Growth device and growth method for preparing high-purity semi-insulating carbonized silicon single crystals efficiently

A silicon carbide single crystal and growth device technology, which is applied in the directions of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of increasing equipment cost, increasing the number of processes and operation complexity, increasing equipment complexity, etc., and achieving reduction The effect of nitrogen impurity content and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with drawings and embodiments.

[0031]The present invention provides a growth device and method for reducing the content of nitrogen impurities in silicon carbide crystals and preparing high-purity semi-insulating silicon carbide crystals with high efficiency. The specific examples are as follows:

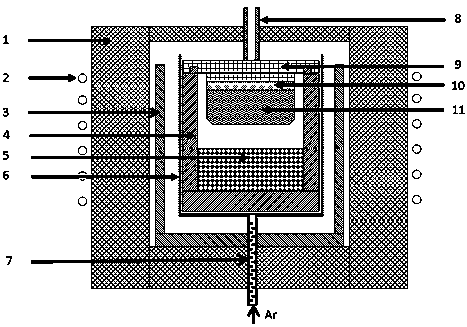

[0032] refer to figure 1 and figure 2 , the high-efficiency preparation of high-purity semi-insulating silicon carbide single crystal growth device of the present invention comprises the insulation system that is made of graphite insulation felt 1, the heating system that is made of induction heating coil 2 and graphite heater 3, is made of graphite crucible 4, SiC powder Source 5, graphite suspender 8, graphite seed crystal support 9, SiC seed crystal 10 constitute the growth system, the growth system of this growth device also includes graphite current limiting cover 6 and graphite flow guide tube 7; a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com