Pressure adjustable casting method and crucible therefor

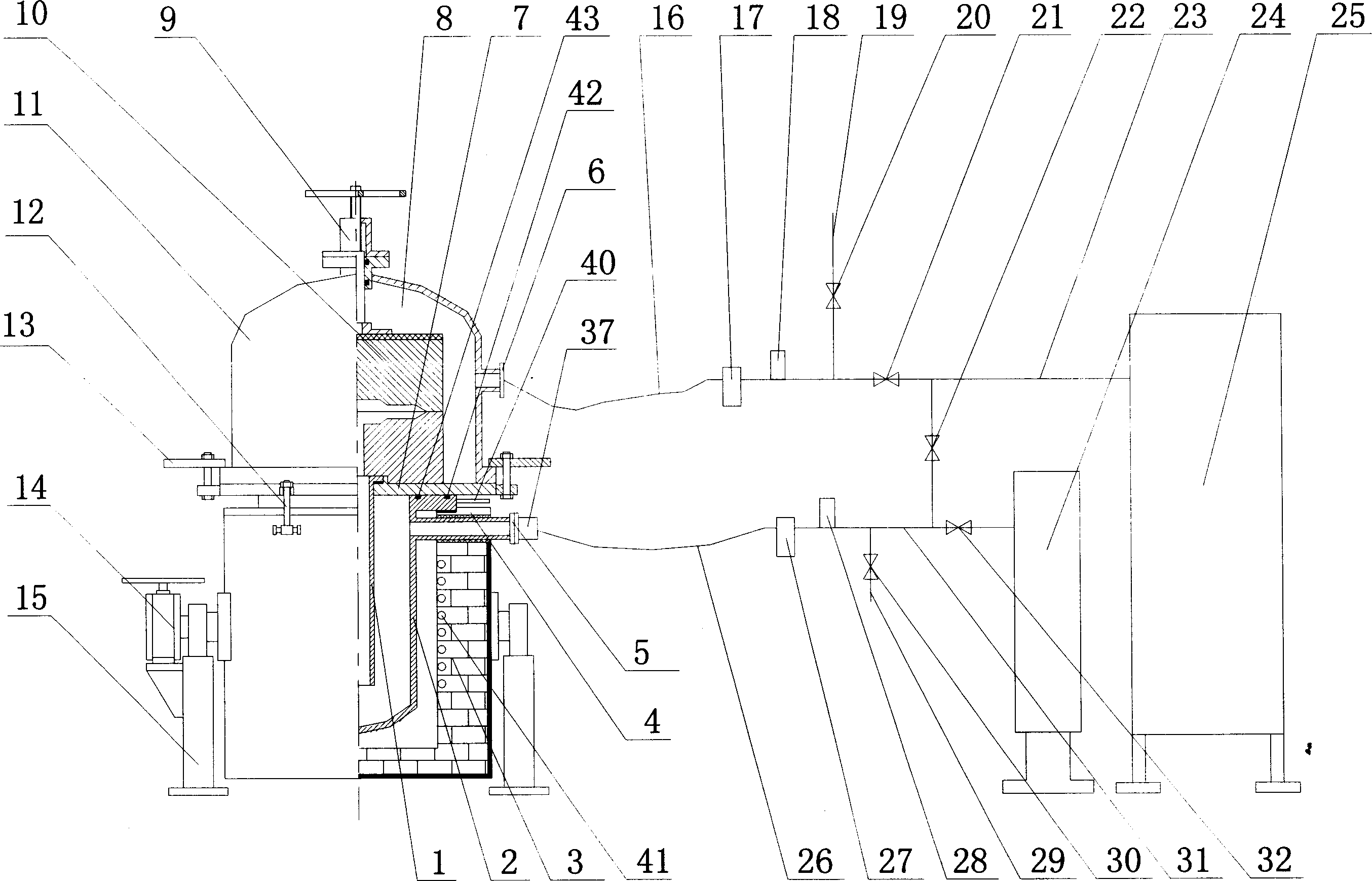

A crucible and pressure technology, applied to crucible furnaces, furnaces, lighting and heating equipment, etc., can solve the problems of difficult sealing of the lower sealing chamber, limited feeding capacity of castings, large pressure adjustment space, etc., and achieves simple structure, consistent structure, The effect of increasing the coagulation pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

