Porous materials and methods including nanoporous materials for water filtration

a technology of nanoporous materials and water filtration, applied in the field of porous materials, can solve the problems of large energy footprint, high capital cost, and high energy consumption of thermal desalination methods such as multi-stage flash and multiple-effect distillation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

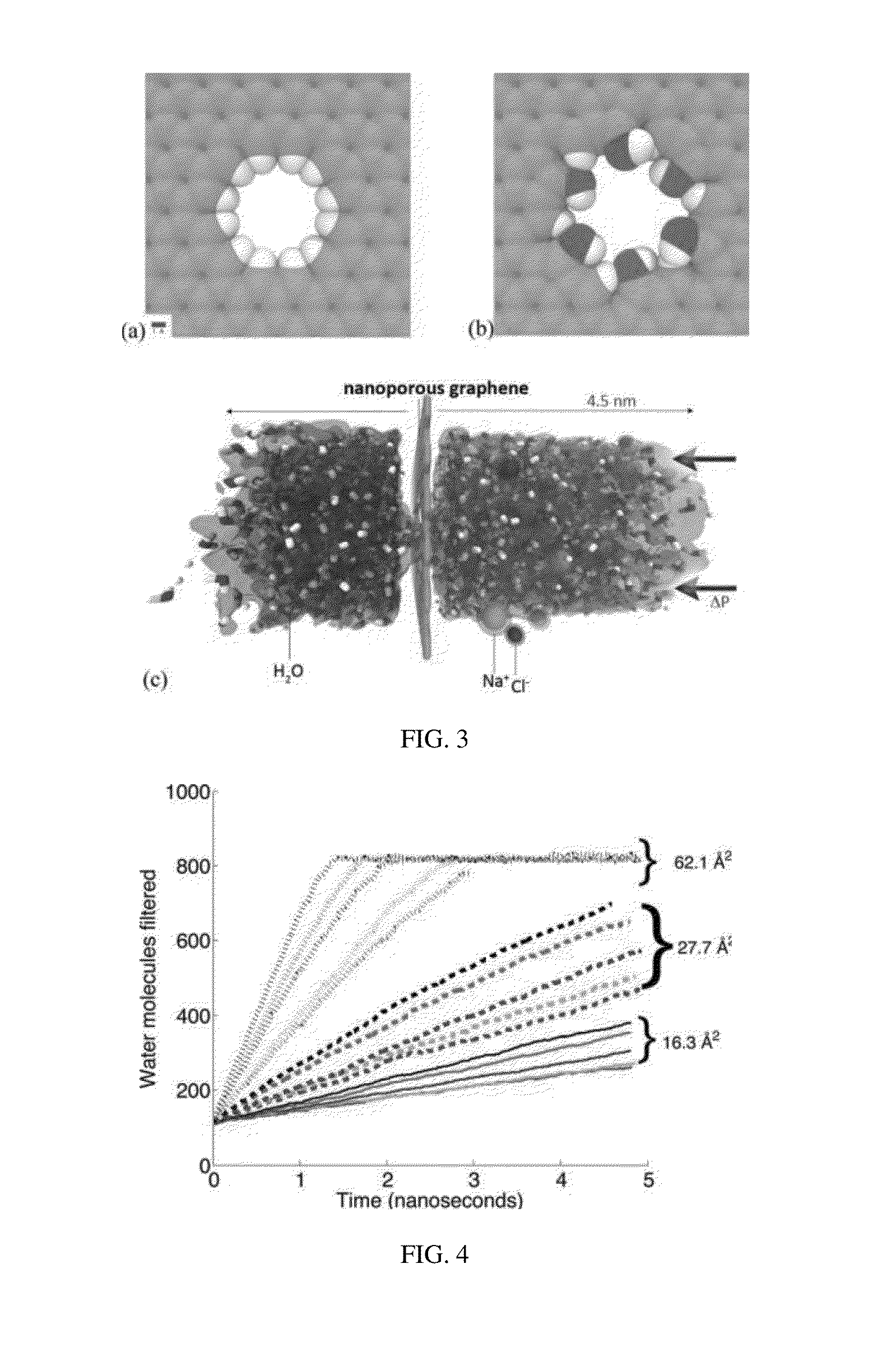

[0088]Because flux across a membrane scales inversely with the membrane's thickness, new types of ultrathin membranes offer the promise of greatly increased water permeability. Graphene, which consists of a 2D sheet of sp2-bonded carbon atoms in a hexagonal honeycomb lattice, is a candidate for use as a thin membrane. Graphene can be manufactured on a large scale with roll-to-roll production of 30 inch graphene films already available. Potential advantages of graphene over existing reverse osmosis membranes include negligible thickness (one or several atomic layers) and high mechanical strength, which may enable faster water transport, low pressure requirements, and a wider range of operating conditions than previously possible. Nanopores can be introduced into graphene's structure with the unsaturated carbon atoms at the pore edge passivated by chemical functional groups.

