usb socket and its forming method

A molding method and mounting seat technology, which are applied in the manufacture of bases/shells, contact boxes/bases, etc., can solve the problems of poor bonding force, poor waterproof performance of USB sockets, and easy separation of iron shells and plastic layers, etc. The effect of bonding force, miniaturization, and thickness reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

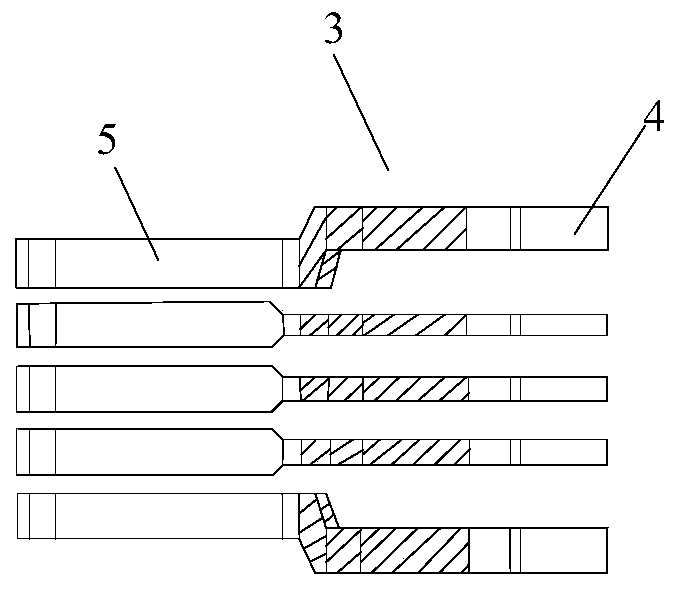

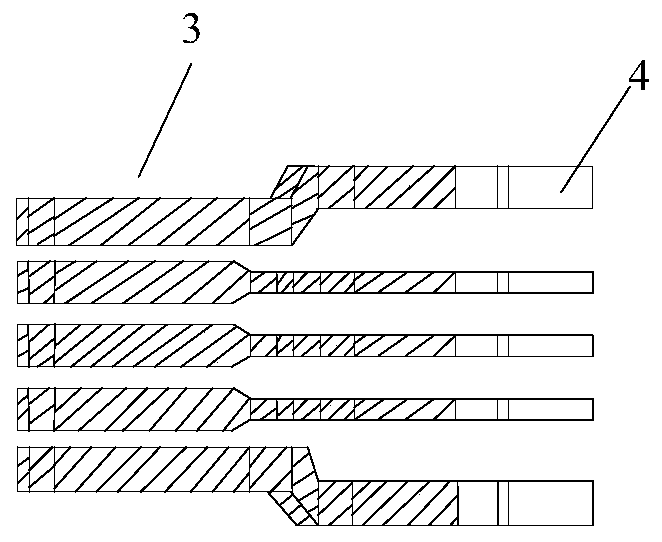

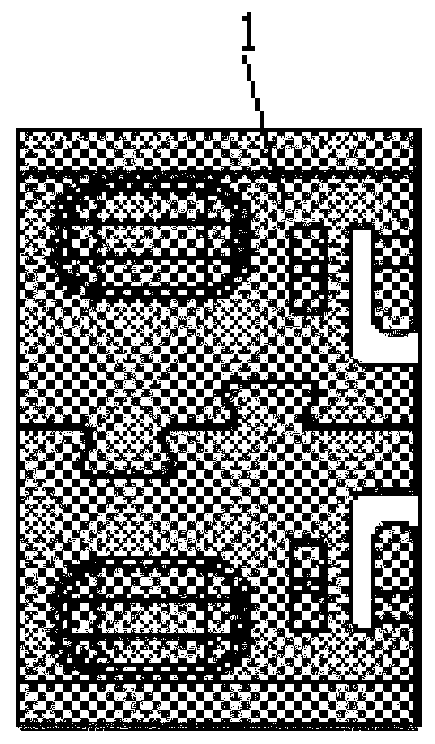

[0025] In order to more clearly illustrate the technical solutions in the embodiments of the present invention, the drawings that need to be used in the description of the embodiments will be briefly introduced below. Obviously, the drawings in the following description are only some embodiments of the present invention. For those skilled in the art, other drawings can also be obtained based on these drawings without creative effort. The invention can be embodied in a multitude of different ways as defined and covered by the claims.

[0026] The grid shaded part in the figure is the T-treated surface.

[0027] see Figure 1 to Figure 13 As shown, according to the embodiment of the present invention, the USB socket includes a housing 1, a mounting base 2 and a terminal 3, the terminal 3 is formed in the mounting base 2, the mounting base 2 is formed in the housing 1, and the outer surface of the housing 1 is a rough surface Treated rough surface, the rough surface of the casi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com