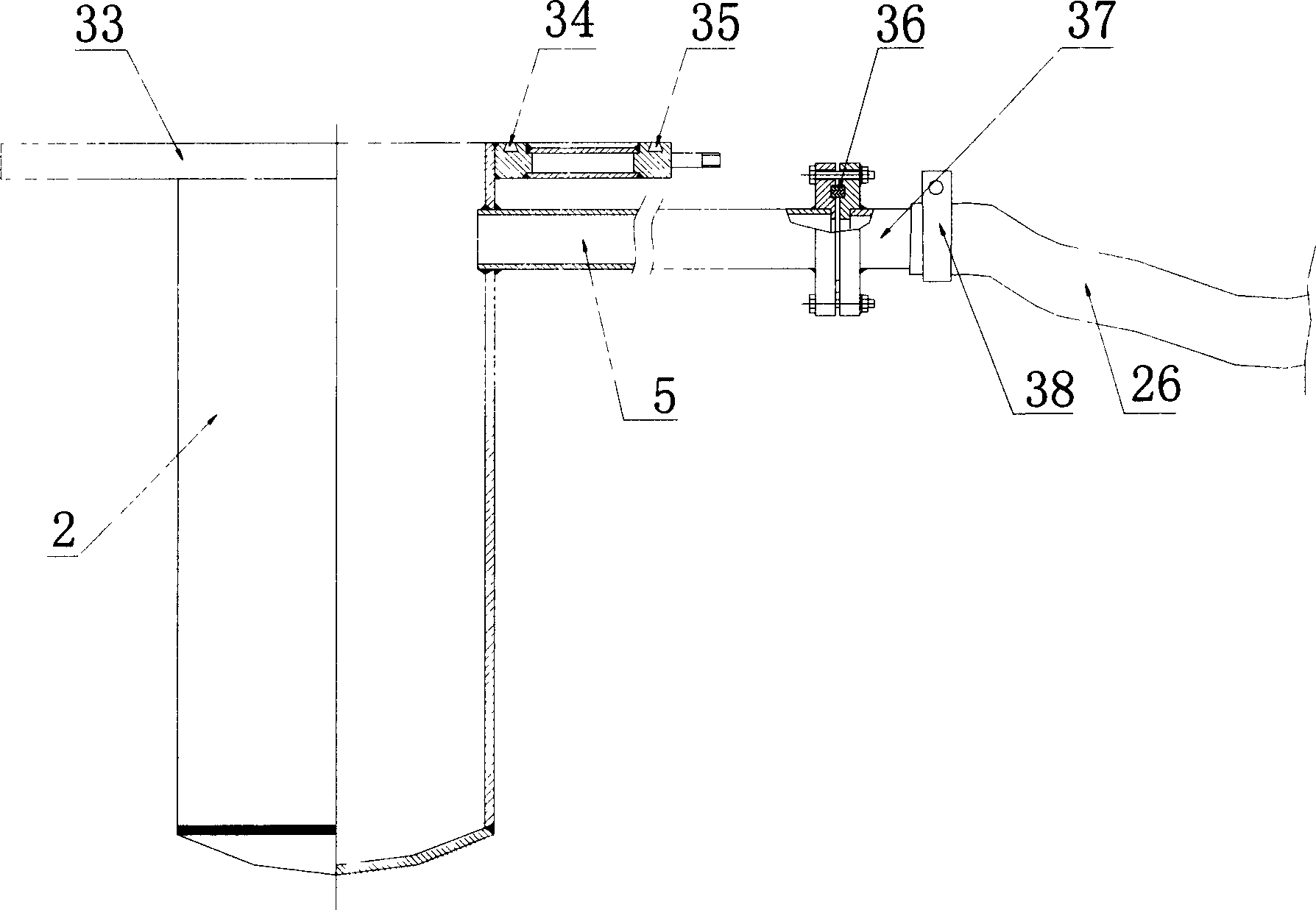

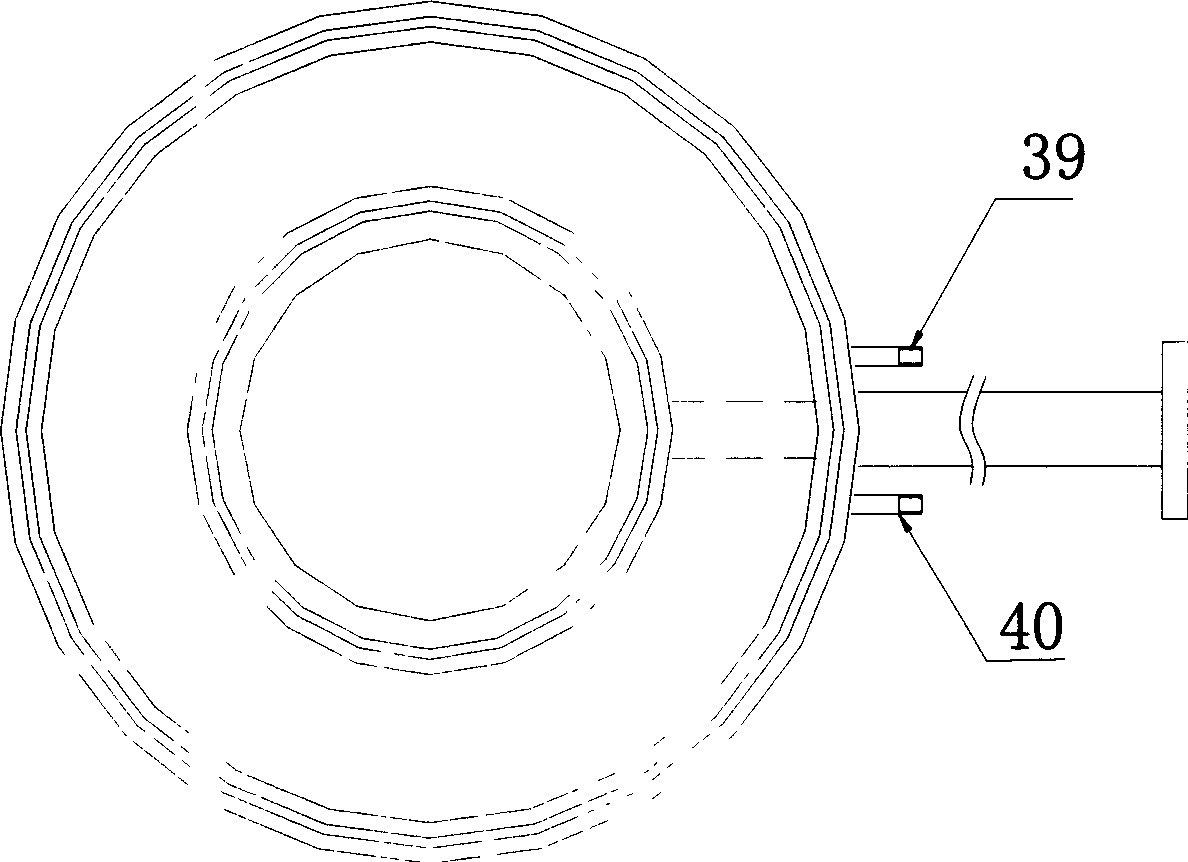

[0019] A crucible for pressure regulating casting, the crucible includes a crucible body 2 and a water-cooled flange 33 . The water-cooling flange is welded on the upper end of the crucible body, and the heat-insulating asbestos groove 34 and the rubber sealing ring groove 35 are arranged on the upper surface of the water-cooling flange 33. A cavity is provided inside the water-cooling flange for cooling of circulating water. A water inlet port 39 and a water outlet port 40 for circulating water are arranged on the outer edge, and the crucible gas path interface 5 is arranged on the upper part of the crucible body 2 .

[0020] The material of the crucible body 2 is 1Cr18Ni9Ti, and the material of the water-cooled flange 33 is A3; 2 Water filling pressure without leakage.

[0021] The gas path interface 5 of the crucible is welded by a seamless steel pipe and a flange, and the other end of the seamless steel pipe is welded with the crucible body 2, and the material of the seam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com