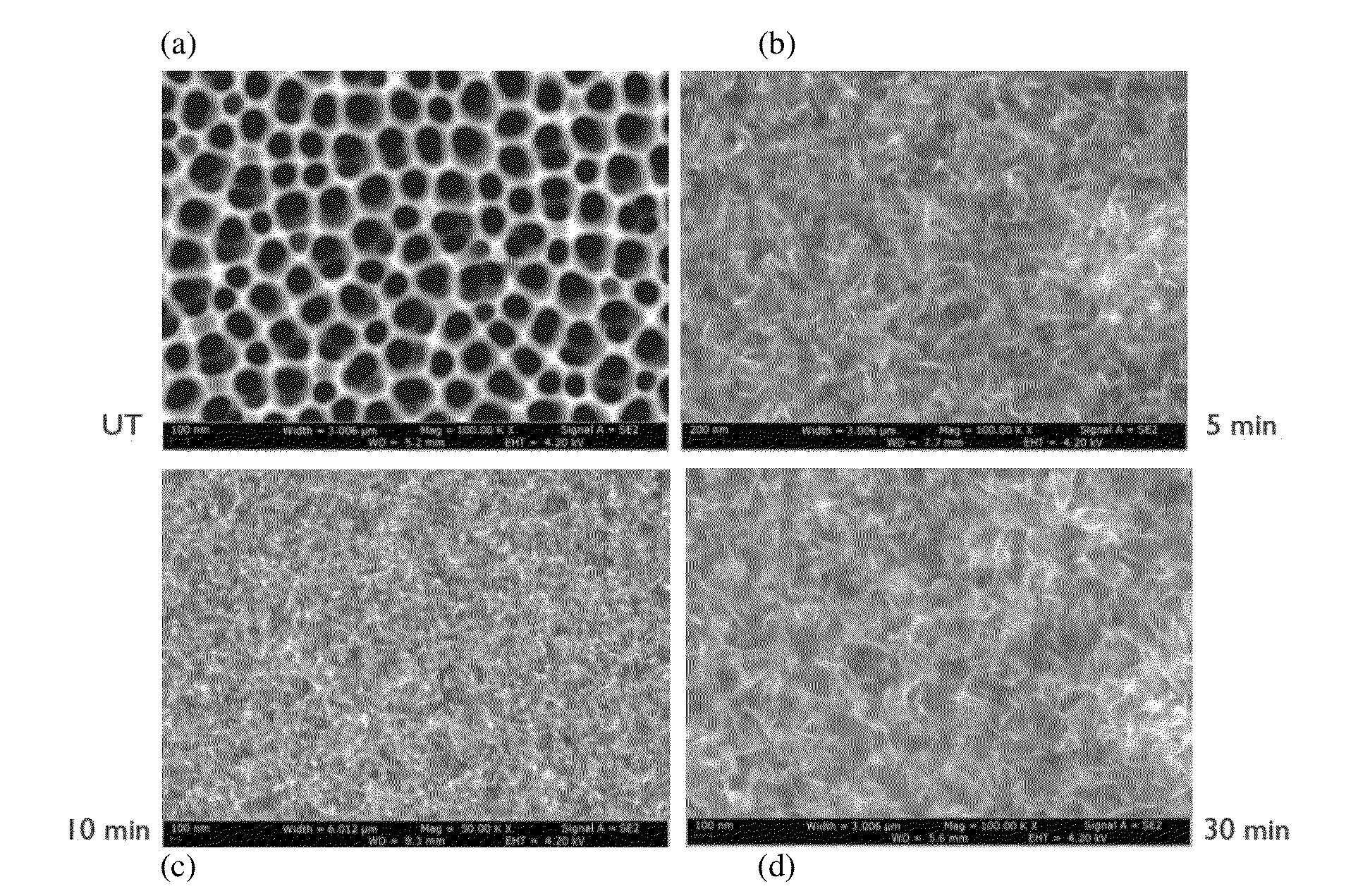

[0089]Experimental studies have explored a wide variety of methods for introducing nanopores in graphene, includ...

