Cast-in-place synthetic surface gas-breathable film, synthetic surface sports field and construction process

A construction technique and breathable membrane technology, applied in pavement, roads, buildings, etc., can solve the problems of damage, impact on use, and unevenness of sports fields, and achieve the effect of preventing poor exhaust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

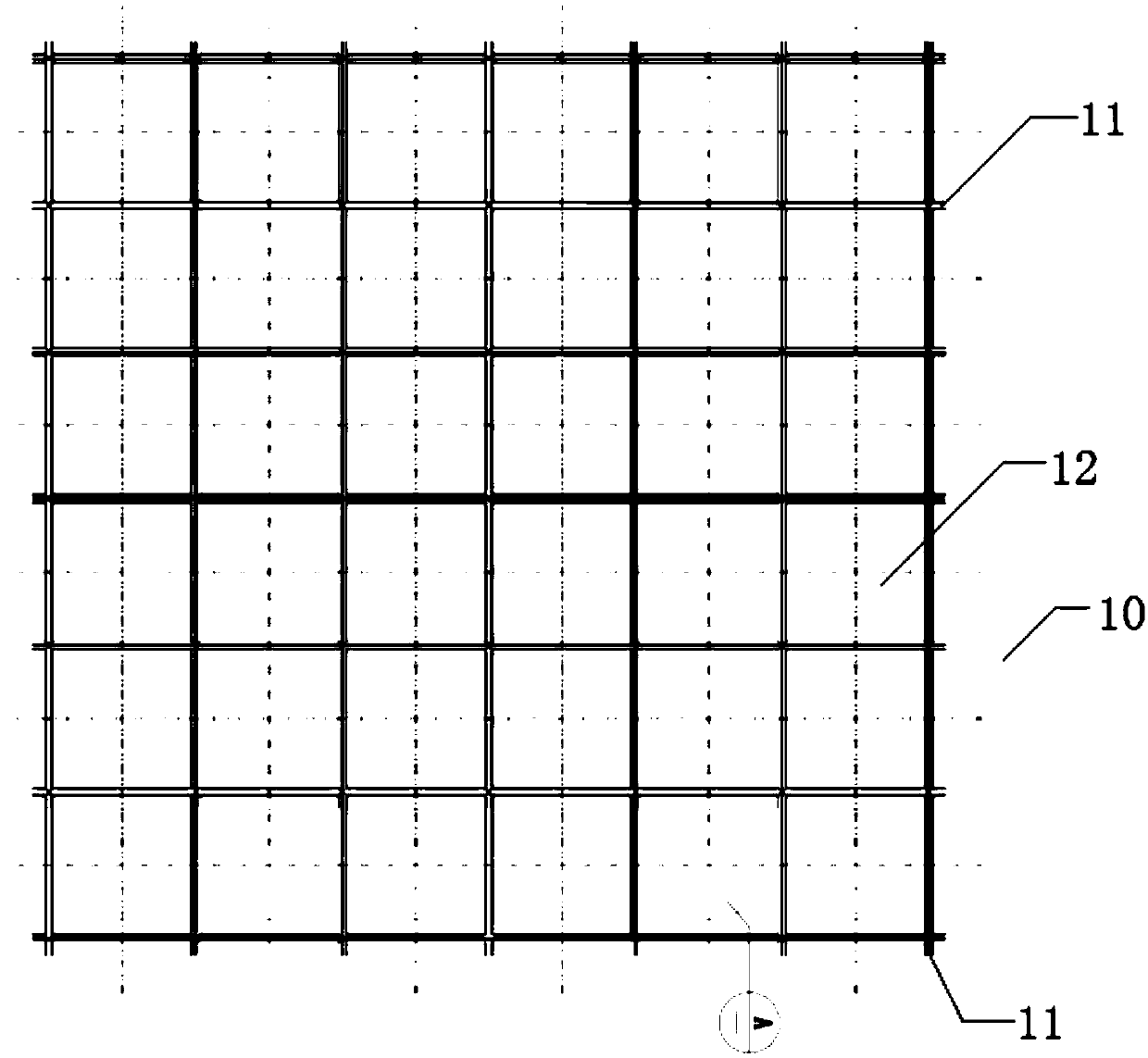

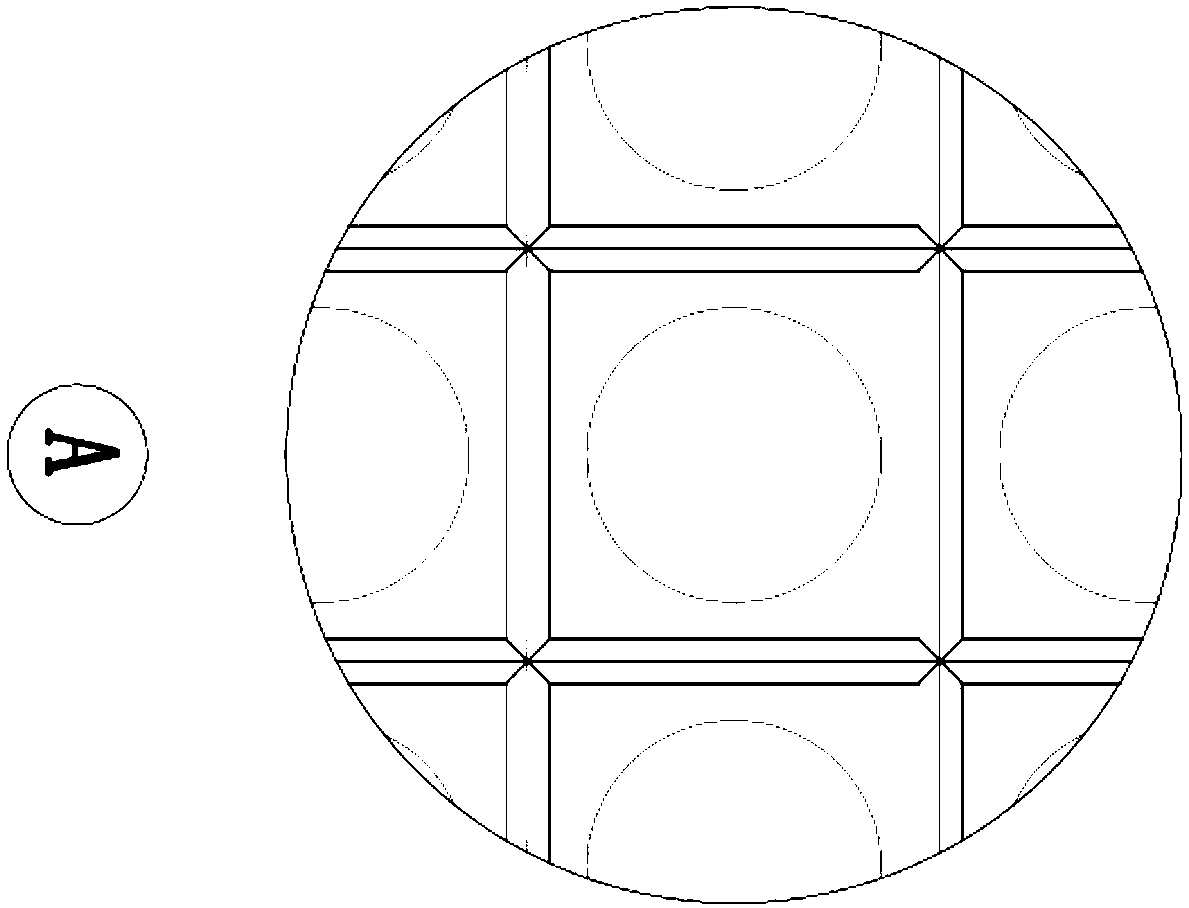

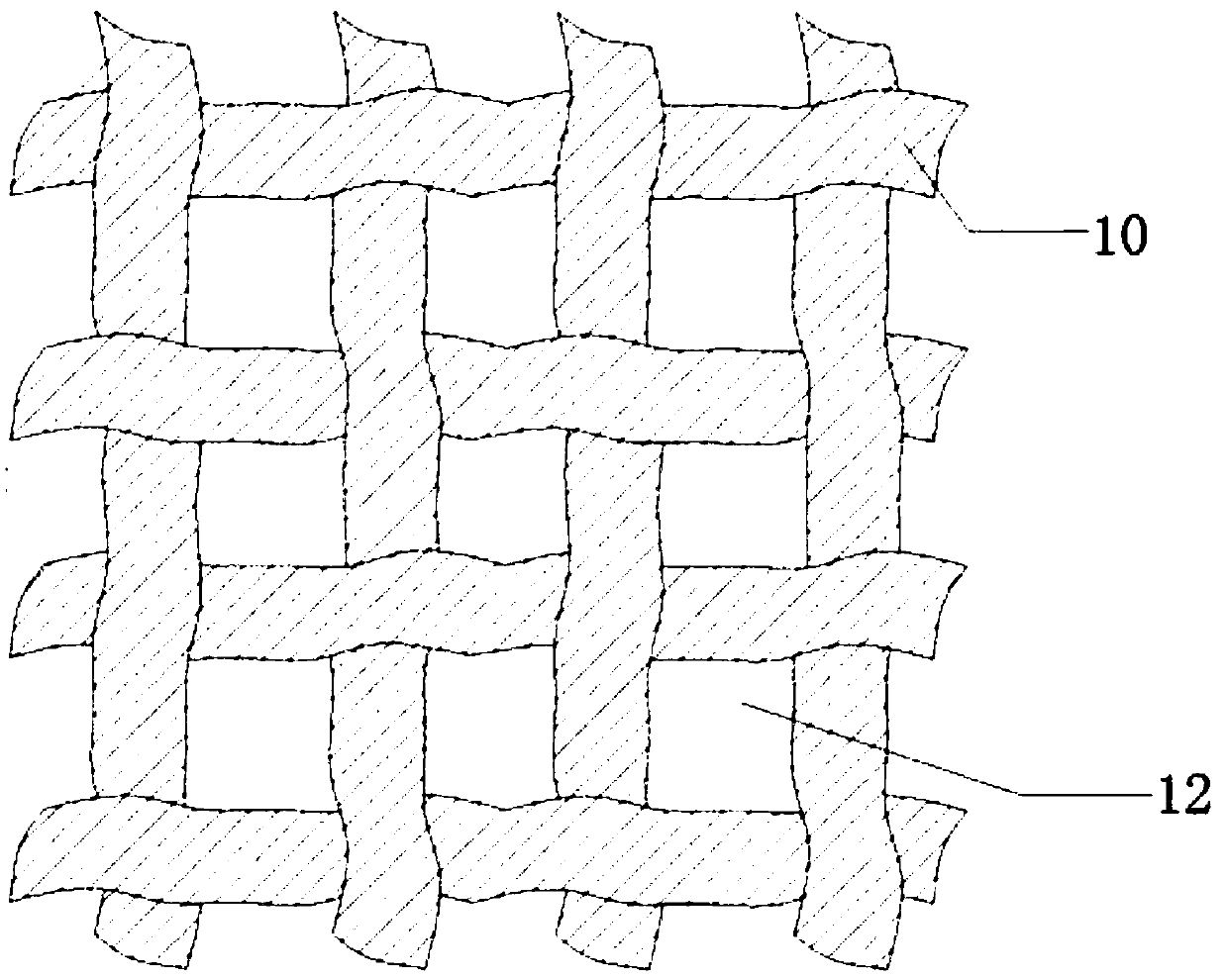

[0024] Figure 1 ~ Figure 3 Shown is a cast-in-place synthetic material surface breathable membrane 10 , the breathable membrane 10 includes a plurality of mesh holes 12 , and the bottom has an air channel 11 sunken inward and extending to the end of the breathable membrane 10 . The breathable membrane 10 can be made of polyethylene, and the thickness can reach about 1 mm. The mesh 12 can be in various shapes, such as circular, square and so on. The area of the mesh 12 is greater than 50% per square meter, that is, to ensure that the surface bonding area of the synthetic material surface layer 14 and the concrete base layer 13 should be greater than 50% per square meter to enhance stability.

[0025] refer to figure 1 , figure 2 , The breathable membrane 10 can be integrally formed, similar to a mesh structure, the air channels 11 at the bottom are criss-crossed, and there are multiple mesh holes 12 (through holes) in the middle.

[0026] refer to image 3 , the brea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com