Crystal growing device and method

A technology of crystal growth and crystal growth furnace, which is applied in the field of compound systems, and can solve the problems of reduced total length and low yield of grown crystals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be explained in detail below with reference to the examples shown in the accompanying drawings. The embodiments mentioned in the following description do not represent all embodiments consistent with the claimed invention. Rather, they are merely examples of certain aspects consistent with the invention. Wherever possible, the same reference numbers will be used throughout the drawings to refer to the same or like parts.

[0013] The apparatus and method are particularly suitable for gallium arsenide (GaAs) crystal growth and will be described in this context herein. However, it should be understood that the apparatus and method can also be used to manufacture other III-V, II-VI and related single crystal compounds, so it has broader applications.

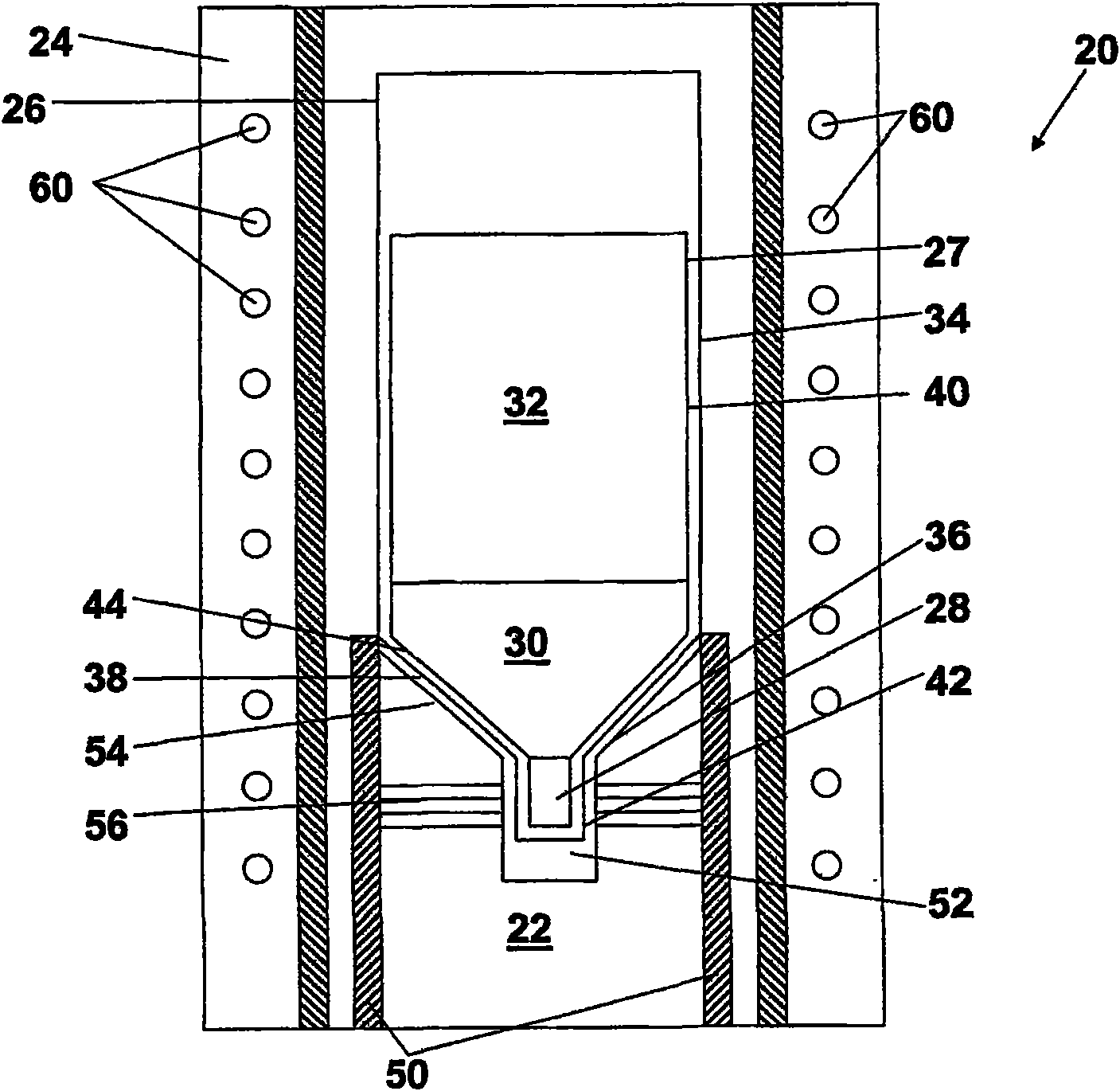

[0014] figure 1 is a cross-sectional view of an example of a crystal growth apparatus 20 . The apparatus includes a crucible frame 22 in a furnace 24, such as a furnace that establishes a cryst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com