A gas generator for bait

A gas generator and decoy technology, applied in projectiles, weapon accessories, weapon types, etc., can solve the problems of high airbag strength, high outlet gas temperature, short working time, etc., and achieve good filtration and outlet pressure. Smooth, long working time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

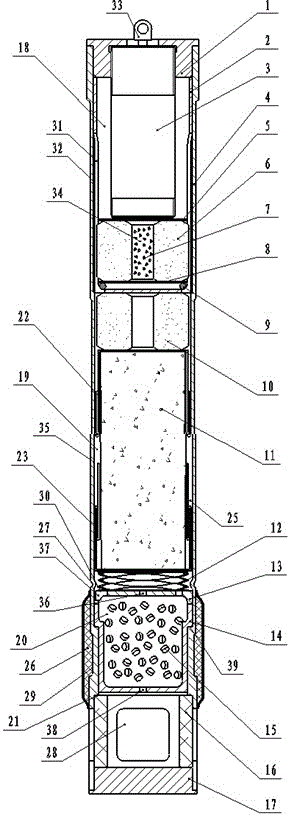

[0031] figure 1 Among them, the main body of the present invention is a cylinder 4 made of metal such as alloy steel, stainless steel, and low carbon steel, and an igniter sleeve 1 made of metals such as duralumin and super duralumin fixed at both ends of the cylinder 4 and a connecting end cap. 17 poses. The cylinder body 4 has an aspect ratio between 5 and 10, which can ensure the minimization of the volume of the whole bait after the bag coat is folded. Since the diameter of the mother bomb is fixed, to ensure that the bait can be smoothly loaded into it, its radial size must be strictly controlled. On the one hand, the smaller volume is convenient for loading the bomb, and on the other hand, it can prevent the capsule from being squeezed. Damage caused by force.

[0032] The two ends of the barrel 4 are processed with oppositely rotating threads, which are connected to the igniter sleeve and the connecting end cap through threaded connection. By setting the anti-rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com