Polymer foam glue for thermal-insulating foam concrete

A foam concrete and polymer technology, applied in the field of bonding foam glue, can solve the problems of increasing the building's own weight and material cost, not having thermal insulation performance, affecting the bonding effect, etc., to improve the effect of thermal insulation and energy saving, and save labor and materials , Fast and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The polymer foam glue for thermal insulation foam concrete of this embodiment includes a solid component and a liquid component. The mass ratio of the solid component to the liquid component is 1.5. Among them, the solid component is 47% by mass. % Cement, 11% ultra-fine cement, 15% silica fume, 24% fly ash, 5% expansion agent, 1.5% solid rubber powder and 1.5% water reducing agent. The liquid component is composed of 95% water, 1 % Foaming agent, 2% latex and 2% foam stabilizer;

[0017] The solid rubber powder is made of rosin, and the foaming agent is a 12-alkane foaming agent;

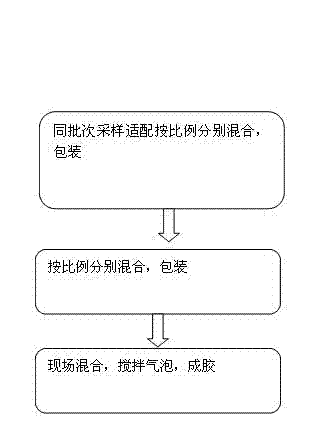

[0018] During production, the solid components and the liquid components are separately configured, packaged separately in proportion, and then made with a foaming agent to become foam glue for use.

[0019] According to the material entering the field, sampling and adapting, after meeting the requirements, after the solid material and the liquid material are mixed uniformly, they are packaged in ...

Embodiment 2

[0021] The polymer foam glue for thermal insulation foamed concrete of this embodiment includes a solid component and a liquid component. The mass ratio of the solid component to the liquid component is 2.85, which accounts for the entire solid component, in terms of mass percentage, The solid components include 45% cement, 11% ultra-fine cement, 10% silica fume,? 25% fly ash, 5% expansion agent, 2% solid rubber powder HPMC, 2% water reducing agent.

[0022] The liquid ingredients include 95% water, 1% foaming agent, 2% latex and 2% foam stabilizer,

[0023] During production, the solid components and the liquid components are separately configured, packaged separately in proportion, and then made with a foaming agent to become foam glue for use. The denser the foam, the higher the ratio

[0024] According to the material entering the field, sampling and adapting, after meeting the requirements, after the solid material and the liquid material are mixed uniformly, they are packaged...

Embodiment 3

[0026] The polymer foam glue for thermal insulation foam concrete of this embodiment includes a solid component and a liquid component, and the mass ratio of the solid component to the liquid component is 2.0, which accounts for the entire solid component, in terms of mass percentage, The solid components include 50% cement, 10% ultra-fine cement, 15% silica fume, 21% fly ash, 5% expansion agent, 2% solid rubber powder and 2% water reducing agent.

[0027] The liquid ingredients include 95% water, 1% foaming agent, 2% latex and 2% foam stabilizer.

[0028] When making, the solid component and the liquid component are configured separately, and the two materials are separately packaged in proportion. When using the two materials, just mix the two materials and use a foaming agent to make it into foam glue.

[0029] According to the material entering the field, sampling and adapting, after meeting the requirements, after the solid material and the liquid material are mixed uniformly, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com