Surface treating method for foaming products

A surface treatment and product technology, which is applied in the field of treatment of residual release agent on the surface of polyurethane partial foaming products in automotive interiors, can solve the problems of residual release agent on the surface of foaming process, and achieve the effect of meeting the requirements of bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

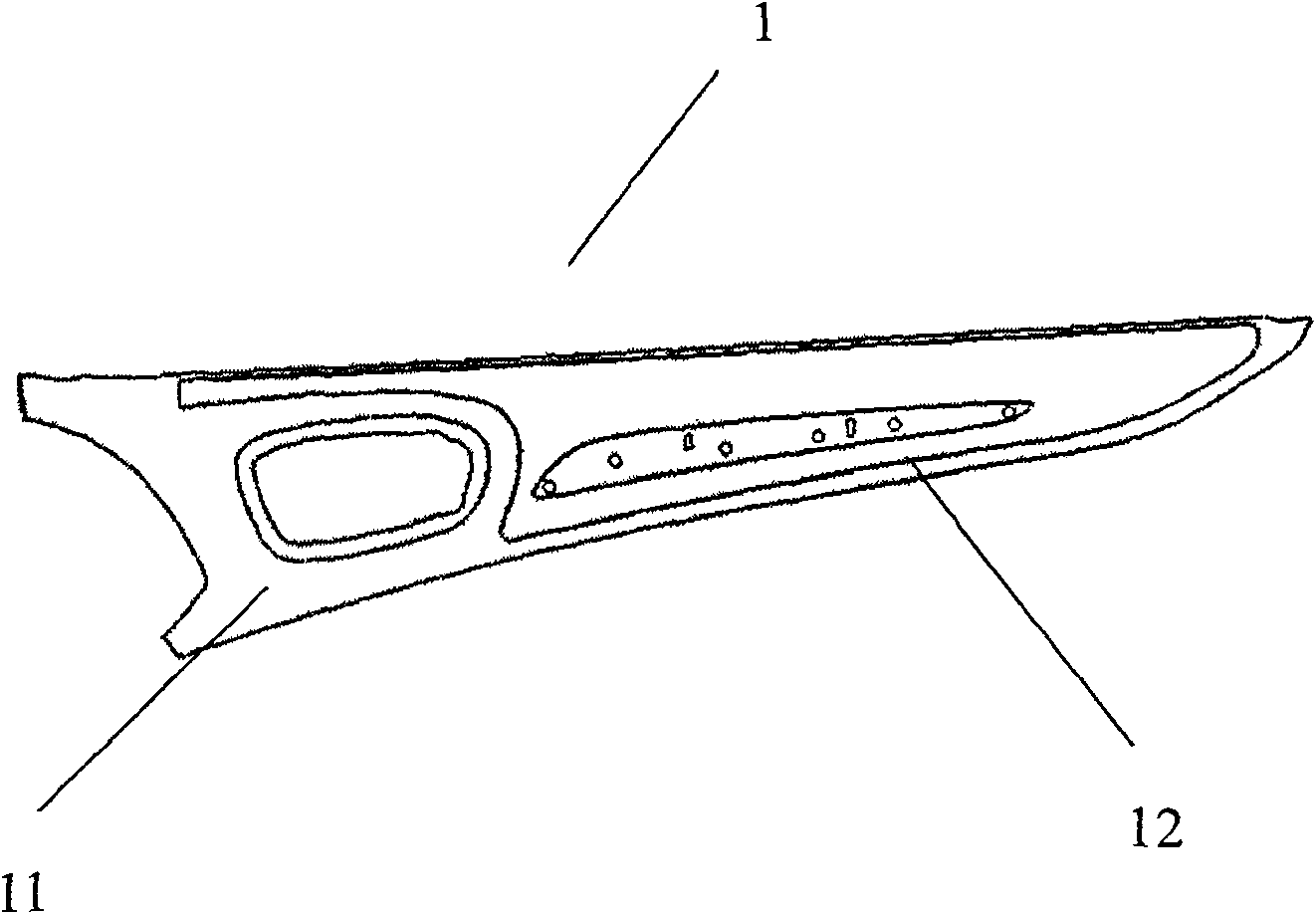

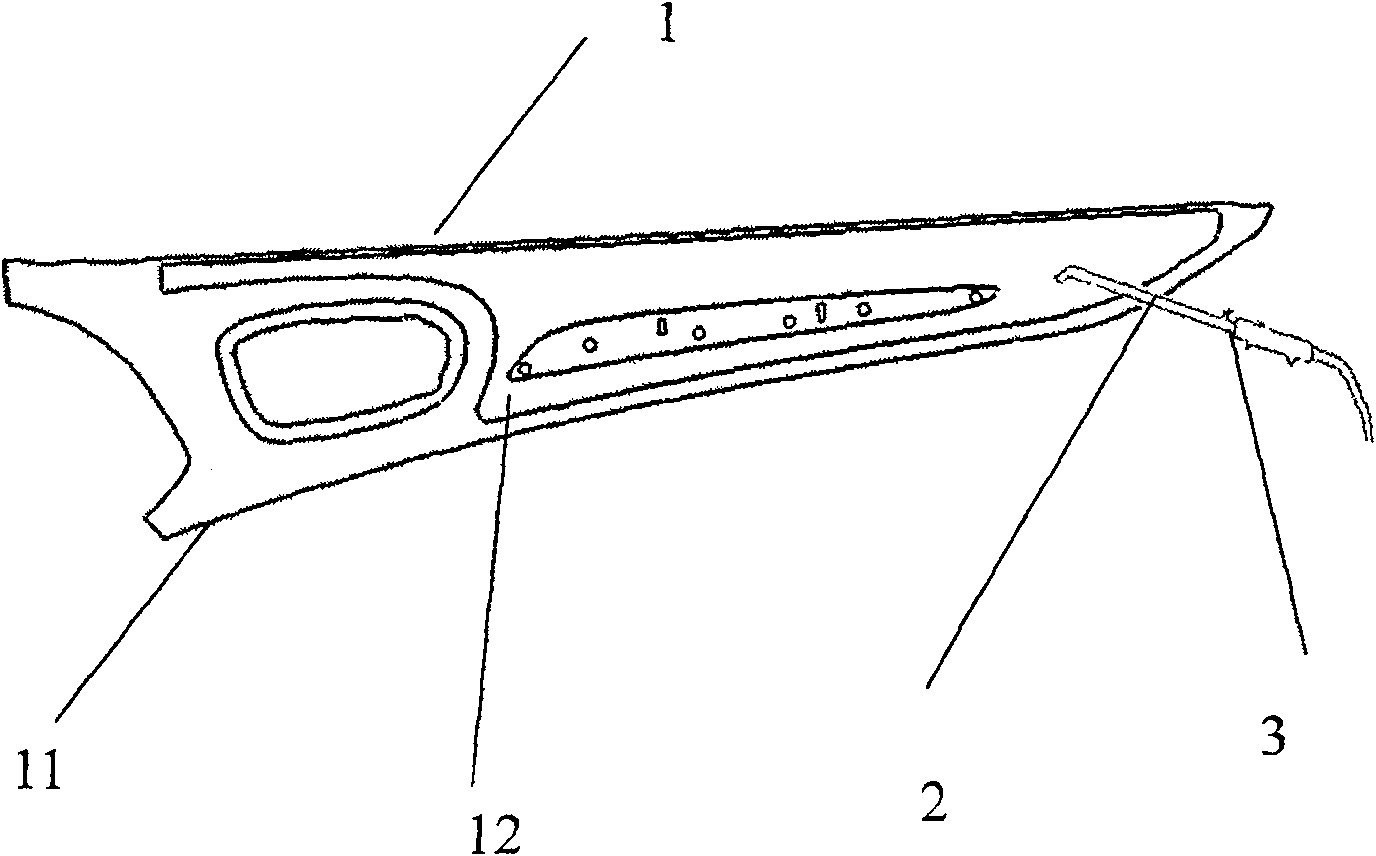

[0019] The following is based on Figure 1 to Figure 2 , give a preferred embodiment of the present invention, and give a detailed description, so that the functions and characteristics of the present invention can be better understood.

[0020] In an embodiment of the present invention, the foamed product 1, such as the upper decorative panel of a certain car model, is produced by a partial polyurethane foam method, and its structure is divided into three layers: ABS plastic skeleton 11, local foamed layer 12 , and PVC skin (not shown in the figure). refer to figure 1 , shows the structure of skeleton plus partial foaming layer, the outline on the right side of the skeleton 11 is a local foaming area, and the rest of the area is a hard plastic skeleton. The foam is a semi-rigid polyurethane foam formed by foaming isocyanate and polyol. After the foam layer 12 is surface-treated, it is bonded with the PVC skin by glue.

[0021] In order to prevent the foam from sticking to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com