Metal interconnection structure and bonding method thereof

A metal interconnection and bonding technology, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems of low specific heat capacity, unfavorable chip operation with large workload, and nitrogen-doped silicon carbide material heating, etc., to prevent harmful diffusion, The effect of meeting the requirements of bonding strength and reducing the interface temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific embodiments of the metal interconnection structure and the bonding method of the metal interconnection structure provided by the present invention will be described in detail below with reference to the accompanying drawings.

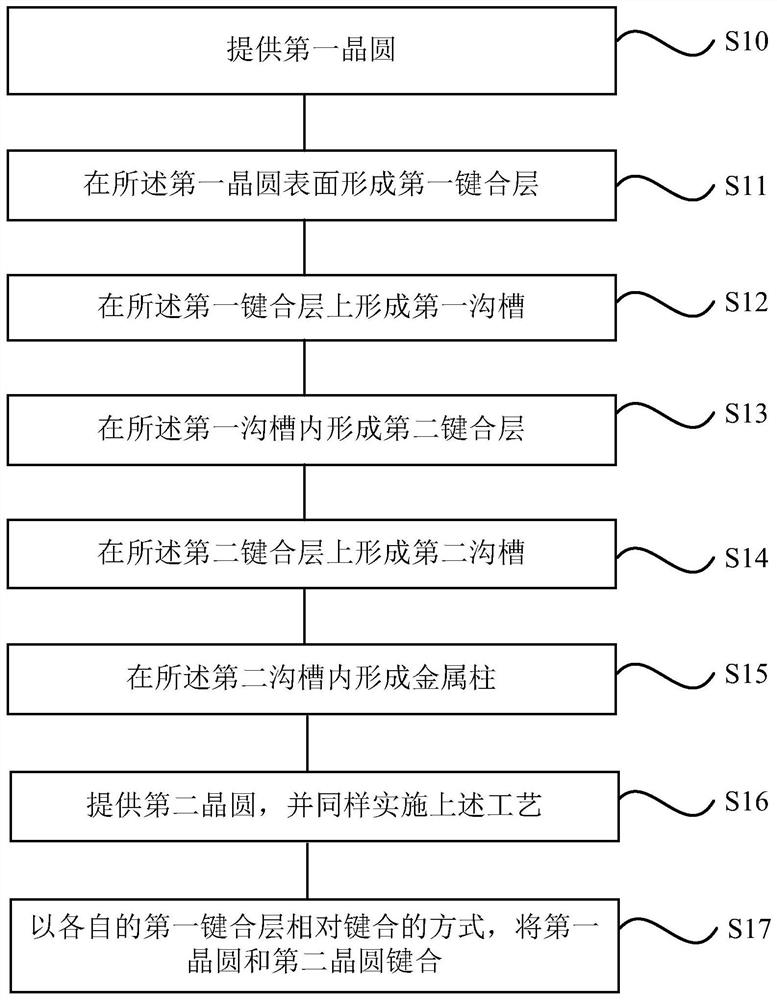

[0012] attached figure 1 Shown is a schematic diagram of a specific embodiment of the present invention. The bonding method of the metal interconnect structure includes: step S10, providing a first wafer; step S11, forming a first bonding layer on the surface of the first wafer ; Step S12, forming a first trench on the first bonding layer; Step S13, forming a second bonding layer in the first trench; Step S14, forming on the second bonding layer second trenches; step S15, forming metal pillars in the second trenches; step S16, providing a second wafer, and performing the same process; step S17, relatively bonding the first bonding layers manner, the first wafer and the second wafer are bonded.

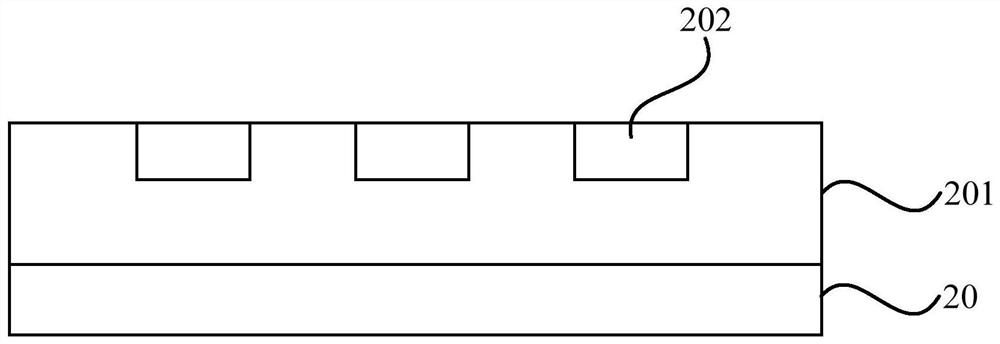

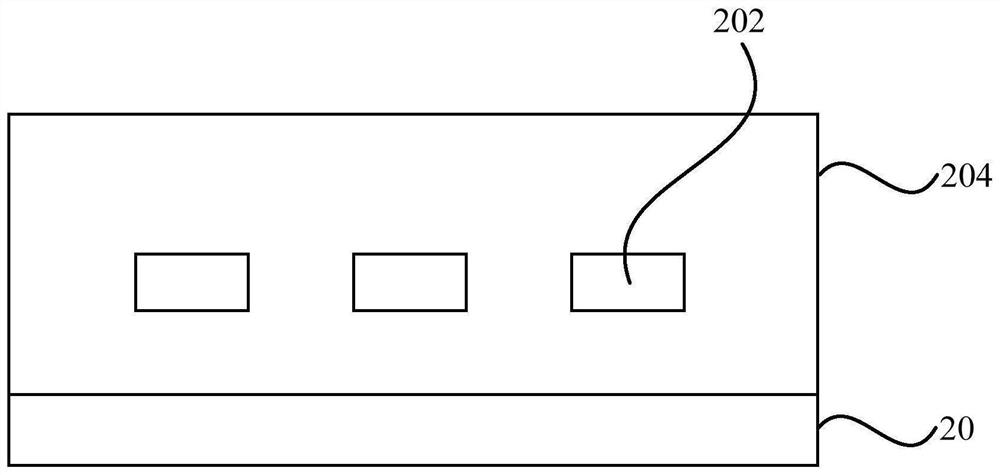

[0013] attached Figure 2A , referr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com