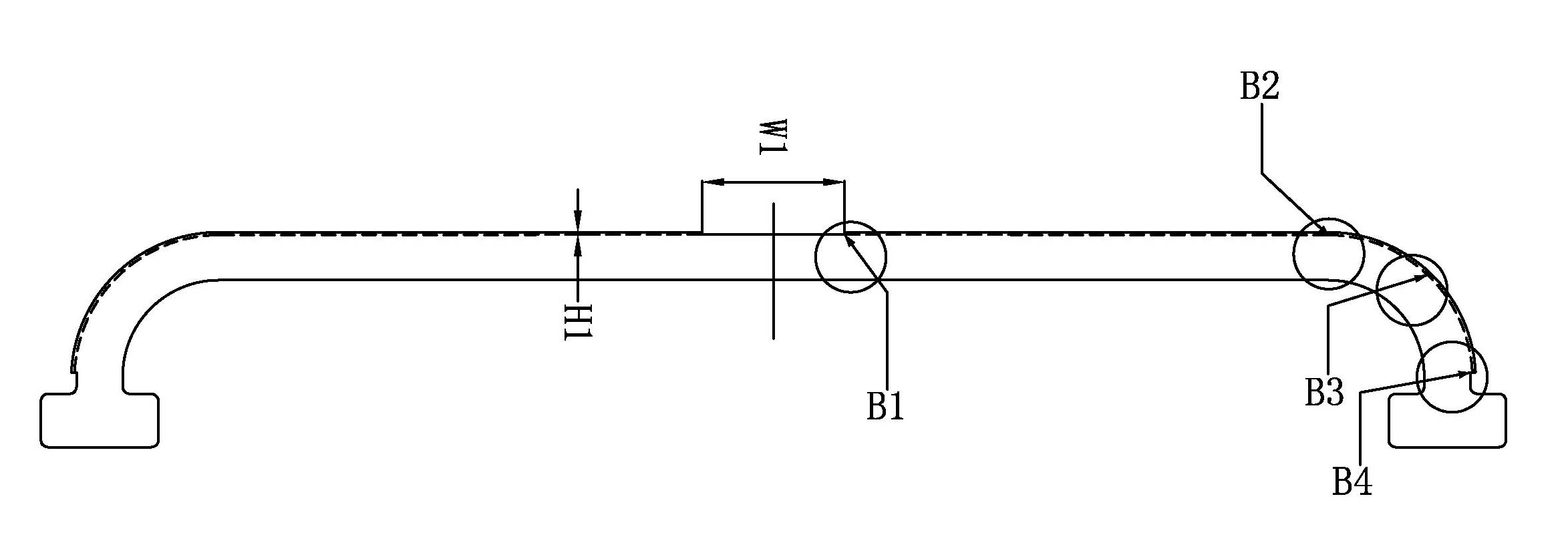

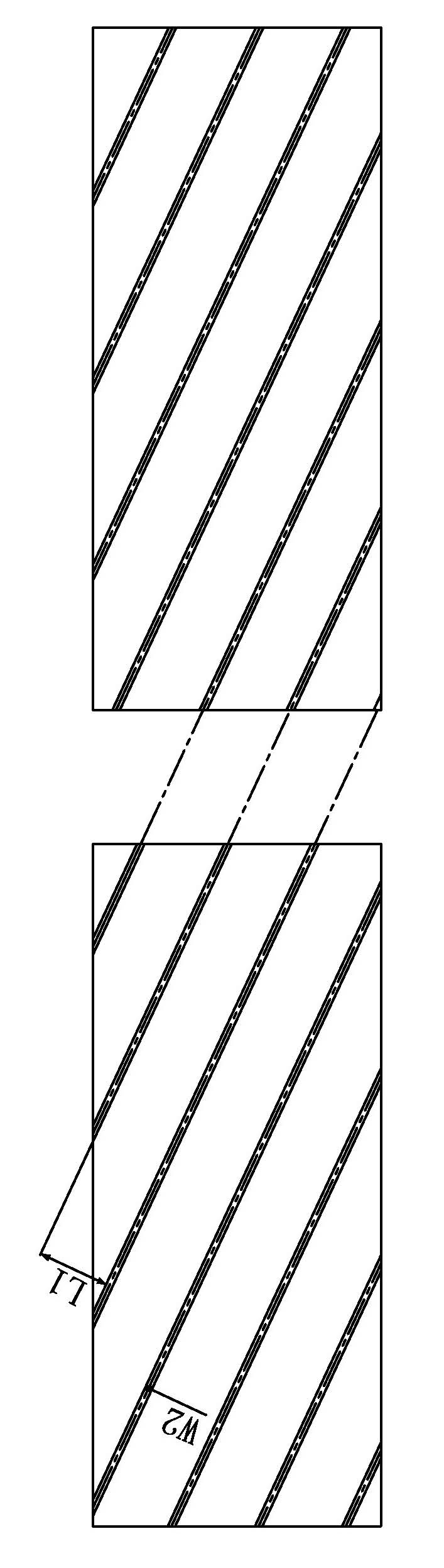

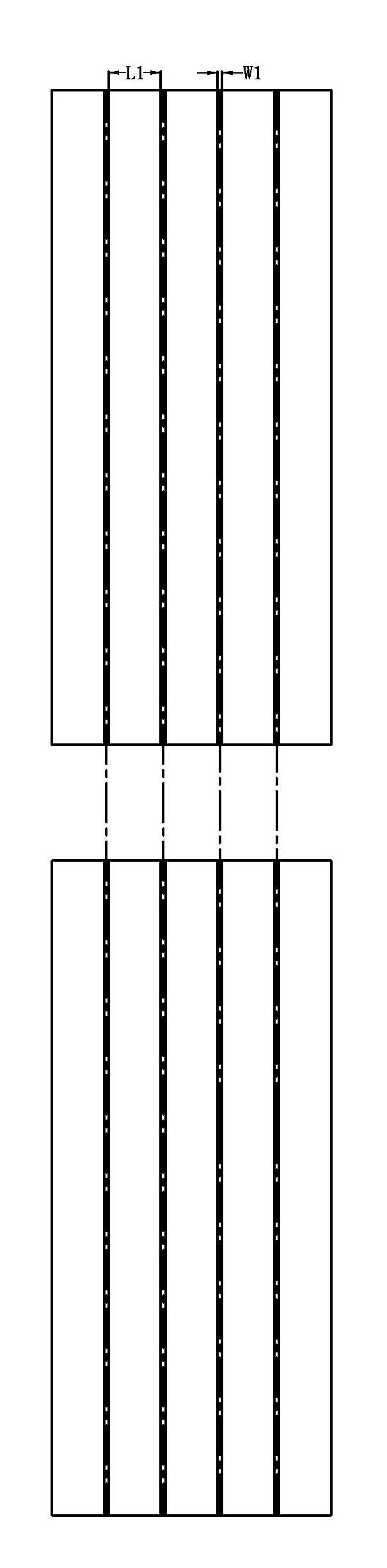

[0023] Such as Figure 4 to Figure 7 As shown, the present invention discloses a tire curing bladder structure, which is a pair of airbags corresponding to the shape of the inner surface of the tire, the outer surface of which is in contact with the inner surface of the tire. Similarly, in order to better close the mold and avoid the tire crown overflow caused by the capsule, a smooth surface A with no pattern is formed on the outer surface of the capsule corresponding to the tire crown area. The width W1 of the smooth surface A is set to 10mm~25mm, and at the same time The outer surface of the bladder is provided with the tread area B1 corresponding to the tire, the transition area B2 between the tread and the shoulder, the shoulder area B3, and the shoulder and bead area B4. Continuous straight or oblique lines are arranged on these four areas. Line exhaust ditch D, each exhaust ditch D is set in parallel; the height H1 of the exhaust ditch D is set below 0.2mm, and the widt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com