example 2

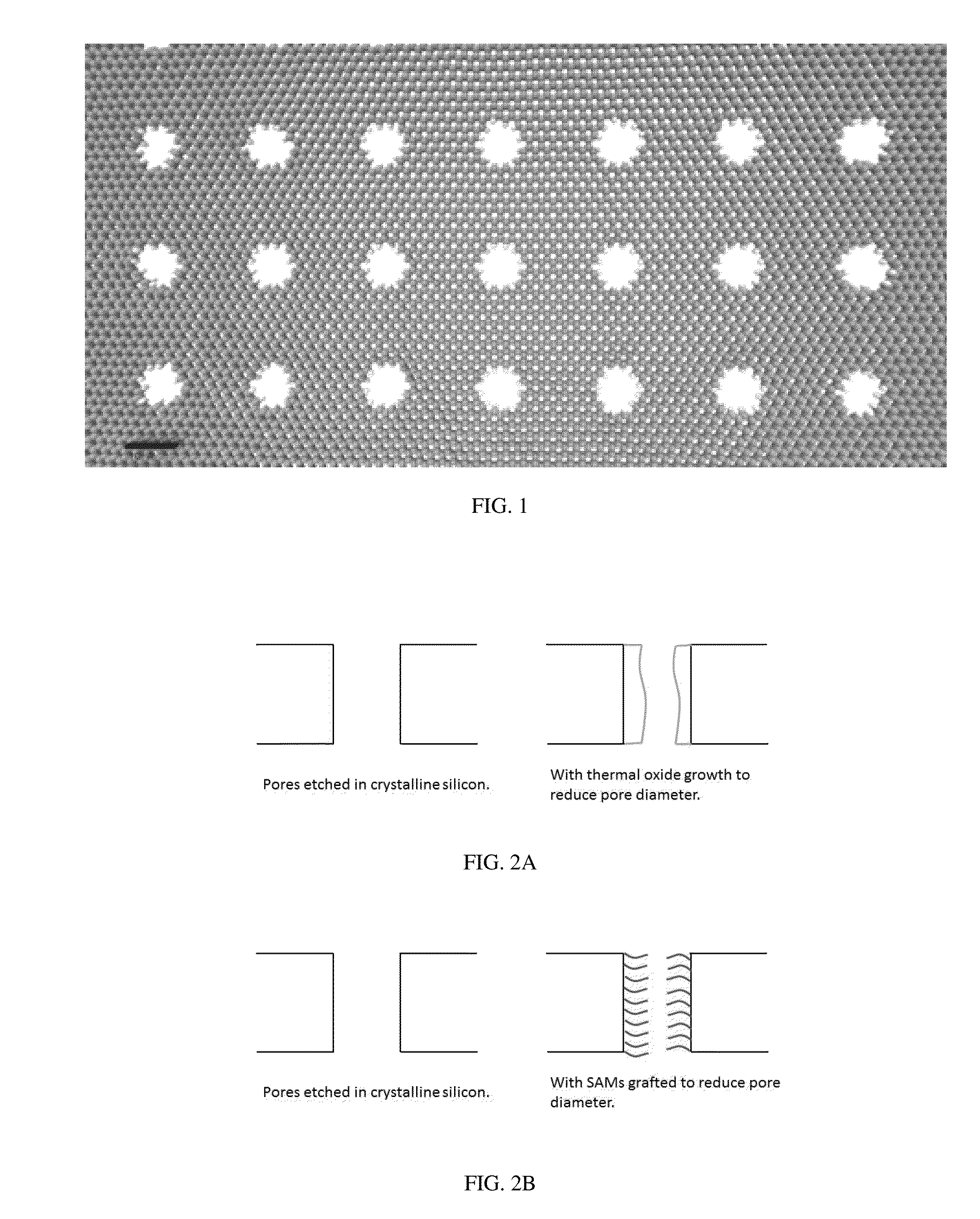

[0112]The following example examines the ability of graphene materials to withstand the mechanical requirements of reverse osmosis. The resistance of freestanding NPGs to applied hydraulic pressure was quantified by investigating the maximum water pressure that a patch of NPG can withstand before the C—C bonds in the pore vicinity might begin to dissociate. This critical pressure may depend not only on the size and spacing of the nanopores, but also on the diameter of the pores and / or cavities in the supporting structure. Table 2 lists the mechanical properties of graphene used in this example.

[0113]RO membranes can extract fresh water from pressurized saltwater. In conventional thin-film composite (TFC) membranes, an active layer that is typically composed of polyamide extends about 100-200 nm in thickness, and may be supported by a polysulfone substrate that is more porous and thicker than the active layer, with cavities around 0.1-0.5 μm and an overall layer thickness around ˜100...

example 3

[0127]The following example describes the evaluation of filtration performance for commercial, fabricated, and surface modified filtration membranes.

[0128]In order to calibrate the filtration system to achieve consistent results, the permeability of several membranes was compared. 100 mL of deionized water and 0.3% by weight NaCl solution were inserted in the Sterlitech HP 4750 (Slide 10) cell in separate experiments and flux was measured for various commercial membranes and surface modified membranes at given parameters. FIG. 15A shows the effect of pressure on the flux across a GE Osmonics AG brackish water membrane. Lower pressure dramatically reduces the flow of permeate especially at higher recovery ratios. FIG. 15B shows the effect of the use of a magnetic stir bar to maintain well mixed conditions and prevent the accumulation of salt at the surface of the membrane. Further, the stir bar dramatically affects the salt rejection associated with the same membrane, holding all oth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com